InTandem® Table System - Dividers & Privacy Screens

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

7

Note: For better alignment

when securing dividers and

privacy screens with the

male/female fasteners, it is

recommended that the larger

diameter female fastener

be used at locations where

any type of bracket is being

installed. And, a nylon spacer

is required at any no-bracket

attachment side of a divider or

privacy screen where a short

side bracket is secured using

male/female fasteners (Figures

3, 4 & 7).

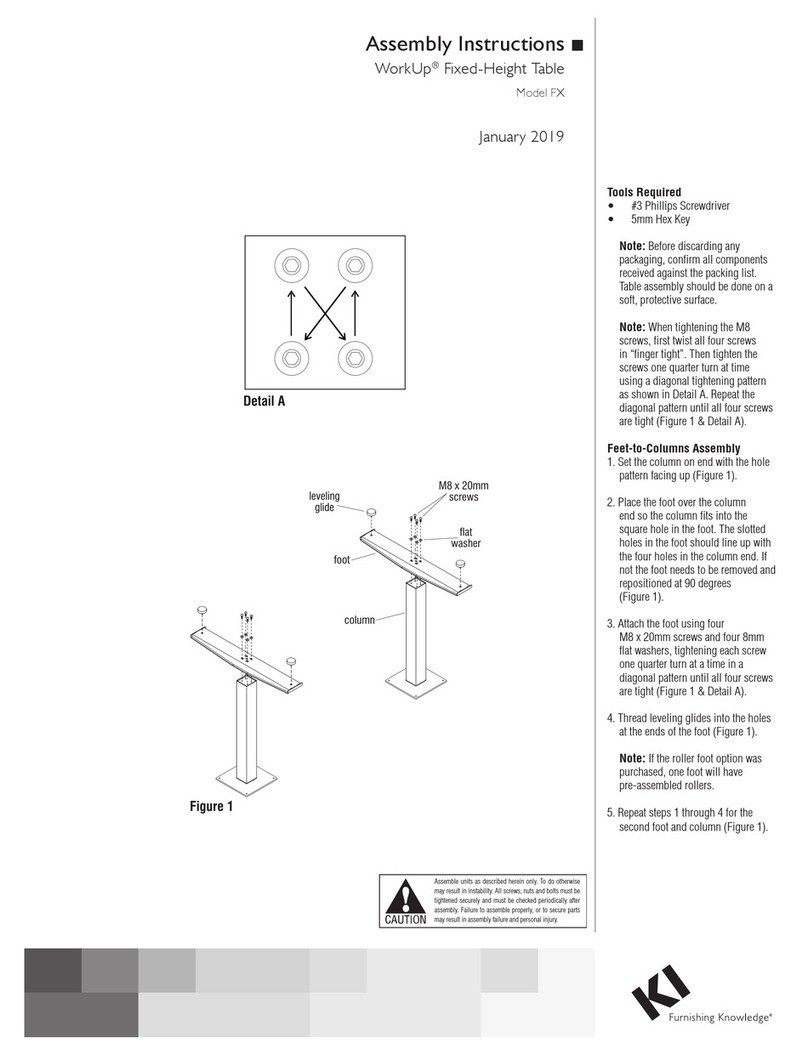

5. Next determine the location

of left-end and right-end

dividers. Both divider types

are assembled from the same

parts. Attach a bottom bracket

to the appropriate side at the

front, outside of each divider

using male/female fasteners as

illustrated (Figure 3).

6. Attach two short side brackets to

the left- and right-end dividers

at the inside rear locations

using male/female fasteners as

illustrated (Figure 3).

7. Align the bottom bracket of

the end dividers to the correct

mounting holes at the underside

of the worksurface. The correct

location will allow a privacy

screen to be mounted at the back

edge of the table. Secure the

bottom bracket of the right-end

and left-end dividers to the

underside of the worksurfaces

using the short T-25 driver bit

to thread in two #10 x 3/4" wood

screws into the pre-drilled holes

(Figure 3).

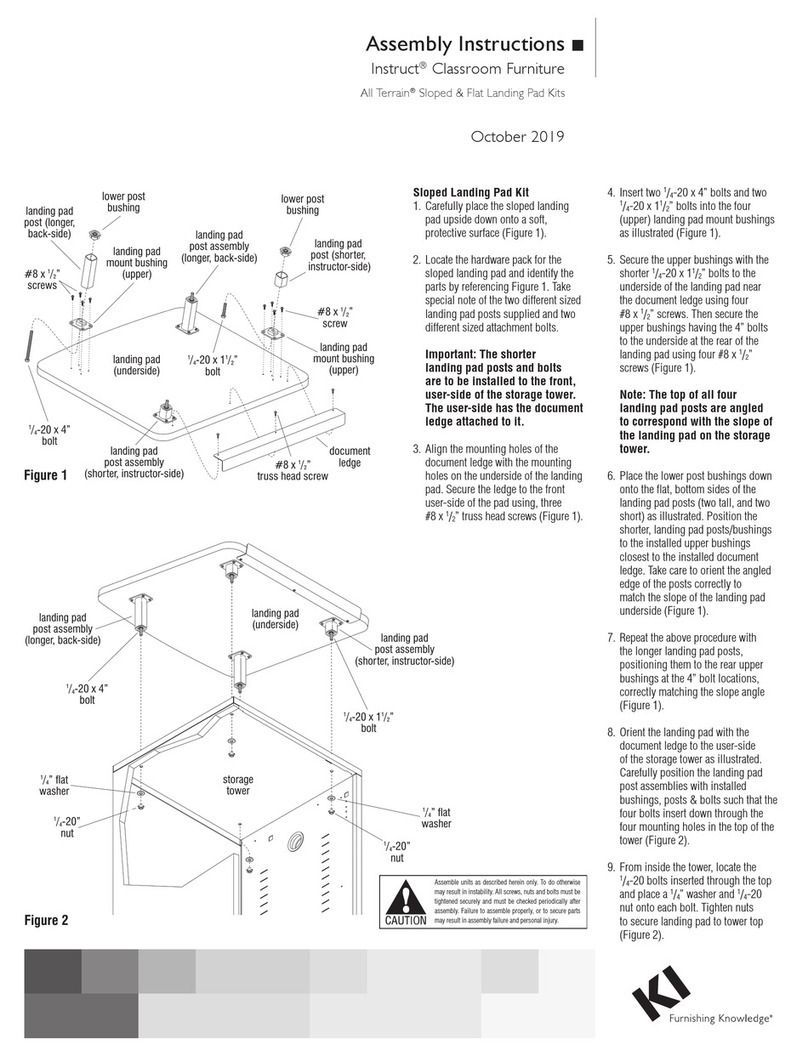

8. To install privacy screens,

first insert two male fasteners

through two bottom brackets

and press the fasteners into the

mounting holes at the lower,

outside mounting holes of

the privacy screen. Position

the privacy screen into place,

aligning the screen's bottom

mounting holes with the short

side bracket mounting holes.

From the inside, thread a female

fastener through the short side

brackets and into the male

fastener to hold the divider in

place at the bottom brackets

(Figure 4).

9. Secure the top of the privacy

screen to the short side brackets

of the dividers using male/

female fasteners and nylon

spacers where required. As

described above, when securing

the privacy screen to the divider,

use the larger diameter female

part of the male/female fasteners

on the inside of the table. Use

a male fastener with a nylon

spacer at the back, top of the

privacy screen. This will aid to

properly align the divider screen

(Figure 4).

10. Secure each bottom bracket to

the underside of the worksurface

using two #10 x 3/4" wood

screws into pre-drilled holes

(Figure 4).

shared

divider

front

bracket right-end

divider

short

side bracket

(end divider)

short

side bracket

(end divider)

left-end

divider

bottom

bracket

bottom

bracket

15

/ -20 x/"

machine screw

48

#10 x/”

wood screw

34

#10 x/”

wood screw

34

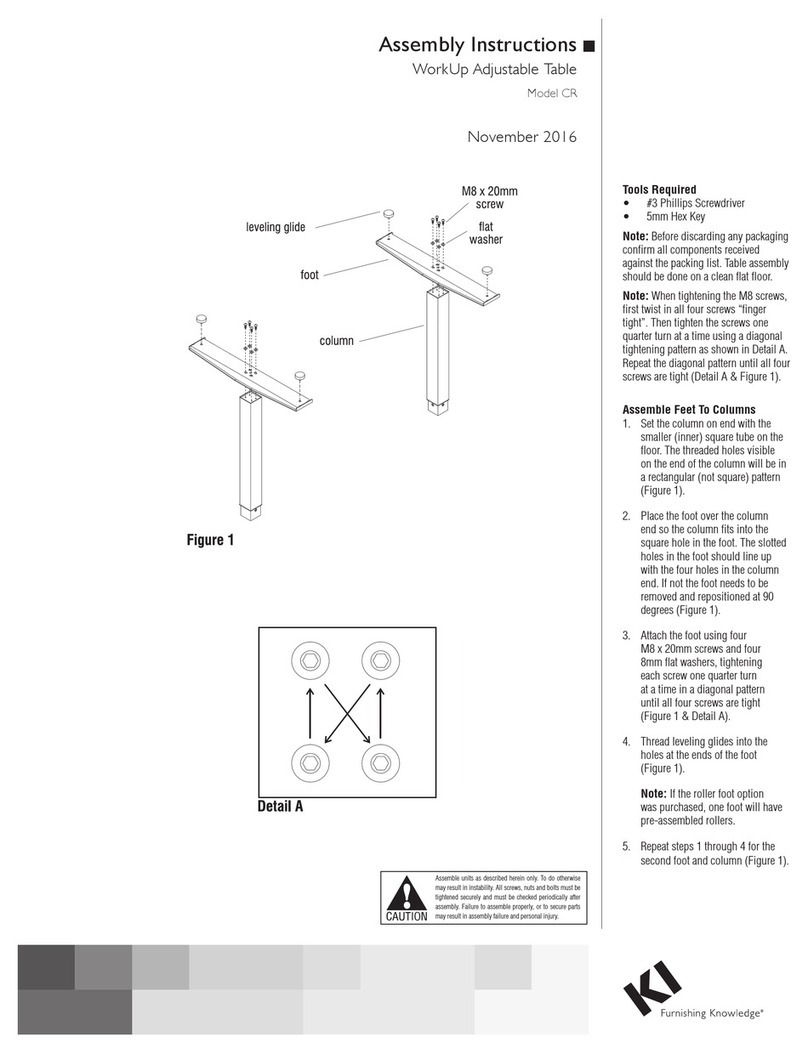

3. Attach the front bracket of the shared

divider(s) to the threaded inserts at the

underside of the worksurface using two

1/4-20x5/8" machine screws each (Figure

3).

Shared dividers require the use of

"long side brackets" to attach dividers to

privacy screens. Long side brackets have

two mounting holes that each are 1.5" from

the corner of the bracket (Detail A). End

dividers require the use of "short side

brackets" which has one hole at 1.5" from

the corner, and one hole which is 1.063"

from the corner (Detail B). The side of the

short side bracket which has the hole at the

"shorter" 1.063" distance form the corner is

the side of the bracket that must be oriented

to attach to the privacy screen (Figure 3).

4. Attach two pair of long side brackets to

the rear of the shared divider using

male/female fasteners (Figure3&Detail A).

Note:

Note: For better alignment when securing

dividers and privacy screens with the

male/female fasteners, it is recommended

that the larger diameter female fastener be

used at locations where any type of bracket

is being installed. And,anylon spacer is

required at any no-bracket attachment side

ofadivider or privacy screen whereashort

side bracket is secured using male/female

fasteners (Figures 3,4&7).

5. Next determine the location of left-end

and right-end dividers. Both divider types

are assembled from the same parts. Attach

a bottom bracket to the appropriate side at

the front, outside of each divider using

male/female fasteners as illustrated (Figure

3).

6. Attach two short side brackets to the

left- and right-end dividers at the inside rear

locations using male/female fasteners and

nylon spacers to the outside as illustrated

(Figure 3).

7. Align the bottom bracket of the end

dividers to the correct mounting holes at the

underside of the worksurface. The correct

location will allowaprivacy screen to be

mounted at the back edge of the table.

Secure the bottom bracket of the right-end

and left-end dividers to the underside of the

worksurfaces using the short T25 driver bit

to thread in two #10x3/4" wood screws

into the pre-drilled holes (Figure 3).

male

fastener

male

fastener

nylon

spacer

nylon

spacer

nylon

spacer

male

fastener

female

fastener

female

fastener

female

fastener long

side brackets

(shared divider)

Figure 3

Detail A Detail B

InTandem Table System-Assembly Instructions

long side bracket short side bracket

#10 x/"

wood screw

34

#10 x/"

wood screw

34

shared

divider

end divider

bottom

bracket

bottom

bracket

privacy screen

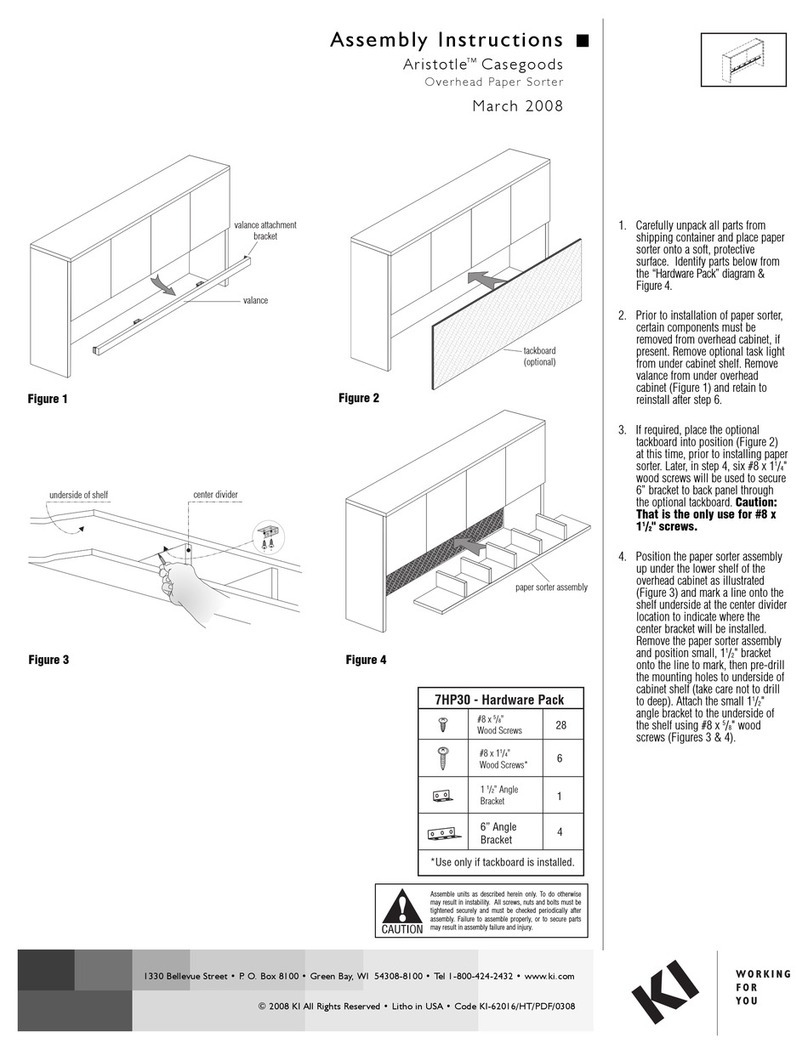

8. To install privacy screens, first insert two

male fasteners through two bottom

brackets and press the fasteners into the

mounting holes at the lower, outside

mounting holes of the privacy screen.

Position the privacy screen into place,

aligning the screen's bottom mounting

holes with the short side bracket mounting

holes. From the inside, threadafemale

fastener through the short side brackets

and into the male fastener to hold the

divider in place at the bottom brackets

(Figure 4).

A nylon spacer is required at any no-

bracket attachment side ofadivider where

a shortor long side bracket is attached

using male/female fasteners (Figure 7).

9. Secure the top of the privacy screen to

the short side brackets of the dividers using

male/female fasteners and nylon spacers

where required. As described above, when

securing the privacy screen to the divider,

use the larger diameter female partof the

male/female fasteners on the inside of the

table. Useamale fastener withanylon

spacer at the back, top of the privacy

screen. This will aid to properly align the

divider screen (Figure 4).

10. Secure each bottom bracket to the

underside of the worksurface using two

#10x3/4" wood screws into pre-drilled

holes (Figure 4).

Note:

Figure 4

female

fastener

female

fastener

male

fastener

male

fastener

short

side bracket

long

side bracket

InTandem Table System-Assembly Instructions

nylon

spacer

nylon

spacer

nylon

spacer

nylon

spacer