1502

Rod

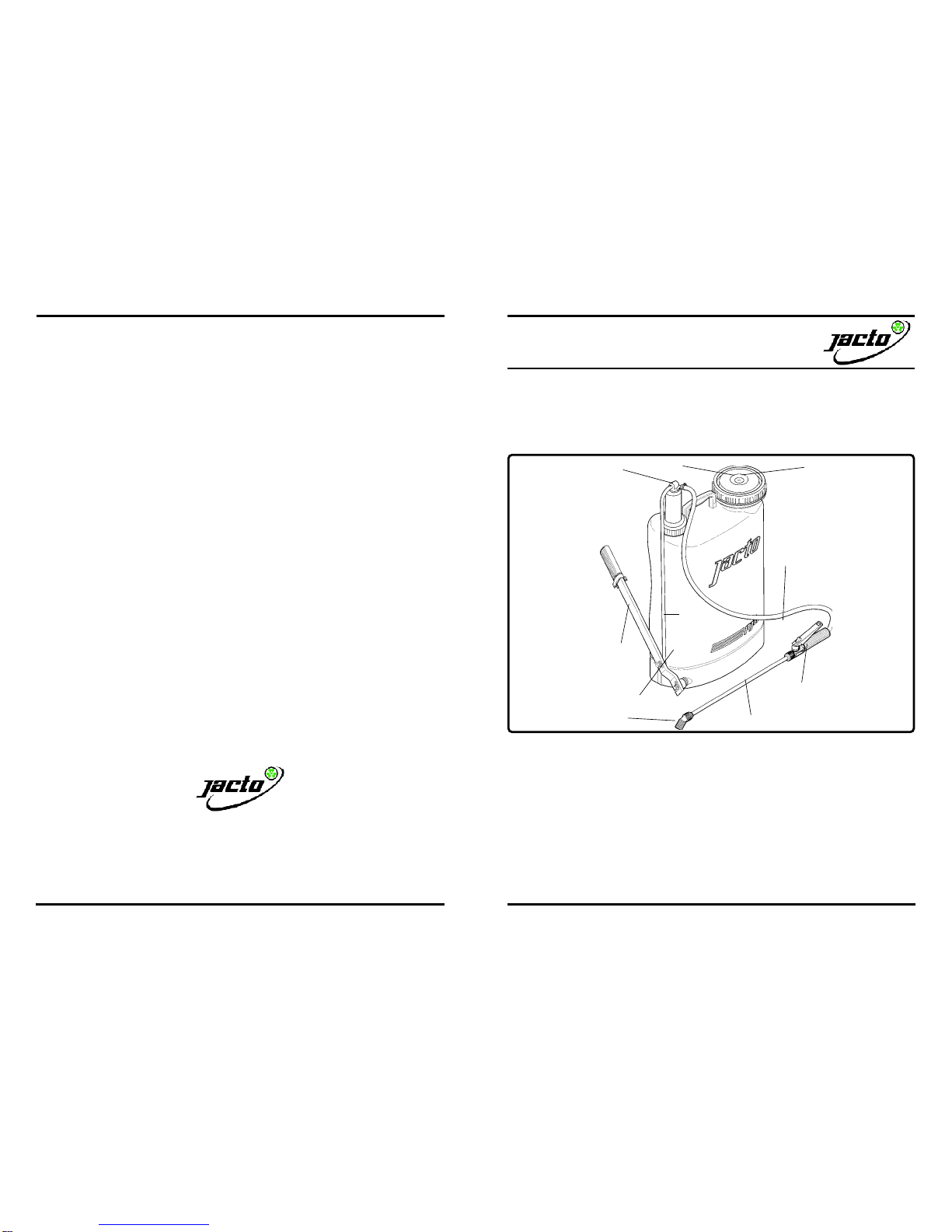

Tankwithlever

Lance

Accessories

plastic bag Hosewith

triggervalve

Contentsof

the plastic bag

ATTENTION:Becarefulwhentakingthesprayeroutofthecartonbecausethelever

is loose and cause damage or personal injury.

4-ASSEMBLYPROCEDURES

Takeoutof the sprayercartonthe following parts.

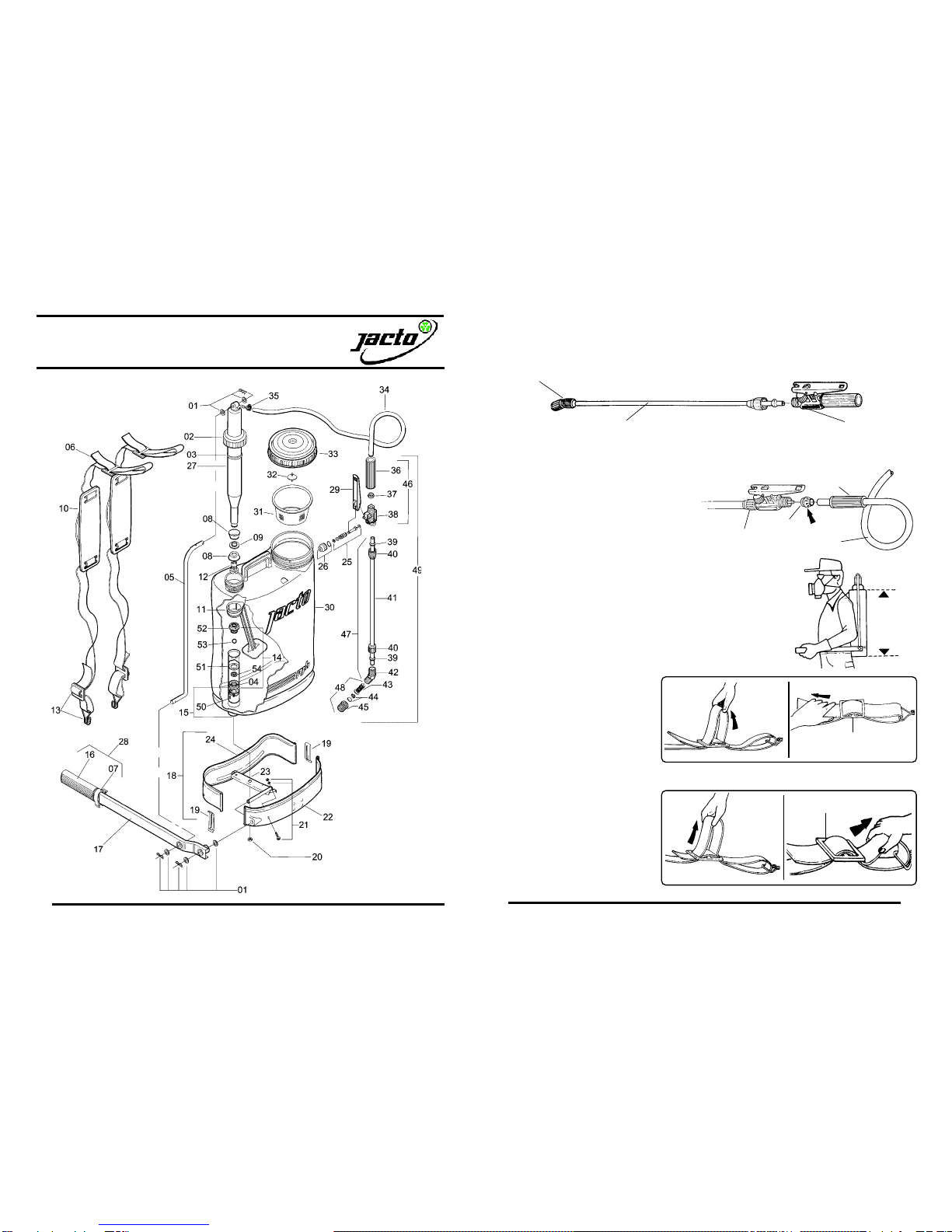

5-INSTALLINGTHELEVERONTHESHAFTANDTHERODONTHECHAMBERTOP

Rod

Lever

Shaft

Cotterpin

Washers

Cotterpin

- Grease slightly the lever orifice and install it on the

rod. Fit a flat washer before the cotter pin.

- Grease slightly the orifice on the chamber top.

- Fit a flat washer on the shaft and rod.

- For easy assembly, install the lever on

the shaft and the rod on the chamber

top at the same time.

- Install the other flat washers on the

shaft and rod and lock with the

cotter pin.

Description

Item Description

Item Part no. Qtd

Qtd

Part no.

00 - PJH manual knapsack sprayer 01

01 942102 Washers and cotter pins 01

02 831222 Gasket holder 62 01

03 831230 Gasket 7 x ø 50.6 01

04 120188 Fastener 01

05 009654 Pumpingrod 01

06 915926 Strap assembly 01

07 495648 Lever lock 01

08 942755 Piston cup 02

09 942763 Piston cup spacer 01

10 012120 Shoulder protector 02

11 300582 Agitator 01

12 402297 Chamber valve 01

13 942110 Buckles and hook set 01

14 661124 Fastener assembly (supplied

with items: 51, 52, 53, 54

and 55) 01

15 925917 Cylinder assembly (supplied

with items 14, 20 and 50) 01

16 002683 Handgrip 01

17 615005 Pumping lever and handgrip 01

18 229484 Tank base assembly (supplied

with items 19, 21, 22, 23,

24, two washers and one

cotter pin) 01

19 825471 Base clamp 02

20 636118 Flanged nut M-8 01

21 229476 Bolts, washers and nuts set 01

22 825448 Rear body 01

23 942714 Reinforcement 01

24 825430 Front body 01

25 105239 Trigger valve needle

assembly (supplied with

items 27 and 28) 01

26 996058 Trigger valve cap 01

27 635284 Chamber assembly (supplied

items 08, 09 and 12) 01

28 495812 Grip assembly 01

29 105247 Trigger 01

30 942086 Tank with lid 01

31 647131 Strainer 01

32 560573 Diaphragm 01

33 120527 Tank with diaphragm 01

34 530576 Hose ø 5/16" x 1350 01

35 938159 ClampMA-913 01

36 909192 Trigger valve handle 01

37 920470 Lock 01

38 909283 Trigger valve body 01

39 909309 Cone packing 02

40 915744 Screw cap 02

41 904235 Tube 01

42 635276 Elbow with cone packing 01

43 592139 Nozzle strainer M-40 01

44 217174 NozzleJD-12P 01

45 229724 Nozzle cap 01

46 908889 Trigger valve assembly

(supplied with items 25, 26, 29,

36, 37 and 38) 01

47 100131 Extension 601 (supplied with

items: 39, 40, 41and 42) 01

48 427062 Nozzle (supplied with items

43, 44 and 45) 01

49 915769 Spray lance assembly

(supplied items 46, 46, 47

and 48) 01

50 120170 Cylinder body 01

51 011668 RingOR1-122 01

52 570788 Ball holder 01

53 715474 Ball 01

54 565960 Packing ring 17 x 12 x 3 01

LLM-172