10 ENGLISH

WARNING: Wear ear protection.

WARNING:

The noise emission during actual

use of the power tool can dier from the declared

value(s) depending on the ways in which the tool is

used especially what kind of workpiece is processed.

WARNING:

Be sure to identify safety measures

to protect the operator that are based on an estima-

tion of exposure in the actual conditions of use (tak-

ing account of all parts of the operating cycle such

as the times when the tool is switched o and when

it is running idle in addition to the trigger time).

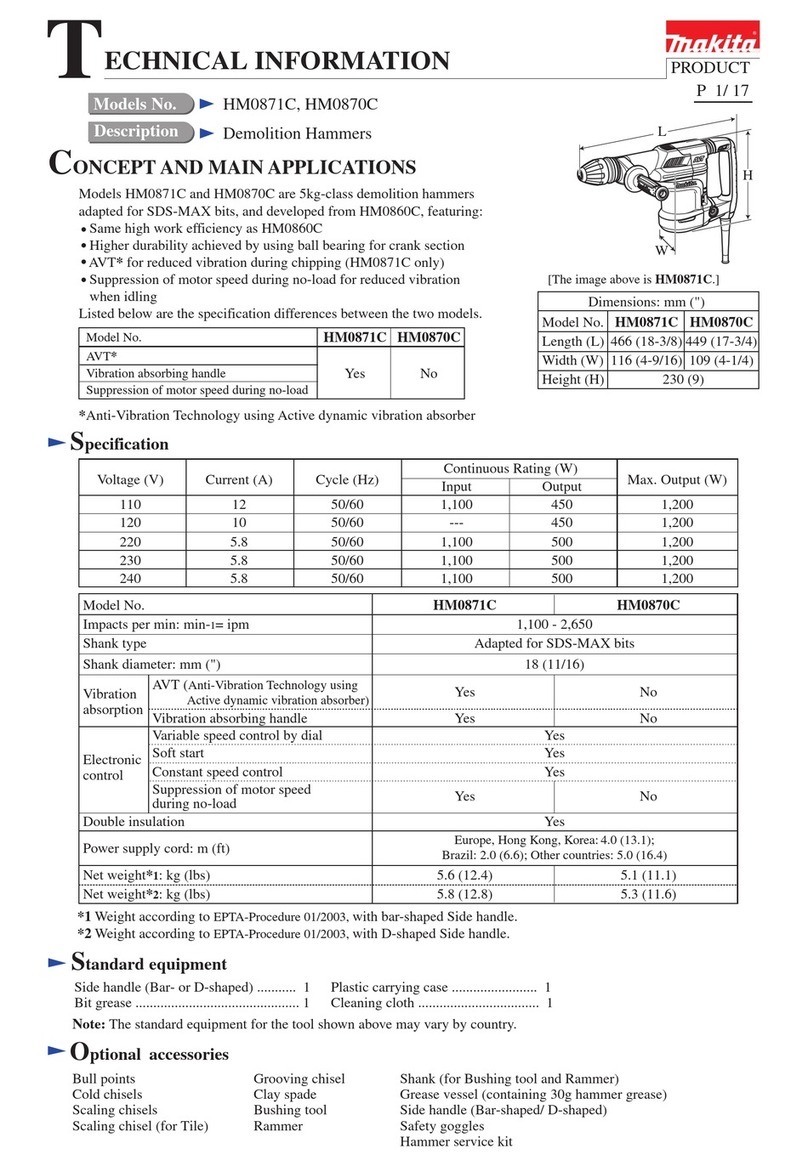

Vibration

The following table shows the vibration total value

(tri-axial vector sum) determined according to applica-

ble standard.

Model HR3011FC

Work mode Vibration

emission

Uncertainty (K)

Applicable

standard

Hammer

drilling into

concrete

(ah, HD)

9.5 m/s21.5 m/s2EN60745-2-6

Hammer

drilling into

concrete with

DX10 (ah, HD)

9.5 m/s21.5 m/s2EN60745-2-6

Chiselling func-

tion with side

grip (ah, Cheq)

6.0 m/s21.5 m/s2EN60745-2-6

Drilling into

metal (ah, D)

5.5 m/s21.5 m/s2EN62841-2-1

Model HR3012FC

Work mode Vibration

emission

Uncertainty (K)

Applicable

standard

Hammer

drilling into

concrete

(ah, HD)

9.5 m/s21.5 m/s2EN60745-2-6

Hammer

drilling into

concrete with

DX11 (ah, HD)

8.0 m/s21.5 m/s2EN60745-2-6

Chiselling func-

tion with side

grip (ah, Cheq)

5.5 m/s21.5 m/s2EN60745-2-6

Drilling into

metal (ah, D)

6.0 m/s21.5 m/s2EN62841-2-1

Model HR3001C

Work mode Vibration

emission

Uncertainty (K)

Applicable

standard

Hammer

drilling into

concrete

(ah, HD)

13.5 m/s21.5 m/s2EN60745-2-6

Chiselling func-

tion with side

grip (ah, Cheq)

11.0 m/s21.5 m/s2EN60745-2-6

Drilling into

metal (ah, D)

6.0 m/s21.5 m/s2EN62841-2-1

NOTE: The declared vibration total value(s) has been

measured in accordance with a standard test method

and may be used for comparing one tool with another.

NOTE: The declared vibration total value(s) may also

be used in a preliminary assessment of exposure.

WARNING:

The vibration emission during actual

use of the power tool can dier from the declared val-

ue(s) depending on the ways in which the tool is used

especially what kind of workpiece is processed.

WARNING:

Be sure to identify safety measures

to protect the operator that are based on an estima-

tion of exposure in the actual conditions of use (tak-

ing account of all parts of the operating cycle such

as the times when the tool is switched o and when

it is running idle in addition to the trigger time).

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A

to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool. Failure to follow all instructions

listedbelowmayresultinelectricshock,reand/or

seriousinjury.

Save all warnings and instruc-

tions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

ROTARY HAMMER SAFETY WARNINGS

1. Wear ear protectors. Exposure to noise can

cause hearing loss.

2. Use auxiliary handle(s), if supplied with the

tool.Lossofcontrolcancausepersonalinjury.

3.

Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live"

and could give the operator an electric shock.

4.

Wear a hard hat (safety helmet), safety glasses and/

or face shield. Ordinary eye or sun glasses are NOT

safety glasses. It is also highly recommended that

you wear a dust mask and thickly padded gloves.

5.

Be sure the bit is secured in place before operation.

6.

Under normal operation, the tool is designed to

produce vibration. The screws can come loose

easily, causing a breakdown or accident. Check

tightness of screws carefully before operation.