TxIsoBlock-HRT

NOVUS AUTOMATION 2/4

CONFIGURATION

When the transmitter is used with the factory setting, no further

action is required and the transmitter is ready to be installed.

Changes to the configuration are possible through the TxConfig II

software, provided free of charge.

The TxConfig II configuration software allows the device configuration.

A TxConfig-HRT interface is required to allow the communication

between a computer and the device. The Txconfig II configuration

software is continuously updated and new versions can be downloaded

at no charge from the manufacturer’s website. To install, execute the

TxConfigIISetup.exe file and follow the instructions.

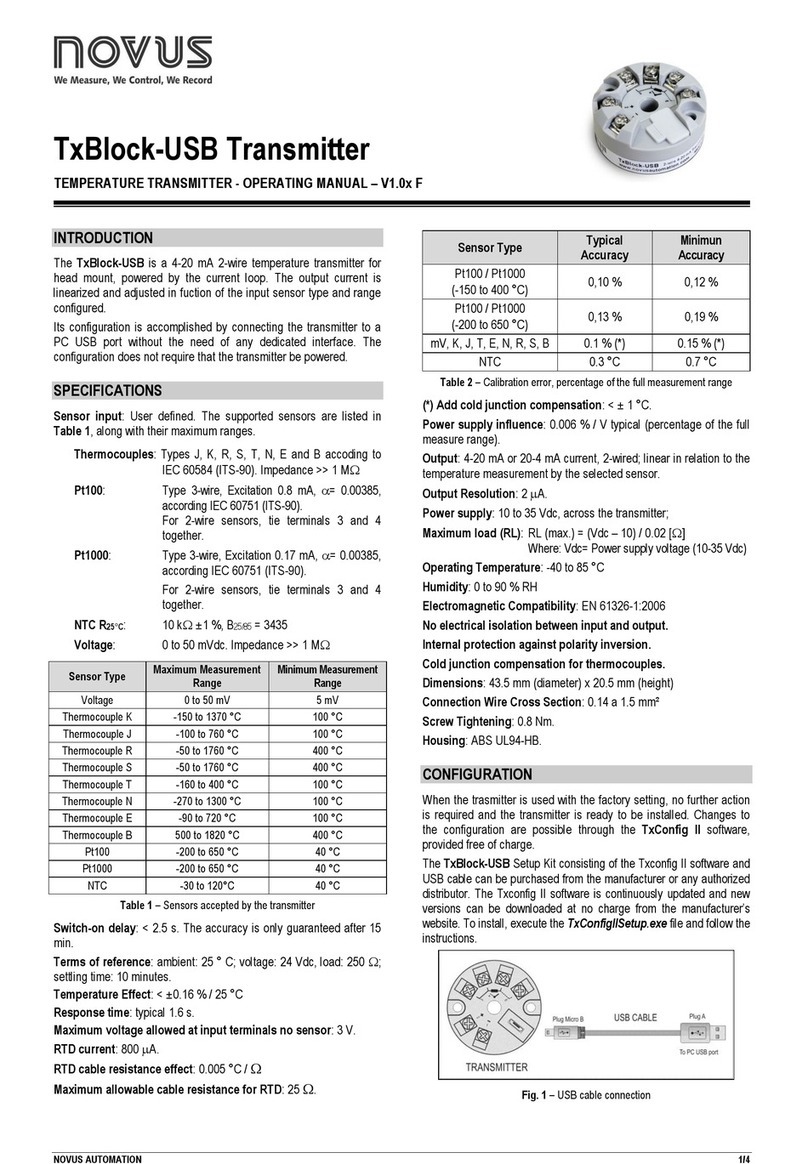

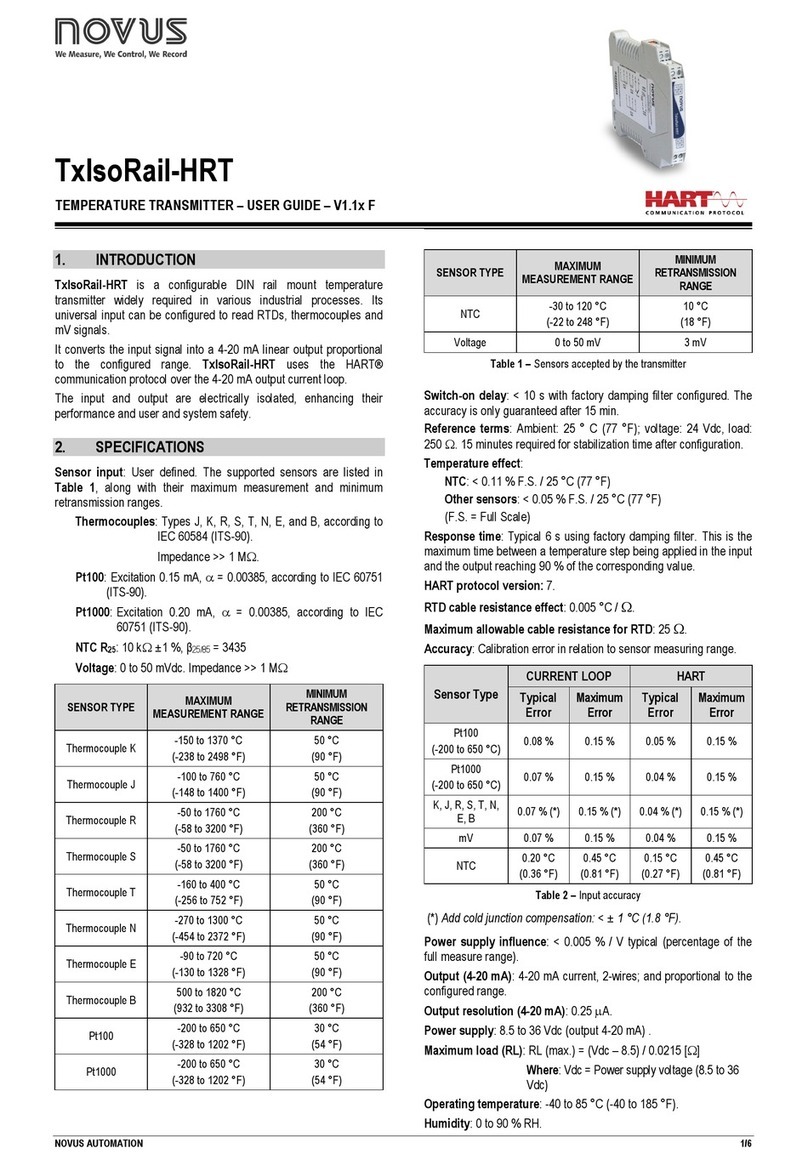

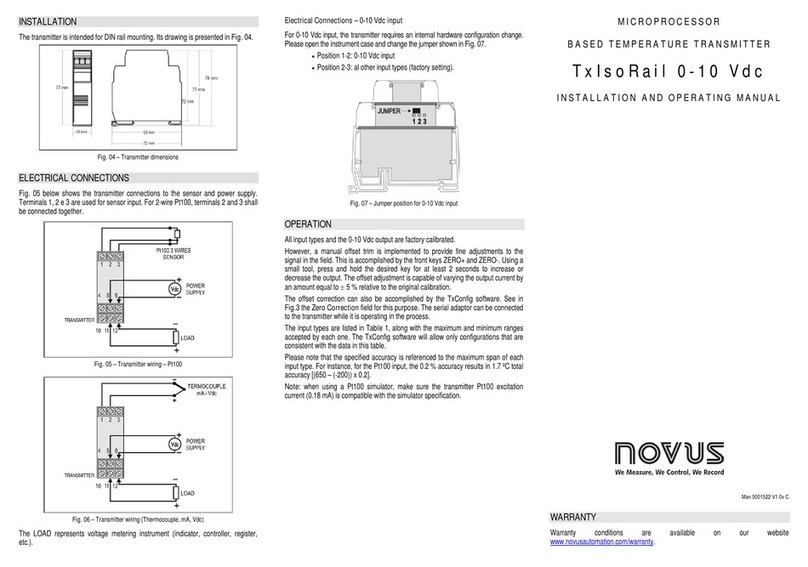

The interface connects the transmitter to the computer, as shown in

Fig. 1:

Fig. 1 – TxConfig-HRT Interface connection to the TxIsoBlock-HRT

SOFTWARE CONFIGURATION

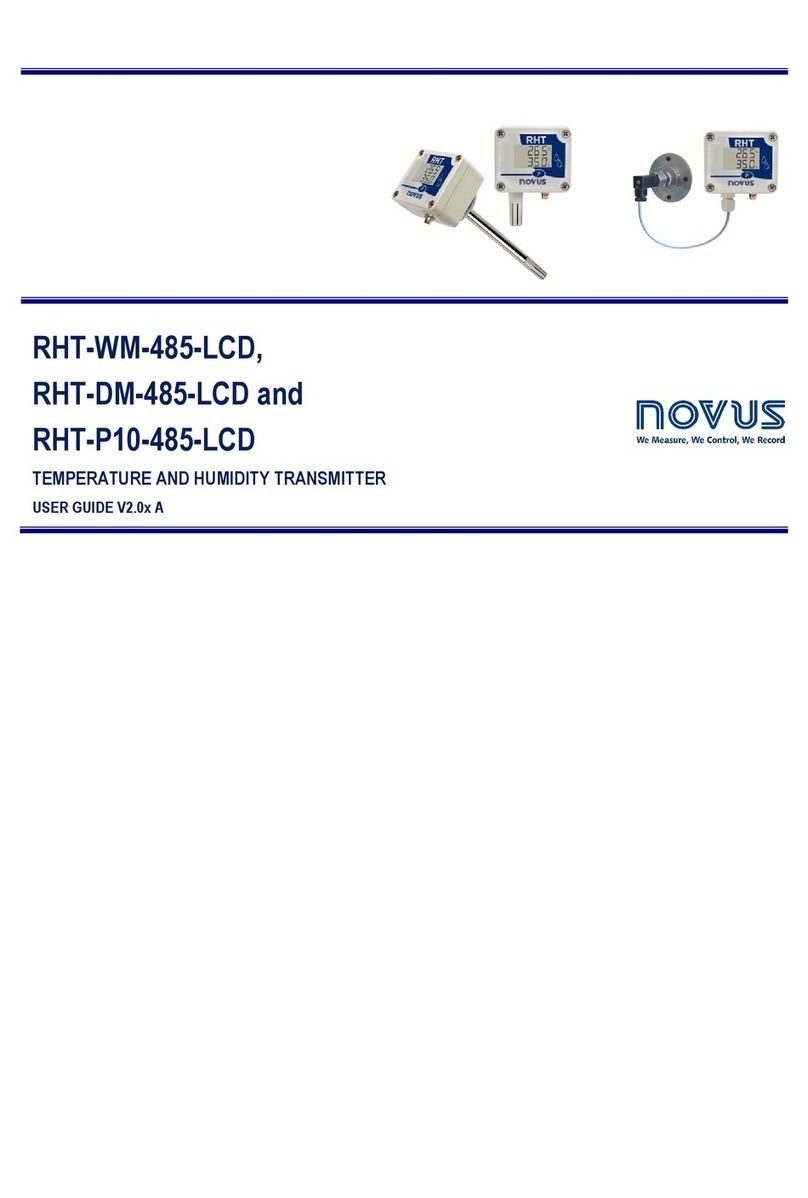

Fig. 2– TxConfig II software main screen

The fields in the screen mean:

1. General Information: This field shows information that identifying

the transmitter. This information should be sent to the

manufacturer in an eventual request for technical assistance.

2. Sensor: Select the type of sensor to be used. See Table 1.

3. Unit: Select the temperature unit to °C (Celsius) or °F

(Fahrenheit).

4. Range: Sets de measurement range of the transmitter.

Lowest Limit: Equivalent temperature for a current of 4 mA.

Highest Limit: Equivalent temperature for a current of 20 mA.

Sensor Range: The values chosen cannot exceed the Range of

Sensor shown in this field. See Table 1 of this manual.

Minimum Range:It is not possible to establish a range with a

span less than the Minimum Range value indicated below in this

field. See Table 1 of this manual.

5. HART Information:

Tag: Field with a brief identification of the device (up to 8

characters).

Descriptor: Descriptor used by the master for registering (up to

16 characters).

Message: Message used by the master for registering (up to 32

characters).

6. Sensor Failure: It establishes the output behavior, when the

transmitter indicates a failure, as recommended NAMUR NE 43:

Minimum: Output current goes to <= 3.6 mA (down-scale),

typically used for refrigeration.

Maximum: Output current goes to >= 21.5 mA (up-scale),

typically used for heating.

7. Zero Offset: It corrects small deviations presented in the

transmitter output, for example, when the sensor is replaced.

8. Filter: Damping filter.

The damping filter changes the response time of the transmitter in

order to smooth the variations in the output. The value set in the

filter indicates the time interval at which the PV will reach 63% of

its final value.

The factory setting is 1.0 s and can be changed from 0 s to 32 s.

In a case with variation from 0 ° C to 100 ° C, considering the

factory configuration and after 1.0 s, the PV value will be 63 °C.

With zero value in the filter, the function is disabled.

9. Enable write protection: When activated, the configuration

setting is not allowed.

10. Send Configuration: It applies the new setup. Once sent, the

setup will be immediately adopted by the transmitter.

11. Read Configuration: Reads the current setup in the transmitter

connected. The screen now presents the current setup that may

be changed by the user.

FACTORY SETTING

•Sensor: Pt100 3-wire, range 0 to 100 °C;

•Maximum output for sensor failure;

•0 °C zero correction;

•Unit: °C;

•Filter: 1.0 s.

It is possible to configure the device via third-party