i

CONTENTS

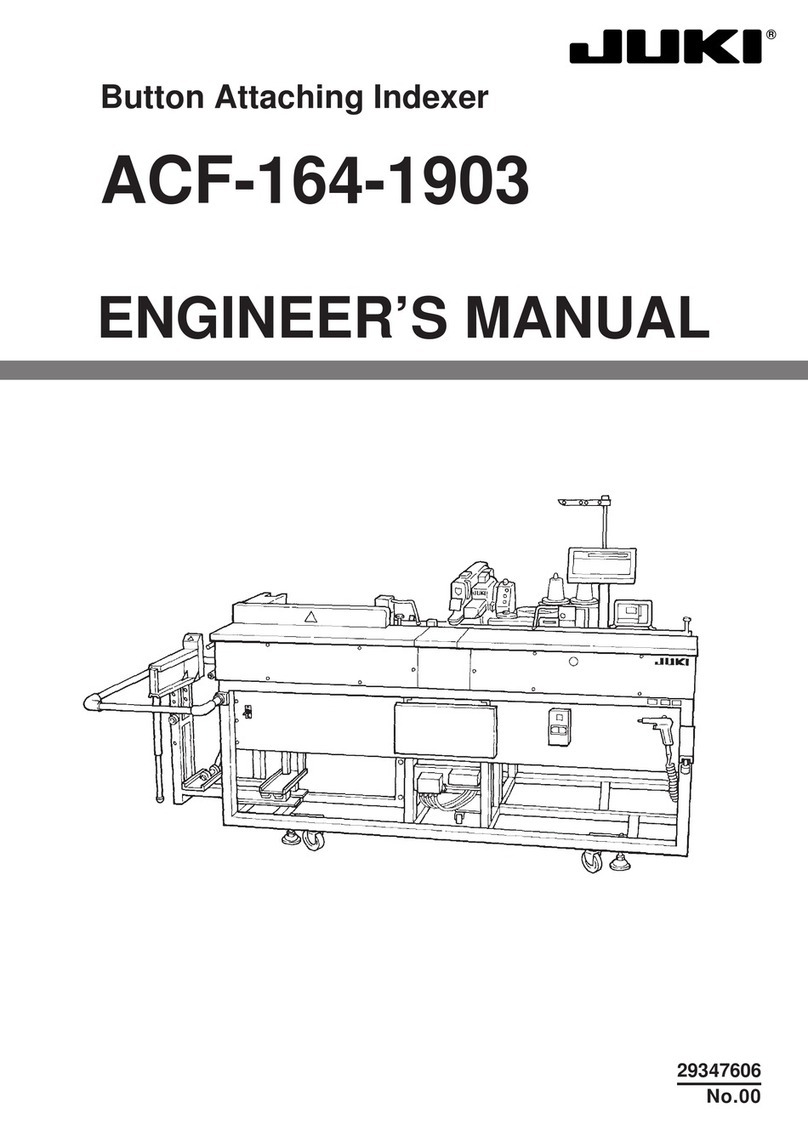

1. SPECIFICATIONS .............................................................................................1

2. CONFIGURATION .............................................................................................3

3. INSTALLATION..................................................................................................4

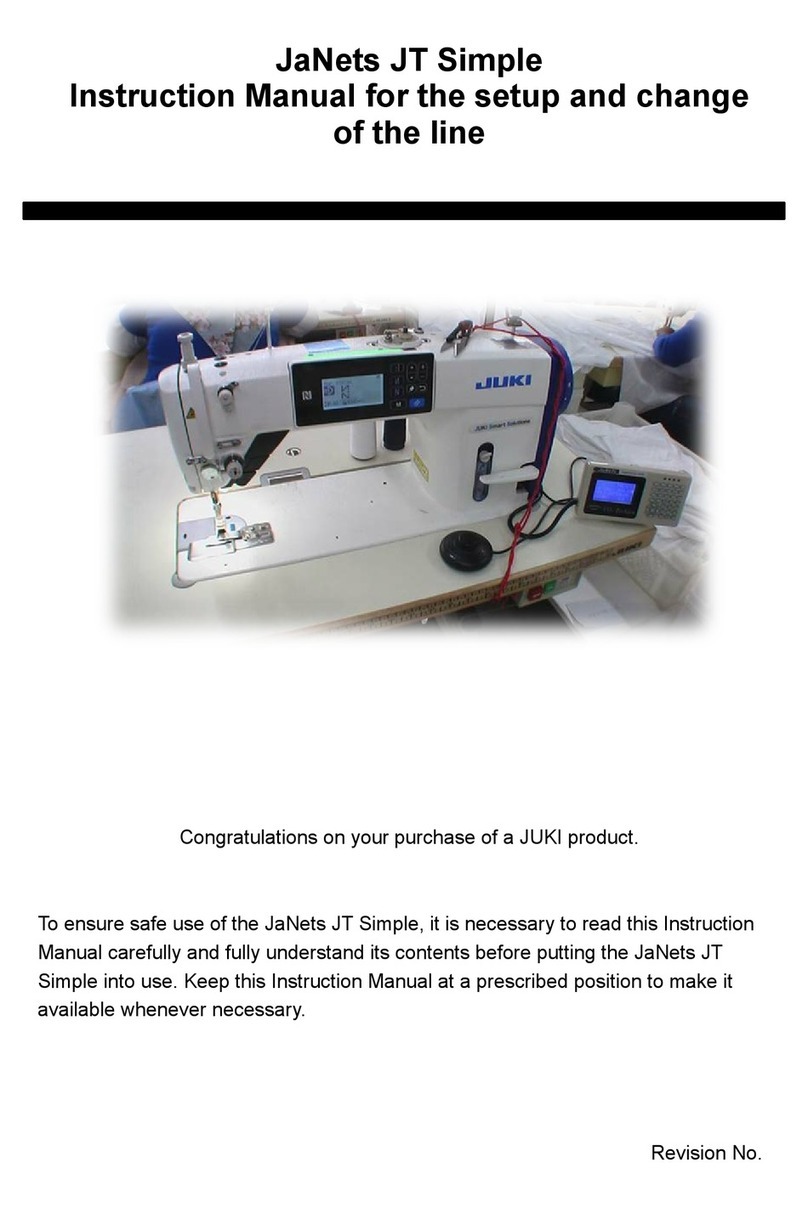

3-1. Setting up the sewing machine ..................................................................................... 4

3-1-1. Unpacking ......................................................................................................... 4

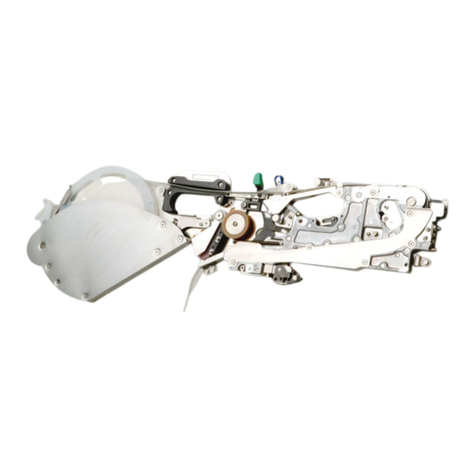

3-1-2. Setting up the X-feed mechanism................................................................... 6

3-1-3. Installation position of the thread stand ........................................................ 8

3-1-4. Changing the position of the thread stand to the front side of the

sewing machine ............................................................................................... 9

3-1-5. Setting up the table ........................................................................................ 10

3-1-6. Setting up the switches, bobbin thread winder and switch button (asm.) 11

3-1-7. Points to be checked and precautions to be taken before turning the

power ON........................................................................................................ 12

3-1-8. Installing the air hose.....................................................................................14

3-1-9. Cautions for the compressed air supply (source of supply air) facility.... 15

3-1-10. Checking the needle entry point and hook timing...................................... 16

3-1-11. Checking the concentricity (How to handle the case where you

have checked the timing between the needle entry and the hook as

described in 3-1-10 and have found it is not correct) ................................. 18

3-2. Installing the bobbin winder device ............................................................................ 22

3-3. Winding the bobbin thread........................................................................................... 23

3-4. Precautions for installation of the machine ............................................................... 24

4. PREPARATION OF THE SEWING MACHINE ................................................25

4-1. How to attach / remove the cylinder lifting plate ....................................................... 25

4-2. Lubricating method and check of the oil quantity..................................................... 26

4-3. Attaching the needle..................................................................................................... 28

4-4. Threading the machine head ....................................................................................... 29

4-5. Bobbin replacement procedure................................................................................... 30

4-6. Adjusting the thread tension ....................................................................................... 31

4-7. Adjusting the thread take-up spring and the thread breakage detector plate ........ 35

4-8. Adjusting the thread take-up stroke............................................................................ 35

4-9. Needle-to-hook relationship ........................................................................................ 36

4-10. How to wind a bobbin................................................................................................... 38

4-11. Adjusting the position of the thread trimmer ............................................................. 39

4-12. How to conrm the amount of oil (oil splashes) in the hook.................................... 42