Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Assembly Instructions

U-Series Pedestals

July 2015

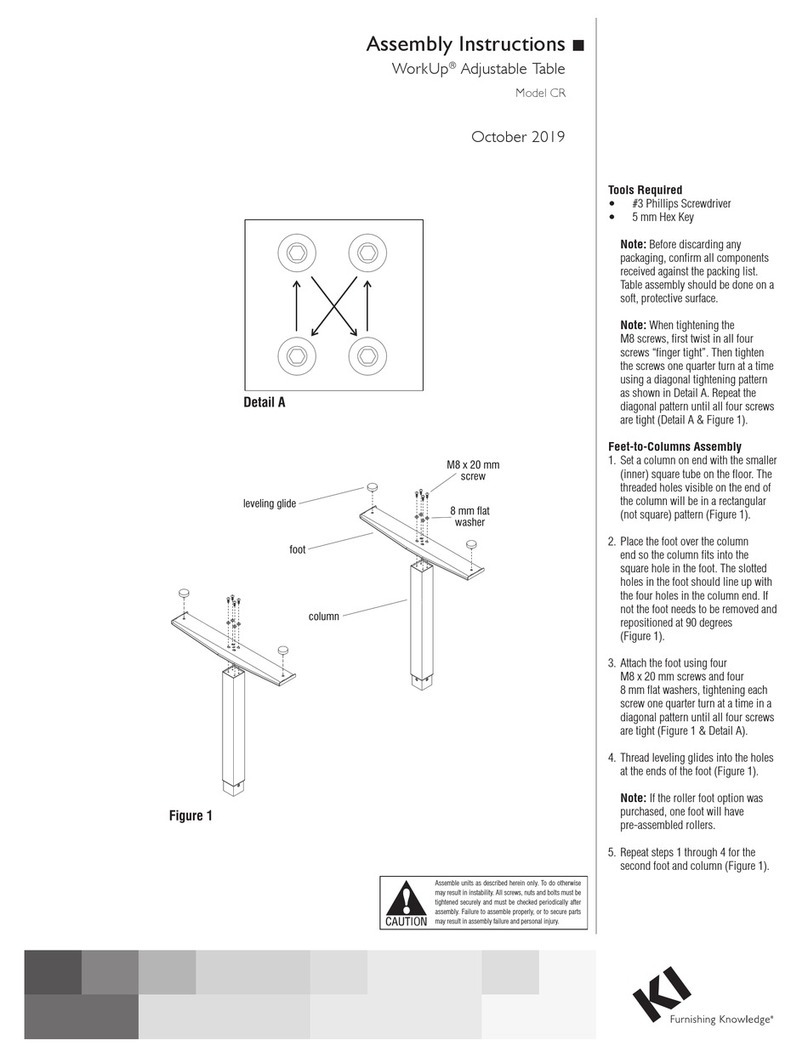

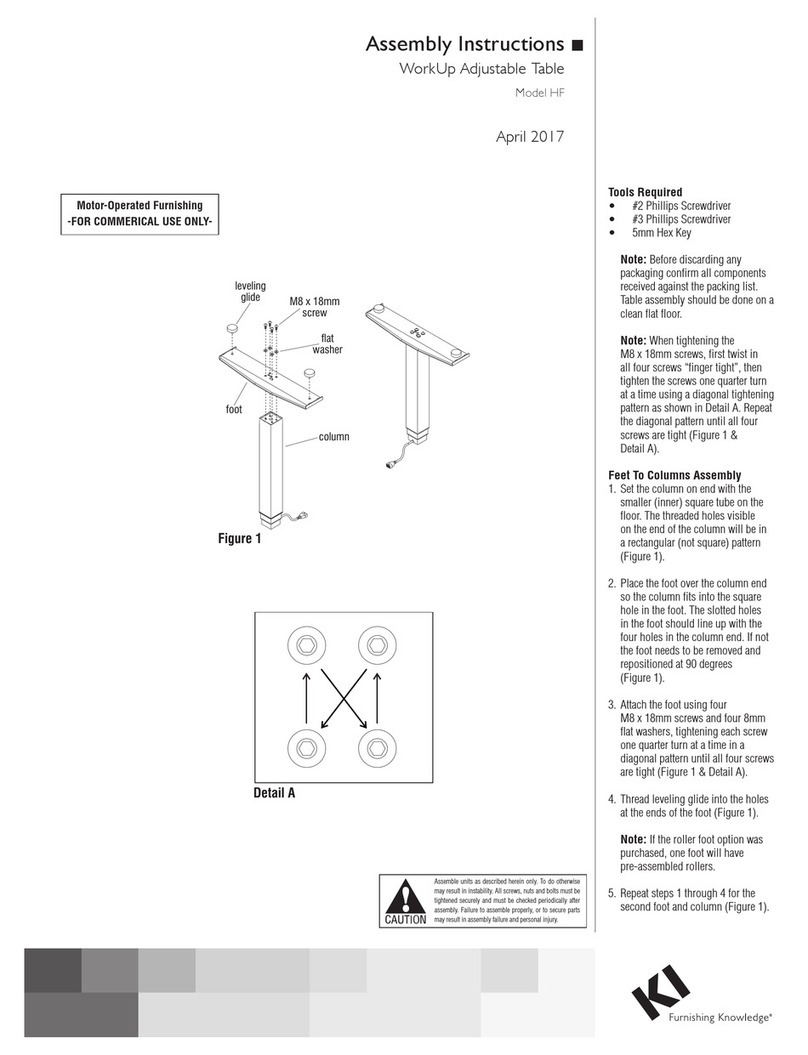

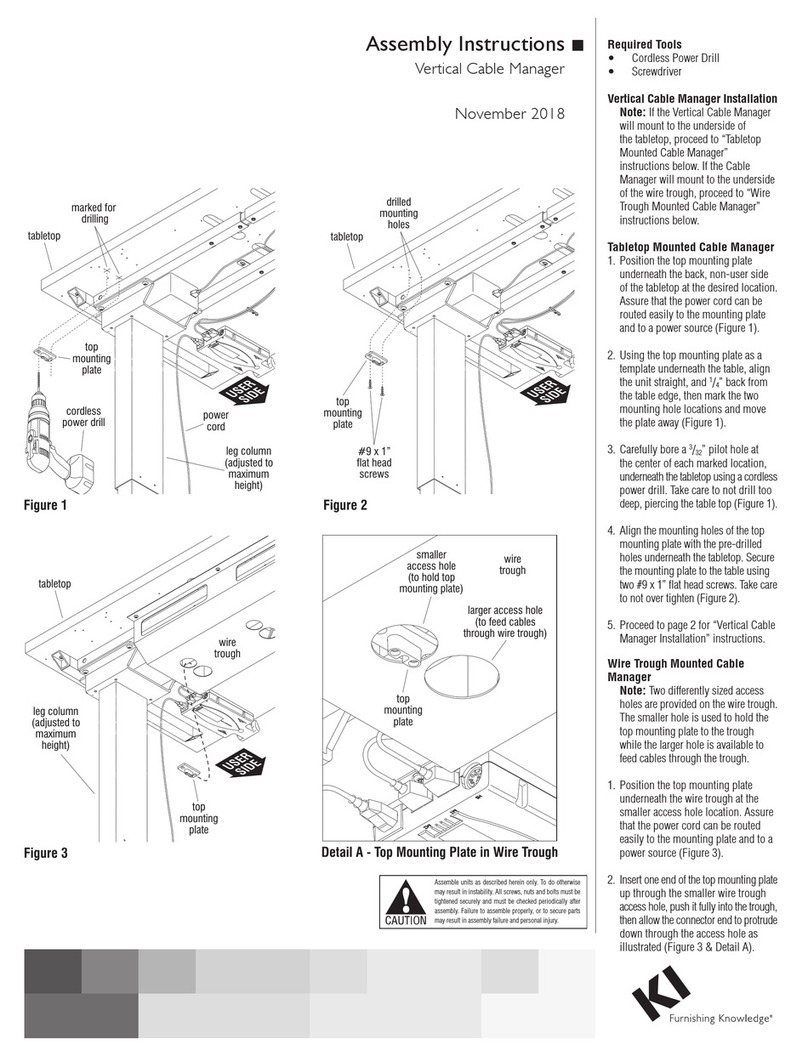

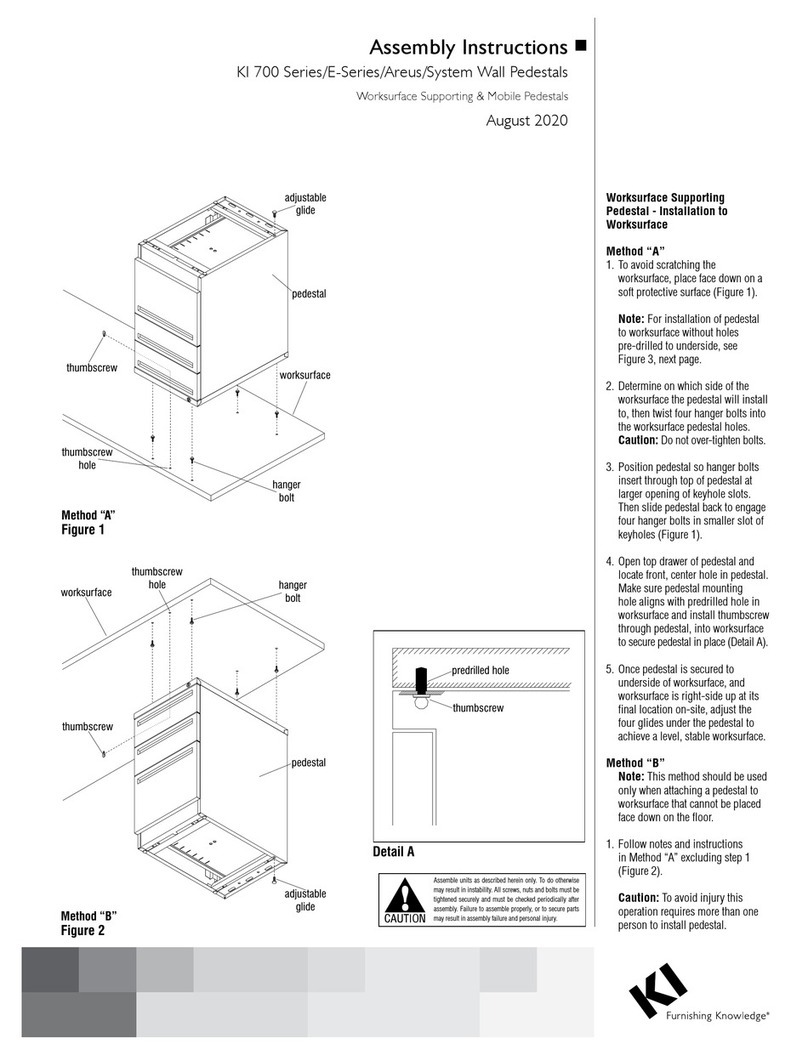

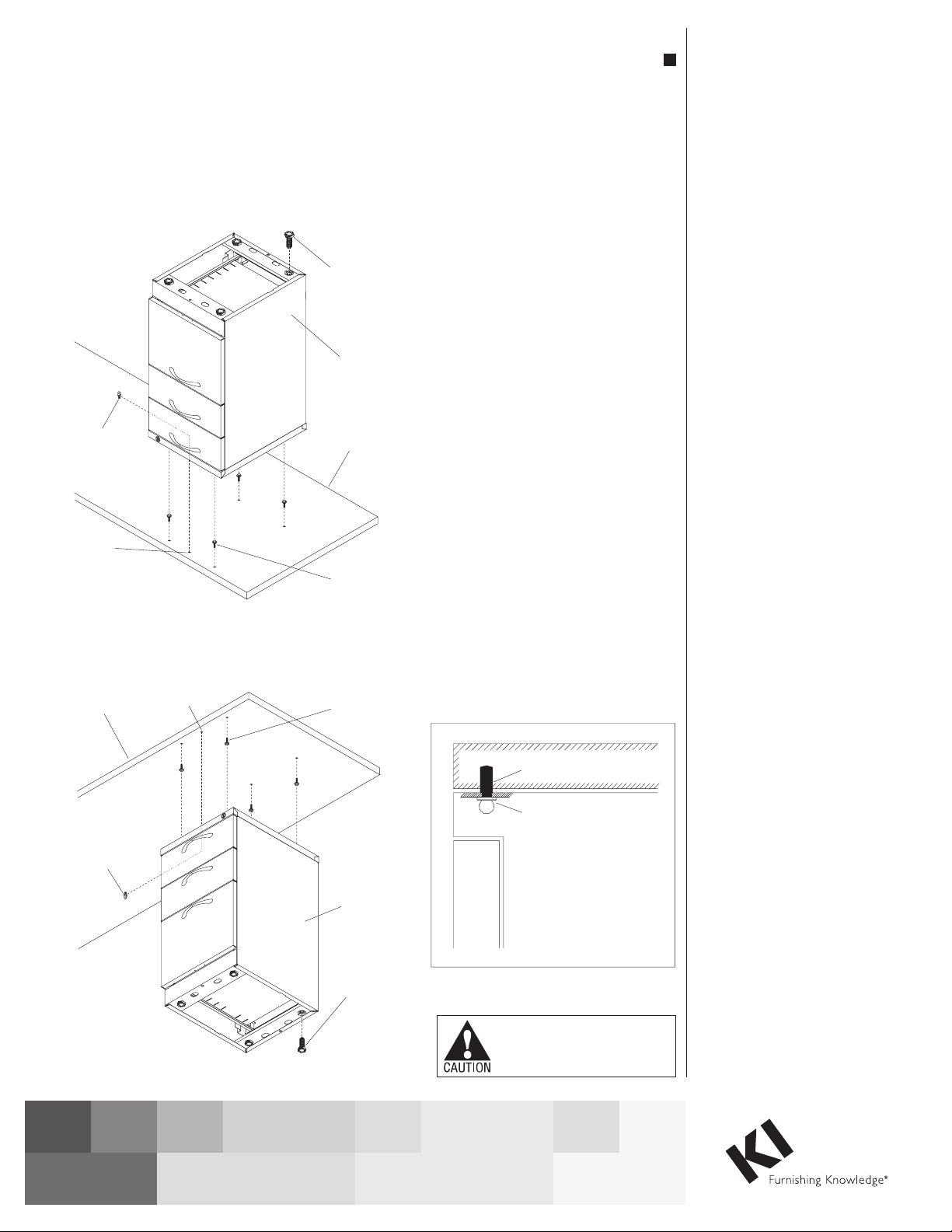

Mounting Worksurface

Supporting Pedestals to

Worksurface

Method “A”

1. To avoid scratching the

worksurface, place face down on a

soft protective surface (Figure 1).

Note: For installation of pedestal

to worksurface without holes

pre-drilled to underside, see

Figure 3, next page.

2. Determine on which side of

the worksurface the pedestal

will install to, then twist four

hanger bolts into the 13/64” dia.

worksurface holes. Caution: Do

not over-tighten bolts.

3. Position pedestal so hanger bolts

insert through top of pedestal

at larger opening of keyhole

slots. Then slide pedestal back

to engage four hanger bolts in

smaller slot of keyholes

(Figure 1).

4. Open top drawer of pedestal

and locate front, center hole in

pedestal. Make sure pedestal

mounting hole aligns with

predrilled hole in worksurface

and install thumbscrew through

pedestal, into worksurface to

secure pedestal in place

(Detail A).

5. Once pedestal is secured to

underside of worksurface, and

worksurface is right-side up

at its final location on-site,

adjust the four glides under the

pedestal to achieve a level, stable

worksurface.

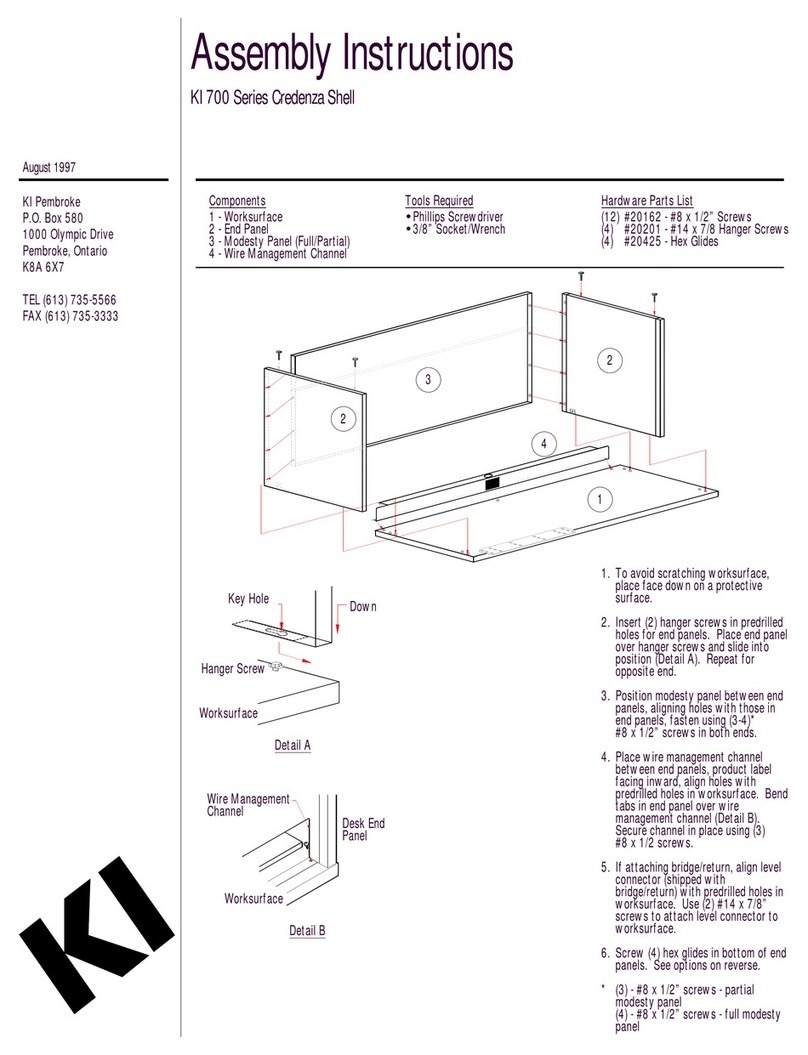

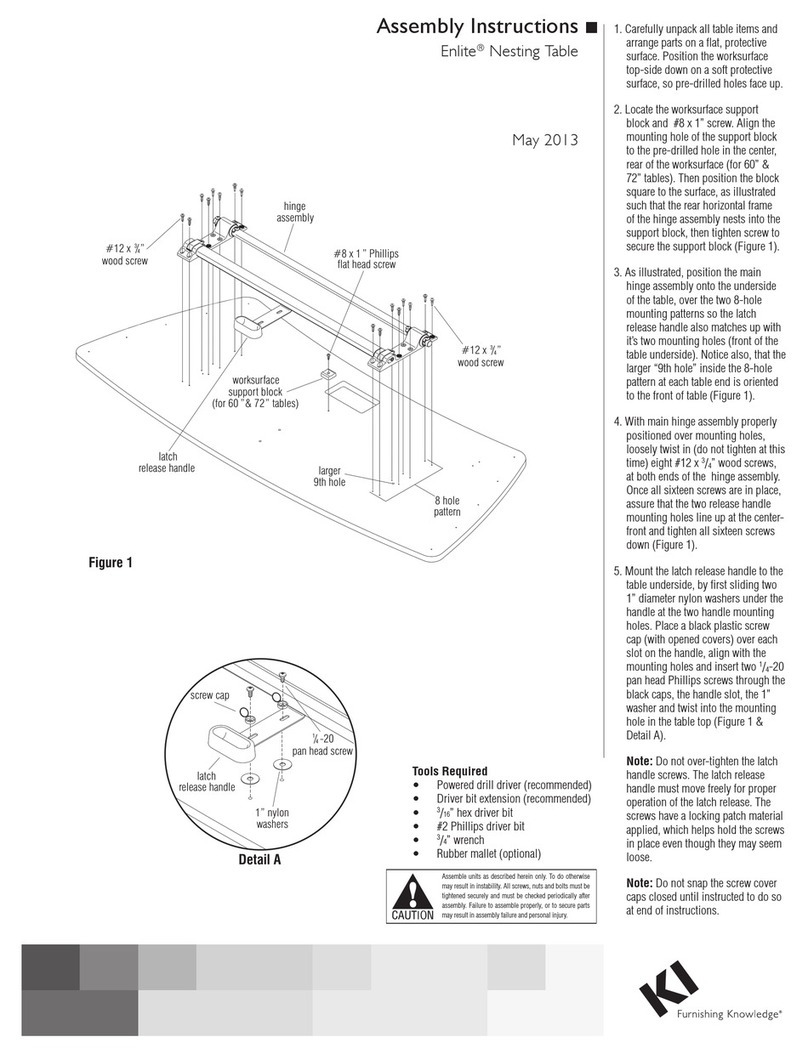

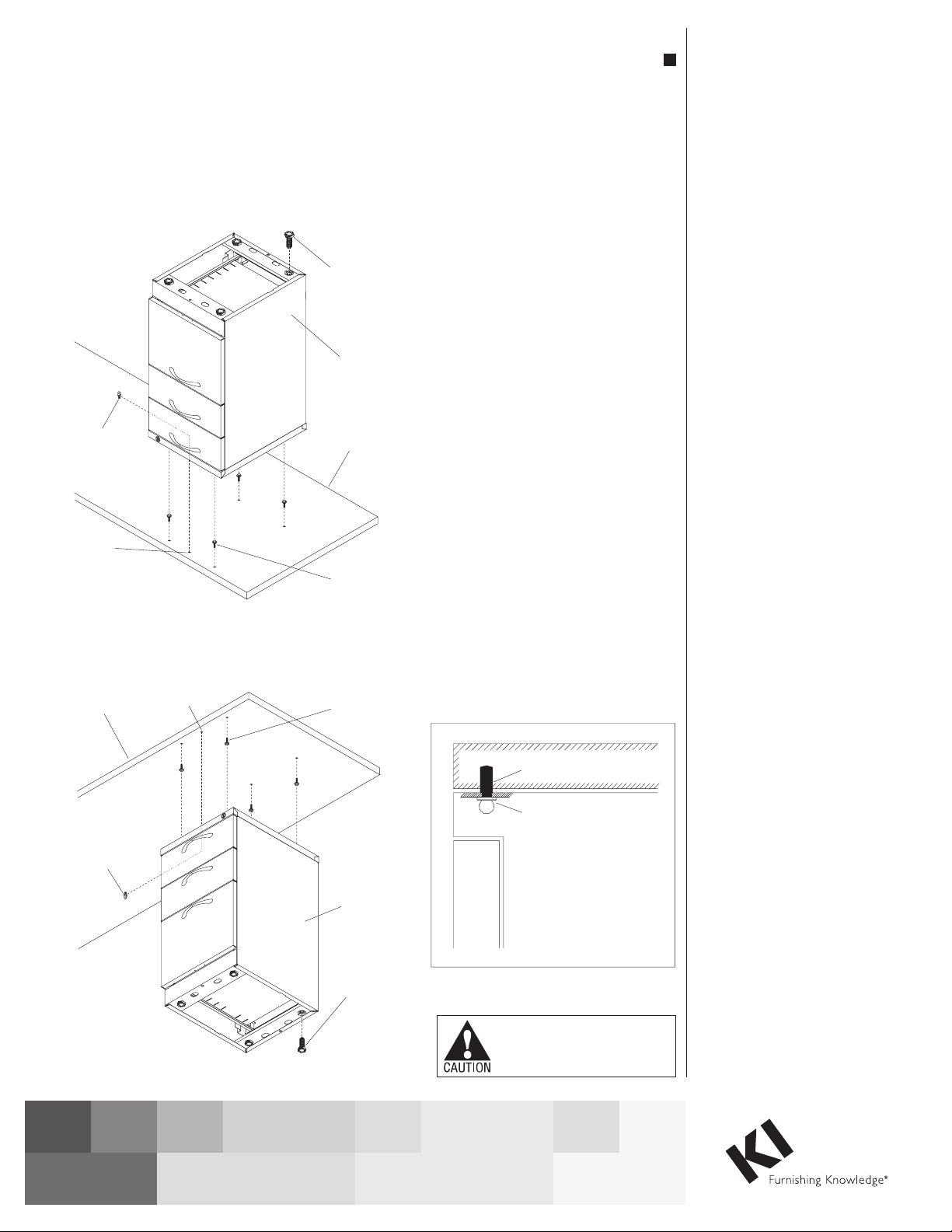

Method “B”

Note: This method should

be used only when attaching

a pedestal to worksurface that

cannot be placed face down on

the floor.

1. Follow notes and instructions

in Method “A” excluding step 1

(Figure 2).

Caution: To avoid injury this

operation requires more than one

person to install pedestal.

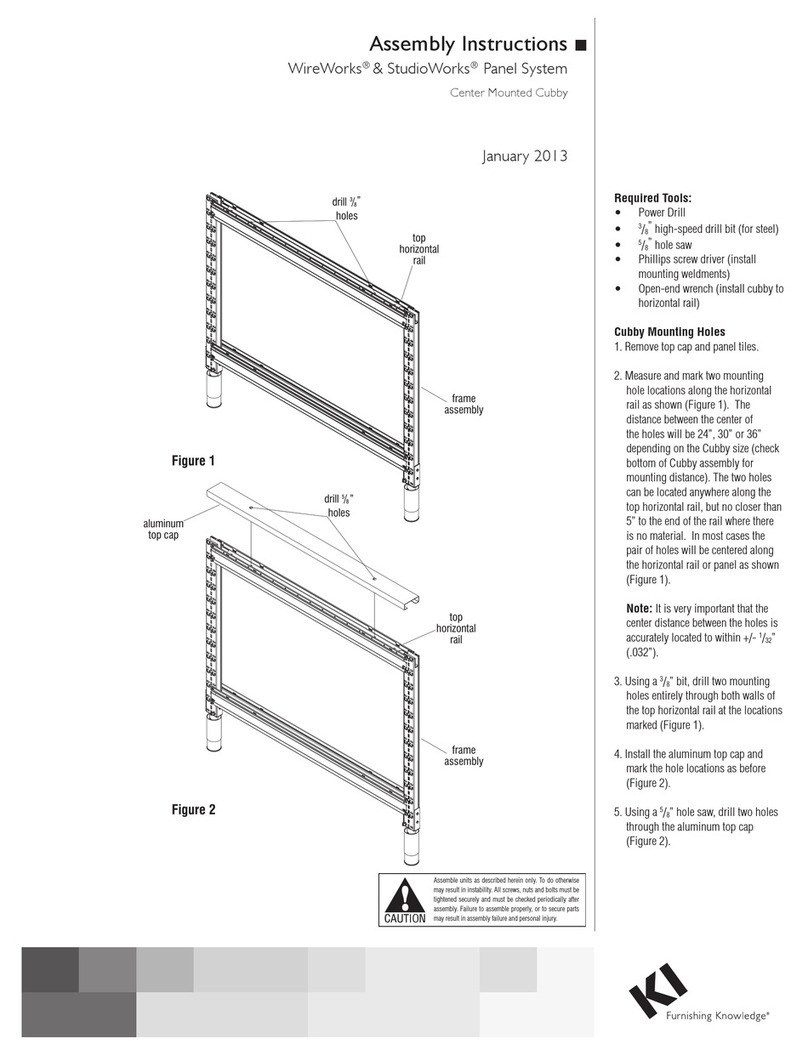

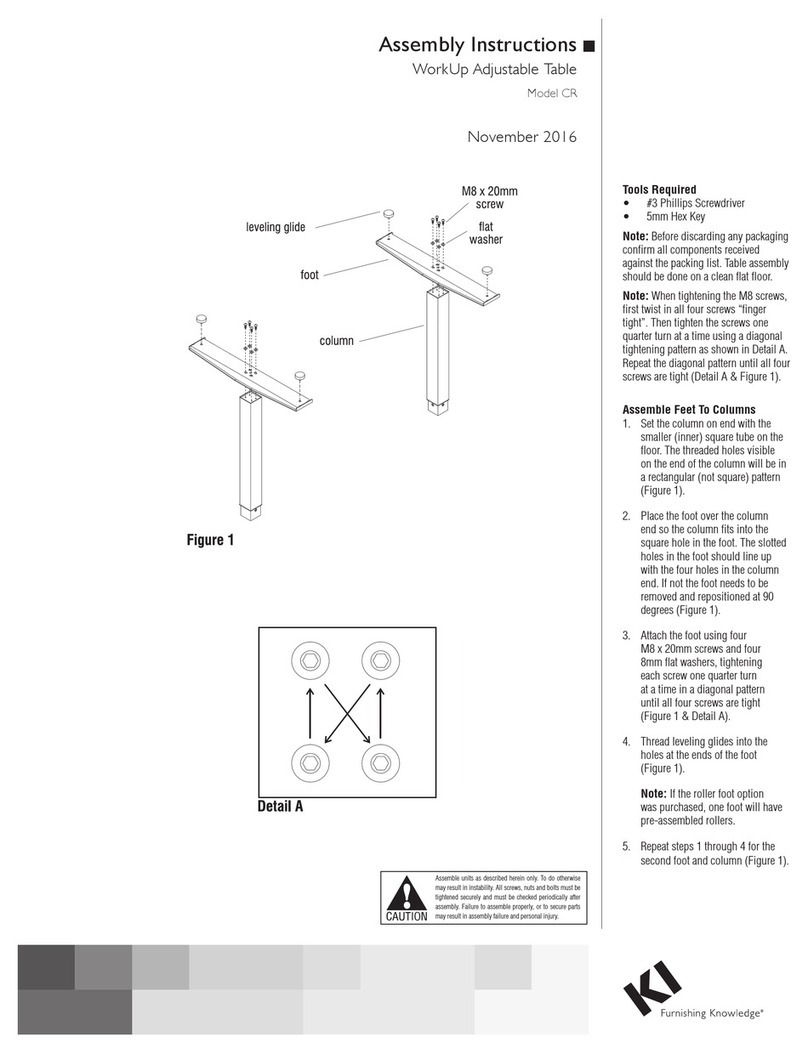

Guide Bracket Installation

5. At the location where a rolling door is to

be installed, remove the intersection top

cap if not already done so (Figure 2).

6. At the isle side of the end-of-run trim,

position two clamp blocks as illustrated,

with mounting holes showing out and

insert blocks into the opening as shown

(Detail C). Place one block at the top of

the attaching trim slot and slide one

bracket to the bottom of the trim (Figure 2

& Detail B).

Important: For the step below, ensure the

“U” shape of the upper and lower guide

brackets face each other as illustrated.

Tighten screws into the plastic blocks

until brackets are snug but can still slide

for final adjustment.

7. Next, correctly position the upper and

lower door guide brackets in place as

illustrated and install using two #10-16 x

3/4” Phillips flat head self-drilling Tek

Screws. Do not tighten completely at this

time (Figure 2, Detail C).

predrilled hole

thumbscrew

Detail A

worksurface

thumbscrew

hole hanger

bolt

pedestal

thumbscrew

adjustable

glide

Method “B”

Figure 2

Method “A”

Figure 1

hanger

bolt

worksurface

pedestal

adjustable

glide

thumbscrew

hole

thumbscrew

Guide Bracket Installation

5. At the location where a rolling door is to

be installed, remove the intersection top

cap if not already done so (Figure 2).

6. At the isle side of the end-of-run trim,

position two clamp blocks as illustrated,

with mounting holes showing out and

insert blocks into the opening as shown

(Detail C). Place one block at the top of

the attaching trim slot and slide one

bracket to the bottom of the trim (Figure 2

& Detail B).

Important: For the step below, ensure the

“U” shape of the upper and lower guide

brackets face each other as illustrated.

Tighten screws into the plastic blocks

until brackets are snug but can still slide

for final adjustment.

7. Next, correctly position the upper and

lower door guide brackets in place as

illustrated and install using two #10-16 x

3/4” Phillips flat head self-drilling Tek

Screws. Do not tighten completely at this

time (Figure 2, Detail C).

predrilled hole

thumbscrew

Detail A

worksurface

thumbscrew

hole hanger

bolt

pedestal

thumbscrew

adjustable

glide

Method “B”

Figure 2

Method “A”

Figure 1

hanger

bolt

worksurface

pedestal

adjustable

glide

thumbscrew

hole

thumbscrew