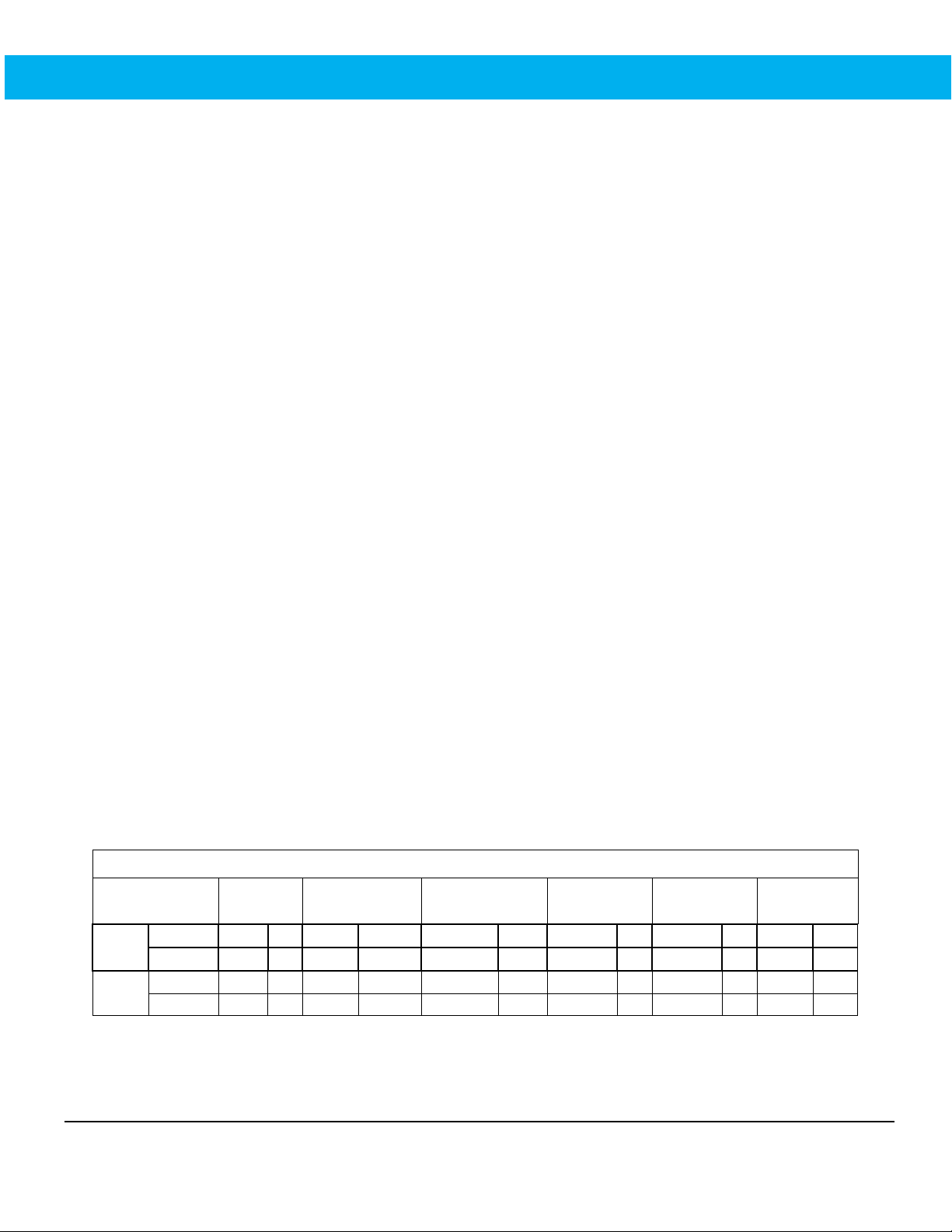

ELECTRICAL INSTALLATION, WIRING AND TROUBLESHOOTING

Nederman Customer Service & Technical Support techsupport.us@nedermen.com +1 (336) 821-0800

4

Section 2.0 – Circuit Sizing

1 Techtop motor nameplate full‐load amps (Used for setting overload only).

2 Minimum size based on 75ᵒC (167ᵒF) insulation and copper wire, such as RHW, THHW, THW, THWN, XHHW,

XHWN,USE, ZW. Verify with table 310.16. Conductor size may need to be increased based on wire type, length

and/or run.

3 Branch circuit protection to be sized at 250% of motor FLC for (Inverse Time) circuit breaker based on tables

430.52, 430.248, and 430.250. Based on 2020 NEC 70 Article 430 and best‐practice.

4 Branch circuit protection to be sized at 175% motor FLC for Dual Element (Time‐Delay) Fuse based on tables

430.52, 430.248, and 430.250. Based on 2020 NEC 70 Article 430 and best‐practice.

5 Branch circuit protection to be sized at 300% motor FLC for Nontime‐Delay fuse (Class CC fuses) on tables

430.52, 430.248, and 430.250. Based on 2020 NEC 70 Article 430 and best‐practice.

6 Recommended setting for overload on Nederman Push Button Starters based on motor nameplate multiplied by

service factor.

7 Wire‐nuts or soldering are

NOT

acceptable means to connect motor leads per NFPA 79, 13.5.9. Use appropriate

components to make motor connections such as split bolts, crimp‐connections and eye‐bolts.

8 It is the responsibility of the end‐user to follow State and Local Codes. This chart is provided as a helpful

resource only. Use of a qualified and licensed industrial electrician is required for proper installation.

TABLE 2 - 3-Phase S-Filter Circuit Sizing Table8

ServiceFactor 1.0 Motor FLA1Conductor Size2,7

Breaker Size3

Time‐Delay

Fuse4Non Time‐Delay5O/L Setting6

S‐500

460V 6.18 A 12 AWG 20 A 15 A 25 A 8 A

S‐750

208V 19.2 A 10 AWG 70 A 45 A 80 A 24 A

460V 8.6 A 12 AWG 30 A 20 A 35 A 11 A

575V 7.08 A 12 AWG 25 A 20 A 30 A 9 A

S‐1000

230V 23.9 A 8 AWG 70 A 50 A 90 A 30 A

575V 9.55 A 12 AWG 30 A 20 A 30 A 12 A