1502

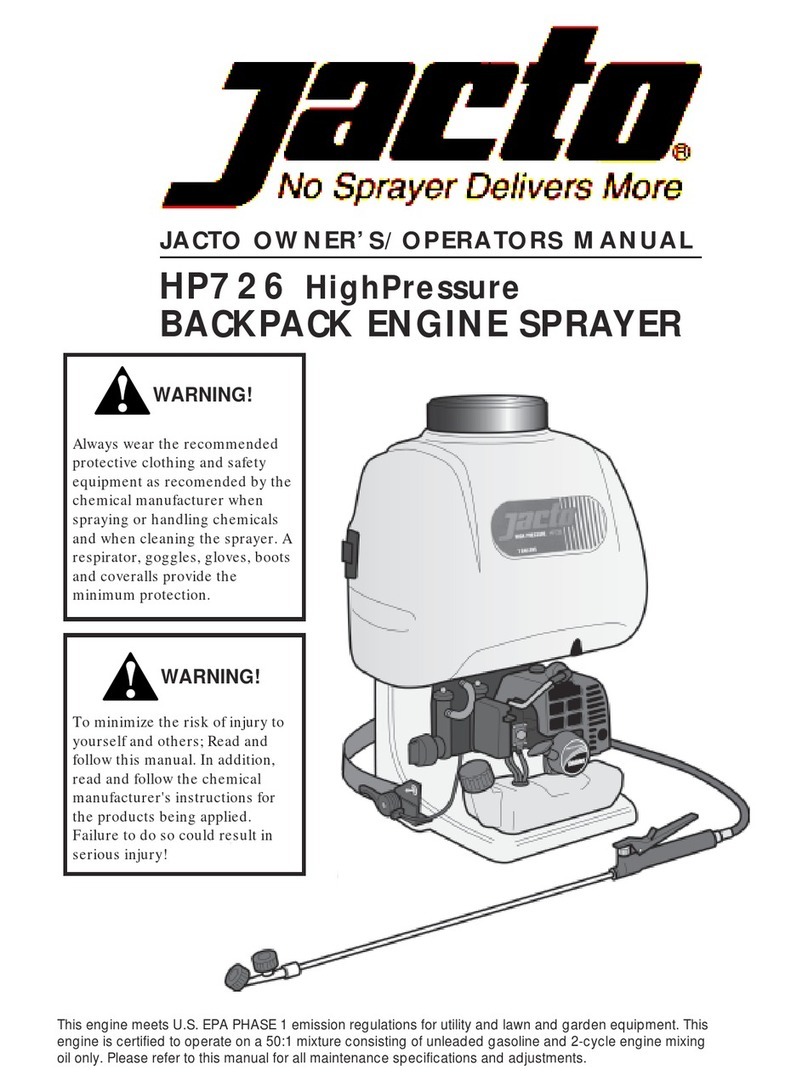

Description

Item Qtd

Part no.

LLM-384

- Open the tank lid and visualize the agitator;

- With one hand pull up the chamber, but without

removing it from the tank, up to the level it will

be possible to t the agitator in its body (Image

A). With the other hand, t the agitator and make

sure it is rm and tight;

- Lower the chamber with the agitator assembled

until it ts in the cylinder (image B).

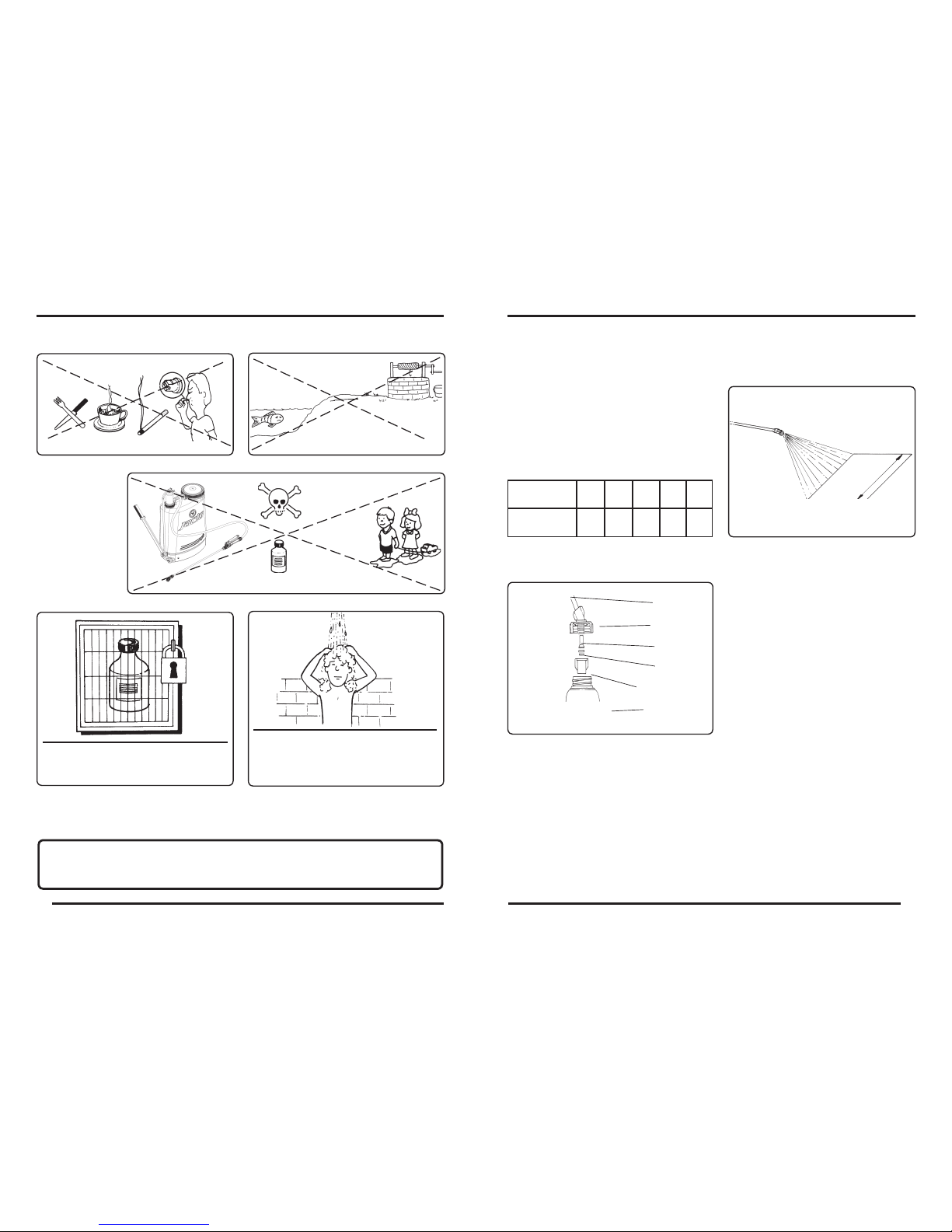

4- ASSEMBLY PROCEDURES

5- INSTALLING THE LEVER ON THE SHAFTAND THE ROD ON THE CHAMBER TOP

- Grease slighty the lever orice and instal it on

the rod. Fit

a at washer before the locked ring.

- Grease slighty the orice on the chamber top.

- Fit a at washer on the shaft and rod.

- For easy assembly, install the lever on the

shaft and the rod on the chamber top at

the same time.

- Install the other at washers on the shaft

and rod and lock with the locked ring. locked

ring

Rod

Lever

Shaft

Washers

Contents of

the plastic bag

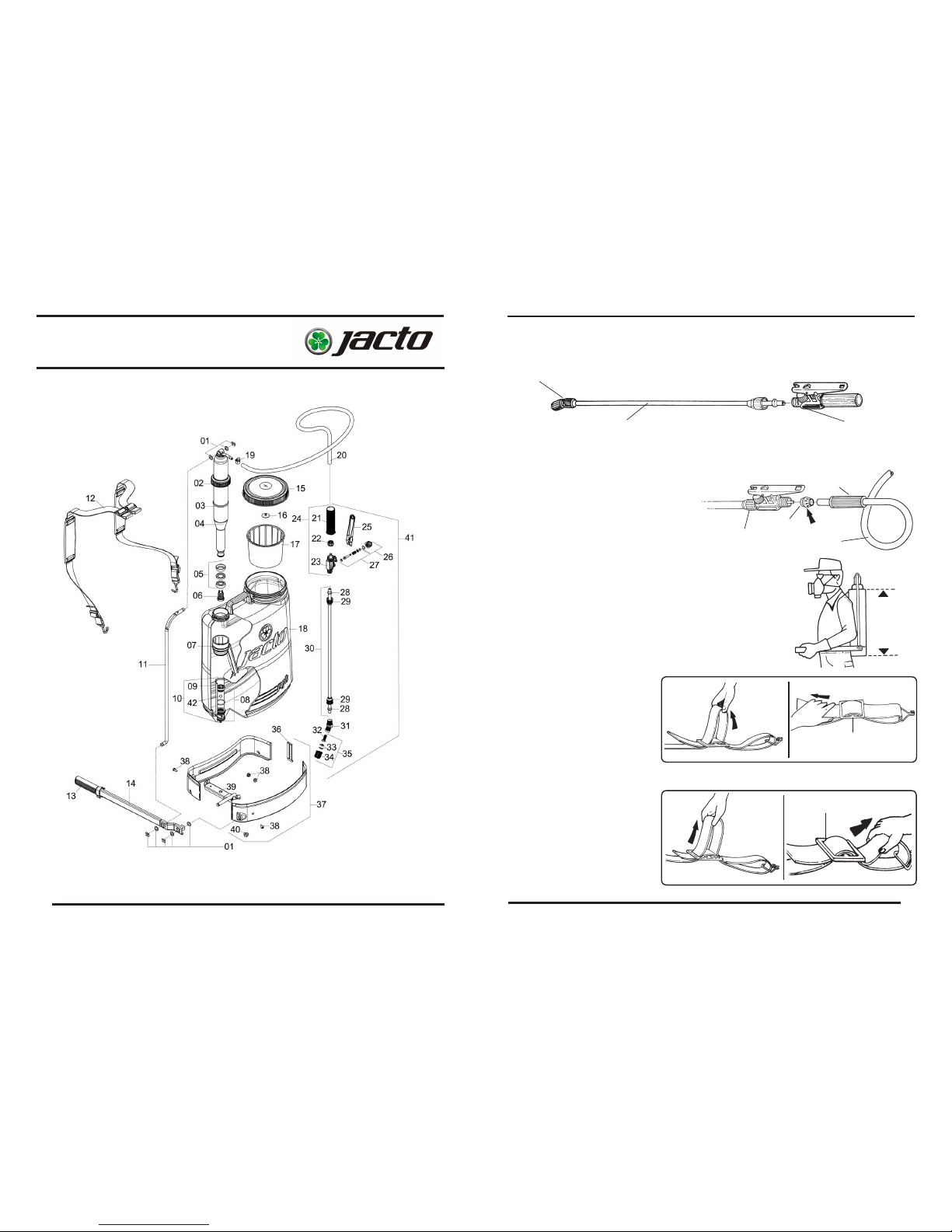

Lever

Tank

Accessories plastic

bag Rod

Hose with

trigger valve

Lance

Take out of the sprayer carton

the following parts:

ATTENTION: Be careful when

taking out the sprayer out of

the carton because the lever is

loose and can cause damage or

personal injury.

- Note that the agitator is loose

inside the tank and must be pro-

perly assembly.

(A) (B)

1 1198800 Washers and lock ring set 1

2 831222 Gasket holder 1

3 831230 Gasket 7 x Ø 50,6 1

4 635284 Chamber assembly

(supplied items: 05 and 06) 1

5 336479 Piston cup with spacer 1

6 1192736 Chamber valve 1

7 300582 Agitator 1

8 661124 Fastener assembly 1

9 925917 Cylinder assembly

(supplied items: 08 and 39) 1

10 1197400 Orange rod with lock rings 1

11 915926 Strap assembly 1

12 495812 Handgrip with lock 1

13 615005

Pumping lever with handgrip

1

14 120527 Lid tank with diaphrgm 1

15 647131 Strainer 1

16 942086 Tank with lid 1

17 1187239 Clamp 1

18 530576 Hose Ø 5/16" x 1350 1

19 909192 Trigger valve handle 1

20 920470 Trigger valve lock 1

21 909283 Trigger valve body 1

22 908889 Trigger valve assembly 1

23 105247 Trigger 1

24 996058 Trigger valve cap 1

25 105239 Nozzle assembly 1

26 915744 Screw cap 2

27 100131 Lance 601 1

28 635276 Elbow with cone packing 1

29 592139 Nozzle lter M40 1

30 1168547 Nozzle JD-12 P 1

31 1168546 Nozzle cap 1

32 427062 Nozzle JD-12 P assembly 1

33 825471 Base clamp 1

34 229484 Tank base assembly 1

35 229476

Bolts, washers and nuts set

1

36 942714 Reinforcement 1

Description

Item Qtd

Part no.

37 942060 Flanged nut M-8 1

38 915769 Spray lance 1

39 715474 Ball 1

40 560573 Diaphrgm 1

41 502757 Buckle 2

42 433474 Hook 2