FX-1/FX-1R Maintenance Manual

CONTENTS

[1] X-Y UNIT.................................................................................................1-1

1-1. Replacing the Timing Belt and Adjusting the Belt Tension....................................1-1

1-1-1. Timing Belt YM..................................................................................................................... 1-1

1-1-2. YB-Belt................................................................................................................................. 1-2

1-1-3. Adjustment Procedure ......................................................................................................... 1-3

1-1-4. Measurement Positions and Specification Values................................................................ 1-3

1-1-5. Adjusting Method ................................................................................................................. 1-4

1-2. Replacing the Pulleys............................................................................................1-5

1-2-1. Replacing the Pulley YA....................................................................................................... 1-5

1-2-2. Replacing the Pulley YM ...................................................................................................... 1-5

1-2-3. Replacing the Pulley YB....................................................................................................... 1-5

1-3. Replacing the Servomotors...................................................................................1-5

1-4. Replacing the Magnescale (For FX-1R, see Section 1-8.) ....................................1-6

1-4-1. X-axis Magnescale Affixing Position (For FX-1R, see Section 1-8-1.) ................................. 1-6

1-4-2. Y-axis Magnescale Affixing Position (For FX-1R, see Section 1-8-2.).................................. 1-7

1-4-3. Gap of Magnescale (For FX-1R, see Section 1-8-4.)........................................................... 1-7

1-5. Replacing the Limit Sensor and the X-Axis Home Position Sensor.......................1-8

1-5-1. Replacing the XL-, XR-, and XC-limit sensors,

XL- and XR-near sensors, XL- and XR-ORG sensors ......................................................... 1-8

1-5-2. Replacing the YB- +/−limit sensors and YB-near sensor...................................................... 1-8

1-6. Replacing the Home Position Sensor....................................................................1-9

1-6-1. Y-Axis................................................................................................................................... 1-9

1-7. Replacing the Plastic Rail ...................................................................................1-10

1-7-1. Replacing the X-Axis Plastic Rail ....................................................................................... 1-10

1-7-2. Replacing the Y-Axis Plastic Rail ....................................................................................... 1-11

1-8. Replacing the magnescale (FX-1R) ....................................................................1-12

1-8-1. X-axis magnescale affixing position (FX-1R) ..................................................................... 1-12

1-8-2. YB-axis magnescale affixing position (FX-1R) ................................................................... 1-13

1-8-3. YA-axis magnescale affixing position (FX-1R) ................................................................... 1-13

1-8-4. Gap of magnescale (FX-1R) .............................................................................................. 1-14

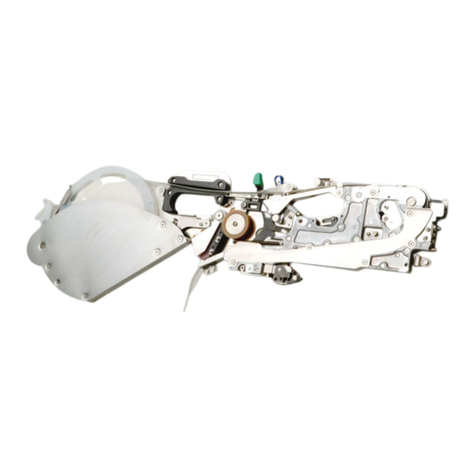

[2] HEAD UNIT.............................................................................................2-1

2-1. Replacing and Adjusting the Head ........................................................................2-1

2-1-1. MNLA Head.......................................................................................................................... 2-1

2-2. Replacing the Motor ..............................................................................................2-4

2-2-1. Z-Motor (MNLA Head).......................................................................................................... 2-4

2-2-2. θ-Motor (MNLA Head) .......................................................................................................... 2-6

i

Rev. 2.00