TROUBLESHOOTING AND CORRECTIVE MEASURES FOR THE SENSOR FUNCTION

Sensor function

gives no water

Transformer fault set, AC not

selected and activated on the

circuit board.

The water is shut off

Poor or batteries turned the

wrong way

Sensor distance too short

The solenoid valve is not

working

Dirt in the solenoid valve

Inlet filter clogged

Fault in the electronics

Check that the transformer is set to 12V. And

that the circuit board has AC selected.

Check the water connection

Check the batteries, 4 ea R6 á 1.5 volt, which

must be mounted according to the instructions

in the battery compartment

Try moving your hand closer to the sensor eyes

Activate the sensor eyes and listen for a click-

ing sound

see above

Examine the inlet filter mounted between the

solenoid valve and valve block

Conduct a ”self-test” as described above

Set the Transformer to 12V. Select AC.

Press RESET.

Open any shut offs

Replace batteries, or correct the position

of the battery. NOTE: Use alkaline bat-

teries!

Adjust the sensor gap

If you hear no sound: Replace the

solenoid coil or if necessary the entire

solenoid valve

If you hear a clicking sound - clean the

solenoid valve or replace the membrane

disk, see figure below

Clean the inlet filter

Replace the sensor eyes or circuit board

POSSIBLECAUSE TROUBLESHOOTING CORRECTIVEMEASUREPROBLEMS

The tap will not

turn off

Before additional tests can be made, establish whether the fault is electrical or mechanical by disconnecting the batteries.

If the tap shuts off with disconnected current, the fault is electrical. If the tap continues to run there is a mechanical fault.

Mechanical fault - dirt in the

solenoid valve

Electrical fault - the elec-

tronics prevent the solenoid

valve from shutting off

-

Conduct a ”self-test” as described above

Dismantle the solenoid valve for clea-

ning, see figure below

Replace the sensor eyes or circuit board

Dirt in the solenoid valve, or

leaky membrane disk

Screw apart the solenoid valve and look for dirt

and check the membrane disk

Clean and where necessary replace the

membrane disk, see figure below

The tap is dripping

The sensor distance is too far - Adjust the sensor distance to about 5

cm in front of the sensor eyes

The tap opens/

shuts off con-

stantly The sensor eyes are defective The sensor distance setting is not reacting Replace the sensor eyes

Normal function

When activating the sensor function, a red flashing light is to be visible on the indication lamp (under the sensor eyes) just when the flow

starts.Test:

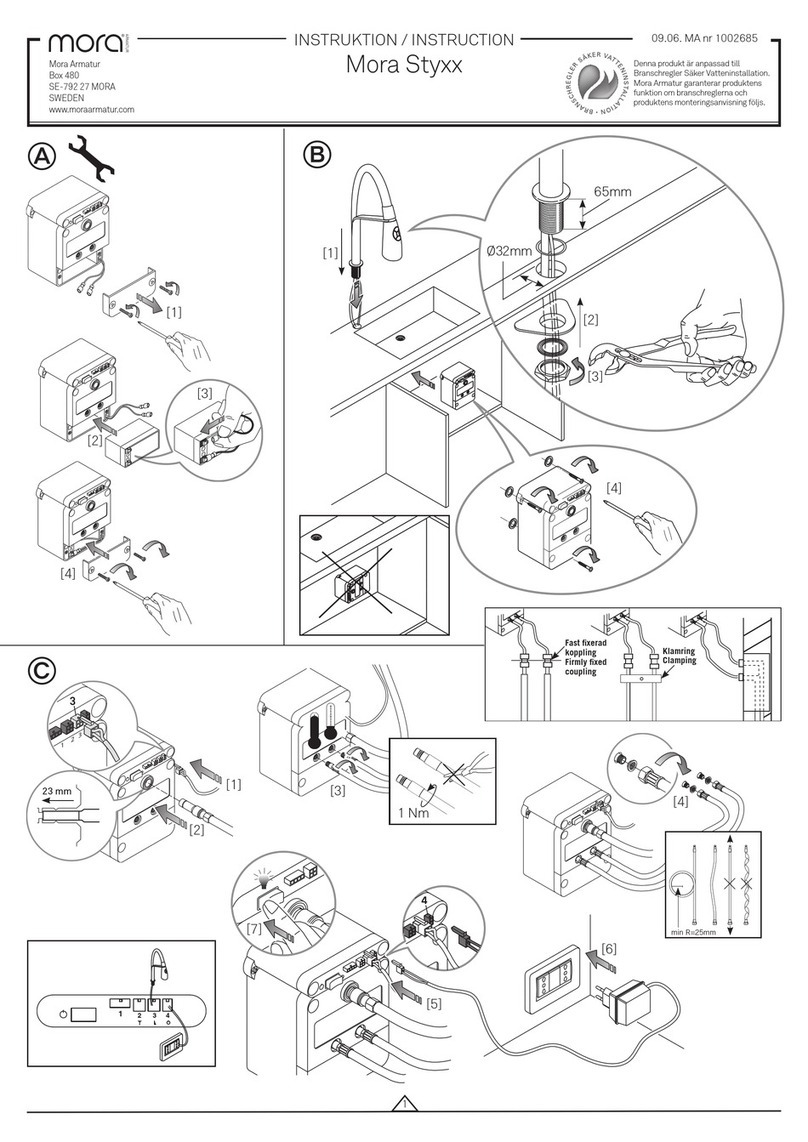

MoraTemp Duo has a built-in function for self-testing in the electronics unit. This is what you do: Open the control box cover and pull out the

circuit board. Press the ”RESET” button briefly. The result should then be a red flashing light both from the indication lamp on the tap and from

the circuit board, a clicking sound from the solenoid valve and the tap should open. Then a green flashing light on the circuit board, clicking

from the solenoid valve, the tap shuts off, then two red flashes from the indication lamp and on the circuit board. This test confirms that the

electronics are OK.

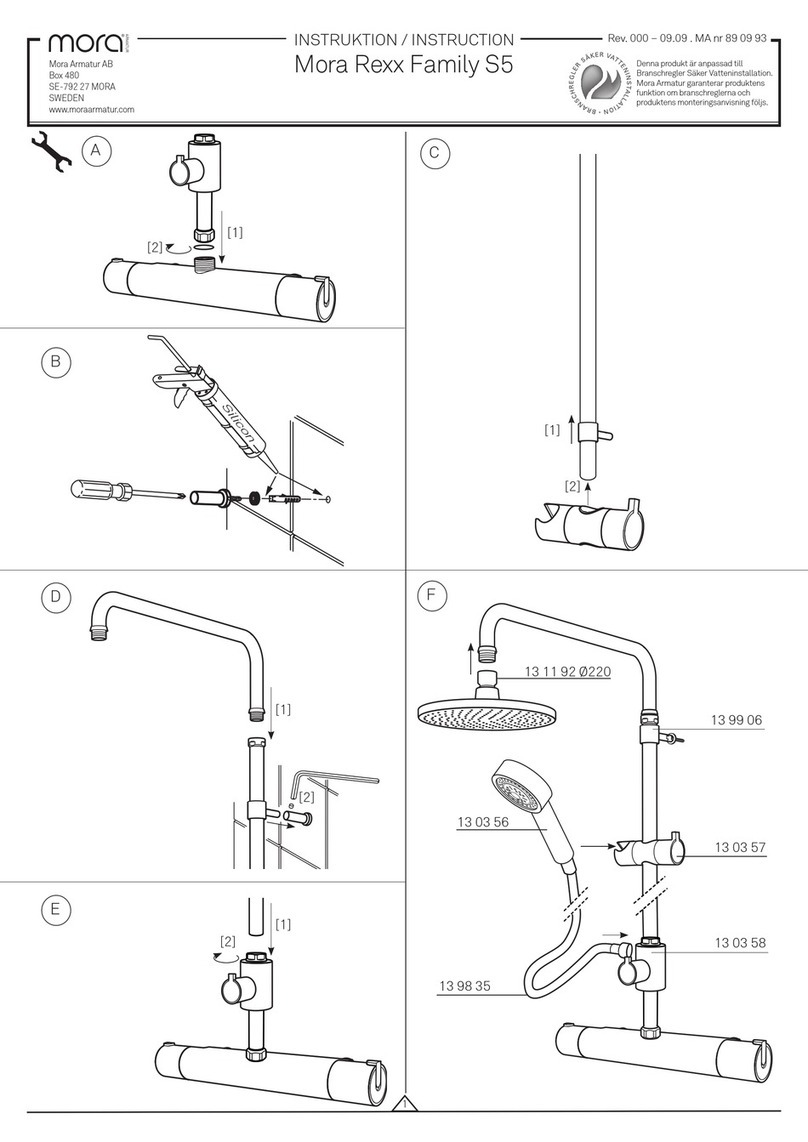

Clean the

holes when

necessary

Membrane

disk

Maintenance and cleaning

Themaintenancenormallyrequiredinvolves,forthemostpart,keepingthesensor

eyes clean. Use no abrasive cleaning agent or strong substances that might

damage the lenses. If the water contains a lot of particles and dirt, you might

sometimes need to remove and clean the solenoid valve’s water affected parts,

and the dirt filter that is fitted between the valve block and solenoid valve. Be

particularly careful with the small holes in the membrane disk and the surfaces

to which they seal.

Strong sunlight aimed directly at the sensor eyes may also disturb the function.

Theinterval betweenbatteryreplacementvariesalot,but fornormaluse working

life should be year or so.

Always use alkaline batteries for best performance.

When assem-

bling check

that this hole is

correctly aligned

with the cor-

responding hole

on the solenoid

valve.

Reset to AC but

nothing is working

4

07.04. MA nr 1001032

INSTRUCTION