P 4/ 7

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Drill Chuck S10, Spiral Bevel Gear 26 (cont.)

ASSEMBLING

1) If the jaws of Drill chuck are open, make them close for smooth assembling of Ball bearing 6806DDW and Spiral bevel

gear 26. Refer to Fig. 6.

2) Do not forget to assemble Key 4 to Drill chuck S10. Refer to Fig. 7.

3) Do the reverse of the disassembling steps.

Repair

DISASSEMBLING

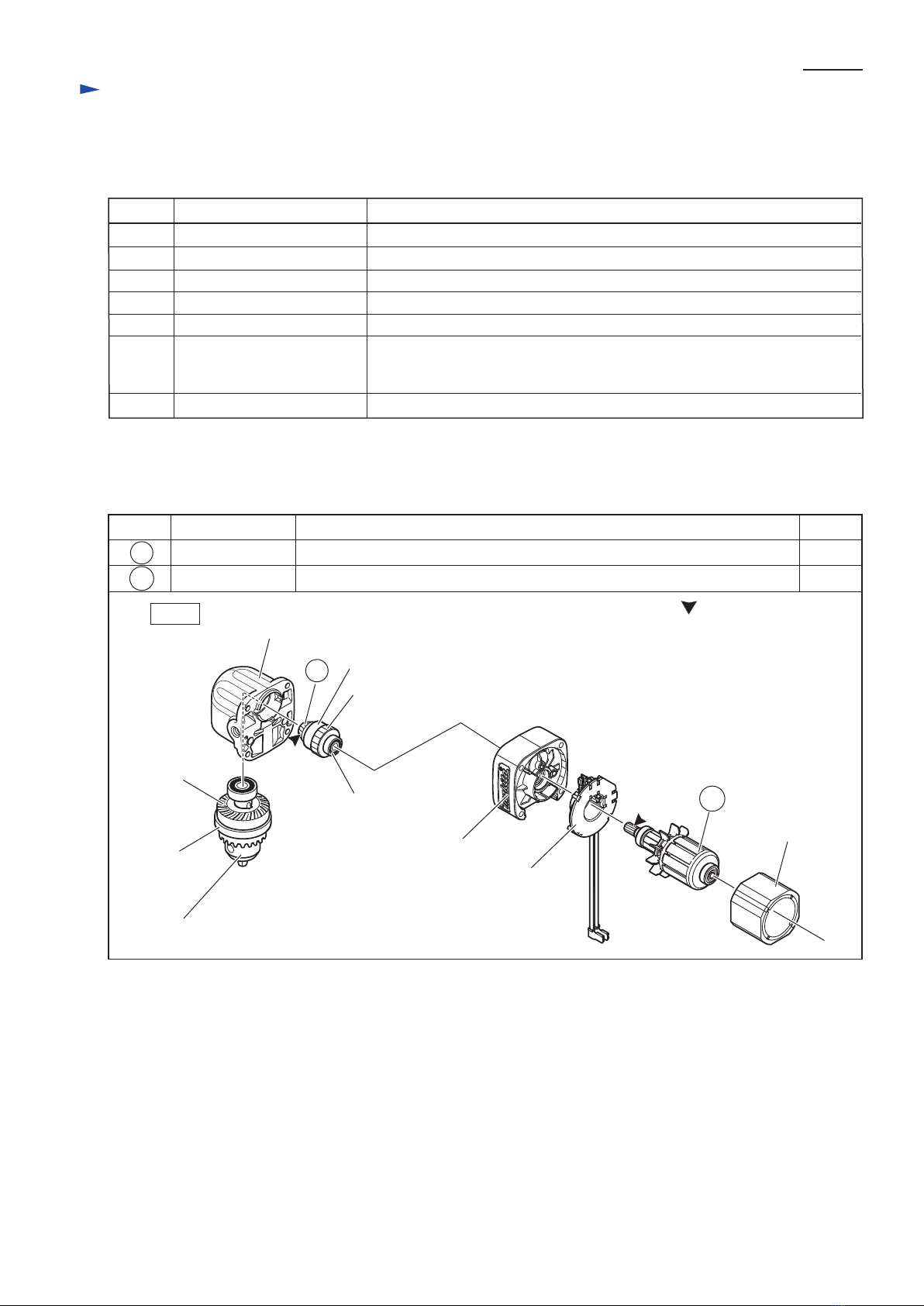

[3]-2. Spur Gear 29, Spiral Bevel Gear 9

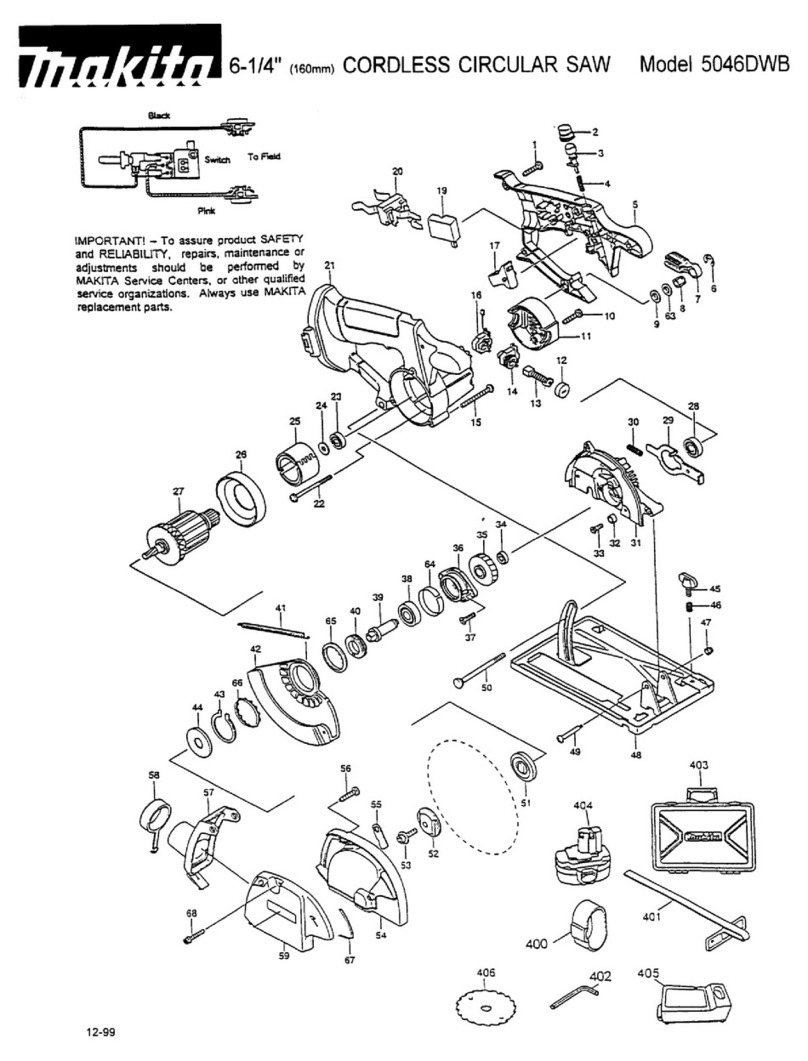

1) Disassemble Bearing retainer, Drill chuck S10 from Gear housing as illustrated in Figs. 2, 3, 4.

2) Disassemble the Gear section as illustrated in Fig. 8.

3) The Gear section is disassembled as illustrated in Fig. 9.

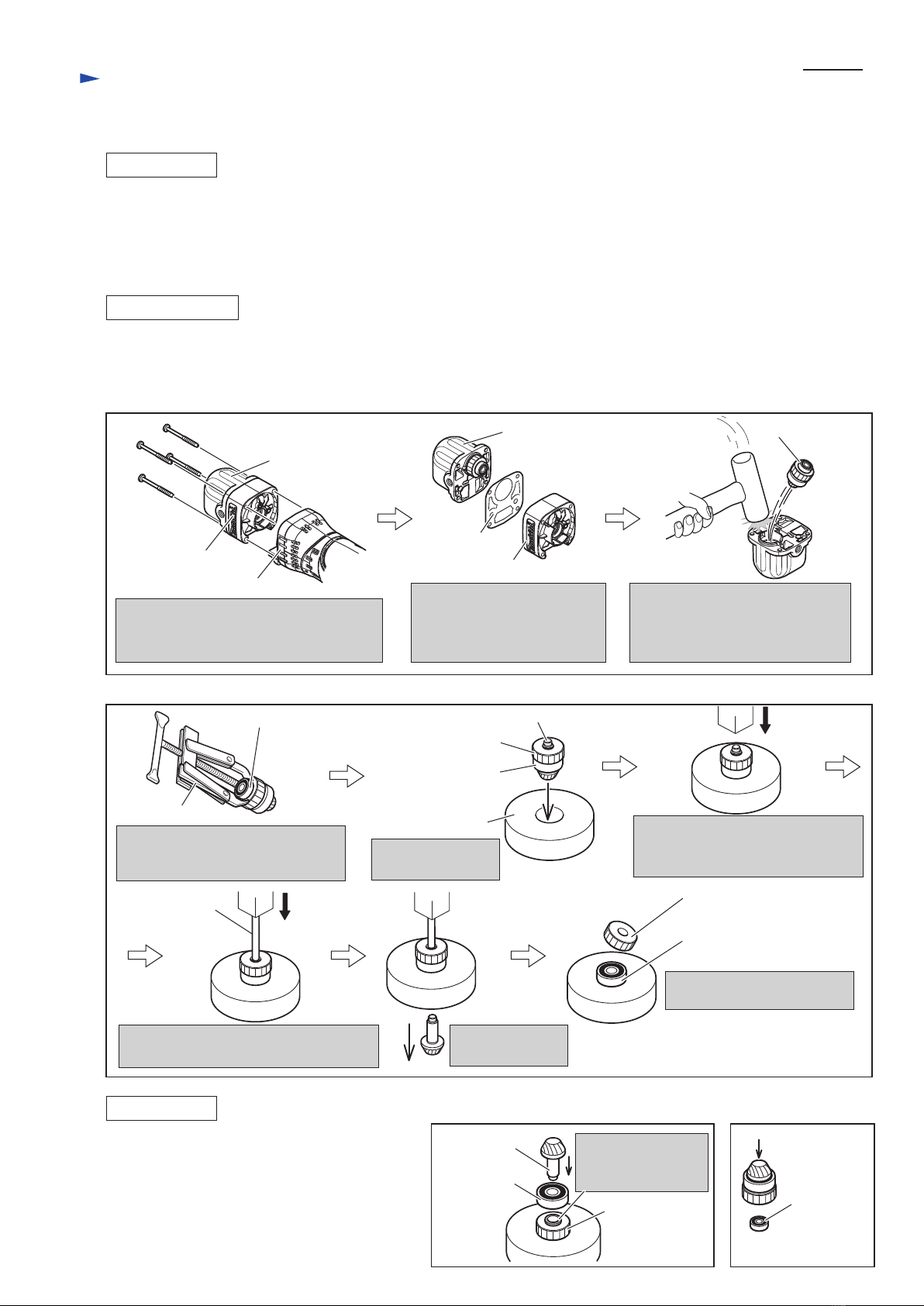

Disassemble Gear housing together with

Gear housing cover from Motor housing

by unscrewing 4x45 Tapping screw.

Remove Gear housing cover

from Gear housing by pulling

off. Pay attention not to lose

Gasket in this step.

Strike the edge of Gear housing

with plastic hammer.

Now Gear section can be removed

from Gear housing.

4x45 Tapping screw (4pcs.)

Gear housing

Gasket

Motor housing

Gear housing cover

Gear housing

Gear housing

cover

Gear section

Fig. 8

Fig. 9

ASSEMBLING

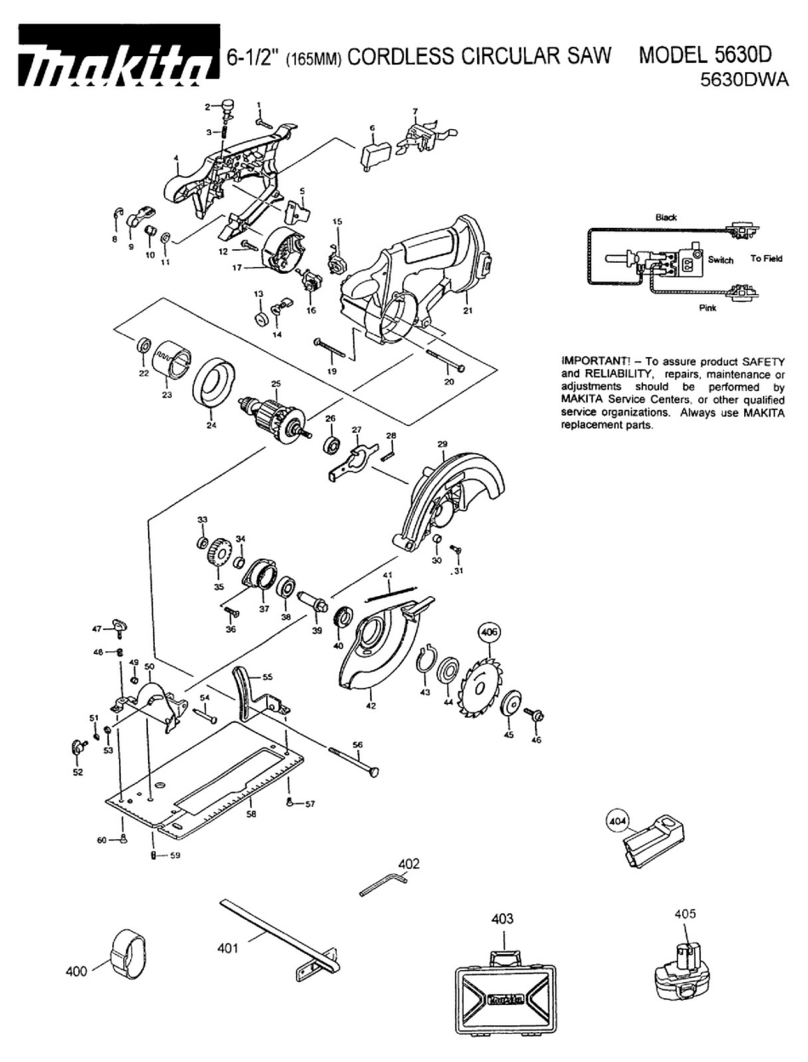

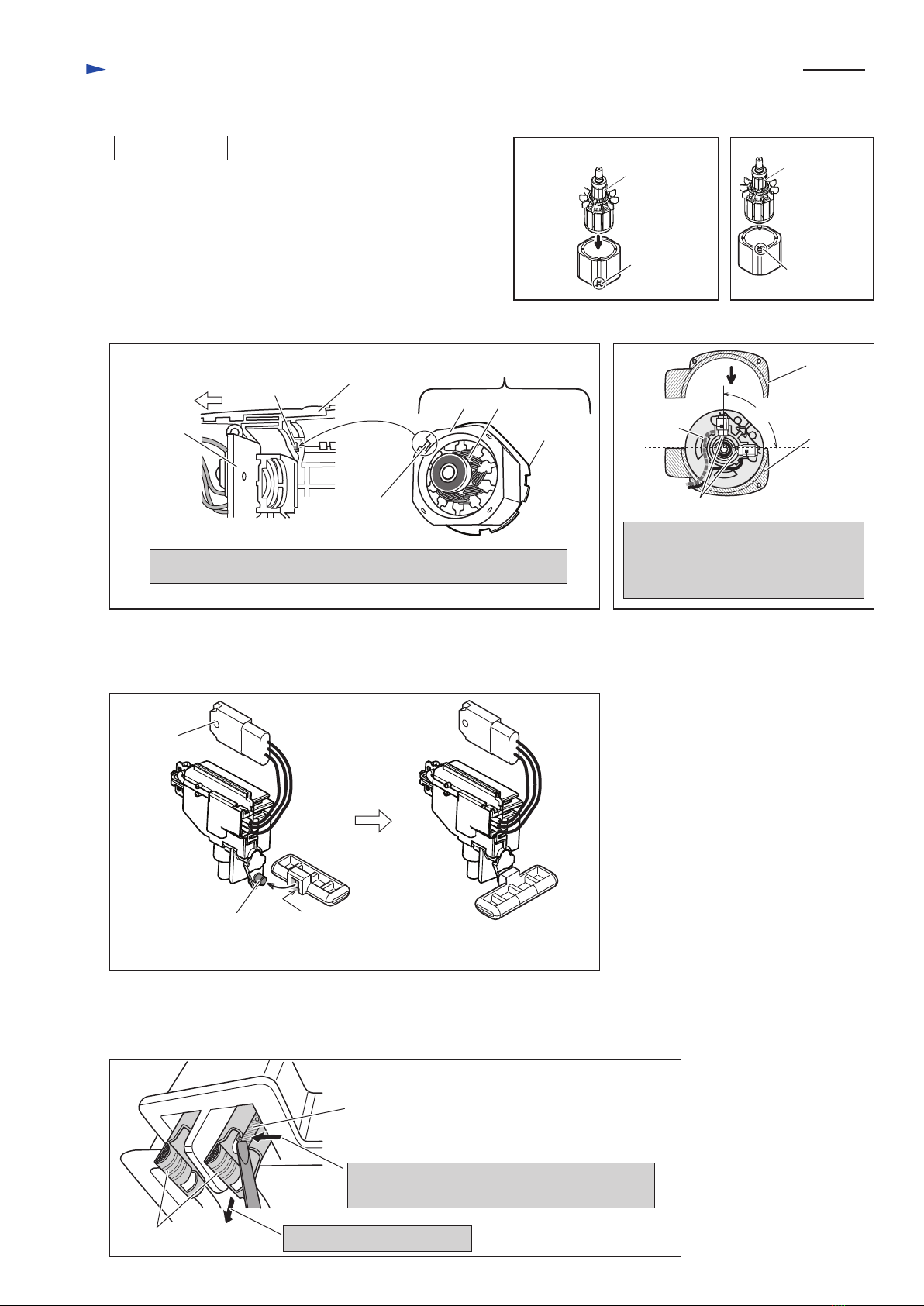

1R269

1R280

1R036

Disassemble Ball bearing 696ZZ

from the shaft of Spiral bevel gear 9

with 1R269.

Ball bearing

608ZZ

Accept Ball bearing

608ZZ with 1R036.

Push Shaft end of Spiral bevel gear 9

to ths surface of Spur gear 29 with

arbor press.

Spiral bevel gear 9

is removed.

Spur gear 29 and Ball bearing

608ZZ are separated.

Applying 1R280 to the shaft end of

Spiral bevel gear 9, press with arbor press.

Spur gear 29

shaft end of Spiral bevel gear 9

Ball bearing 608ZZ

Spur gear 29

Ball bearing 696ZZ

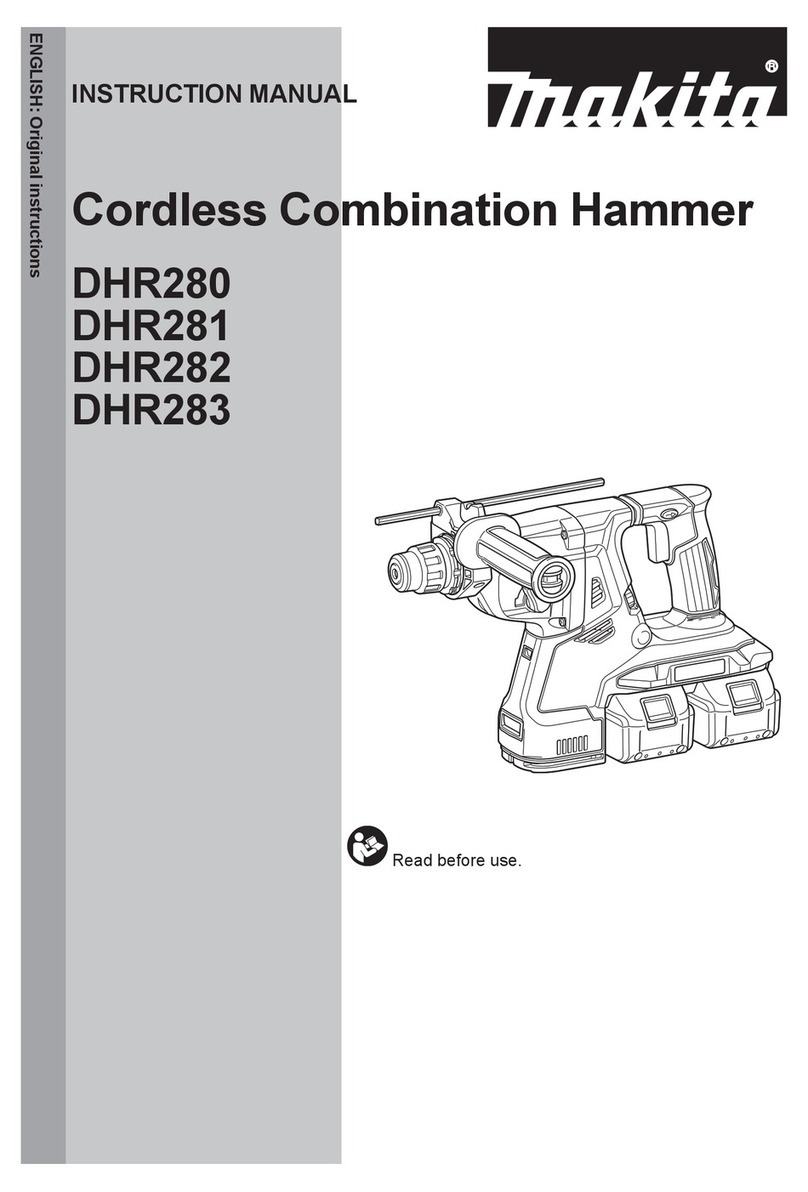

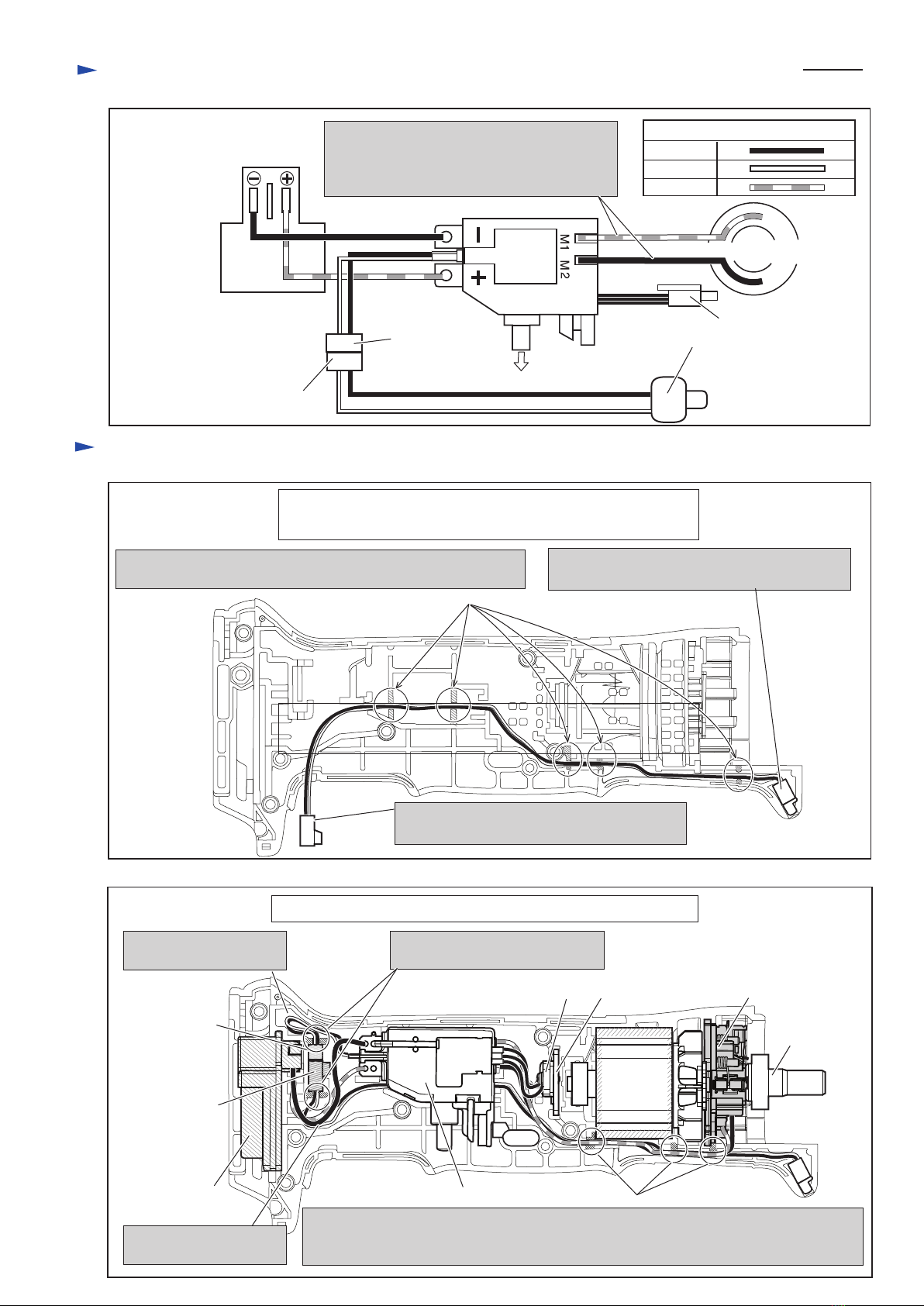

(1) Assemble Ball bearing 608ZZ and Spur gear 29

to Spiral bevel gear 9. (Fig. 10)

(2) Assemble Ball bearing 696ZZ to the shaft end

of Spiral bevel gear 9. (Fig. 11)

(3) Do the reverse of the disassembling steps.

Refer to Fig. 8.

Spur gear 29

< Note >

Rib has to face

Ball bearing 608ZZ.

Ball bearing

608ZZ Ball bearing

696ZZ

Spiral bevel

gear 9

Fig. 10 Fig. 11