5 of 30 DI-129/11/07.07.15

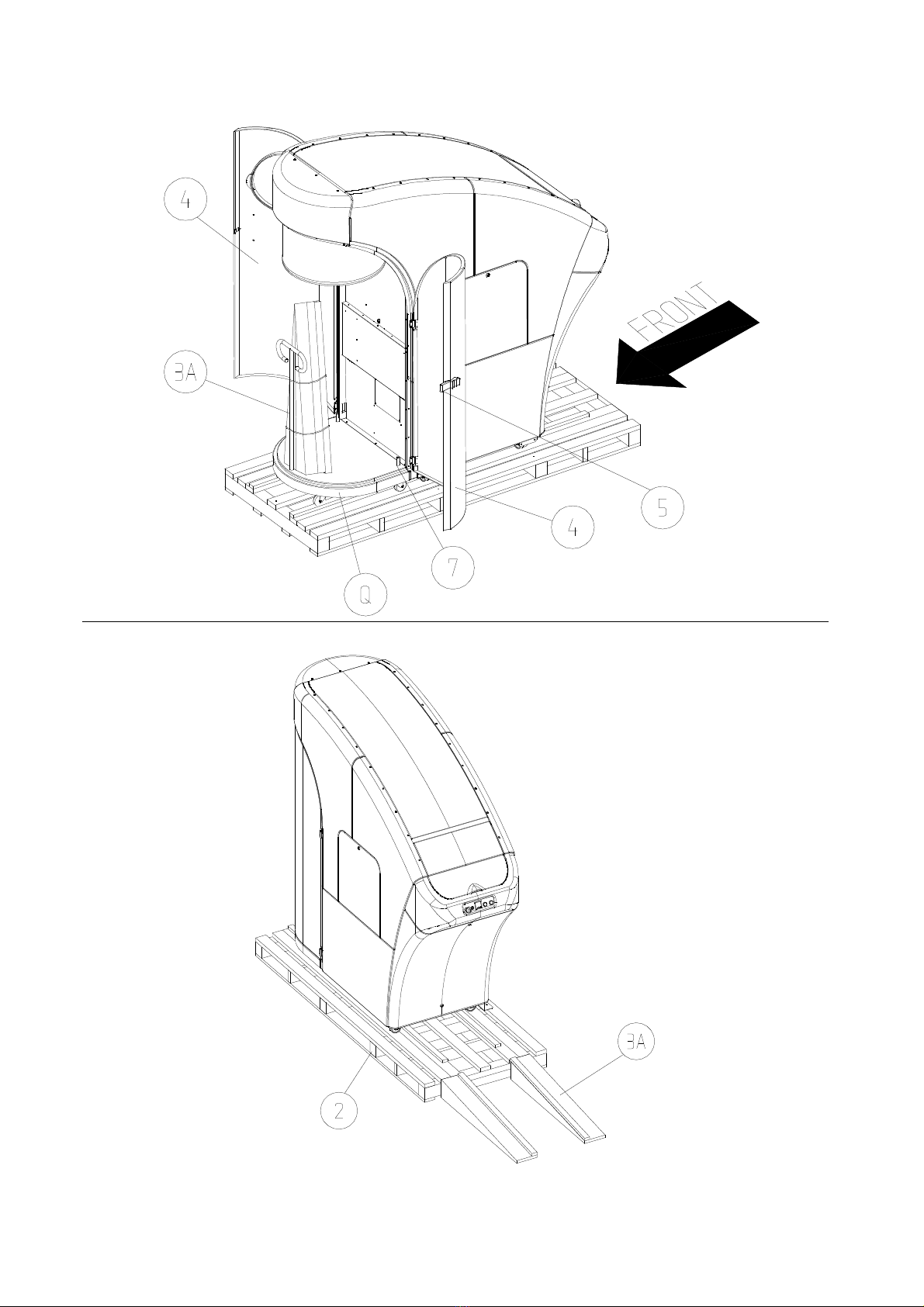

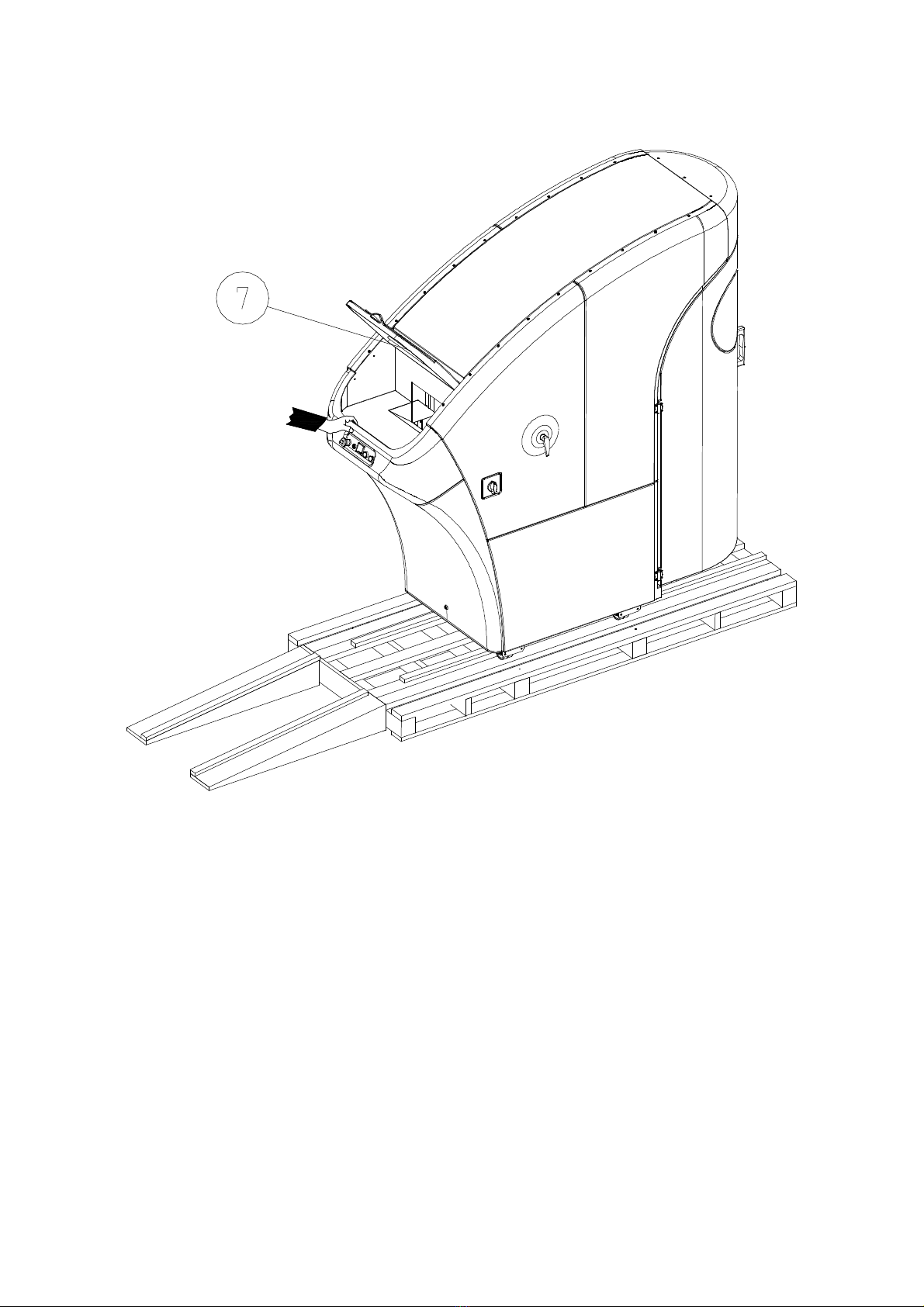

KOBRA CYCLONE

USA

WARNING – IMPORTANT

PLEASE READ THE FOLLOWING INSTRUCTIONS BEFORE OPERATING THE MACHINE

•Ask your electrician to check the electrical supply voltage and frequency to confirm it meets your

Cyclone’s requirements. Refer to your site certification form for additional information.

•To operate the machine, it is suggested to wear earmuffs, gloves and goggles.

•The machine must be operated only when plastic waste bag is installed and when air filter for dust

collection is installed.

•Do not operate the machine when plastic waste bag is full.

•Check the filter if dust is observed at the entry opening.

DISCONNECT THE ELECTRICAL POWER FROM THE MACHINE:

•Before changing the waste bag

•Before changing the air filter for dust

collection

•Before each maintenance or service

operation

•Before removing the electrical panel cover

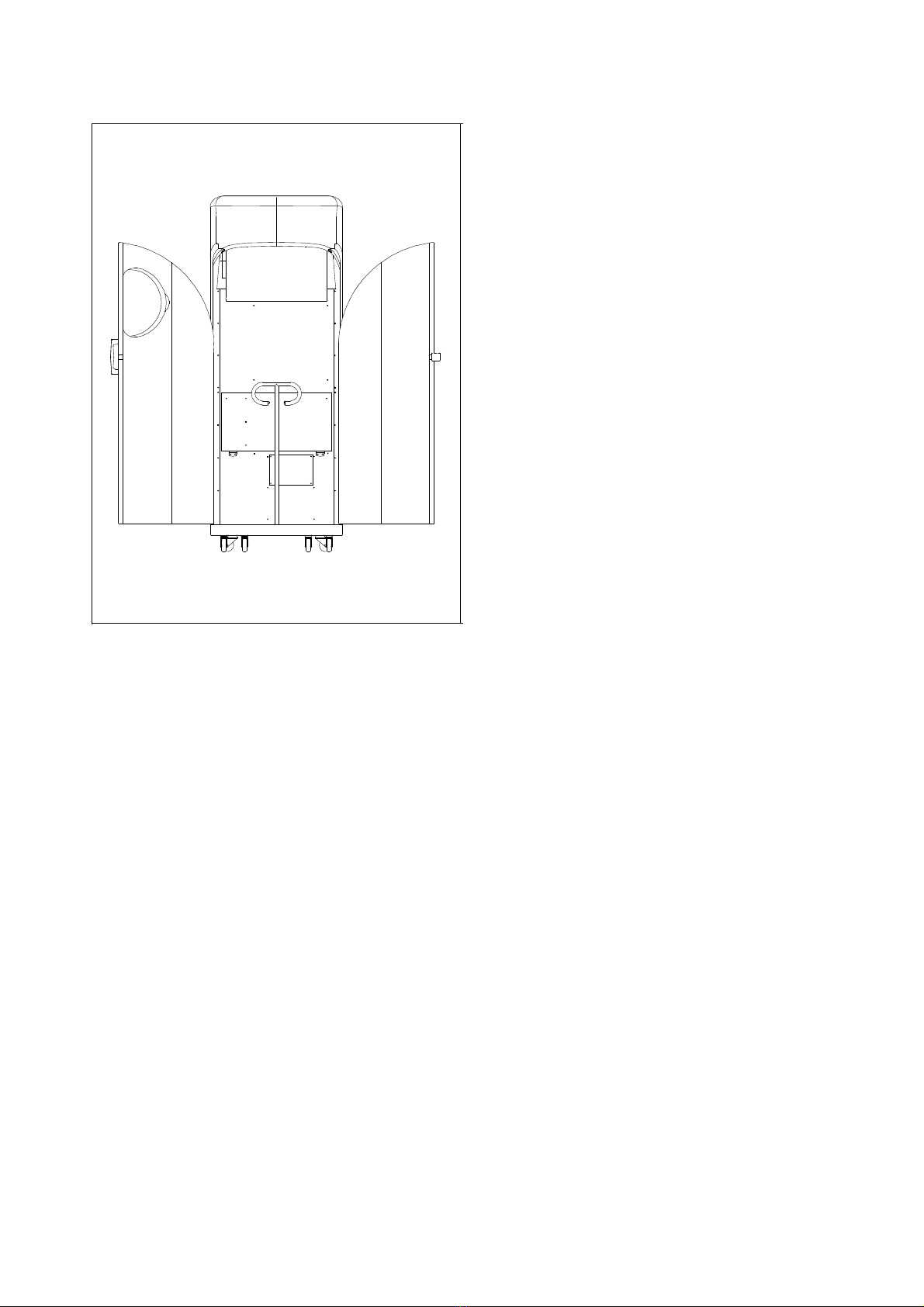

•Before opening the shredding chamber panel

and chamber door

•Before changing the cutting blades or the

security level screen

-

PLEASE BE SURE TO CHECK THE INTERNAL WALLS OF THE CYCLONE SHREDDING CHAMBER ON A REGULAR SCHEDULE, MORE OFTEN IN HEAVY

APPLICATIONS AND IF YOUR APPLICATION REQUIRES SHREDDING OF MATERIALS OTHER THAN PAPER. PLEASE DO NOT OPERATE THE CYCLONE AND

HAVE YOUR KOBRA RETAILER CHECK YOUR MACHINE BEFORE OPERATION IF YOU DISCOVER ANY UNUSUAL WARE OR IRREGULARITIES DURING YOUR

INSPECTION. SHREDDER CHAMBER WALLS MUST BE KEPT CLEAR OF ALL SHREDDING MATERIALS AND IN GOOD CONDITION.