4-5. Replacement and adjustment of stacker lock sensor ...........................................4-5

4-6. Replacement and adjustment of shutter sensor ...................................................4-6

4-7. Layout diagram of Y unit sensor...........................................................................4-7

4-8. Replacement and adjustment of Y-axis origin,

minus limit and plus limit sensor .........................................................................4-8

4-9. Replacement and adjustment of chuck detection sensor .....................................4-9

4-10. Replacement and adjustment of tray pulled-out detection (+) switch .................4-10

4-11. Layout diagram or X unit sensor.........................................................................4-11

4-12. Replacement and adjustment of X-axis origin,

minus limit and plus limit sensor .......................................................................4-12

4-13. Replacement and adjustment of head ascent/descent sensor ...........................4-13

4-14. Layout diagram or shuttle unit sensor ................................................................4-14

4-15. Replacement and adjustment of shuttle origin,

minus limit and plus limit sensor .......................................................................4-15

4-16. Replacement and adjustment of pad size sensor and BGA sensor ...................4-16

4-17. Replacement and adjustment of cover lock sensor............................................4-17

4-18. Replacement and adjustment of cover interlock switch (standard).....................4-18

4-19. Replacement and adjustment of cover OPEN switch ASM (CE machine) .........4-19

4-20. Layout diagram of door sensors .........................................................................4-20

4-21. Replacement and adjustment of door lock detection sensor

and door open sensor.......................................................................................4-21

4-22. Replacement and adjustment of door sensors (CE machine) ............................4-22

4-23. Replacement and adjustment of transfer sensor ................................................4-23

4-24. Replacement and adjustment of wrong tray insertion sensor.............................4-24

4-25. Replacement and adjustment of inspection transfer stop sensor

(transfer inspection specification: optional).......................................................4-25

4-26. Replacement and adjustment of automatic width adjustment origin sensor

(automatic transfer width adjustment: optional) ................................................4-26

4-27. Replacement and Adjustment of the IS unit antenna (IS: Option) ......................4-27

5

Replacement and Adjustment of Motors.......................................... 5-1

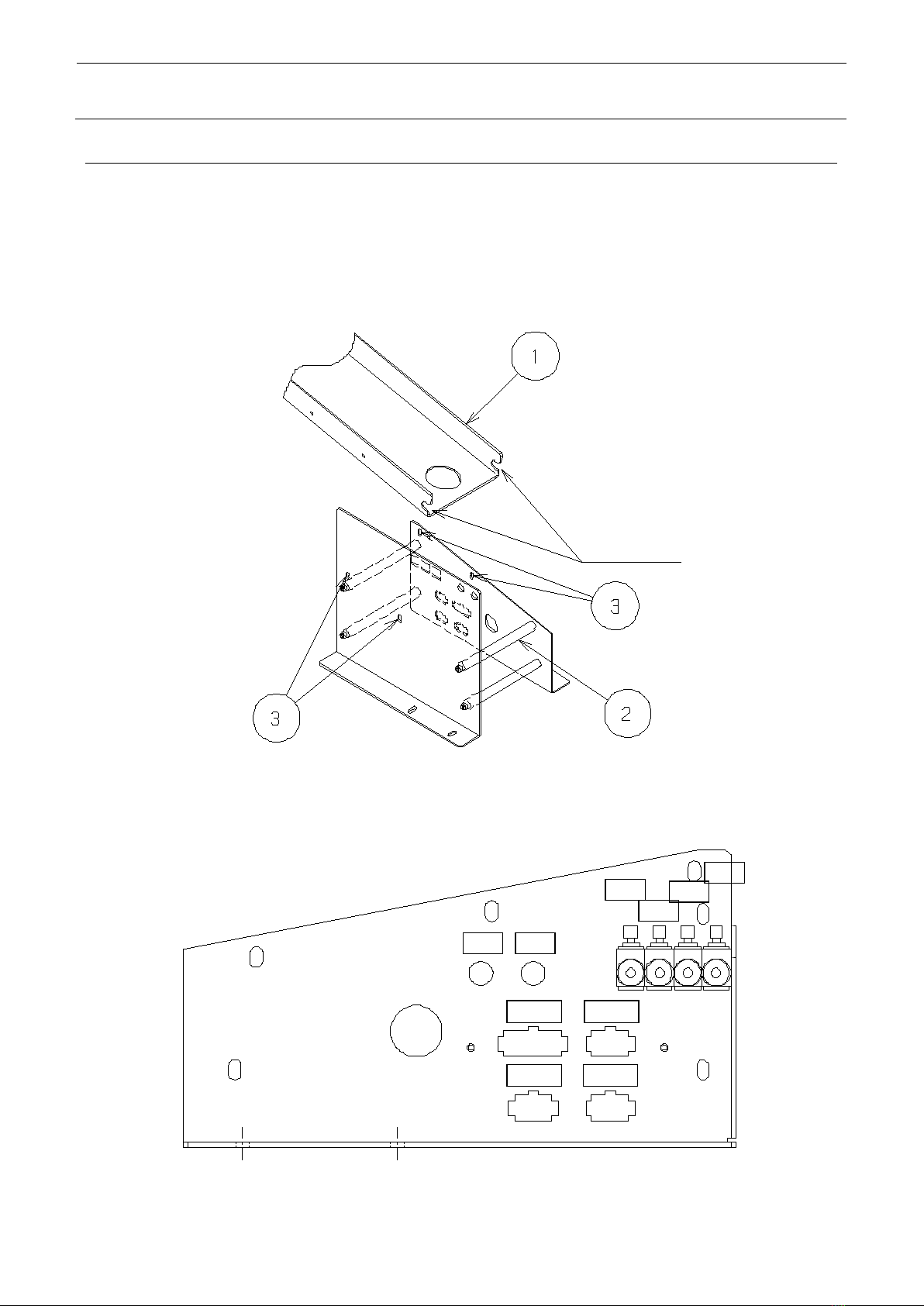

5-1. Layout diagram of motors.....................................................................................5-1

5-2. Replacement of Z-axis motor ...............................................................................5-2

5-3. Replacement of X-axis motor ...............................................................................5-3

5-4. Replacement of Y-axis motor ...............................................................................5-4

5-5. Replacement of shuttle motor ..............................................................................5-5

5-6. Replacement of conveyor motor...........................................................................5-6

5-7. Replacement of automatic width adjustment motor

(optional: automatic width adjustment) ...............................................................5-7