2

Table of Contents

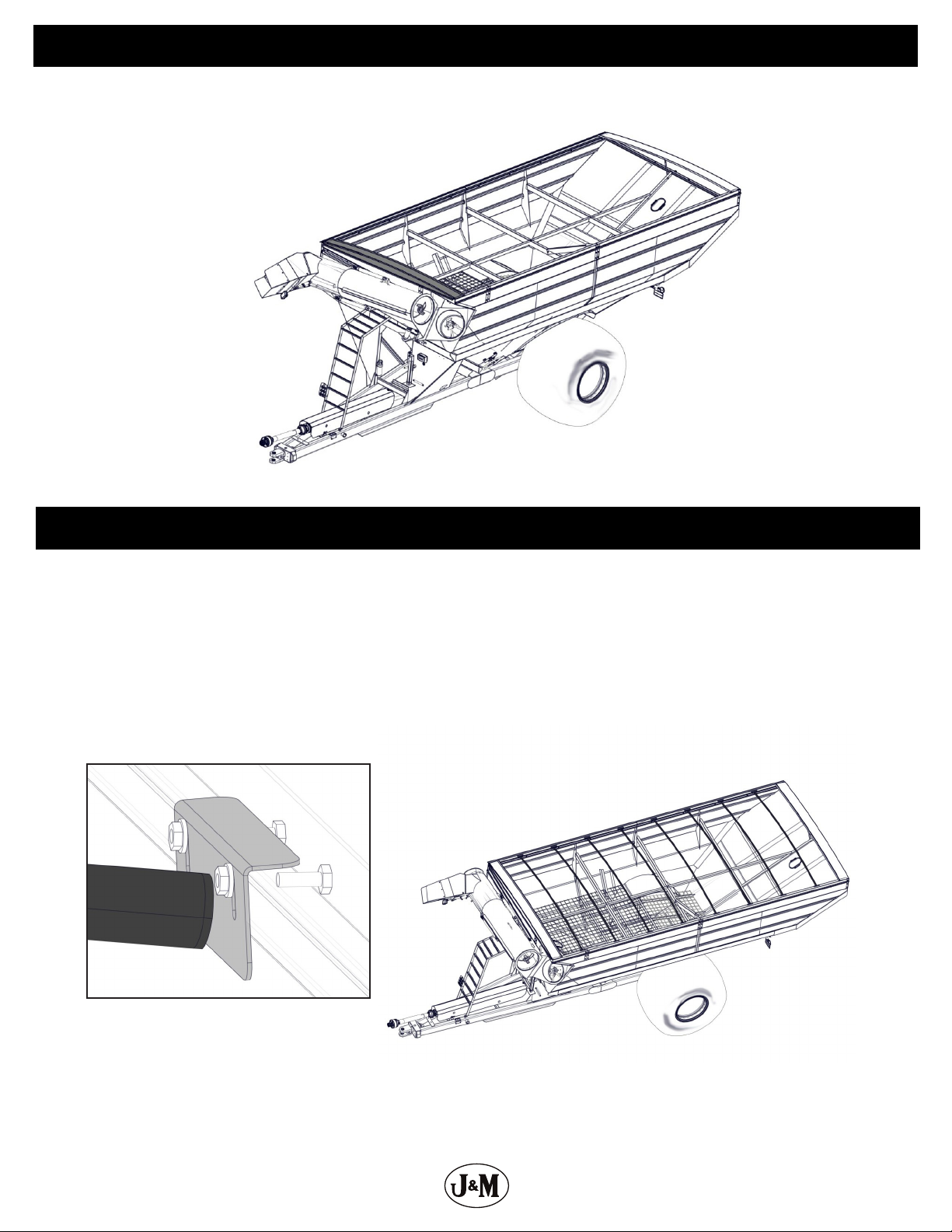

Manual Roll Tarp

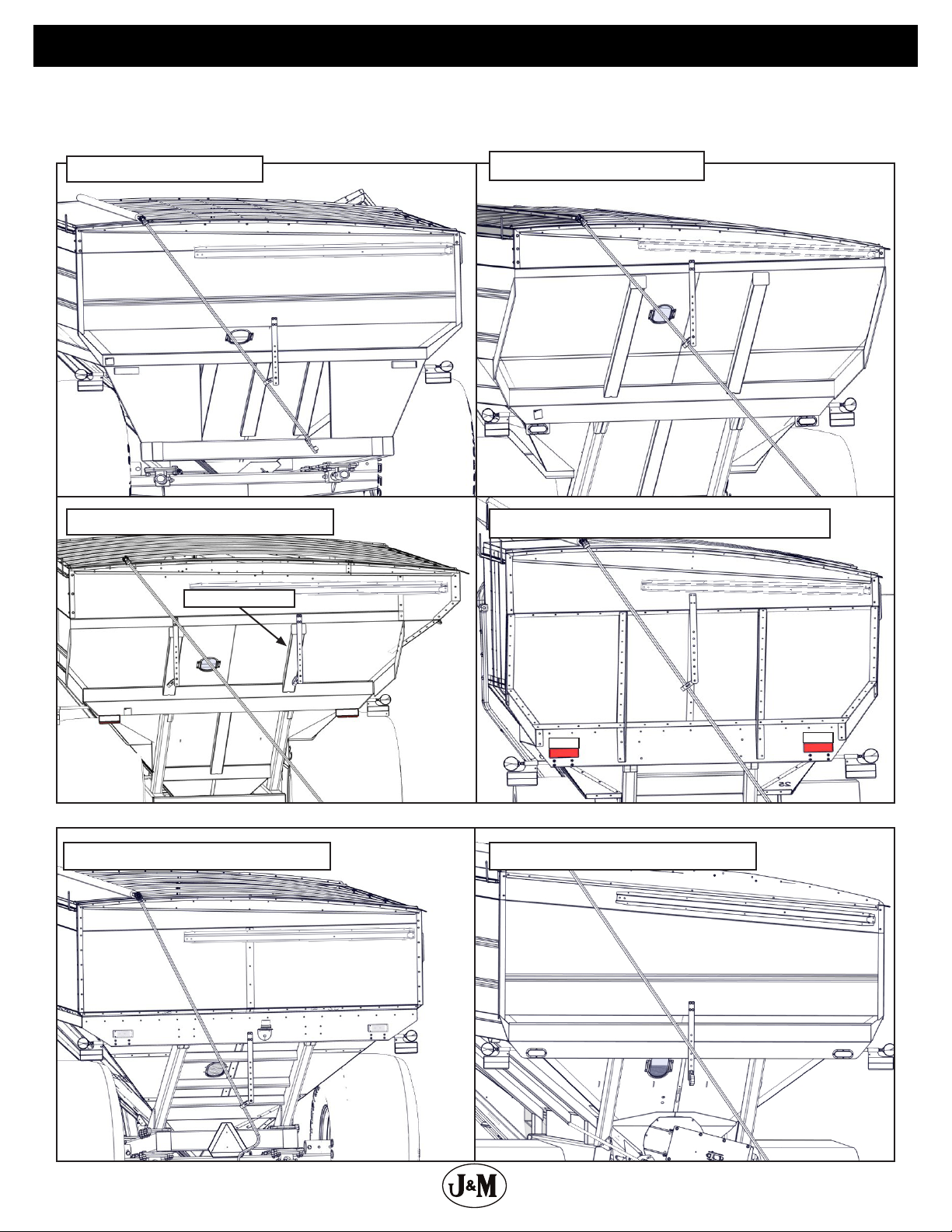

3...............................................................................Endcap Assembly

4....................................................................... Hanger Bracket Locations

5....................................................................... Hanger Bracket Assembly

5..................................................................................Tightening Lip

6...........................................................................Installing Rear Endcap

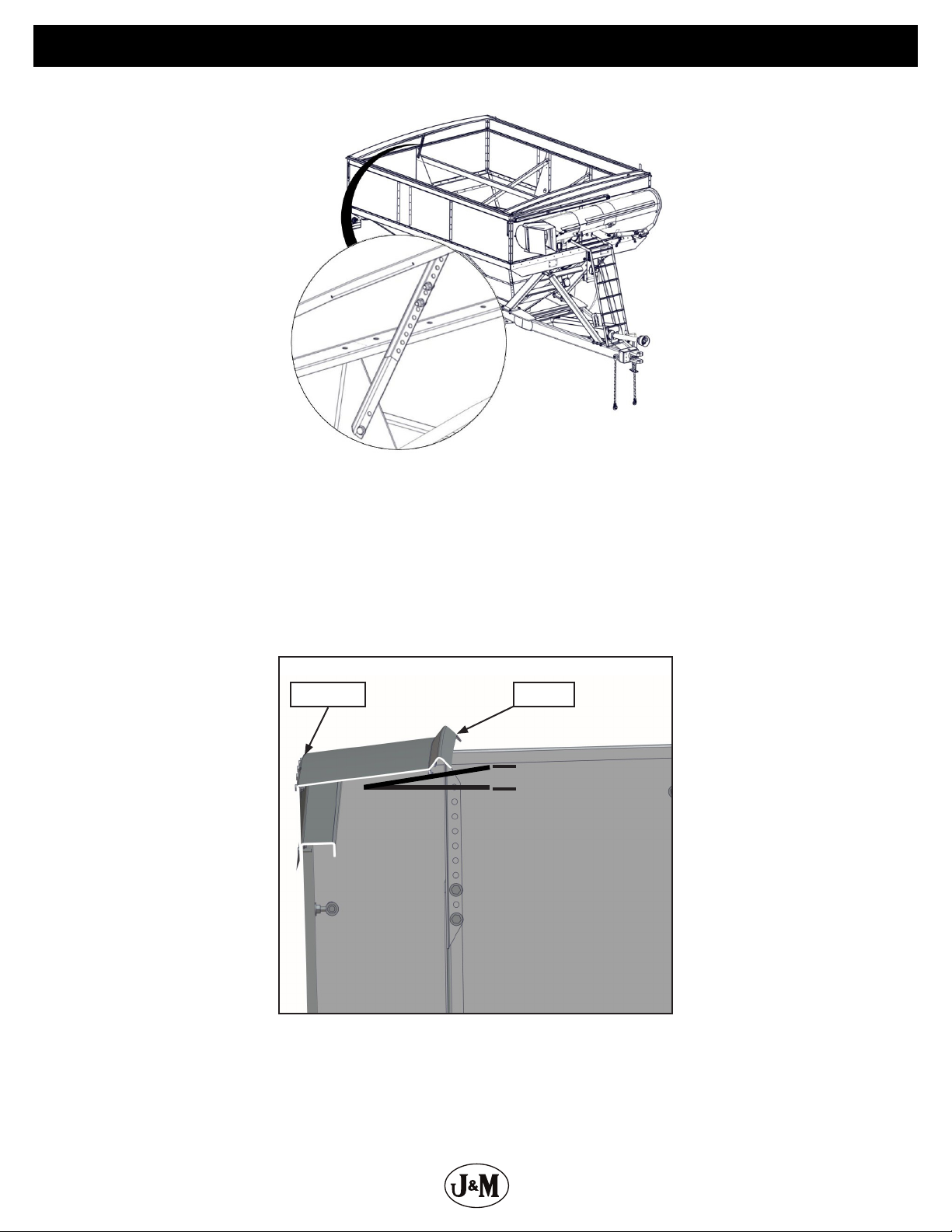

7.....................................................................Rear Endcap Support Braces

8.........................................................................Tightening Rear Endcap

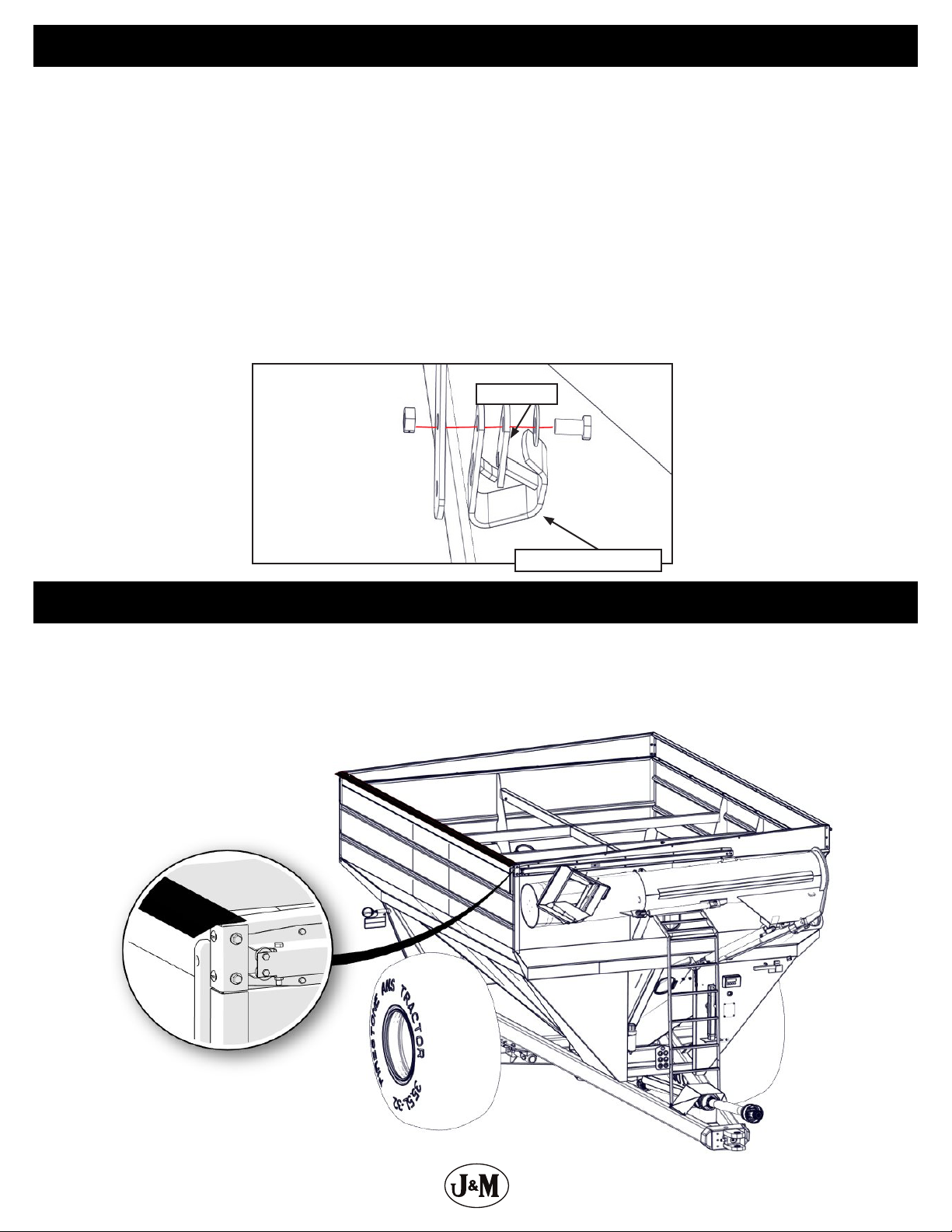

8................................................................................ Installing J-Bolts

9..........................................................................Installing Front Endcap

9.......................................................................................Tarp Bows

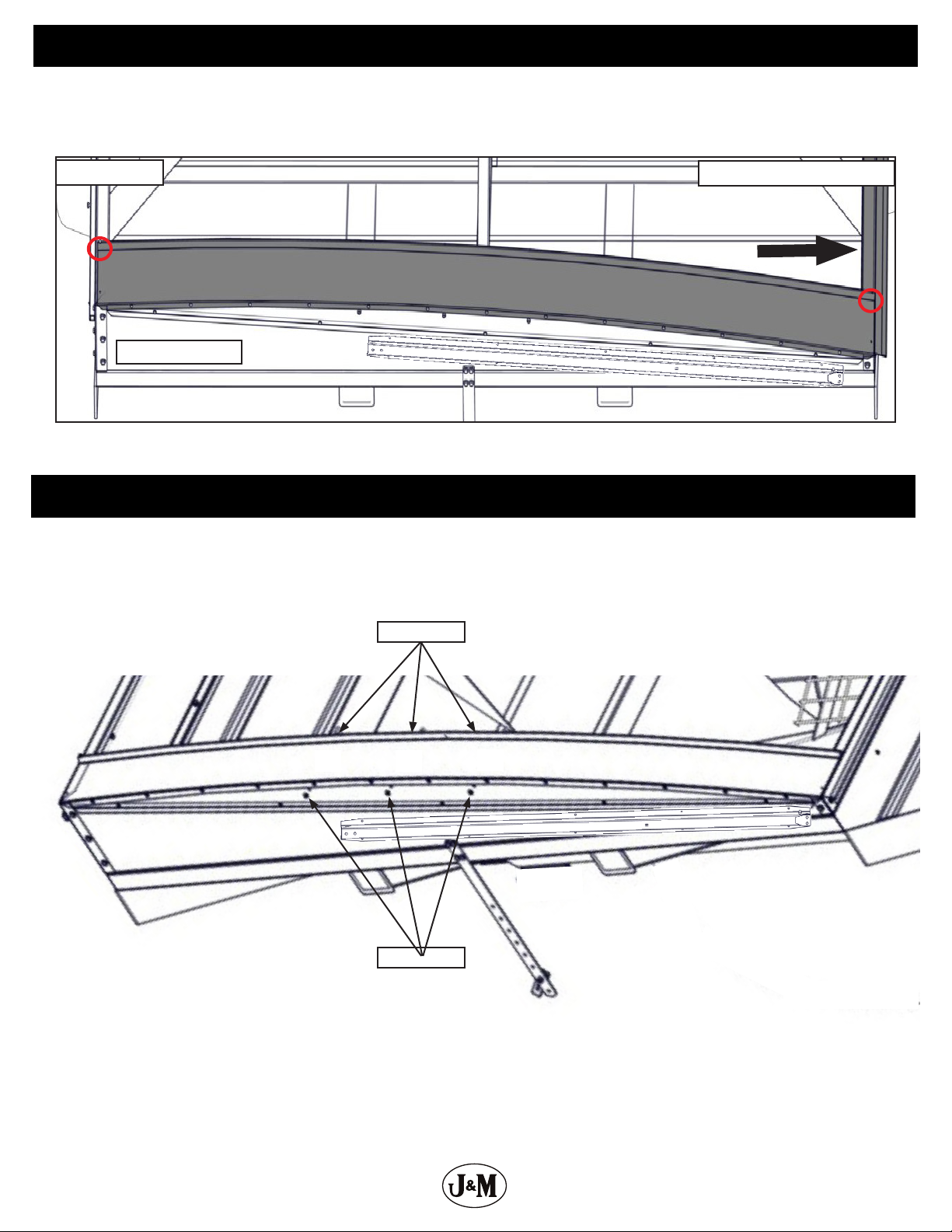

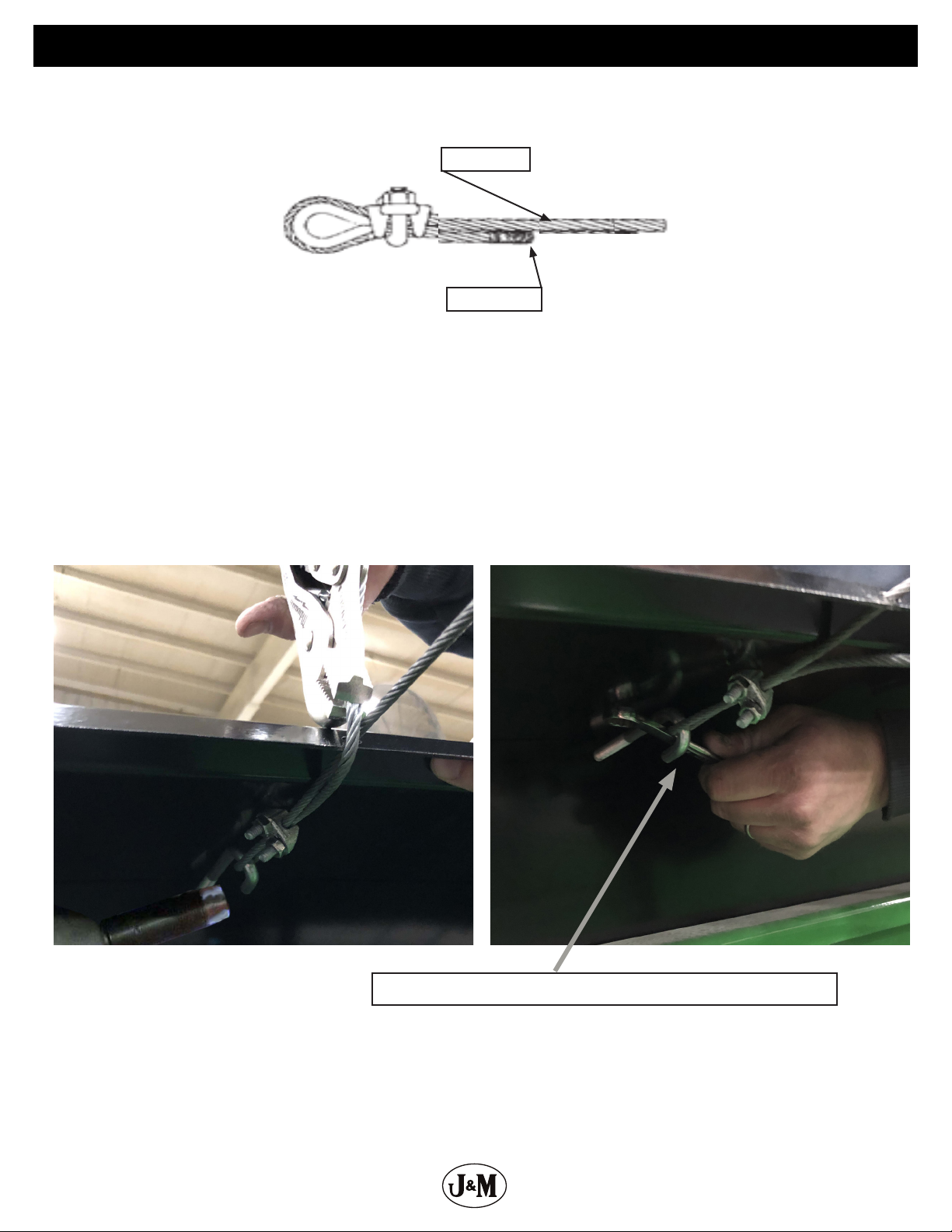

10 ........................................................................ Installing Cable Clamps

11 ....................................................................... Installing Spring Returns

12 .......................................................................Installing 1-1/4” Roll Tube

12 .....................................................................Installing 1”Tie Down Tube

13 ....................................................................... Installing Roll Tarp Stops

13 ....................................................Installing Pop Rivets on 1-1/4”Roll Tarp Tube

14 .....................................................................Installing the Crank Handle

15 ......................................................................................Tarp Rope

Electric Roll Tarp

17 ........................................................Removing Parts (if previously equipped)

17 ........................................................................Electric Roll Tarp Mount

18 ..................................................... Attaching Electric Roll Tarp Arm and Motor

18 ............................................................................Harness Installation

19 ...................................................................................Switchboard

20 ..............................................................................Wiring Schematic

21 ............................................................. Aligning the Tarp/Troubleshooting

Repair Parts List

22-23 ............................................................Repair Parts for Manual Roll Tarps

24 ................................................................Repair Parts List - Standard Carts

25 .........................................................Repair Parts List - Extended Reach Carts

26 ............................................................. Repair Parts List - Drag Series Carts

27-28 ............................................................Repair Parts for Electric Roll Tarps