6

Smart Lift®Table System

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

6

4mm screw

torx drive screw

keyboard/mouse tray

slot

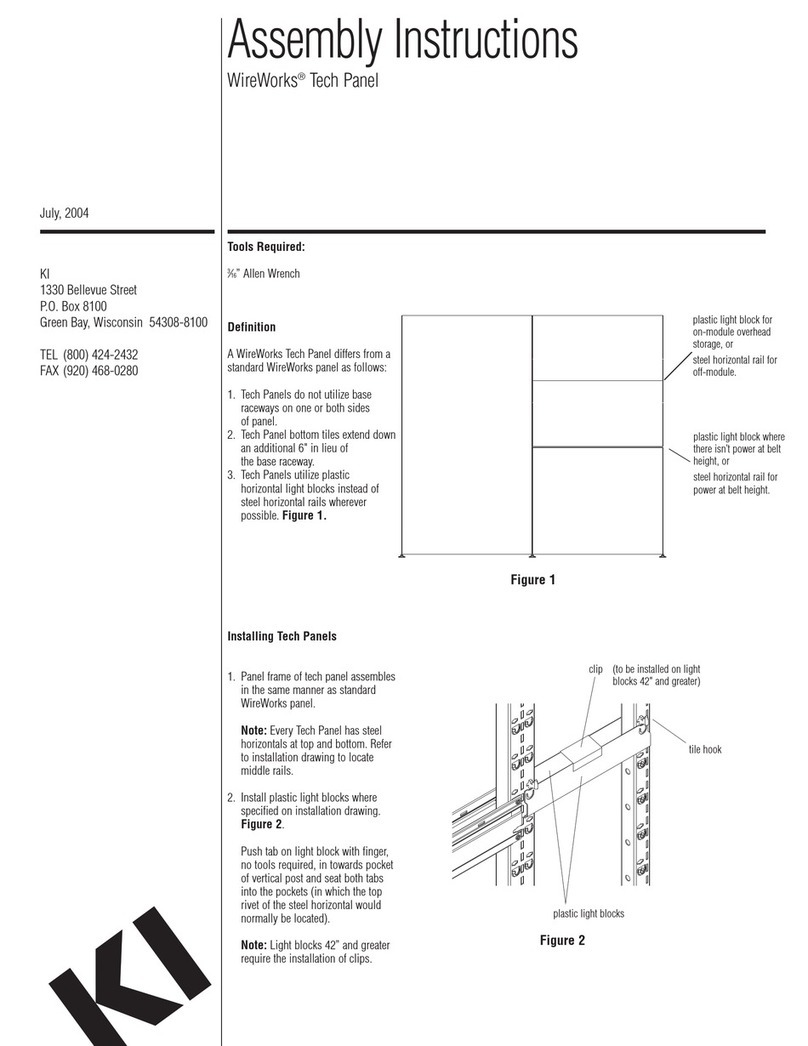

Figure 10

Figure 9

star washer

lift bar

slot

IT/Computer Installation

Instructions

1. Open the unit by pressing firmly

down on center of door and

release, or for a remote lock unit

by pushing the “unlock” button

found on the key FOB and, within

two minutes, pushing down lightly

on center of door. The door should

rise completely. If the front panel

has been assembled, hold in place

while removing the four screws

that attach the front panel to the

garage housing and the three

#10 x 5⁄8” screws that attach the

top flange to the worksurface.

Pivot front panel slightly down and

away from worksurface and garage

housing to remove.

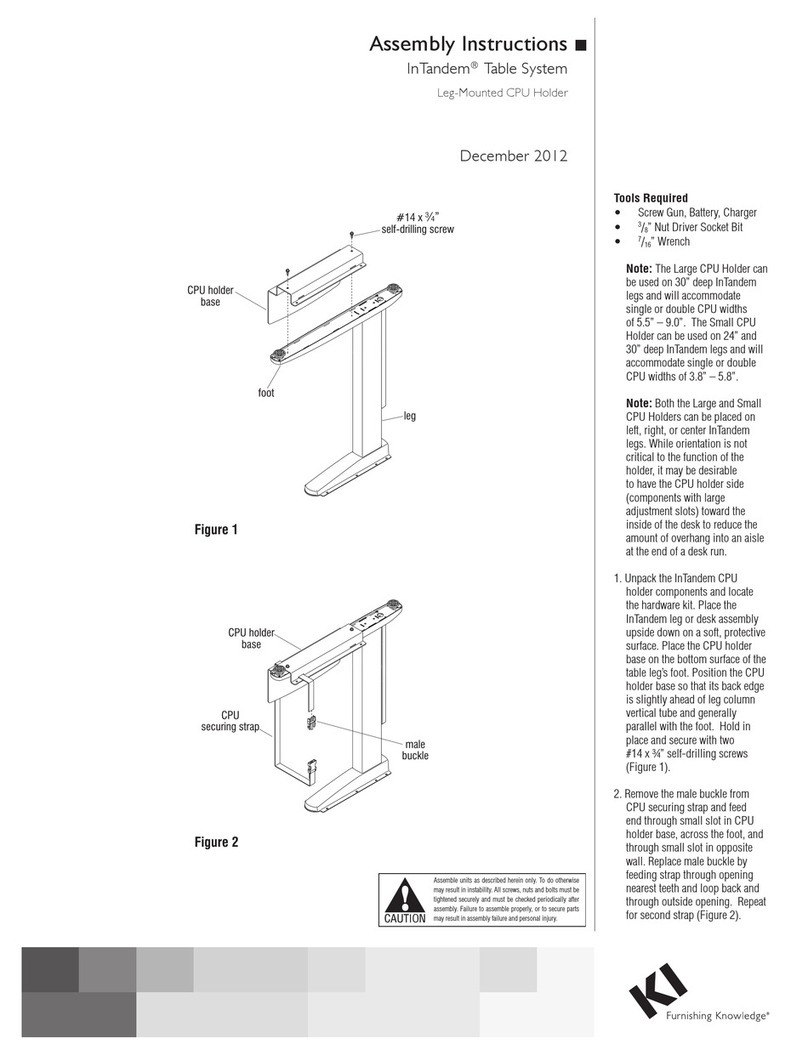

2. Locate the monitor attachment

screws from the installation

kit (See Detail A on page 1)

and determine which length

screws will be needed to attach

the monitor to the lift bar. The

hardware pack contains four

4mm x 16mm screws and four

4mm x 20mm screws and star

washers that will accommodate

most installations. Depending

on the manufacturer and model

design, additional hardware may

be required to properly mount

the flat screen monitor to the

lift bar. Additionally, many flat

screen monitors will have rear

covers or table stand supports

that will require removal prior to

installation.

Note: Not all flat screen monitor

styles are compatible with Smart

Lift monitor storage. Smart

Lift units can accommodate a

VESA compliant monitor with

a maximum size of 3.6” deep

x 19.0” high x 21.0” wide and

maximum weight of 15 lbs. The

combined keyboard and monitor

thickness must be less than 4.8”

thick. The maximum depth of

monitor with the monitor tilt

option is reduced by .6” to 3.0”.

3. Mount the flat screen monitor

carefully to the lift bar at the

desired height, leaving sufficient

room under the monitor for

mouse storage in the keyboard/

mouse tray, with the appropriate

4mm screws and star washers

(Figure 10). If additional height

is required for the flat screen

monitor, the keyboard/mouse tray

can be repositioned on the lift bar

by removing the two torx drive

screws and moving accordingly.

Re-secure in new position with

torx drive screws. Determine on

which side of the unit the CPU

will be placed and route the flat

screen monitor power and VGA

cord through the appropriate slot

in the keyboard/mouse tray.

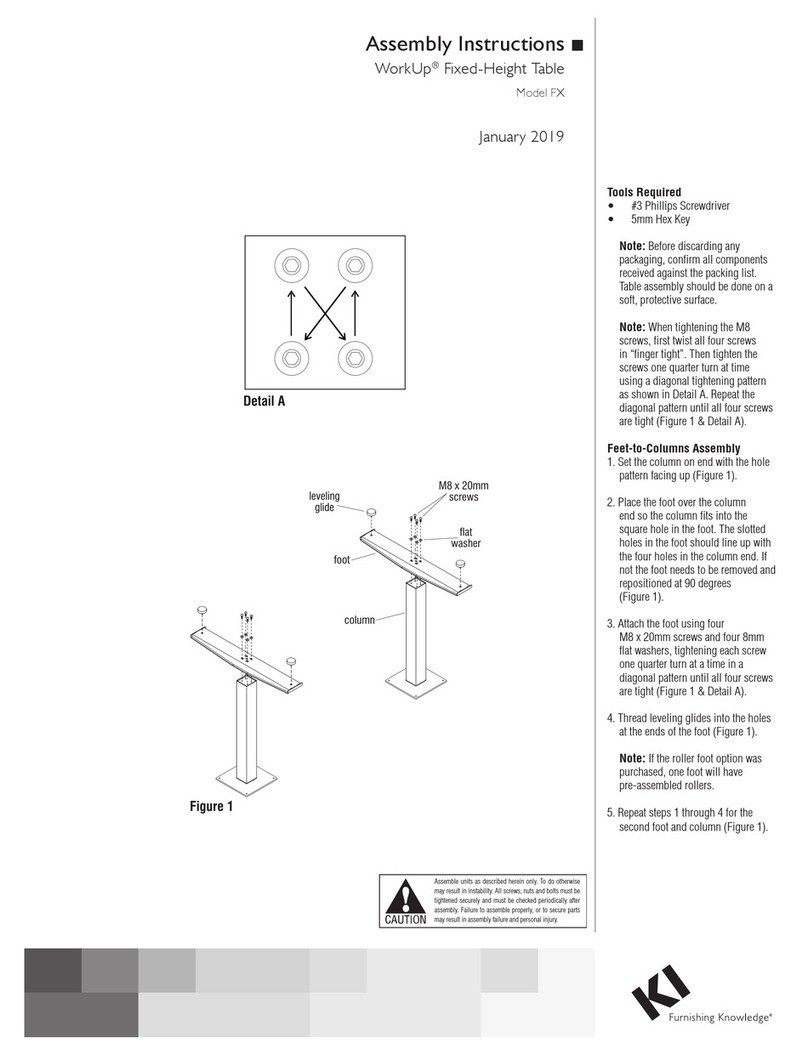

4. Place the keyboard and mouse

on the worksurface in a

comfortable position for the

user. Route the keyboard and

mouse wires through the same

slot in keyboard/mouse tray as

the flat screen monitor cables

leaving only enough cable on the

worksurface to allow proper use

(Figure 11).

Figure 10

Figure 11