5/120

WARNING!

Read all safety warnings and all instructions. Failure to follow the instructions and warnings may result in

electrical shock, re and/or serious injuries.

1. Safety precautions

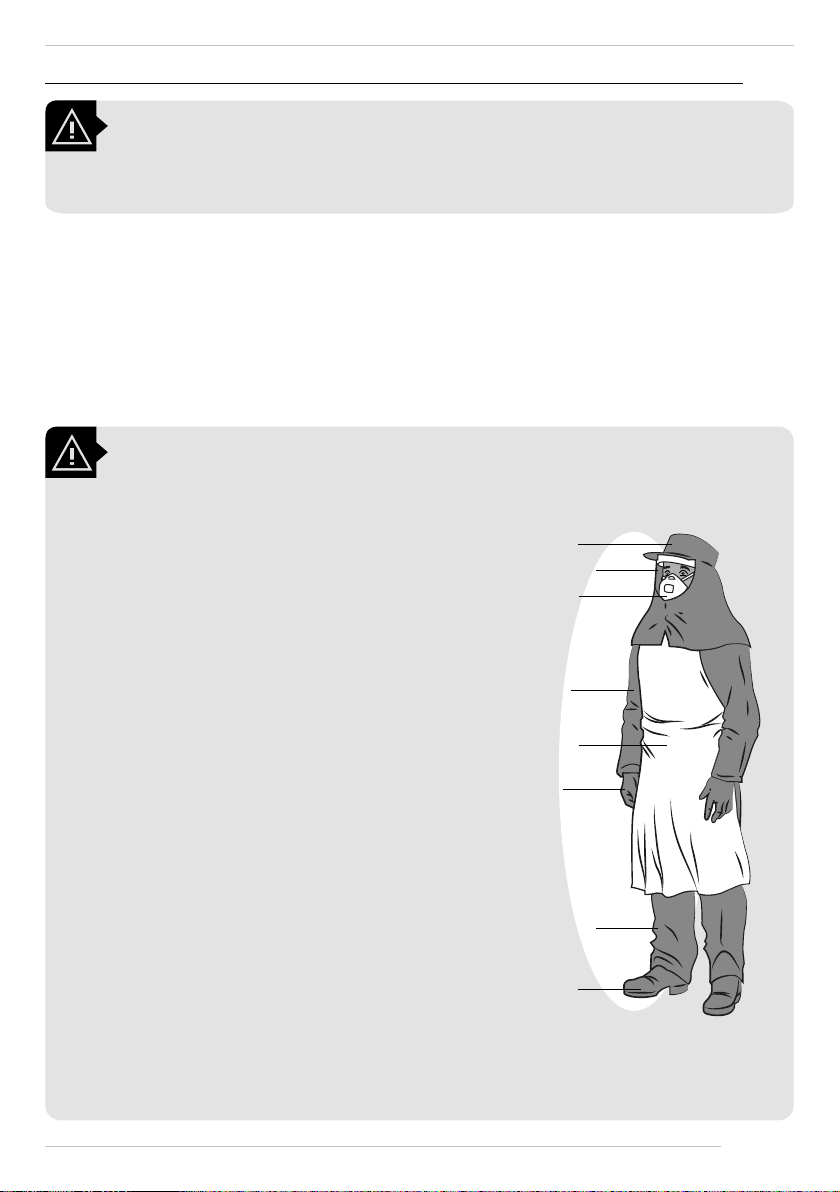

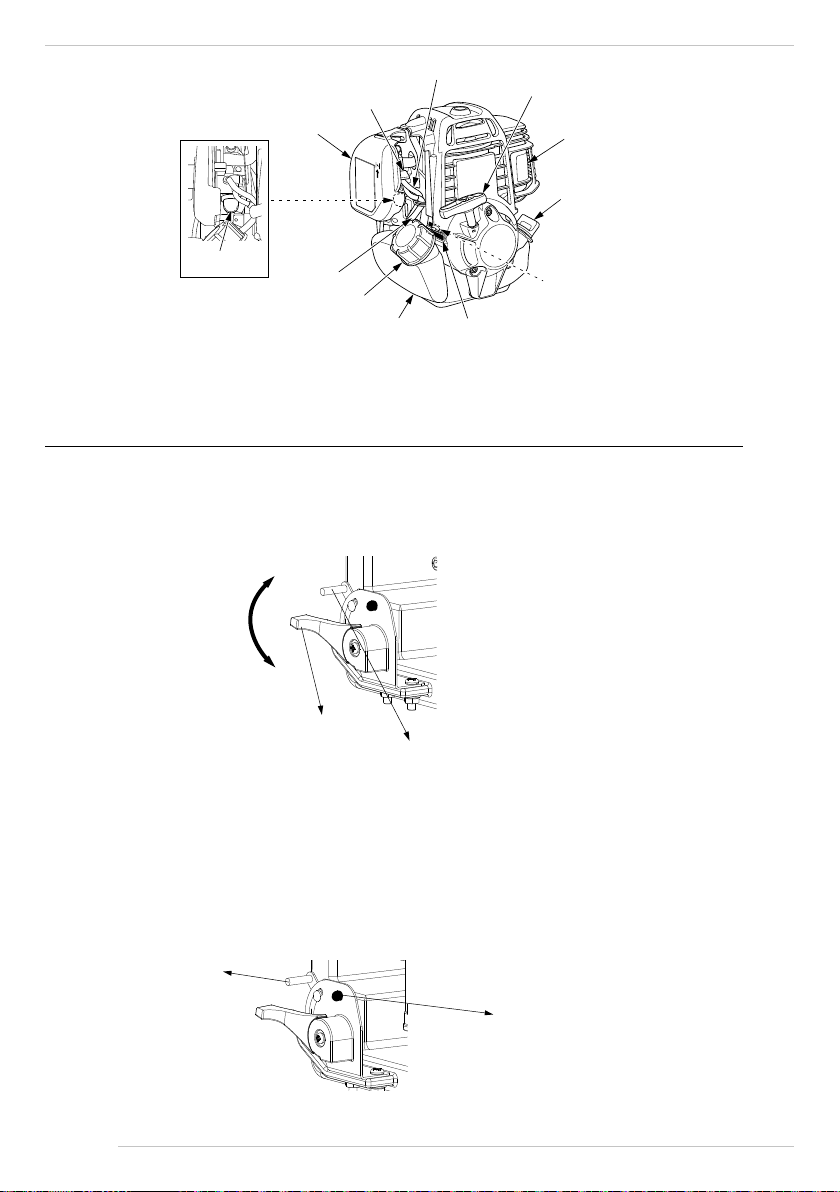

1.2. Personal Safety

Boots

Head protection

Eye protection

Mask

Long sleeve shirt

Apron

Gloves

Pants

1.1. Working area safety

• Keep the work area clean and well lit. Disorganized or dark work areas may cause accidents more easily.

• Keep children and bystanders away from when operating the sprayer. Distractions may cause you to lose control.

• Do not spray areas near bystanders or animals;

• Do not operate the sprayer in enclosed locations – such as sheds, garages, buildings, etc.;

WARNING!

• Read this manual closely. Make sure you understand

how to operate the sprayer correctly before using it.

• Wear the recommended individual protective

equipment (PPE): facial shield, dusk mask, long

sleeveshirt,apron, gloves,pantsandno-slipsole

boots,hearingprotectors (ear mus),etc. aswell

as any other equipment the activity performed

requires.FailuretowearPPEmayresultinseriouslong

and short-term problems to your health;

• Do not spray for long periods of time. Take short

breaks during work.

• Do not use the sprayer if you are tired or under

the inuence of drugs, alcohol or medications;

A moment of inattention during work may result in

personal injuries and serious damages to the sprayer.

• Do not overdo. Keep secure footing and balance

atall times.This allowsbetter controlofthe knapsack

sprayer in unexpected situations;

• Wear proper clothing. Do not wear loose-tting

clothesorjewelry.Keepyourhair,clothingandgloves

clearof movingparts.Loose-tting clothing,jewelryor

long hair may get entangled in moving parts.

• Never modify the sprayer. This may pose real risk to

both the operator and void the warranty;

• Never try to use an incomplete sprayer or one

which has been modied without the manufac-

turer’s authorization;

• After work, take a shower in running water and

use plenty of soap;

• Any clothing and PPE worn during applications

must be washed separately from everyday

clothing.