6

power tool "live" and could give the operator an

electric shock.

3. Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your body

leaves it unstable and may lead to loss of control.

4. Always use safety glasses or goggles.

Ordinary eye or sun glasses are NOT safety

glasses.

5. Avoid cutting nails. Inspect workpiece for any

nails and remove them before operation.

6. Hold the tool firmly.

7. Make sure the application tool is not

contacting the workpiece before the switch is

turned on.

8. Keep hands away from moving parts.

9. Do not leave the tool running. Operate the tool

only when hand-held.

10. Always switch off and wait for the blade to

come to a complete stop before removing the

blade from the workpiece.

11. Do not touch the application tool or the

workpiece immediately after operation; they

may be extremely hot and could burn your

skin.

12. Do not operate the tool at no-load

unnecessarily.

13. Always use the correct dust mask/respirator

for the material and application you are

working with.

14. Some material contains chemicals which may

be toxic. Take caution to prevent dust

inhalation and skin contact. Follow material

supplier safety data.

15. This tool has not been waterproofed, so do not

use water on the workpiece surface.

16. Ventilate your work area adequately when you

perform sanding operations.

17. Use of this tool to sand some products, paints

and wood could expose user to dust

containing hazardous substances. Use

appropriate respiratory protection.

18. Be sure that there are no cracks or breakage

on the pad before use. Cracks or breakage

may cause a personal injury.

19. Do not use accessories which are not

specifically designed and recommended by

the tool manufacturer. Just because the

accessory can be attached to your power tool, it

does not assure safe operation.

20. Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As

appropriate, wear hearing protectors, gloves

and workshop apron capable of stopping

small abrasive or workpiece fragments. The

eye protection must be capable of stopping flying

debris generated by various operations . The dust

mask or respirator must be capable of filtrating

particles generated by your operation. Prolonged

exposure to high intensity noise may cause

hearing loss.

21. Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken accessory

may fly away and cause injury beyond immediate

area of operation.

22. Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and pull

the power tool out of your control.

23. Do not run the power tool while carrying it at

your side. Accidental contact with the accessory

could snag your clothing, pulling the accessory

into your body.

24. Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

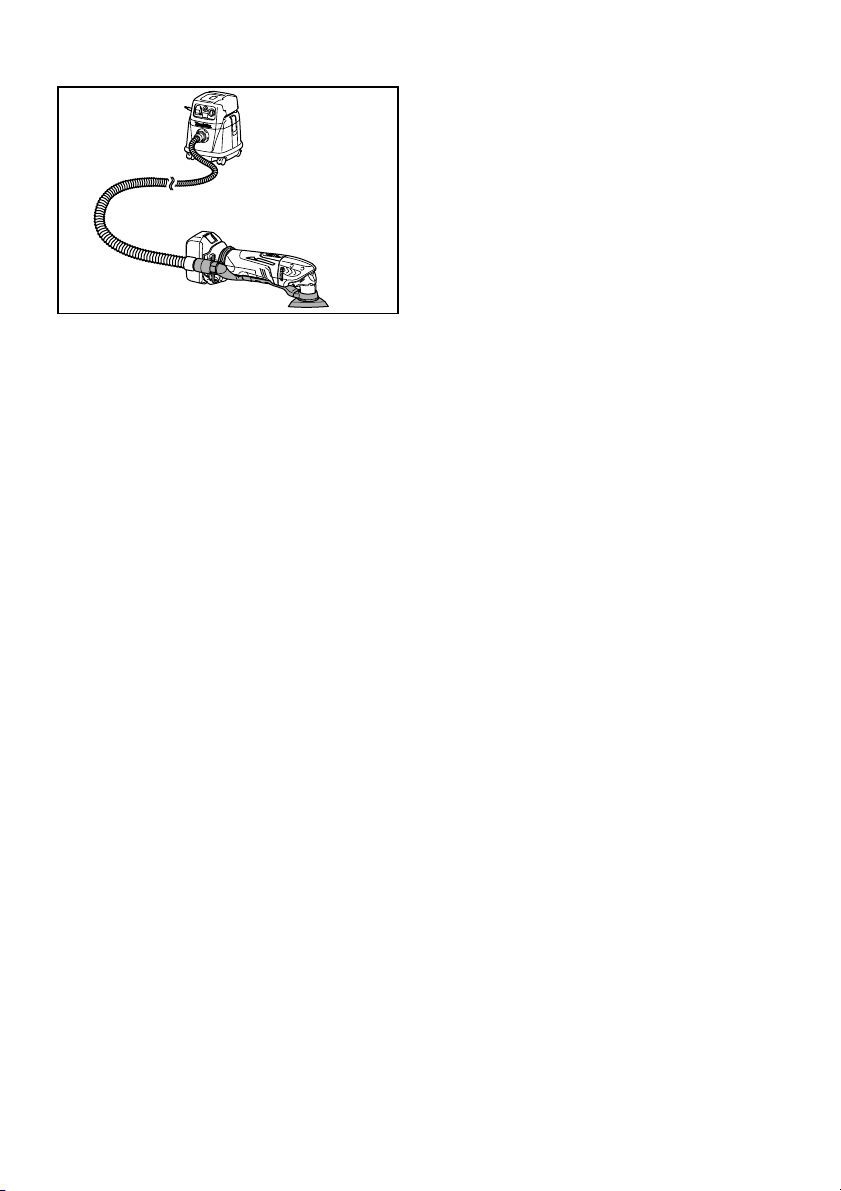

25. Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution or shock.

26. Always be sure that the tool is switched off

and unplugged or that the battery cartridge is

removed before carrying out any work on the

tool.

27. Always be sure you have a firm footing. Be

sure no one is below when using the tool in

high locations.

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to safety rules for the subject product. MISUSE or

failure to follow the safety rules stated in this

instruction manual may cause serious personal

injury.

ENC007-7

IMPORTANT SAFETY

INSTRUCTIONS

FOR BATTERY CARTRIDGE

1. Before using battery cartridge, read all

instructions and cautionary markings on (1)

battery charger, (2) battery, and (3) product

using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them

out with clear water and seek medical