8Photoelectric Sensor

Do not use the Sensor in any atmosphere or environment that

exceeds the ratings.

Do not install the Sensor in the following locations.

(1)Locations subject to direct sunlight

(2)Locations subject to condensation due to high humidity

(3)Locations subject to corrosive gas

(4)Locations where the Sensor may receive direct vibration or

shock

Connecting and Mounting

(1)The maximum power supply voltage is 30 VDC. Before

turning the power ON, make sure that the power supply

voltage does not exceed the maximum voltage.

(2)Laying Sensor wiring in the same conduit or duct as high-

voltage wires or power lines may result in malfunction or

damage due to induction. As a general rule, wire the Sen-

sor in a separate conduit or use shielded cable.

(3)Use an extension cable with a minimum thickness of

0.3 mm2and less than 50 m long.

(4)Do not pull on the cable with excessive force.

(5)Pounding the Photoelectric Sensor with a hammer or other

tool during mounting will impair water resistance. Also, use

M3 screws.

(6)Mount the Sensor either using the bracket (sold separately)

or on a flat surface.

(7)Be sure to turn OFF the power supply before inserting or

removing the connector.

Power Supply

If a commercial switching regulator is used, ground the FG

(frame ground) terminal.

Power Supply Reset Time

The Sensor will be able to detect objects 100 ms after the

power supply is tuned ON. Start using the Sensor 100 ms or

more after turning ON the power supply. If the load and the

Sensor are connected to separate power supplies, be sure to

turn ON the Sensor first.

Turning OFF the Power Supply

Output pulses may be generated even when the power supply

is OFF.

Therefore, it is recommended to first turn OFF the power

supply for the load or the load line.

Load Short-circuit Protection

This Sensor is equipped with load short-circuit protection, but

be sure to not short circuit the load. Be sure to not use an out-

put current flow that exceeds the rated current. If a load short

circuit occurs, the output will turn OFF, so check the wiring

before turning ON the power supply again. The short-circuit

protection circuit will be reset. The load shortcircuit protection

will operate when the current flow reaches 1.8 times the rated

load current. When using a capacitive load, use an inrush

current of 1.8 times the rated load current or lower.

Water Resistance

Do not use the Sensor in water, rainfall, or outdoors.

When disposing of the Sensor, treat it as industrial waste.

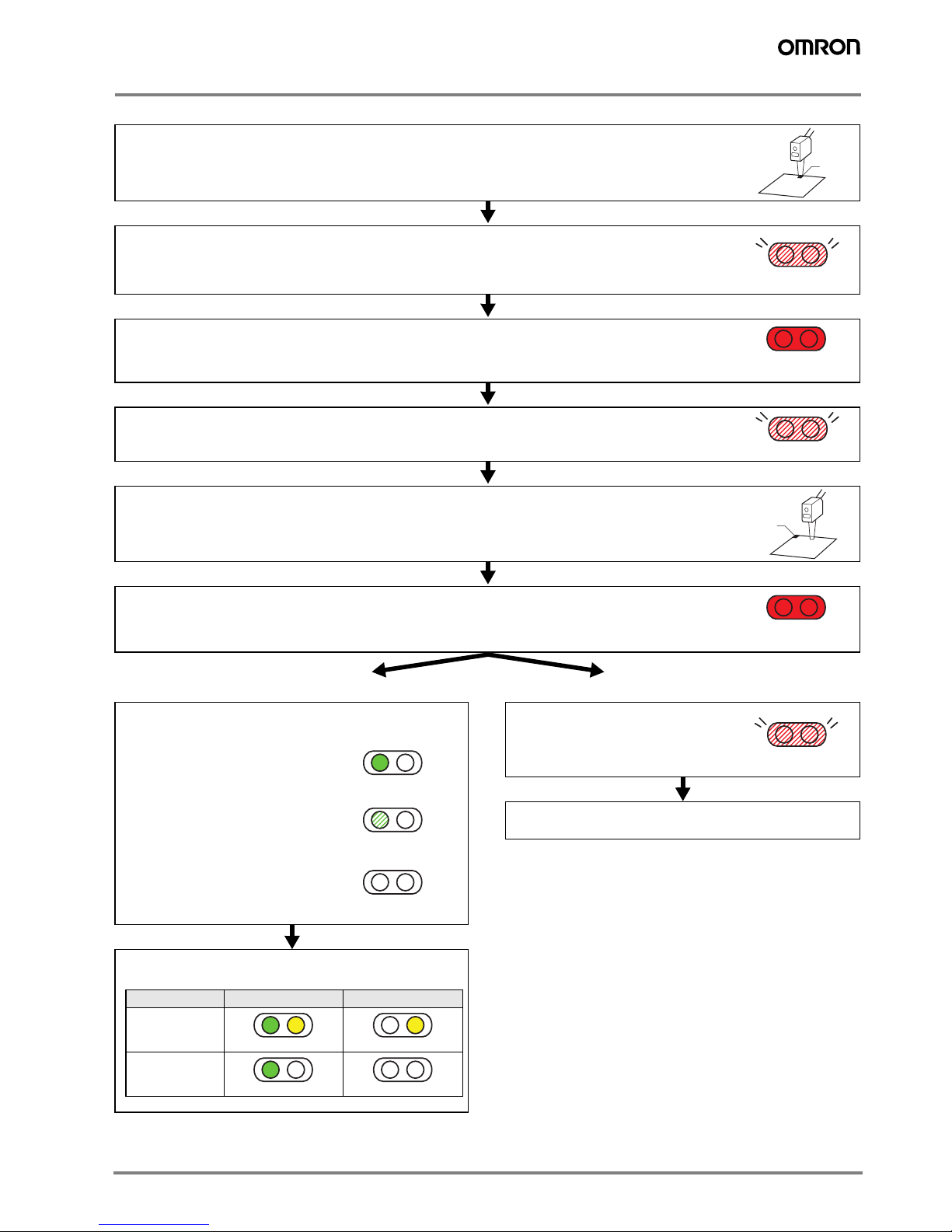

Mounting Diagram

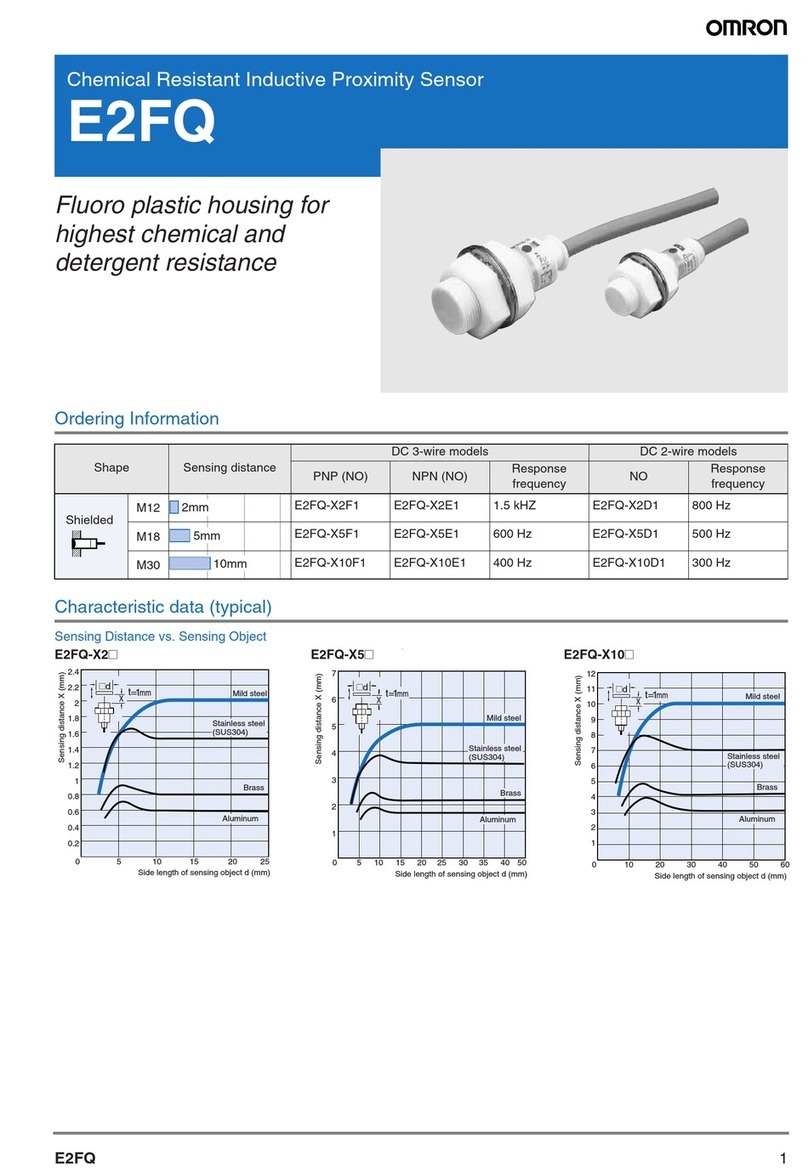

Resistance to Detergents, Disinfectants, and Chemicals

• The Sensor will maintain sufficient performance in typical

detergents and disinfectants, but performance may suffer

in some types of detergents, disinfectants, and chemicals.

Refer to the following table prior to use.

• The E3ZM has passed detergent and disinfectant resis-

tance testing for the substances listed in the following ta-

ble. Use this table as a guide when considering detergents

and disinfectants.

Note: The Sensor was immersed in the above chemicals, detergents, and

disinfectants for 240 h at the temperatures given, and then passed

an insulation resistance test at 100 MW min.

Restrictions on Sensing Objects

Do not use this Sensor if the color and pattern of the back-

ground are similar to those of the mark.

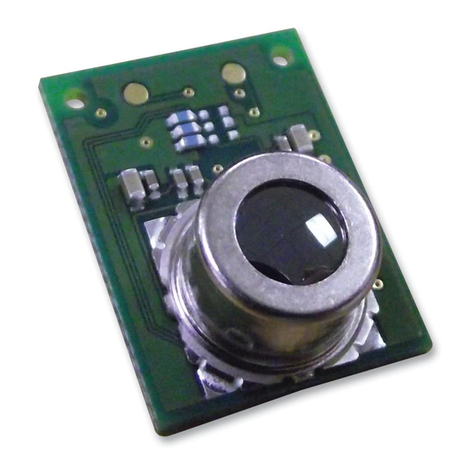

Detection of Glossy Objects

Mount the Sensor at an angle of 5° to 15°, as shown in the fol-

lowing diagram. This will improve the mark detection capabil-

ity.

Precautions for Correct Use

Type Product name Concen-

tration

Tempera-

ture

Time

Chemicals Sodium hydroxide, NaOH 1.5% 70°C 240 h

Potassium hydroxide, KOH 1.5% 70°C 240 h

Phosphoric acid, H3PO42.5% 70°C 240 h

Sodium hypochlorite, NaClO 0.3% 25°C 240 h

Hydrogen peroxide, H2O26.5% 25°C 240 h

Alkaline

foaming

cleansers

Topax 66s (Ecolab) 3.0% 70°C 240 h

Acidic foam-

ing cleansers

Topax 56 (Ecolab) 5.0% 70°C 240 h

Disinfectants Oxonia Active 90 (Ecolab) 1.0% 25°C 240 h

TEK121

(ABC Compounding)

1.1% 25°C 240 h

Use amounting torque of

0.5 N·m max.

E39-L104

Mounting Bracket

(sold separately)

Sensing objects

5°to 15°

Sensing objects

5°to 15°