·

·

·

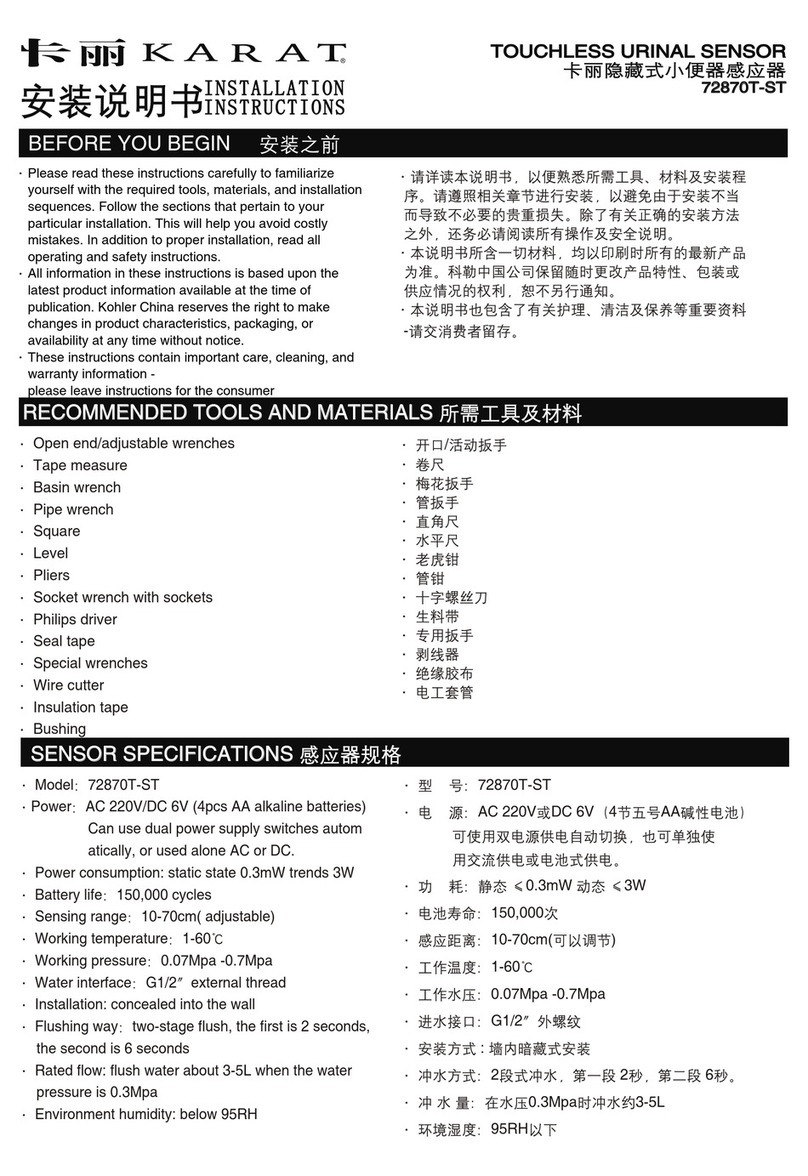

Please read these instructions carefully to familiarize

yourself with the required tools, materials, and installation

sequences. Follow the sections that pertain to your

particular installation. This will help you avoid costly

mistakes. In addition to proper installation, read all

operation and safety instructions.

All information in these instructions is based upon the

latest product information available at the time of

publication. Kohler China reserves the right to make

changes in product characteristics, packaging, or

availability at any time without notice.

These instructions contain important care, cleaning, and

warranty information -

.

please leave instructions for the

consumer

·

·

·-

·

·

·

·

·

·

·

·

·

·

·

·

·

·

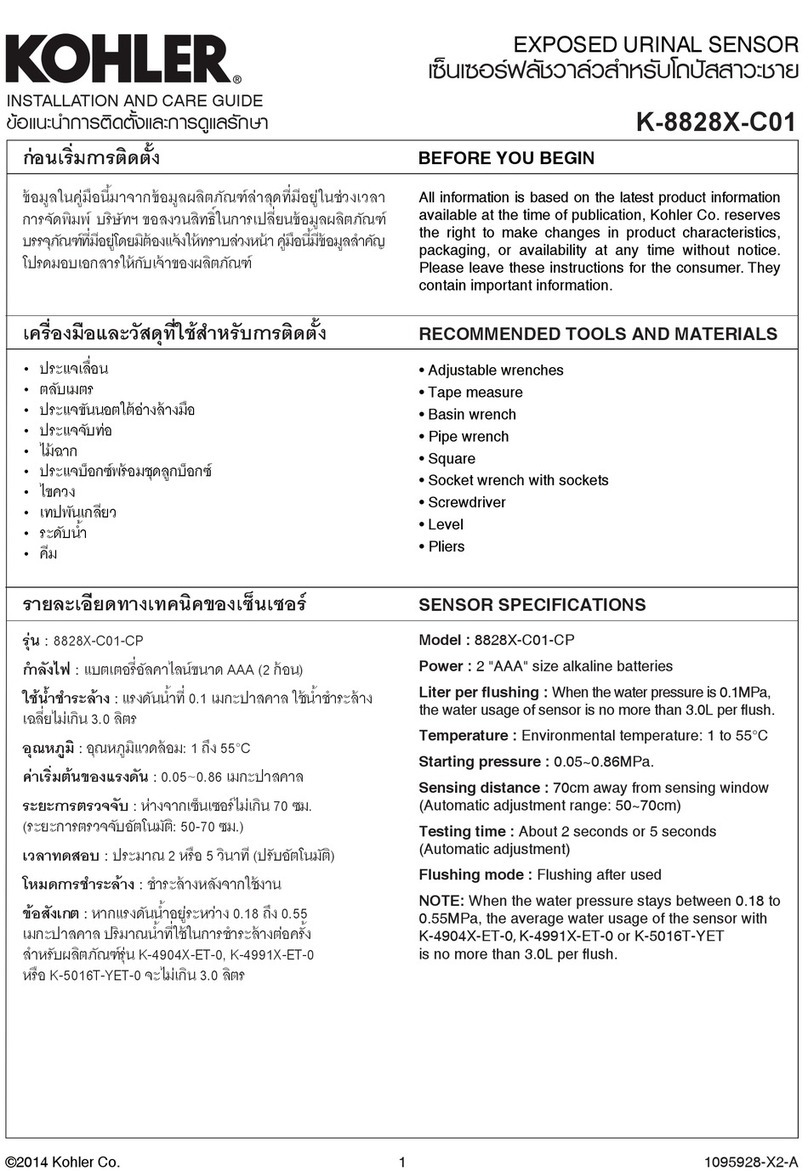

Open end/adjustable wrenches

Tape measure

Basin wrench

Pipe wrench

Square

Level

Pliers

Socket wrench with sockets

Screw driver

Seal tape

Connection wire

Wire cutter

Insulation tape

Bushing

·

·

·

·

·

·

·

·

·

·

·

·

·

·

/

RECOMMENDED TOOLS AND MATERIALSRECOMMENDED TOOLS AND MATERIALS

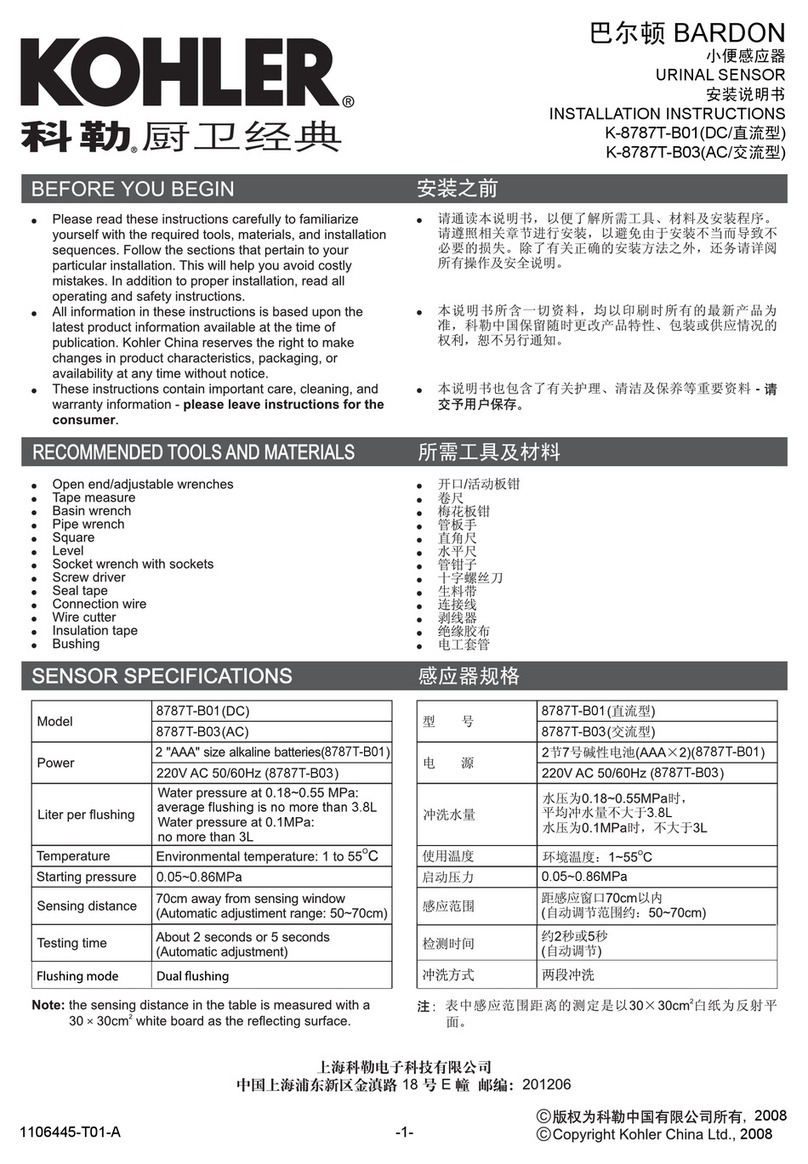

SENSOR SPECIFICATIONSENSOR SPECIFICATION

Model 8787T-C03(AC)

8787T-C01(DC)

Power

4 AA size alkaline batteries

(8787T-C01)

""

220V AC 50/60Hz(8787T-C03)

Liter per flushing

Water pressure 0.3 MPa: about 2~4L

(Automatic adjustment)

Water pressure 0.1MPa no more than 3L

Temperature Environmental temperature: 1 to 60

Starting pressure 0.05~0.7MPa

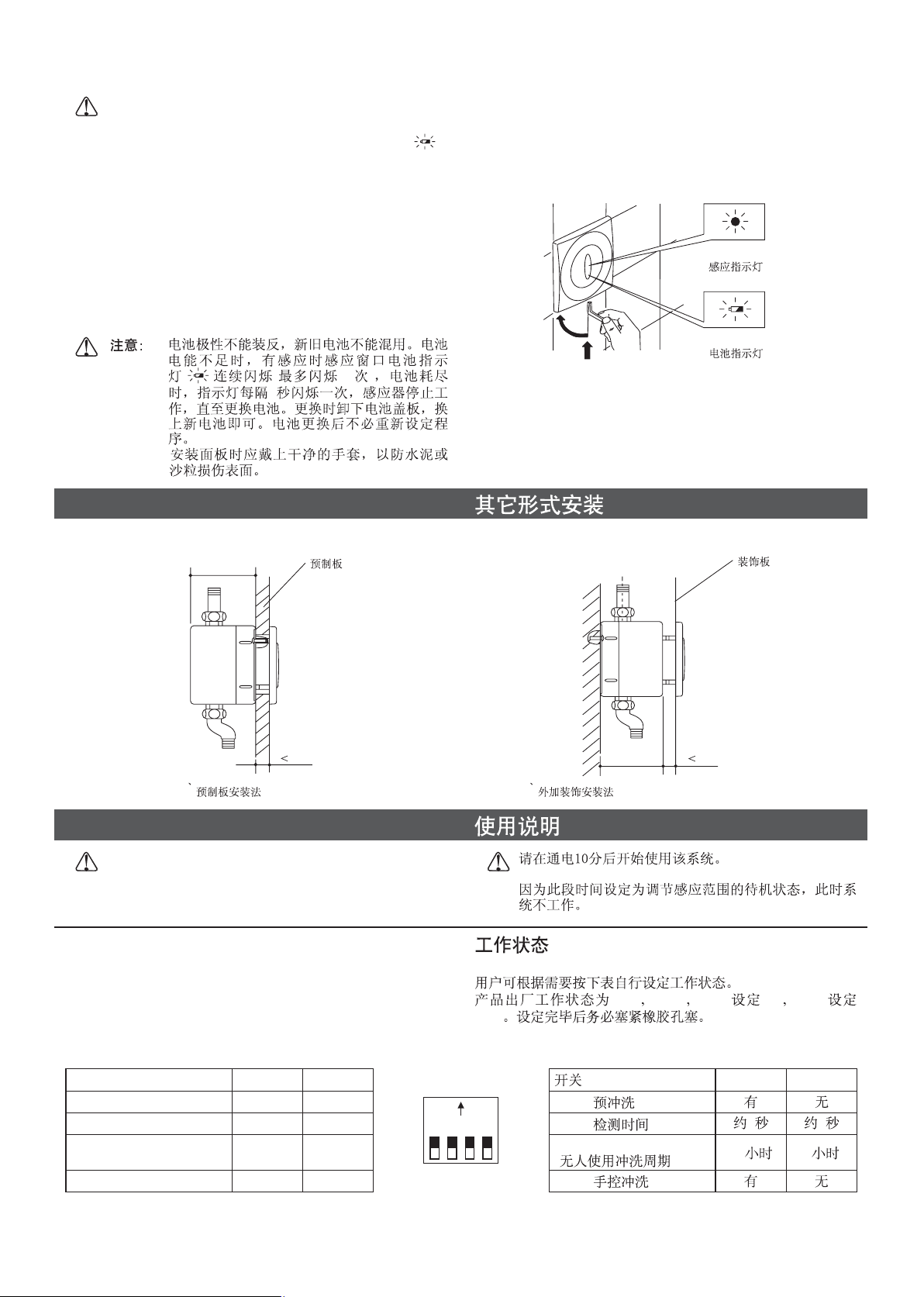

Sensing distance 80cm away from sensing window

(adjustable)

Testing time About 2 seconds (or set to 5 seconds)

30 30cm2

Note: The sensing distance in the table is measured with a

30 30cm white board as the reflecting surface.

2

8787T-C03( )

8787T-C01( )

4 5 (AA 4)

(8787T-C01)

220V AC 50/60Hz(8787T-C03)

0.3 MPa 2~4L

()

0.1MPa 3L

:1 ~60

0.05~0.7MPa

80cm

()

2( 5)

BARDON

TOUCHLESS URINAL SENSOR (WATER SAVING)

INSTALLATION INSTRUCTIONS

K-8787T-C01(DC/ )

K-8787T-C03(AC/ )

-1-

, 2007

Copyright Kohler China Ltd., 2007

18 E 201206

1020018-T01-C