8

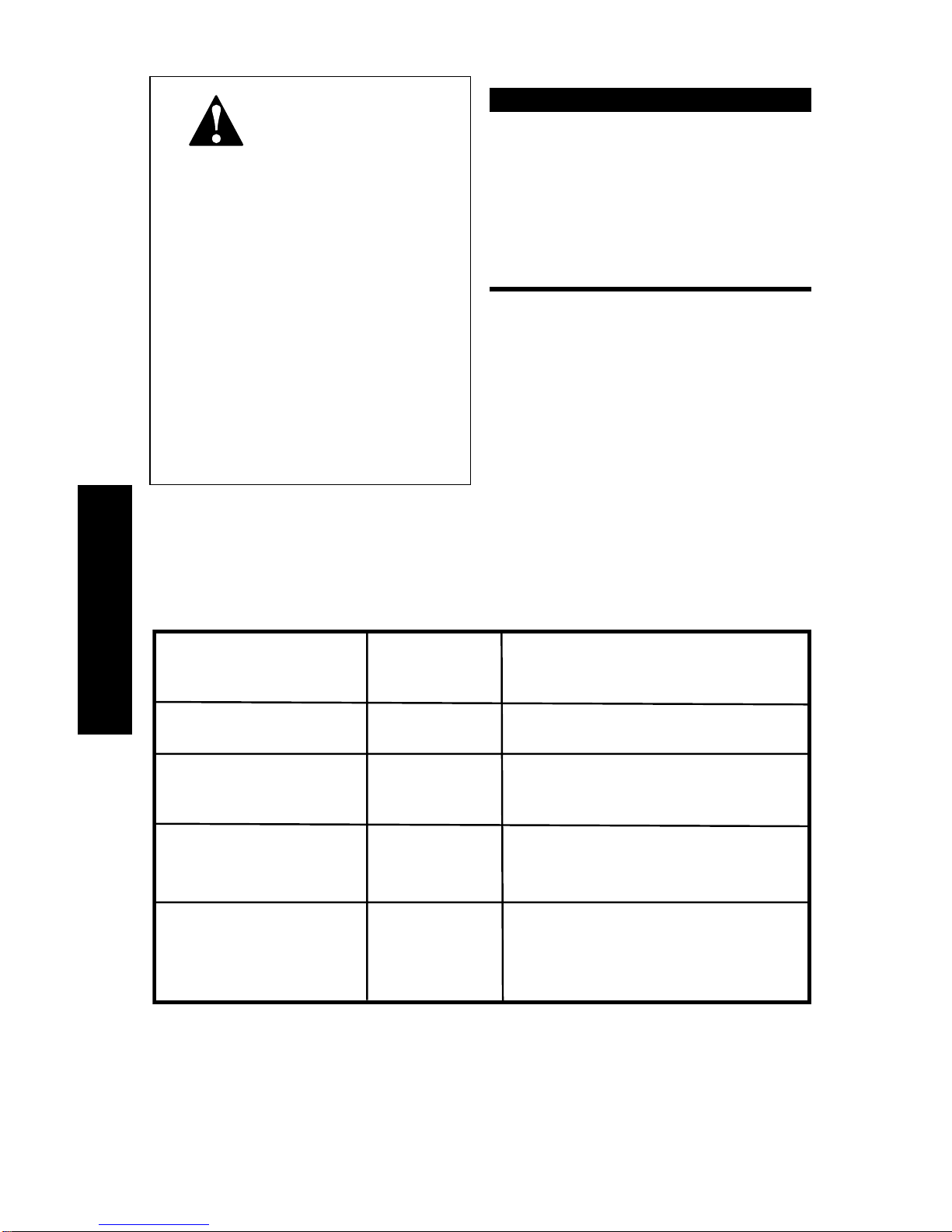

Mixing Fuel

CAUTION!

Some types of gasoline contain

alcohol as an oxygenate.

Oxygenated gasoline may

cause increased operating

temperatures. Under certain

conditions, alcohol-based

gasoline may also reduce the

lubricating qualities of some 2-

cycle mixing oils. Never use

any type of gasoline containing

more than 10% alcohol by

volume!

Generic oils and some out-

board oils may not be intended

for use in high-performance 2-

cycle engines, and should

never be used in your Shin-

daiwa engine.

IMPORTANT!

This engine is certified to operate

on a 50:1 mixture consisting of

unleaded gasoline and 2-cycle

mixing oil only. Mix only enough

fuel for your immediate needs! If

fuel must be stored longer than 30

days, it should first be treated with a

stabilizer such as StaBiI™.

!Mix fuel by combining unleaded

gasoline with Shindaiwa Premium

2-cycle Engine Oil at a ratio of

50:1 (a gallon of gasoline mixed

with 2.6 fl. oz. of 2-cycle mixing oil

or 5 liters of gasoline with 100 ml

of 2-cycle mixing oil).

!Use only fresh, clean, unleaded

gasoline with an octane rating of

87 or higher.

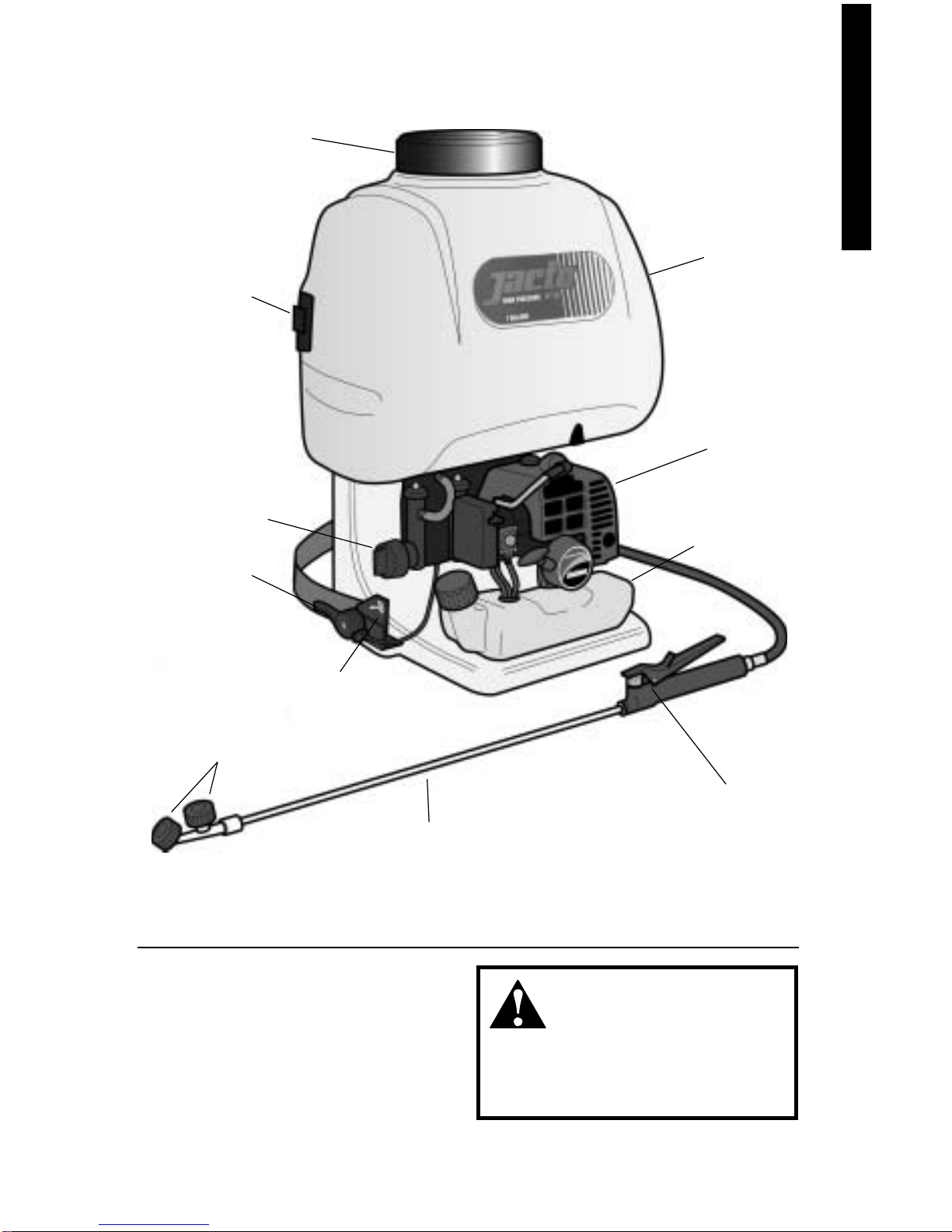

Filling the Fuel Tank

WARNING!

Minimize the risk of fire!

!Always allow the engine to

cool before refueling!

!Wipe all spilled fuel and move

the engine spayer at least 10

feet (3 meters) from the

fueling point and source

before restarting!

!Never smoke or light any fires

near the engine sprayer or

fuel source!

!Never place any flammable

material near the engine

muffler!

!Never operate the engine

without the muffler and spark

arrester in good working

condition.

1. Place the HP726 engine sprayer on

a flat, level surface.

2. Clear any dirt or other debris from

around the fuel filler cap.

3. Remove the fuel cap, and fill the

tank with clean, fresh fuel.

4. Reinstall the fuel filler cap and

tighten firmly.

OPERATION