KE2000 Installation Manual

CONTENTS

1.Basic configuration and name of each part..........................................................................................1

1-1.KE-2010/2020/2040...........................................................................................................................1

1-2. KE-2030................................................................................................................................................2

2. Installing the main unit.............................................................................................................................3

3. Detaching the packing materials from the machine................................................................................4

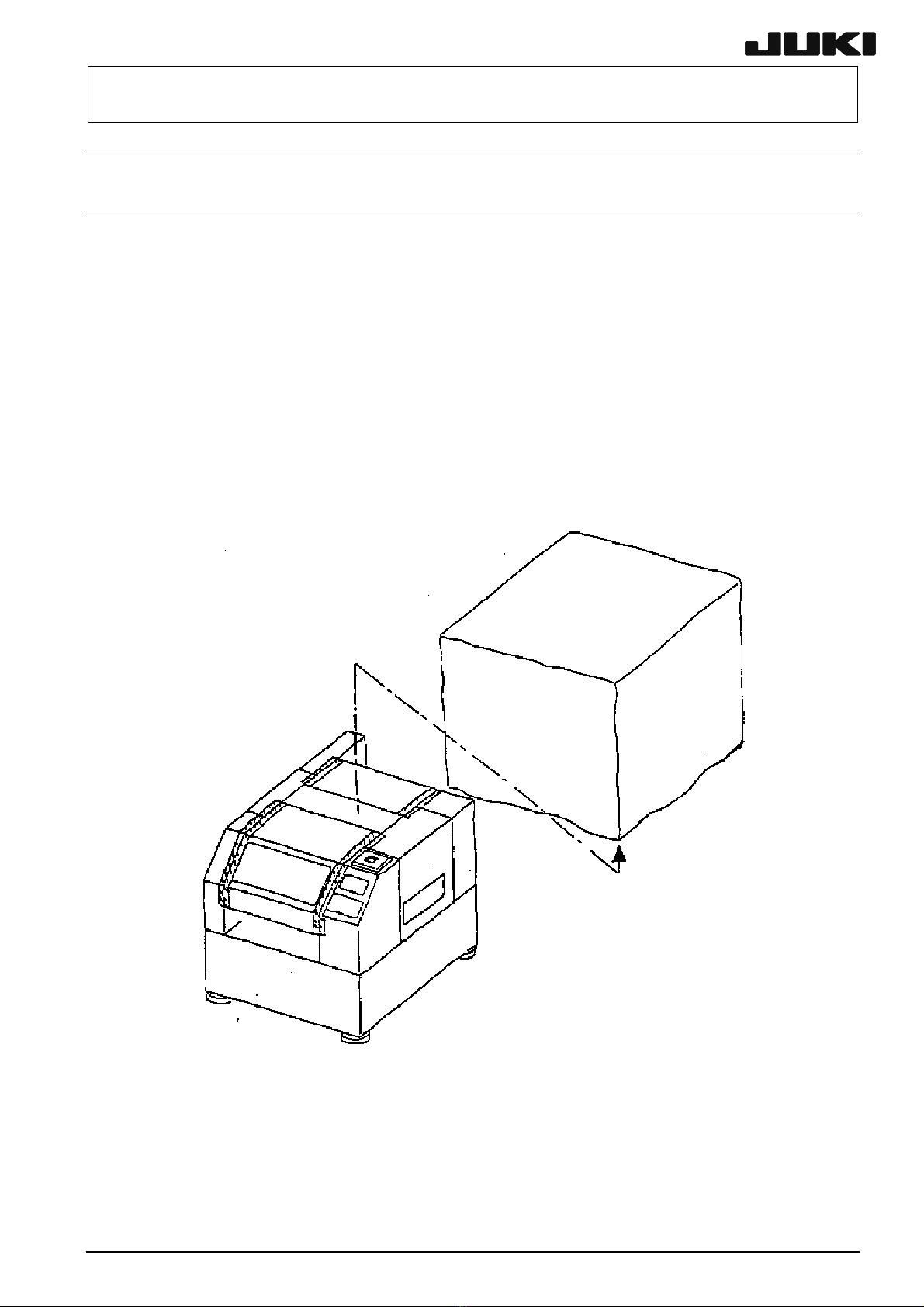

3-1. Overall machine cover .........................................................................................................................4

3-2. Safety cover..........................................................................................................................................5

3-3. Transport cover(only CE Machine) .................................................................................................. 6

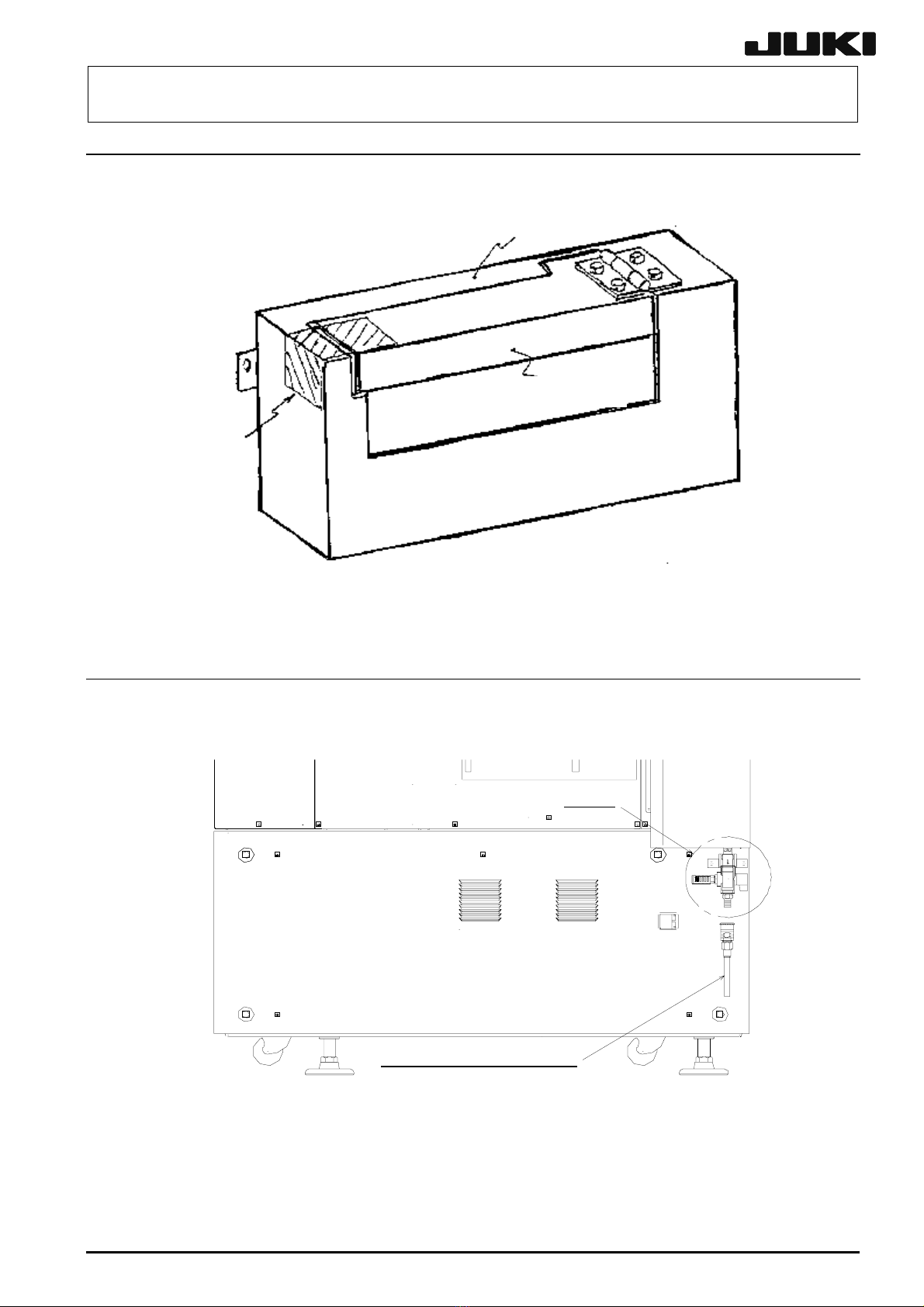

3-4. Pneumatic units....................................................................................................................................6

3-5. Feeder relay cable 8 (For machines with fixed bank specification only)............................................. 7

3-6. Replacement table trolley ....................................................................................................................8

4. Adjusting the transport height and leveling the machine ......................................................................10

4-1. KE-2010/2020/2040 ...........................................................................................................................10

4-2. KE-2030..............................................................................................................................................13

5. X-Y unit...................................................................................................................................................15

5-1. Detaching the X-axis frame fixing parts (For model 2030 only)........................................................15

5-2. Detaching the head fixing parts .........................................................................................................16

6. Head unit................................................................................................................................................17

6-1. Detaching the packing materials........................................................................................................17

6-2. Detaching the head unit fixing parts ..................................................................................................18

7. Board transport unit ...............................................................................................................................20

7-1. Detaching the packing materials from the transport rail....................................................................20

7-2. Detaching the packing materials from the BU table..........................................................................20

7-3. Center station on the Y-axis drive side (For model 2030 only).......................................................21

7-4. Unpacking the supply parts................................................................................................................22

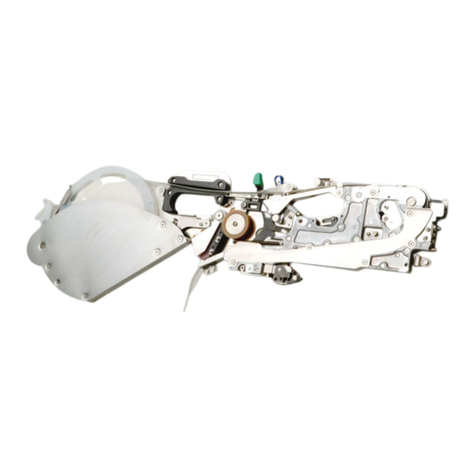

8. ATC unit..................................................................................................................................................23

9. CAL block...............................................................................................................................................23

10. Connecting the compressed air tube................................................................................................. 24

11. Connecting the power cord................................................................................................................ 26

11-1. 2010/2020/2040 ............................................................................................................................... 26

11-2. 2010/2020/2040 ............................................................................................................................... 28

11-2. 2010/2020/2040 ............................................................................................................................... 28

12. Mounting the accessories ..................................................................................................................30

12-1. Signal light........................................................................................................................................ 30

12-2. Vision monitor...................................................................................................................................30

12-3. Keyboard bracket.............................................................................................................................30