5

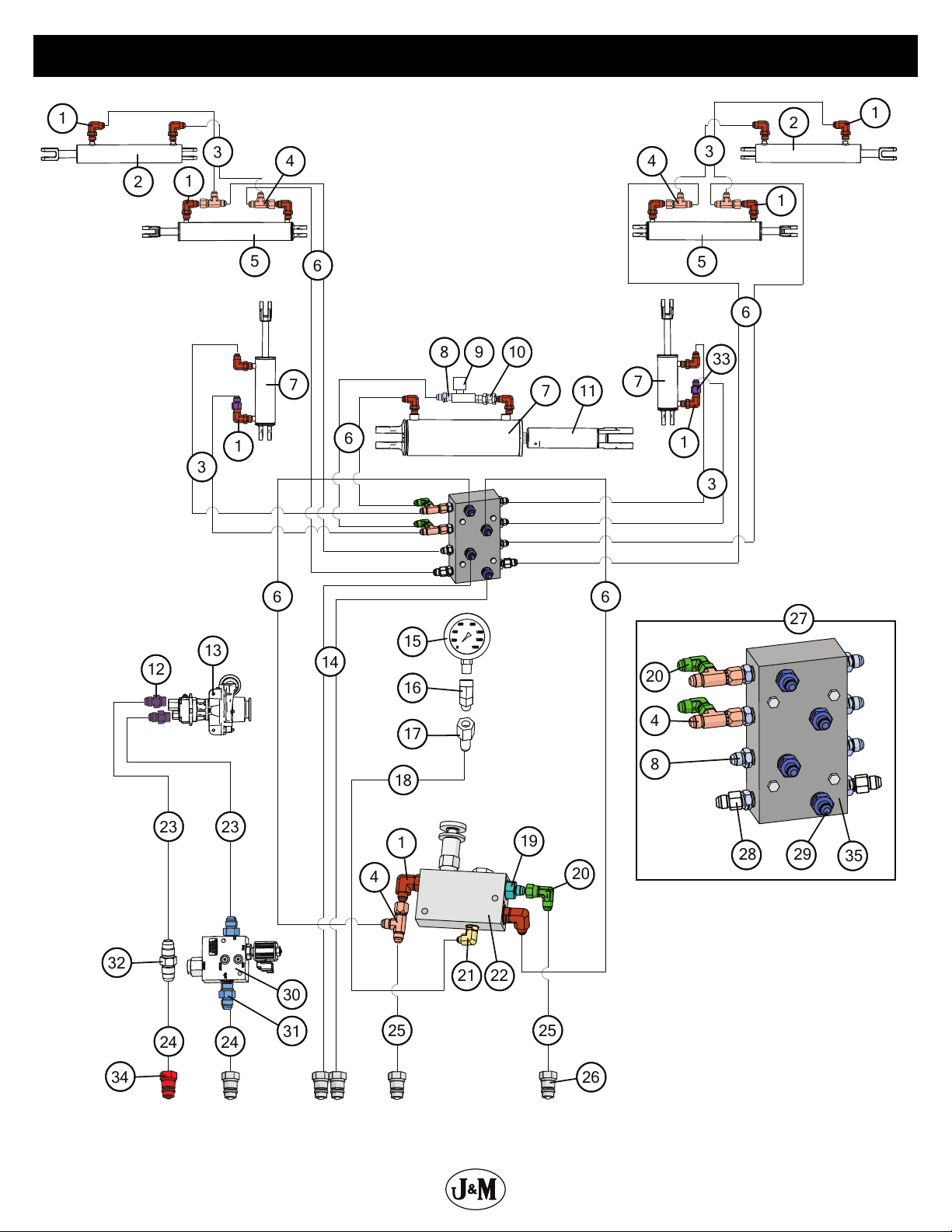

Hydraulic Schematic

Description Part No.

1 3/8”Male JIC x 1/2” Male ORB; 90 Degree Elbow JM0037159

2 3-1/2”x 14”Welded Non-Cushion JD Cylinder JM0055022

2 Seal Kit for 3-1/2”x 14” Hydraulic Cylinder (JD-629) JM0074483

3 3/8”x 108” Hydraulic Hose 108inch6M3K-6G-6FJX-6G-6FJX JM0041615

4 3/8”Male JIC x 3/8” Female JIC Swivel x 3/8” Male JIC; Tee JM0037163

5 4”Bore, 24”Stroke Welded Hydraulic Cylinder - Heavier Clevises JM0030730

5 Seal Kit for 4”x 24” Hydraulic Cylinder (JD-609) JM0039242

6 3/8”x 84” Hydraulic Hose 84inch6M3K-6G-6FJX-6G-6FJX JM0041613

7 4”Bore, 8”Stroke Welded Hydraulic Cylinder - Heavier Clevises JM0030757

7 Seal Kit for 4”x 8” Hydraulic Cylinder (JD-608) JM0039241

8 3/8”Male JIC x 3/8”Male NPT; Straight JM0037167

9 Parker Flow Control Valve (NitroGro) JM0041626

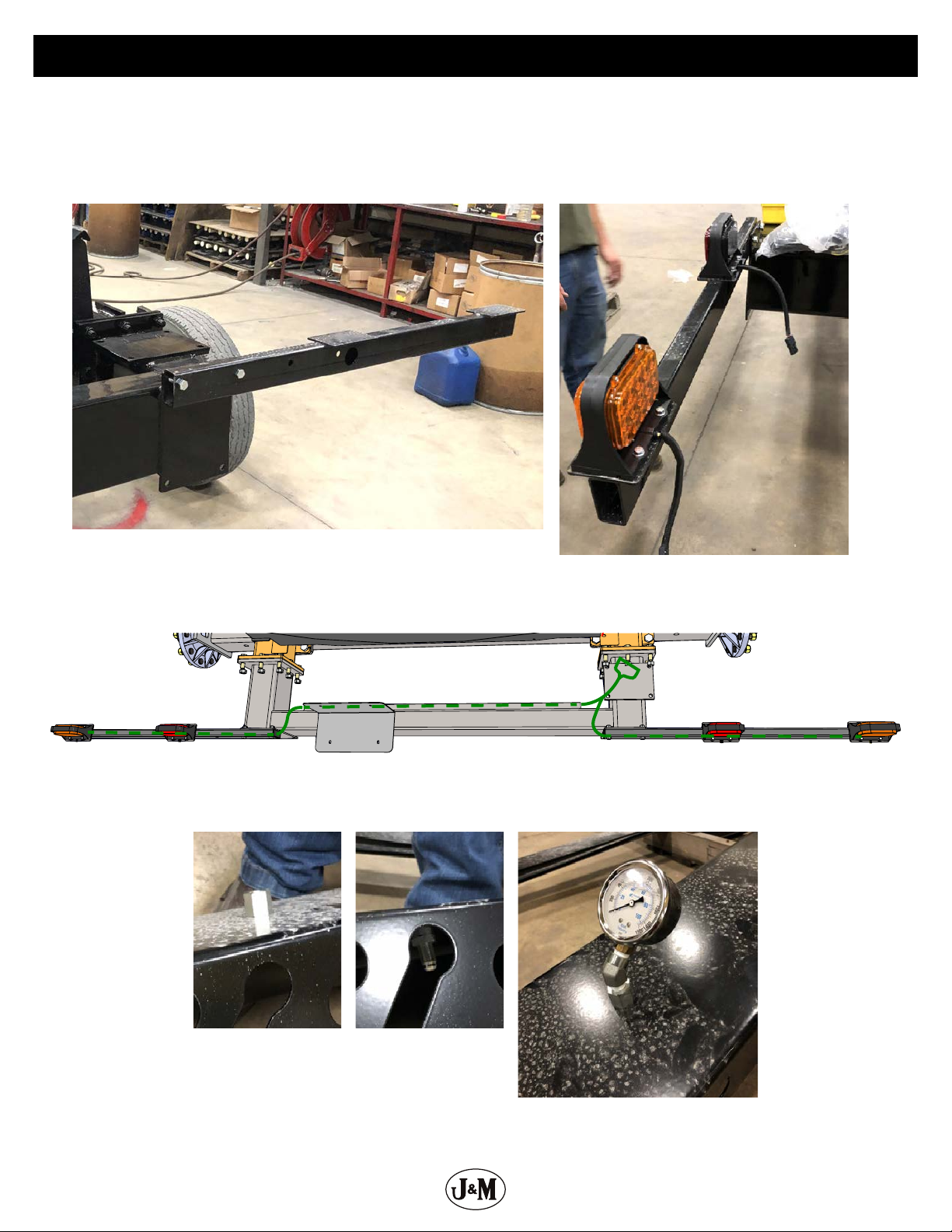

10 3/8”Male NPT x 3/8” Female JIC Swivel JM0073350

11 Shaft for Down Pressure Cylinder (NitroGro) JM0032428

12 1/2”Male JIC x 5/8” Male O-Ring; Straight JM0010294

13 FMCSC-155F-HYD-206 - Ace Pump JM0061538

13 Ace 155 Pump Hydraulic Side Replacement Seal Kit - RK-BAC-75-HYD-L JM0061310

14 3/8”x 165” Hydraulic Hose 165inch6M3K-6G-6FJX-6G-8MP JM0041612

15 Pressure Gauge 0-1500psi (NitroGro) JM0037152

16 1/4”Male NPT x 1/4” Female NPT Rigid; 45 Degree Elbow JM0037156

17 1/4”Female NPT x 3/8” Male JIC Compression Bulk Head Fitting JM0037155

18 3/8”x 29-1/2” Hydraulic Hose 29.5inch6M3K-6G-6FJX-6G-6FJX90S JM0041687

19 3/8”Male JIC x 1/2” Male ORB; Straight JM0010302

20 3/8”Male JIC x 3/8” Female JIC Swivel; 90 Degree Elbow JM0010295

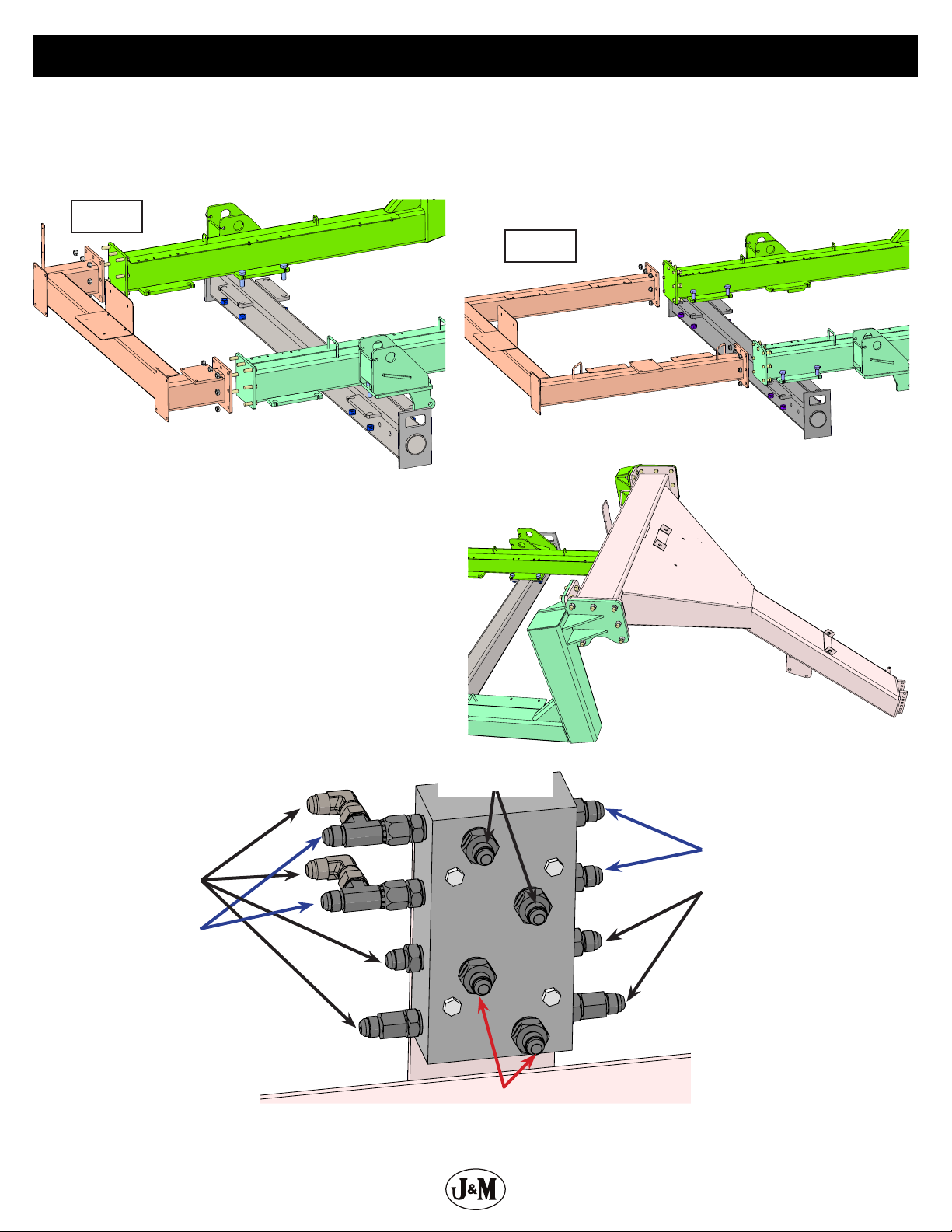

21 3/8”Male JIC x 3/8” Male ORB; 90 Degree Elbow JM0026121

22 Down Pressure Relief Valve JM0034806

23 1/2”x 180” Hydraulic Hose 180inch8M3K-8G-8FJX-8G-8FJX JM0073123

24 1/2”x 168” Hydraulic Hose 168inch8M3K-8G-8MP-8G-8FJX JM0073122

25 3/8”x 84” Hydraulic Hose 84inch6M3K-6G-6FJX-6G-8MP JM0054708

26 1/2”Female NPT x Male Pioneer - Low Flow, Ball Style JM0039220

27 5000 Applicator Manifold Block ASM JM0073299

28 3/8”Male JIC x 3/8” Female JIC with .062 Orice JM0047738

29 3/8”Male JIC x 1/2” Male NPT; Straight JM0037172

30 Hydraulic PWM Control Valve for Nitrogen Fertilizer Pump (F14264A1) JM0059223

31 1/2”Male JIC x 1/2” Male O-ring; Straight JM0010293

32 1/2”Male JIC x 1/2” Male JIC; Straight JM0041452

33 3/8”Male JIC x 3/8” Female JIC with .094 Orice JM0047735

34 1/2”Female NPT x Male Pioneer - High Flow, Cone Style JM0018254

35 Main Manifold Block (NitroGro) JM0028902