3 1377486-IN2-A

INSTALLATION LAYOUT

START UP

OPERATION & FILTER CHANGEOUT

TROUBLESHOOTING

• Clean the filter either with compressed air or flush the housing with pure water to avoid debris or dirt to float in the system.

• Position the filter in such a way that the fluid enters the inlet connection.

• Close the outlet valve and open the vent on top of the filter housing.

• Partially open the inlet valve at pipe before the filter housing and allow fluid to fill completely into housing along with venting

of air from top of the housing.

• After complete venting of air, close the vent valve. Fully open the inlet valve and open the outlet valve simultaneously.

1. Changing the Filter Cartridge

• Follow regulations in force for the disposal of used cartridges.

• Before opening the filter housing turn-off, the water main.

• Release the pressure from the product by un-screwing the vent-valve of the head. Then screw and tighten the vent-valve.

• Open the housing unscrewing the housing using a proper wrench.

• Remove the used cartridge.

• Wipe clean the filter housing with cold water and a soft sponge.

• Open the new cartridge wrap and discard wrap.

• Insert the new cartridge and place it into the housing.

• Tighten the housing bowl to housing’s head using a proper wrench. Do not over-tighten.

• Turn-on the water main.

• Slowly turn-on a water supply (tap) downstream the filter.

• Wait for air purge from the vent-valve, then screw and tighten the vent-valve.

Remark: Let the water flow for at least 5 minutes before the use.

1. Troubleshooting for Leaks

• Check the O-ring for any damage and wear & tear, dirt or swelling etc. If required, replace 0-ring with new one.

• Properly close the housing. Hand tightening is good enough to seal.

• Carefully check all threaded connections. If connections not proper, unscrew and connect again as and when needed.

• Check to see if filter cartridge is dirty and choked up. If this is the case, replace the cartridges as per instructions.

2. Poor Filtration Results

• Check to make sure the filter cartridges is properly seated in the support basket.

• Check all O-rings and sealing surfaces are cleaned before installing.

• Frequent Cartridges Clogging - Selection of proper filter cartridge with proper micron rating.

• Lower filtration flow or High Differential Pressure- Change the Cartridgeas per recommended Differential Pressure.

If Differential Pressure is not achieved -Open the system and check the cartridge condition for damages (if any).

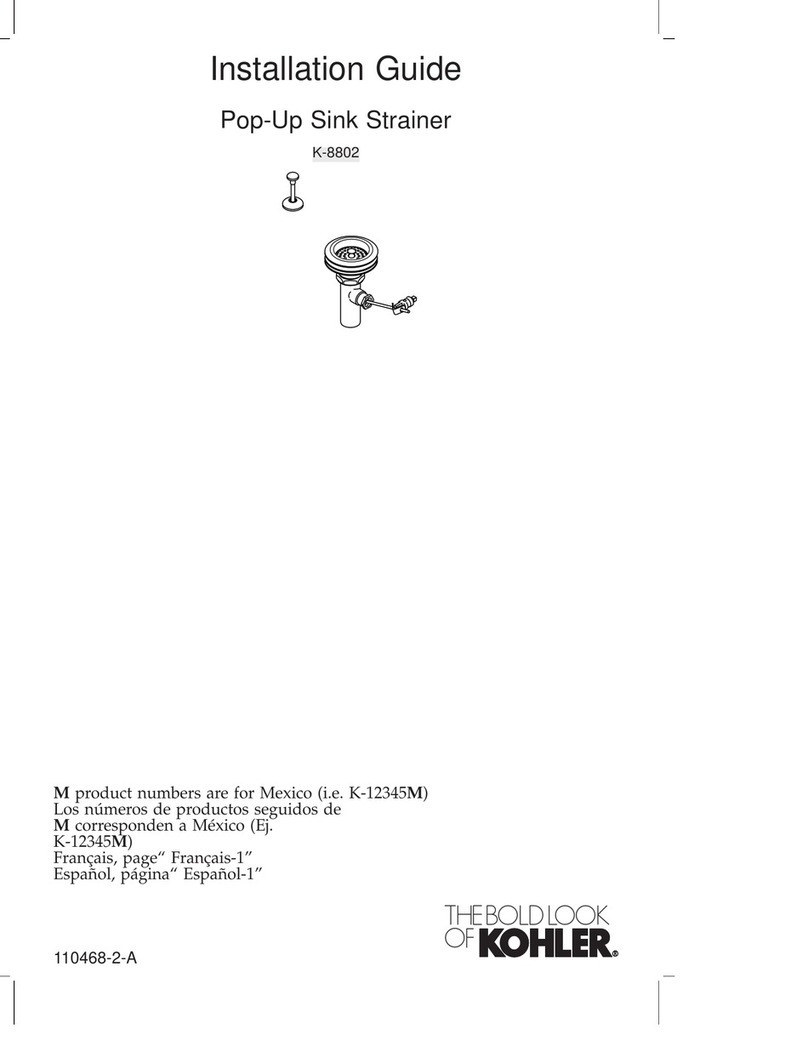

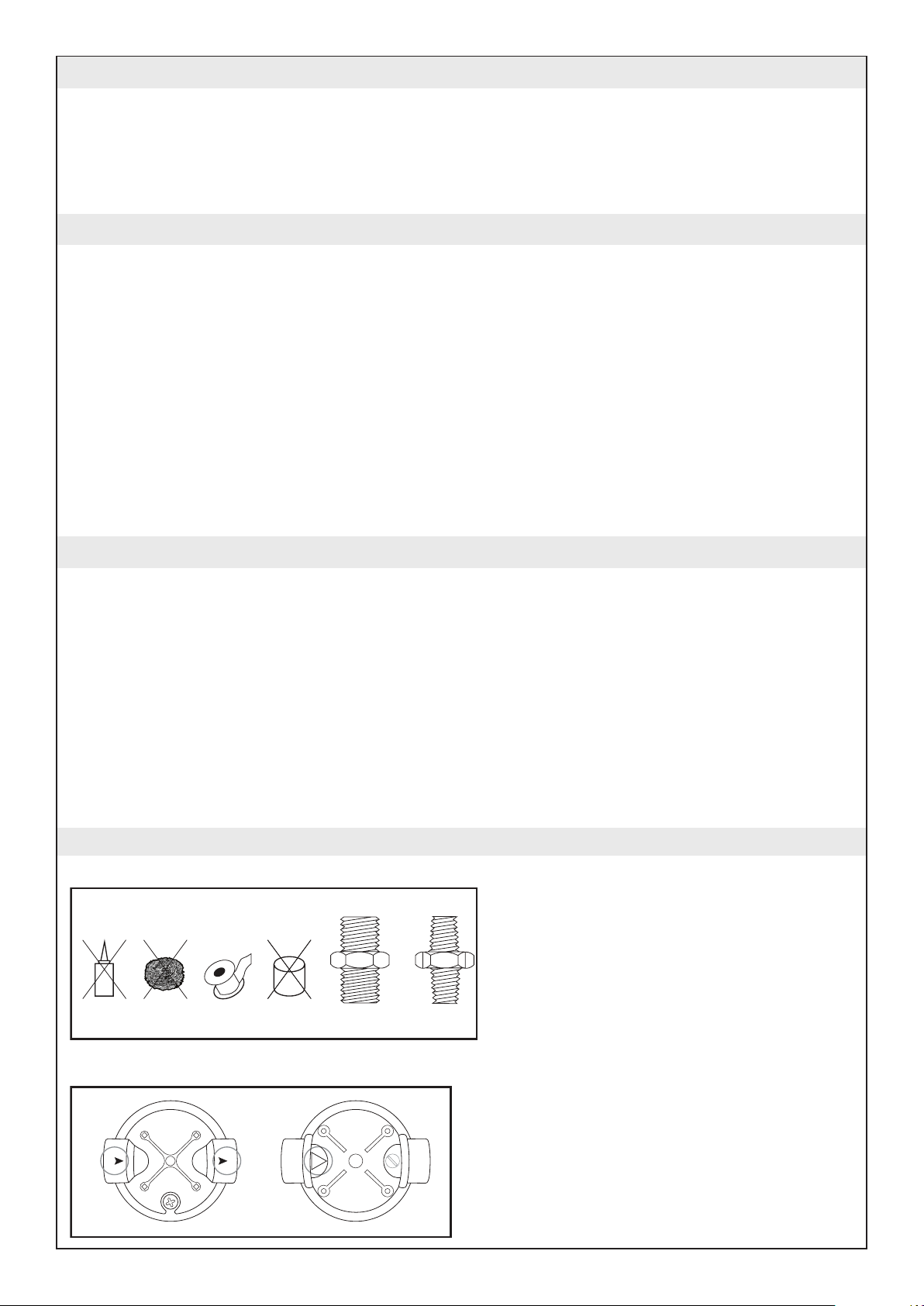

NPT

FITTINGS

BSP

IN

OUT

IN

OUTIN IN OUT

a.

b.

General information.

IN-OUT directions presentation in different lter housings models.