New Holland CX Series Reference guide

Other New Holland Farm Equipment manuals

New Holland

New Holland FR Manual

New Holland

New Holland CX720 User manual

New Holland

New Holland MegaCutter 512 User manual

New Holland

New Holland MZ19H Operating instructions

New Holland

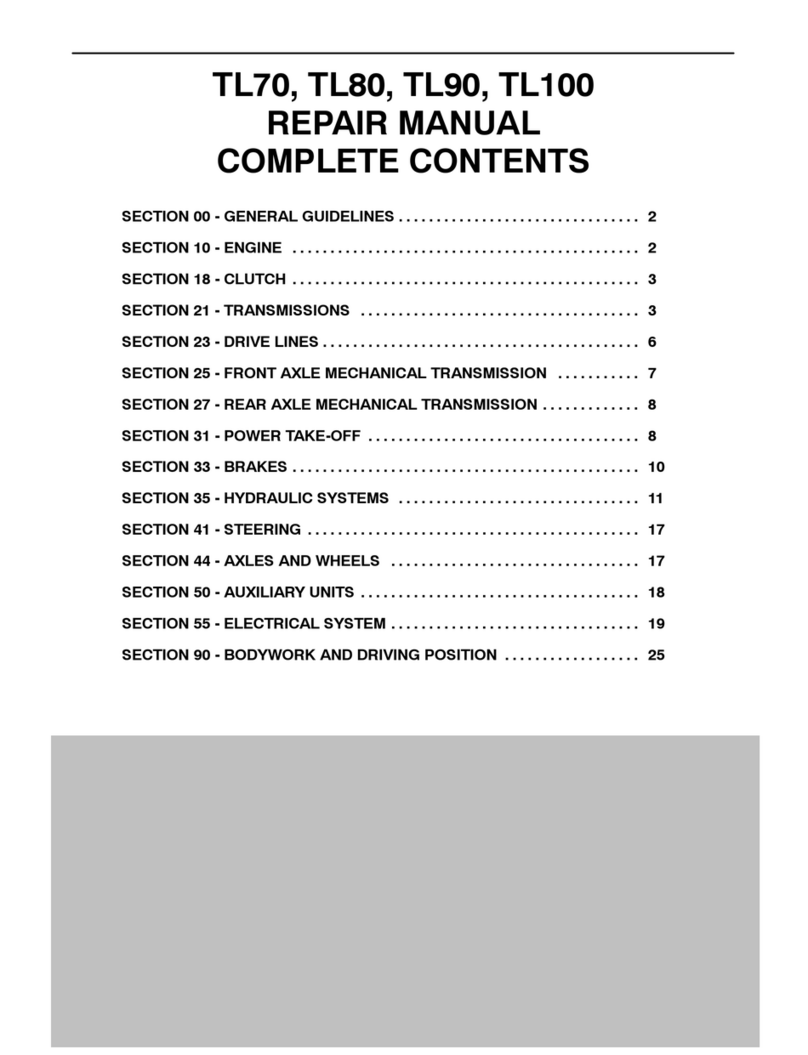

New Holland TL70 Operating instructions

New Holland

New Holland P2350 User manual

New Holland

New Holland Guardian SP.260R User manual

New Holland

New Holland T7.175 User manual

New Holland

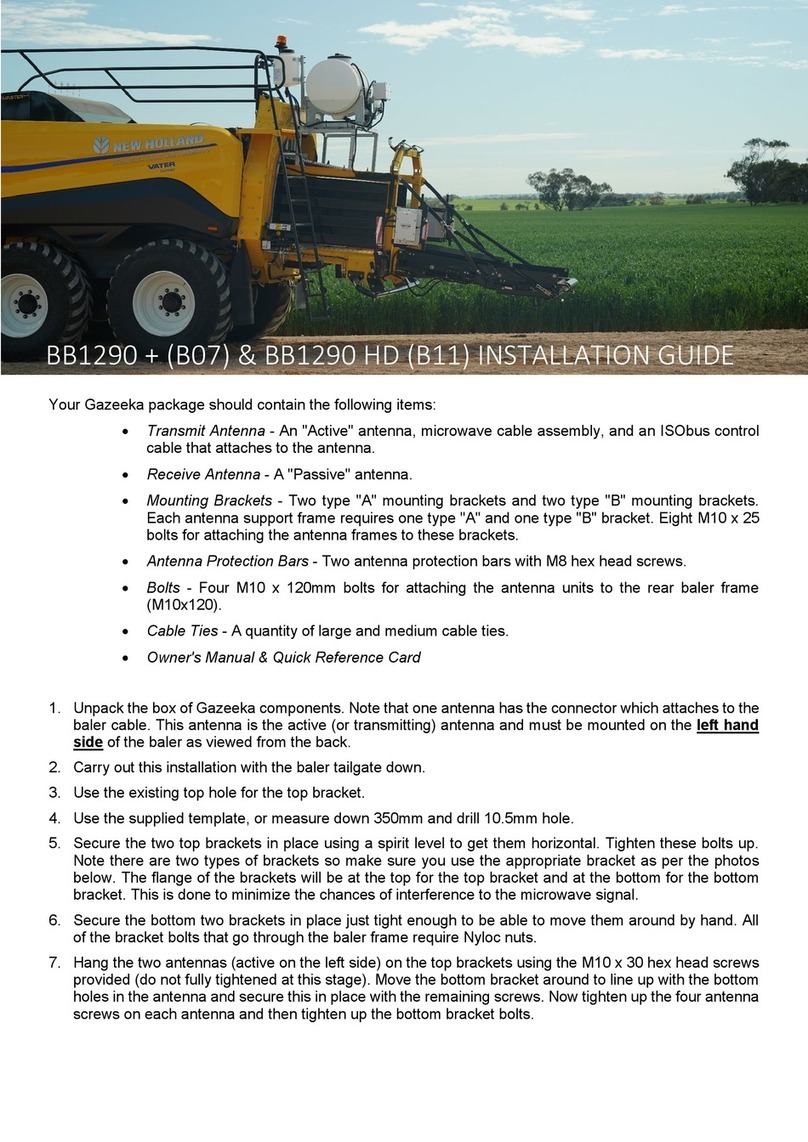

New Holland BB1290 User manual

New Holland

New Holland TX62 User manual

New Holland

New Holland CornMaster 9208-22 User manual

New Holland

New Holland VL5060 User manual

New Holland

New Holland Harvester 1900 User manual

New Holland

New Holland AutoCommand T7.275 User manual

New Holland

New Holland W110C User manual

New Holland

New Holland TC48DA Operating instructions

New Holland

New Holland FR480 Forage Cruiser User manual

New Holland

New Holland LM5040 User manual

New Holland

New Holland SF550 Operating instructions

New Holland

New Holland MZ14H Operating instructions