3

Note: The following instructions

refer to the installation of an

extended (over 60" in length) single

piece rectangular countertop on two

42" and higher panels. Using

standard-height ADA brackets, the

countertop extends no more than

4" into the aisle to comply with

ADA guideline 4.4.1. Countertops

installed onto 32" high (wheelchair-

height) panels require different ADA

countertop support brackets.

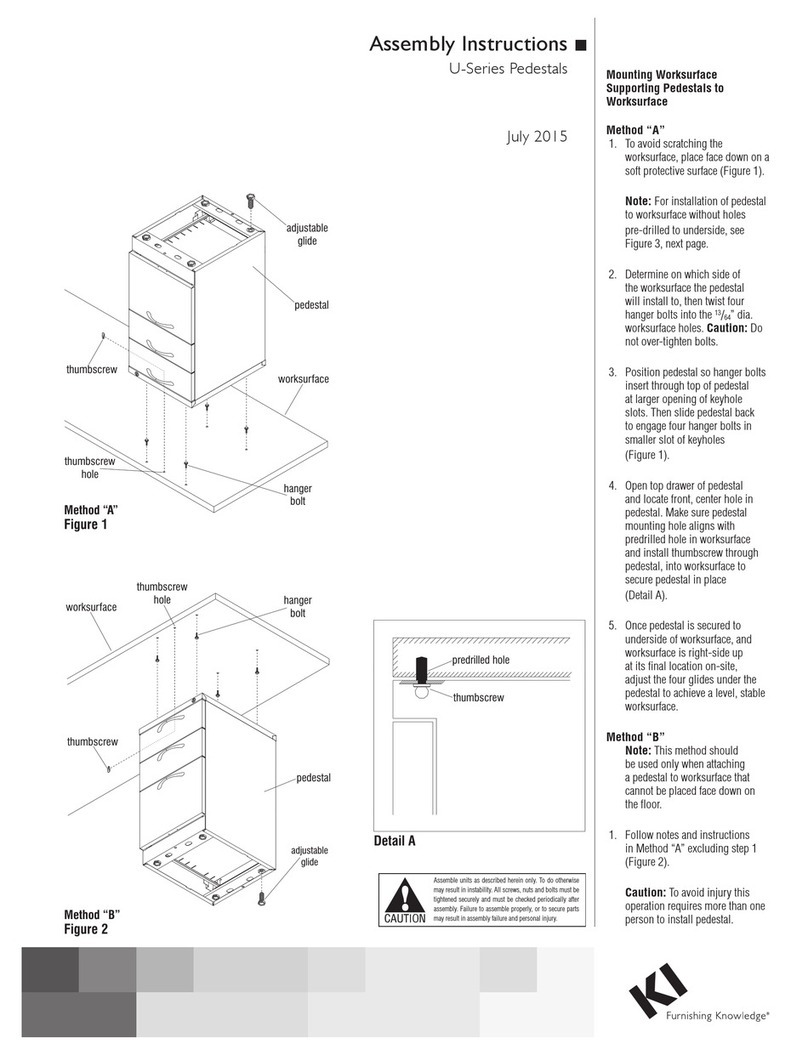

1. Extended rectangular countertops

installed on two standard height

panels require three ADA

standard-height countertop

brackets, two left-, and one

right-hand. Mount the three

countertop brackets to the trimrail

grooves so the mounting flanges

are at the same height as the panel

tops. The right- and left-hand

brackets will be different. Notice

that the mounting flanges of the two

outside brackets face inward as

installed to the panel (Figure 1).

Note: The ADA standard lock clips

are an important part of the bracket

assembly which must be installed

when the extended rectangular

countertop surface is secured.

2. Carefully place the countertop

surface face up onto the wall panels

and standard ADA countertop

brackets. Align the holes of the

three brackets with corresponding

holes at the center, and each end of

the countertop surface (Figure 1).

3. Take the two left- and one

right-hand ADA standard lock clips

and orient the pin ends into the

panel trimrail grooves at the top

tooth of each installed ADA

standard height countertop bracket.

Make sure the mounting flanges of

the two outside clips orient inward

and that the mounting holes of the

lock clip line up with the mounting

holes of the bracket. Secure the

brackets and lock clips to the

underside of the countertop with

two #12 x 1" screw at each bracket

location (Figure 1).

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

System 3000 Countertop

Rectangular Standard Height Extended

Figure 1

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

System 3000 Countertop

90°Corner Standard Height

2

Note: The following instructions

refer to the installation of a 90°

right angle countertop on two 42"

and higher panels. Using

standard-height ADA brackets, the

countertop extends no more than

4" into the aisle to comply with

ADA guideline 4.4.1. Countertops

installed onto 32" high (wheelchair-

height) panels require different ADA

countertop support brackets.

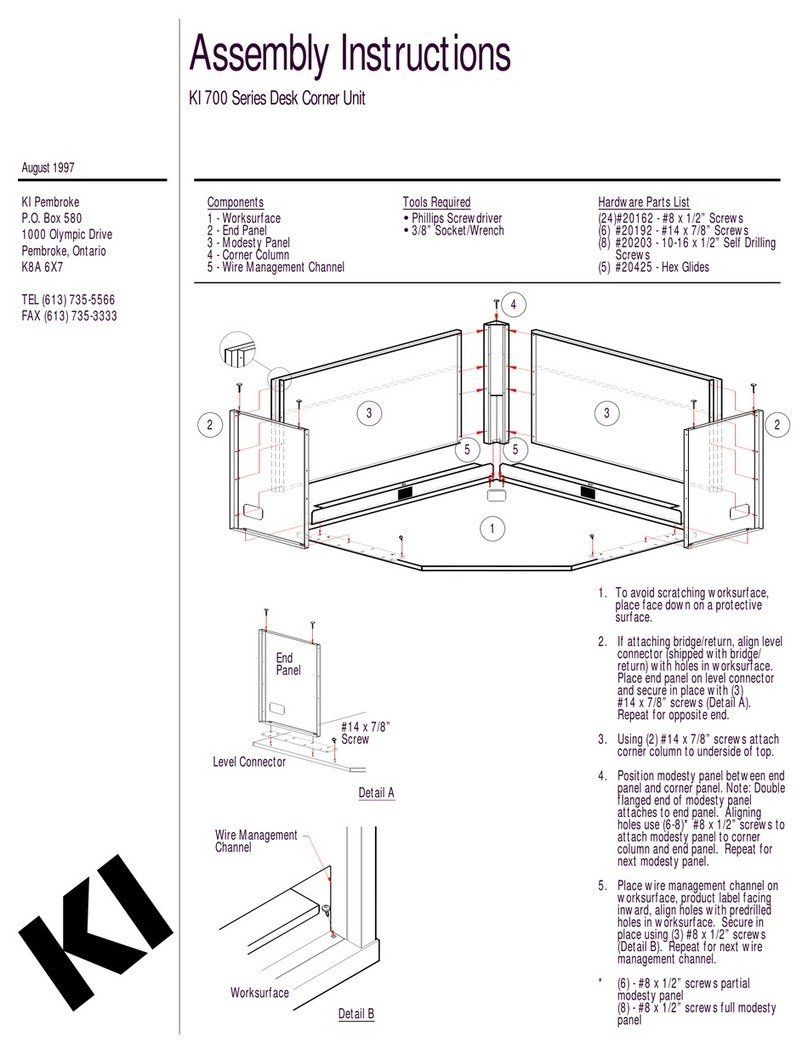

1. Right angle countertop countertops

installed onto standard height

panels require the use of three ADA

standard-height countertop

brackets, two left-, and one

right-hand. Mount the countertop

brackets to the trimrail grooves so

the mounting flanges are at the

same height as the panel tops. The

right- and left-hand brackets will be

different. Notice that the mounting

flanges of the two outside brackets

face inward as installed to the panel

(Figure 1).

Note: The ADA standard lock clips

are an important part of the bracket

assembly which must be installed

when the 90° countertop surface is

secured.

2. Carefully place the countertop

surface face up onto the wall panels

and standard ADA countertop

brackets. Align the holes of the

three brackets with corresponding

holes at the center, and each end

of the 90° countertop surface

(Figure 1).

3. Take the left- and right-hand ADA

standard lock clips and orient the

pin ends into the panel trimrail

grooves at the top tooth of each

installed ADA standard height

countertop bracket. Make sure the

mounting flanges of the outside

clips orient inward and that the

mounting holes of the lock clip line

up with the mounting holes of the

bracket. Secure the brackets and

lock clips to the underside of the

countertop with two #12 x 1" screw

at each bracket location (Figure 1).

Figure 1