3

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Likha Casegoods - Adjustable-Height Units

Assembly Instructions

Adjustable-Height Worksurface

Installation

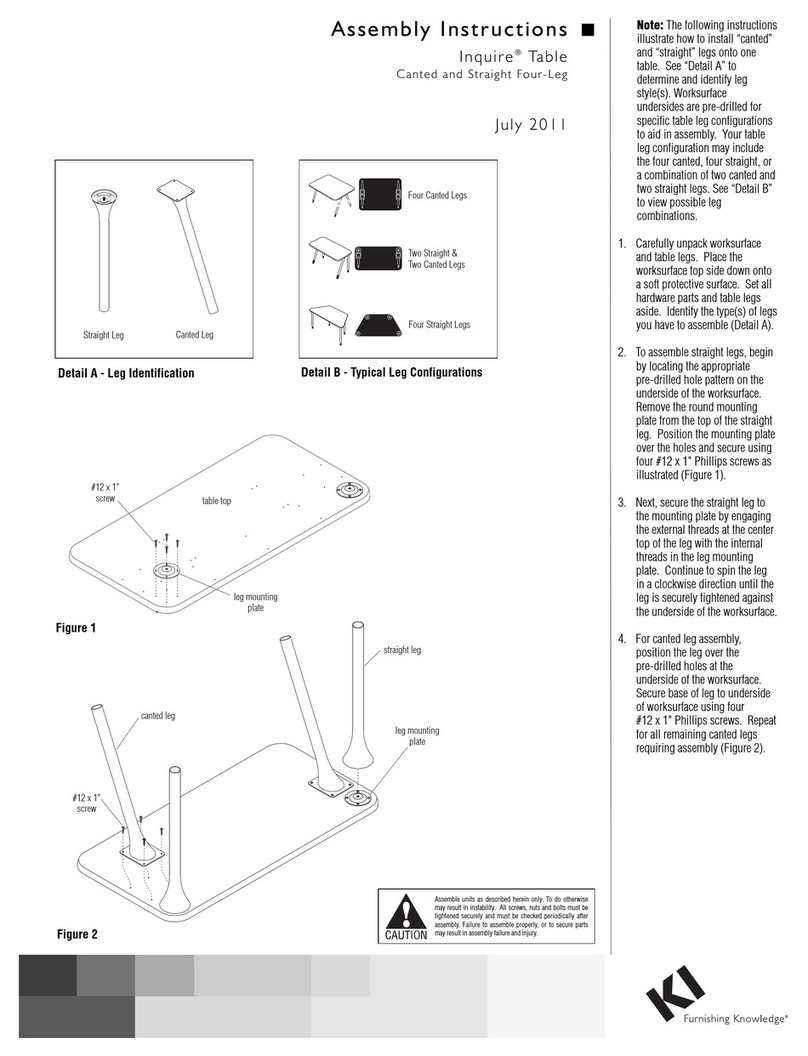

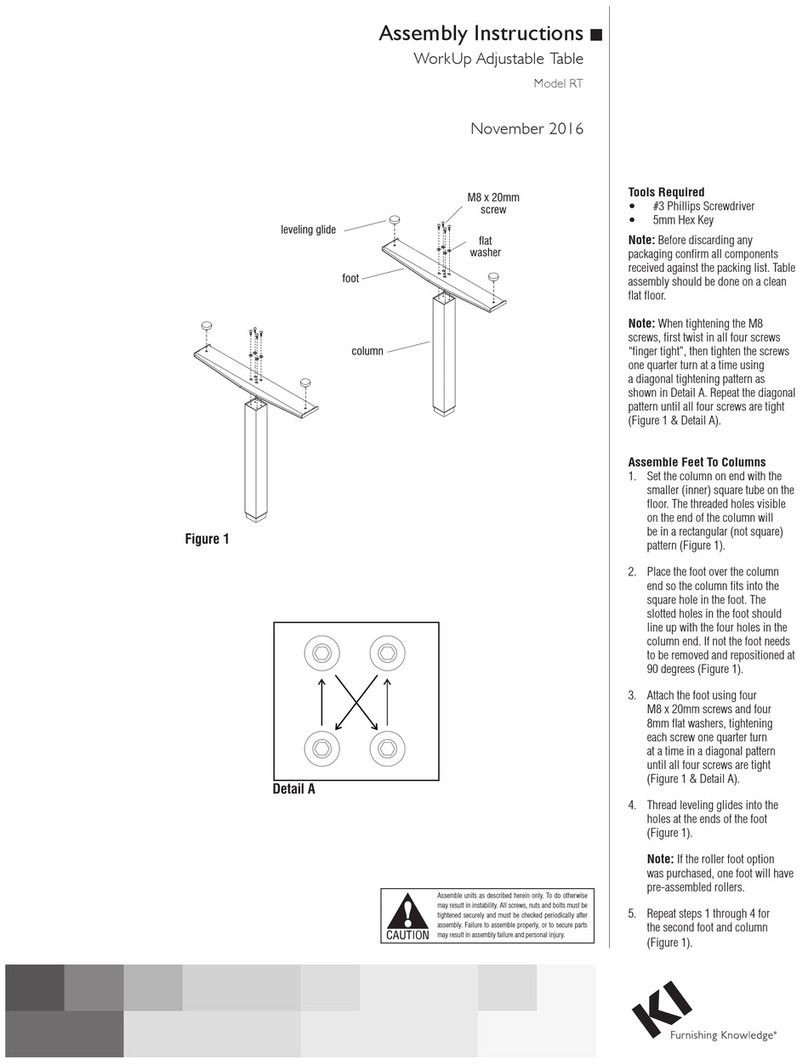

1. Carefully position the worksurface

on top of two adjustable-height

leg assemblies. One side of the

worksurface at a time, align two

mounting holes on each L-bracket

with the four pre-drilled holes in

the worksurface, referencing the

correct illustration that matches your

configuration for correct mounting

hole locations (Figures 3, 4 & 5).

Secure each L-bracket to the

worksurface using two #10 x 7/8”

Phillips pan head screws per bracket

at each side of the table

(Figures 3, 4 & 5).

worksurface

bookcase/cabinet/

credenza leg

assembly

L-bracket

#10 x /”

7

8

T-support

bracket

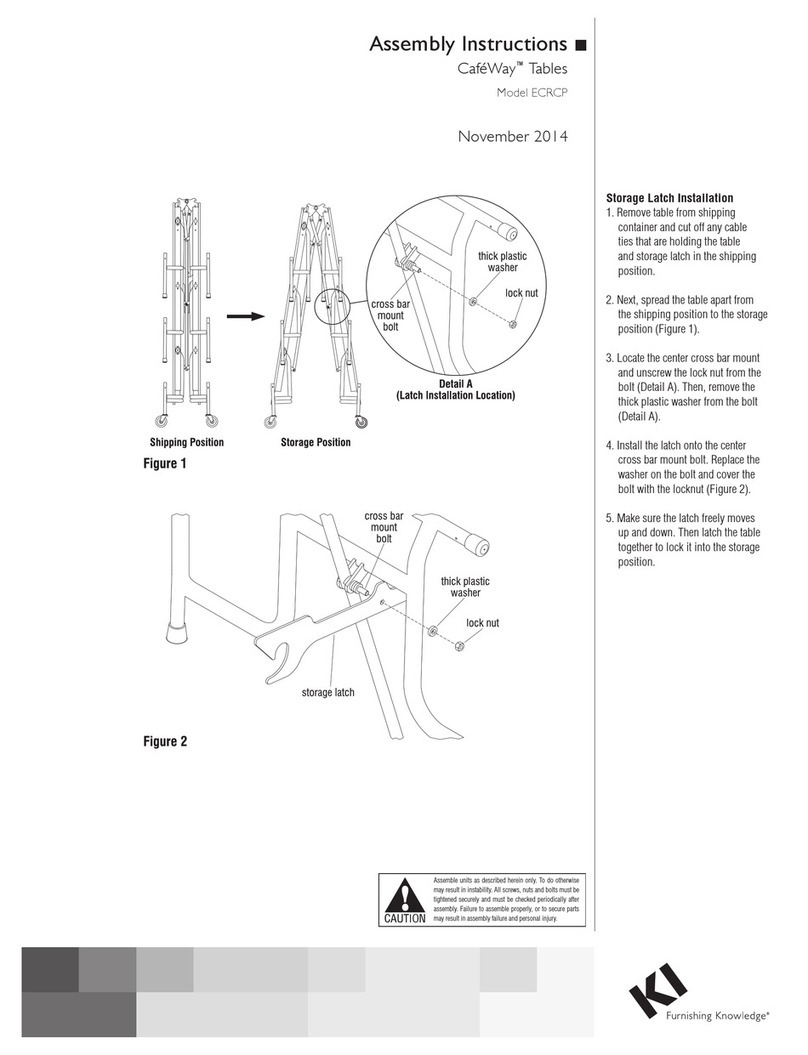

Figure 3 - Adjustable-Height Bookcase

Leg

- Adjustable-Height Cabinet Leg

- Adjustable-Height Credenza Leg

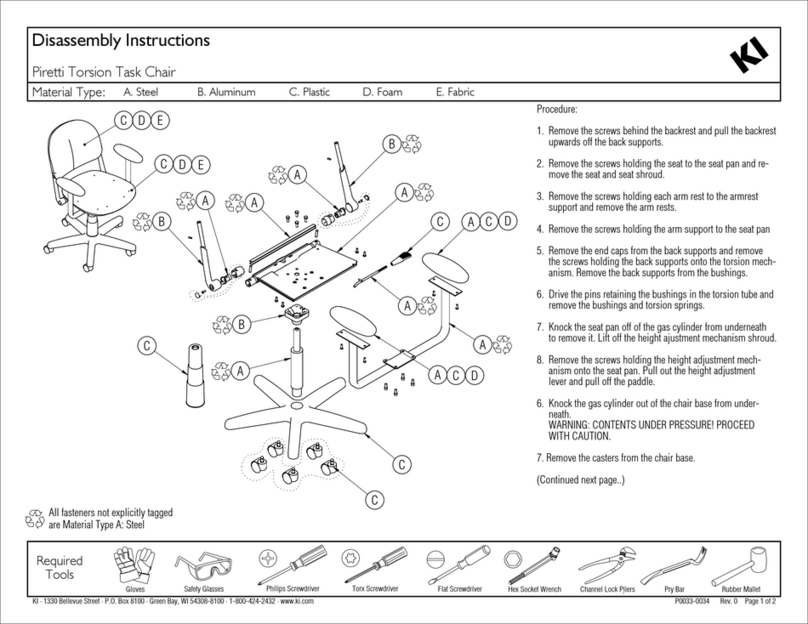

adjustable-height

worksurface

panel leg

T-leg assembly

L-bracket

#10 x /”

7

8

Phillips pan

head screw

T-support

bracket

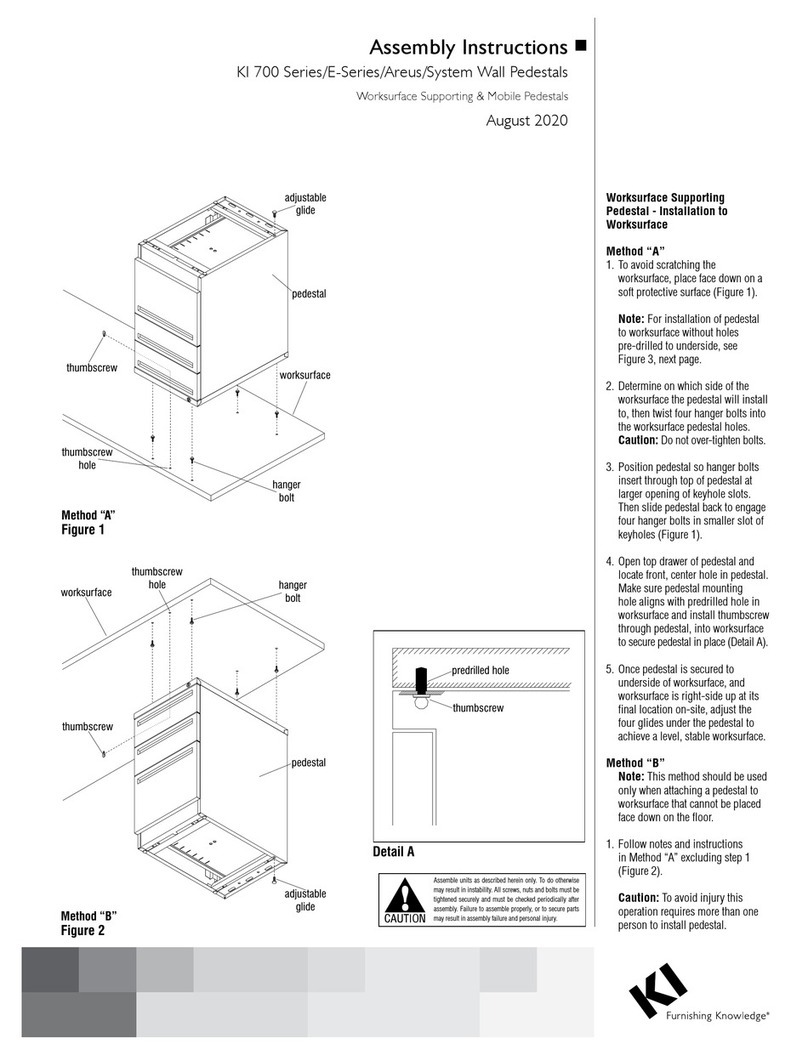

Figure 4 - Adjustable-Height Panel Leg

- Adjustable-Height T-Leg

Figure - Adjustable-Height Panel Leg with Sleeve5

adjustable-height

worksurface

panel leg with sleeve

L-bracket

#10 x /”

7

8

Phillips pan

head screw

T-support

bracket

Table Wiring Installation

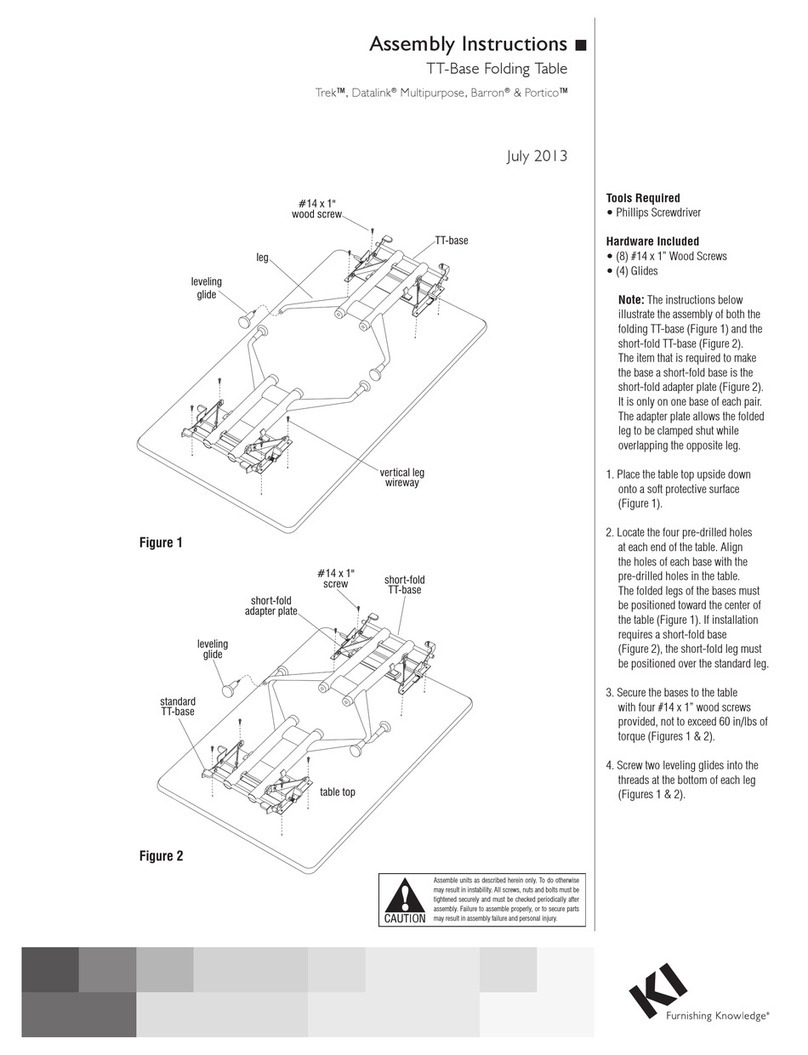

1. Position the control box underneath

the worksurface in the desired

installation location. Transfer and

mark the Velcro hook strip locations

pre-installed on the control box to

the worksurface. Remove the backing

from the individual peel & stick

Velcro loop strips to expose the

adhesive surfaces. Position the loop

strips in the marked locations. Apply

firm pressure to set the adhesive.

Press the Velcro hook strips against

the loop strips to secure the control

box underneath the worksurface.

Note: When plugging leg control

cord ends in, make sure to push in

straight to avoid bending any pins

in the electrical control box or leg

motor.

Note: If any plug needs to be

removed, make sure the power cord

is un-plugged from the power source

outlet first. Then push down on the

release tab on the control cable plug

while simultaneously pulling on the

end to remove from the socket.

2. Plug the leg control cord into one of

the two rectangular sockets on the

control box, then route cord to the

leg. Plug other end of the cord into

the open socket on the leg motor.

Repeat this process to install the

second leg control cord into the

opposite leg motor.

3. Underneath the worksurface on

the user side, position the key pad

in the desired location and secure

using two #8 x 5/8” screws. Do not

overtighten screws. Once key pad

is mounted, route attached cord to

the control box and plug into the

appropriate socket.

4. Five cord strain relief clips are

included to keep cords tight to the

table, but it is not necessary to use

all five. Insert the cable into the

opening of the clip, then secure the

clip to the underside of the table

using one #8 x 5/8” screw. Repeat this

step to install any remaining cord

strain relief clips.

5. The final cord to be installed is the

power cord. Plug power cord into

remaining open socket on the control

box. Route the power cord to an

approved power source.

6. Raise the adjustable-height

worksurface to the maximum height

using the key pad, allowing easier

access to the remaining bracket

mounting hole.

7. Using the L- and T-support bracket’s

remaining mounting holes as

templates (four per L-bracket and

four for the T-Support bracket on

each side of the worksurface), secure

the worksurface to the brackets using

#10 x 7/8” Phillips pan head screws

(Figures 3, 4 & 5).

8. If an adjustable-height bookcase,

cabinet or credenza leg was

assembled to the worksurface

and requires an optional wire

management sleeve, proceed to

“Adjustable-Height Bookcase,

Cabinet & Credenza Leg - Wire

Management Sleeve Assembly”

instructions on page 4. If a

adjustable-height panel leg with

sleeve was assembled to the

worksurface, proceed to

“Adjustable-Height Panel Leg with

Sleeve - Wire Management Sleeve

Assembly” instructions on page 5.