Digital Temperature Controllers E5GN 9

Operation

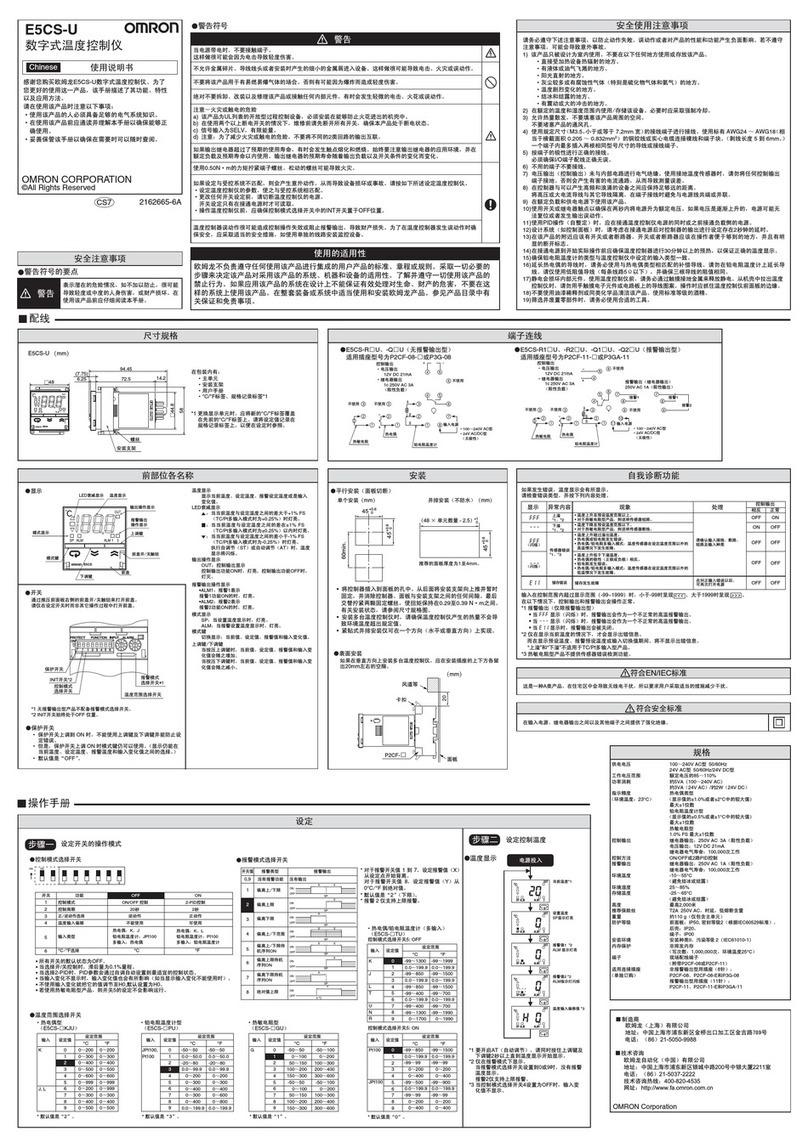

■Specification Setting after Turning ON Power

Outline of Operation Procedures

Key Operation

In the following descriptions, all the parameters are introduced in the display sequence. Some parameters may not be displayed depending on the

protect settings and operation conditions.

Description of Each Level

Operation Level

This level is displayed when you turn the power ON. You can move to

the protect level, initial setting level and adjustment level from this

level.

Normally, select this level during operation. During operation, the

process value, set point and manipulated variable can be monitored,

and the alarm value and upper- and lower-limit alarms can be moni-

tored and modified.

Adjustment Level

To select this level, press the key once for less than one second.

This level is for entering set values and offset values for control. This

level contains parameters for setting the set values, AT (auto-tuning),

communications writing enable/disable, hysteresis, multi-SP, input

shift values, heater burnout alarm (HBA) and PID constants. You can

move to the top parameter of the operation level or initial setting level

from here.

Initial Setting Level

To select this level, press the key for at least three seconds in the

operation level. This level is for specifying the input type, selecting

the control method, control period, setting direct/reverse action and

alarm type. You can move to the advanced function setting level or

communications setting level from this initial setting level. To return to

the operation level, press the key for at least one second. To

move to the communications setting level, press the key once for

less than one second.

Protect Level

To select this level, simultaneously press the and keys for at

least 3 seconds. This level is to prevent unwanted or accidental mod-

ification of parameters. Protected levels will not be displayed, and so

the parameters in that level cannot be modified.

Communications Setting Level

To select this level, press the key once for less than one second in

the initial setting level. When the communications function is used,

set the communications conditions in this level. Communicating with

a personal computer (host computer) allows set points to be read

and written, and manipulated variables to be monitored.

Advanced Function Setting Level

To select this level, you must enter the password (“-169”) in the initial

setting level.

You can move only to the calibration level from this level.

This level is for setting the automatic return of display mode, MV lim-

iter, event input assignment, standby sequence, alarm hysteresis, ST

(self-tune) and to move to the user calibration level.

Calibration Level

To select this level, you must enter the password (“1201”) in the

advanced function setting level. This level is for offsetting deviation in

the input circuit.

You cannot move to other levels by operating the keys on the front

panel from the calibration level. To cancel this level, turn the power

OFF then back ON again.

Power ON

Operation level Adjustment level

+ key

1 second min.

Control stops.

Protect level

Initial setting level

Calibration level

Control in progress

Control stopped

Level change

key

1 second min.

+ key

3 seconds min.

+ key

Display flashes when key pressed.

key

key

Less than

1 second

key

1 second

min.

key

3 seconds

min.

Display flashes when key held

down for more than 1 second.

Communica-

tions setting

level

key

Less than

1 second

Password input

set value "−169"

Advanced function

setting level

Password input

set value "1201"

The time taken to move to the protect level

can be adjusted by changing the "Move to

protect level time" setting.

Note: 1. Of these levels, the initial setting level, communications

setting level, advanced function setting level and cali-

bration level can be used only when control has stop-

ped. Note that control is stopped when these four levels

are selected. When switched back to the operation level

from one of these levels, control will start.

2. For the calibration mode, refer to the relevant User's

Manual.

3. On the E5GN, the Key is the Key.

25

100

25

100