13

04

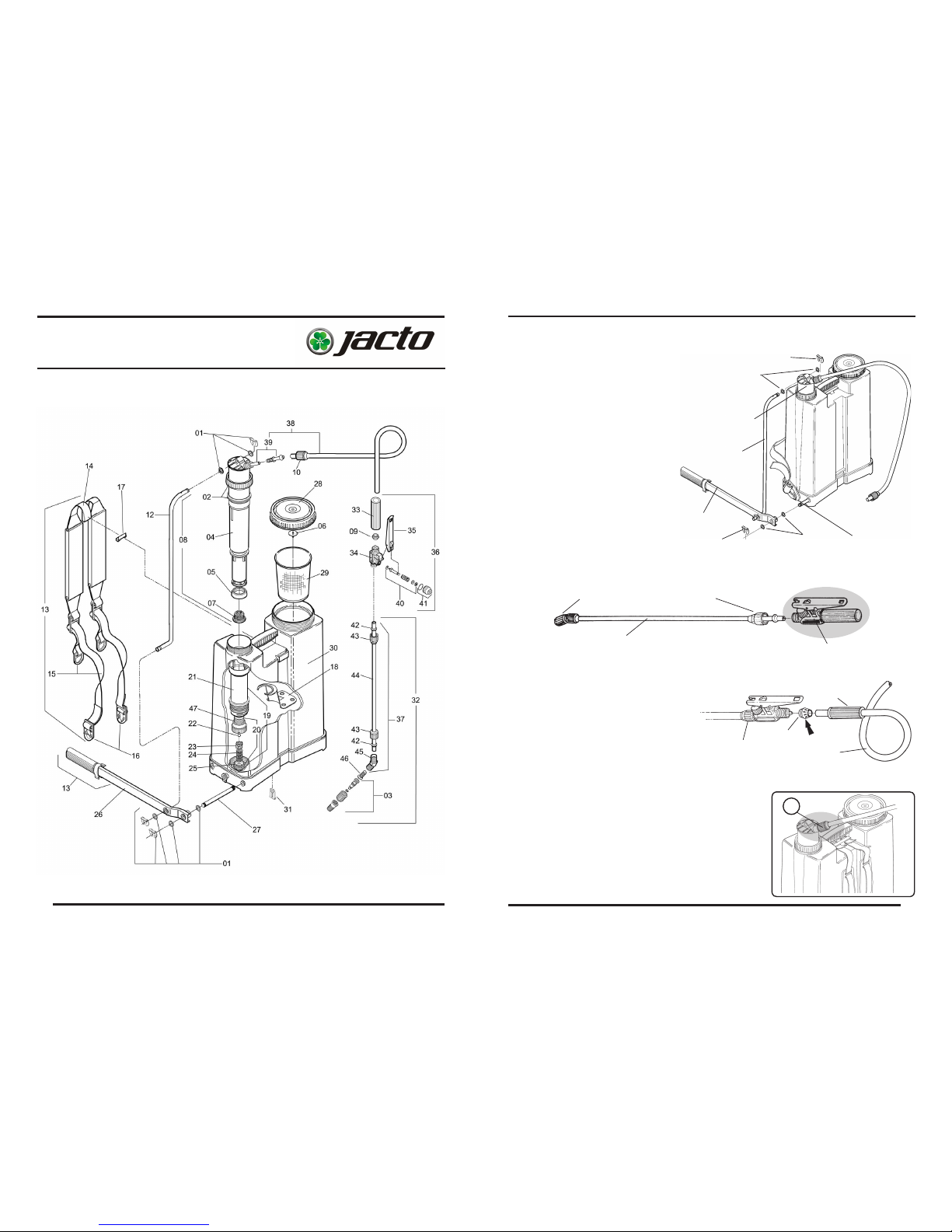

10- ADJUSTING THE SHOULDER STRAP

The tank is contoured for the operator comfort.

The shoulder straps can be quickly adjusted to properly

position the sprayer on the operator's back.

See below.

TIGHTENING

- Hold the strap buckle rmly with one hand,

and pull the handle downward with the other

hand.

Buckle

LOOSENING

- Hold the buckle rmly with one hand, and

pull the strap upward with the other hand.

Handle

Buckle

11- ATTENTION

After assembling the sprayer, ll the tank with clean water and pressure-check the

tank lid, diaphragm, tank bottom, lance and trigger valve for leakage. Most leaks can

be stopped by retightening the appropriate connections and ttings. Any leakage must

be repaired before returning to service.

12- INVERTING THE LEVER POSITION

This sprayer is assembled to mount the lever for left hand operation. In case you wish

to change its position, proceed as follows.

- Remove the locked ring (1) and washers (A) and the rod (2) of the chamber top.

- Turn the chamber top 180°.

- Reinstall the rod (2) on the chamber top, t the washers (A) and secure the rod with

the locked ring (1) again.

- Then, remove the locked ring (4 and 5) and the washers (B).

- Remove the lever (6) and the shaft (7).

- Unfasten the strap assembly (8) and mount it on the other side of the sprayer as shown

in the detail below.

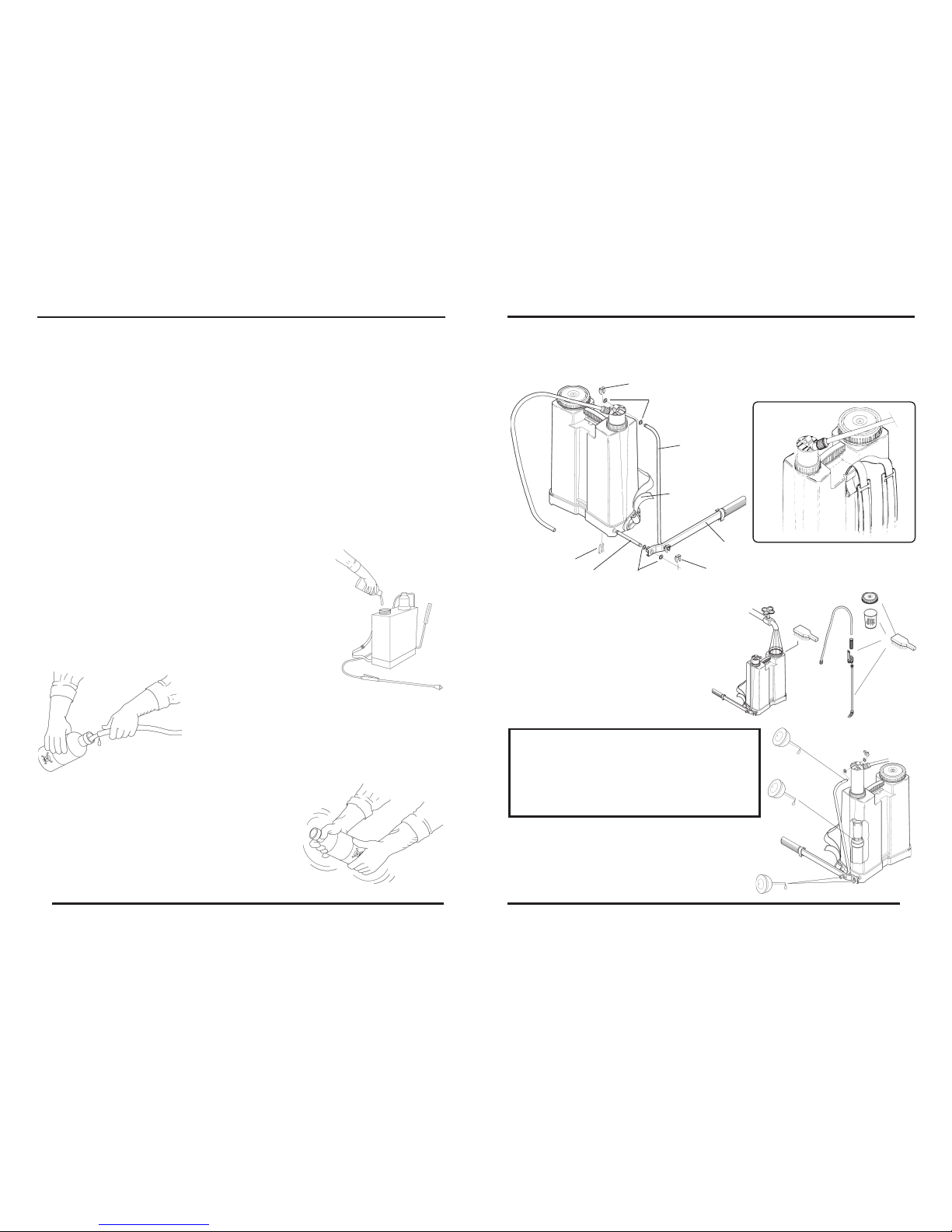

- Take the container cap off and carefully pour the rinse water into

the spray tank.

- Continue holding the container over the spray tank opening

for approximately 30 seconds to the last drop.

- REPEAT this operation twice more. This way, you complete the

TRIPLE WASH.

- Next, make the plastic and metallic containers use-

less by piercing with a pointed instrument the contai-

ners bottom. This way, their labels are not damaged

for identication purposes.

- The useless containers can be placed temporarily in an appropriate place, until nal destina-

tion.

- In the case of mid and large size container (13.2, 26.4 and 52.8 gallons), after washing with the

appropriate volume (1/4 of the total) and tting the cap, roll it on the ground for approximately 30

seconds.

- In the upright position complete the agitation by moving back and forth for approximately 30

seconds.

- Empty the container by pouring the rinse water into the spray tank.

- REPEAT this operation twice more. Finally, totally empty the container by pouring rinse water

in the spray tank.

- The least amount of rinse water that remains in the container, from one wash to the next, the

better the decontamination will be.

- For the performance of the TRIPLE WASH, do not use a water volume either much lower or

much higher than 1/4 of the container capacity.

-The TRIPLE WASH must be done IMMEDIATELY AFTER emptying the container, during the

preparation of the solution

SOURCE - ANDEF (NATIONAL ASSOCIATION OF VEGETAL DEFENSE)