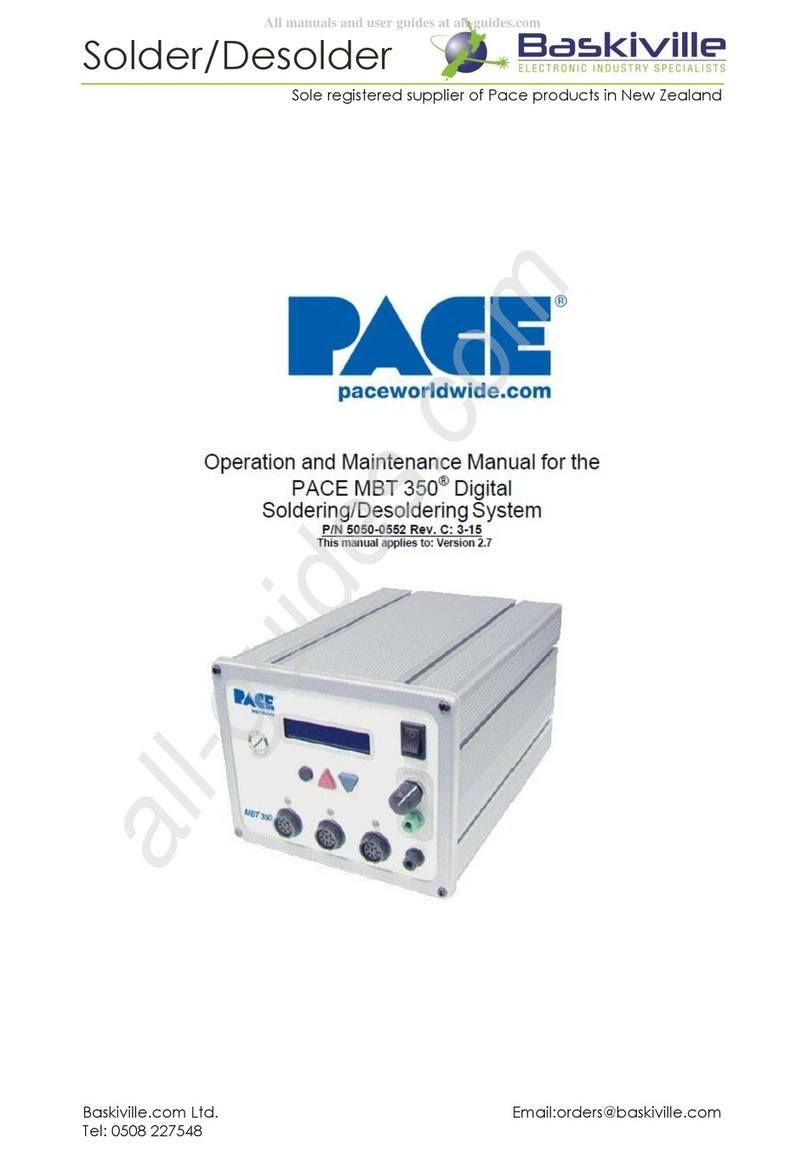

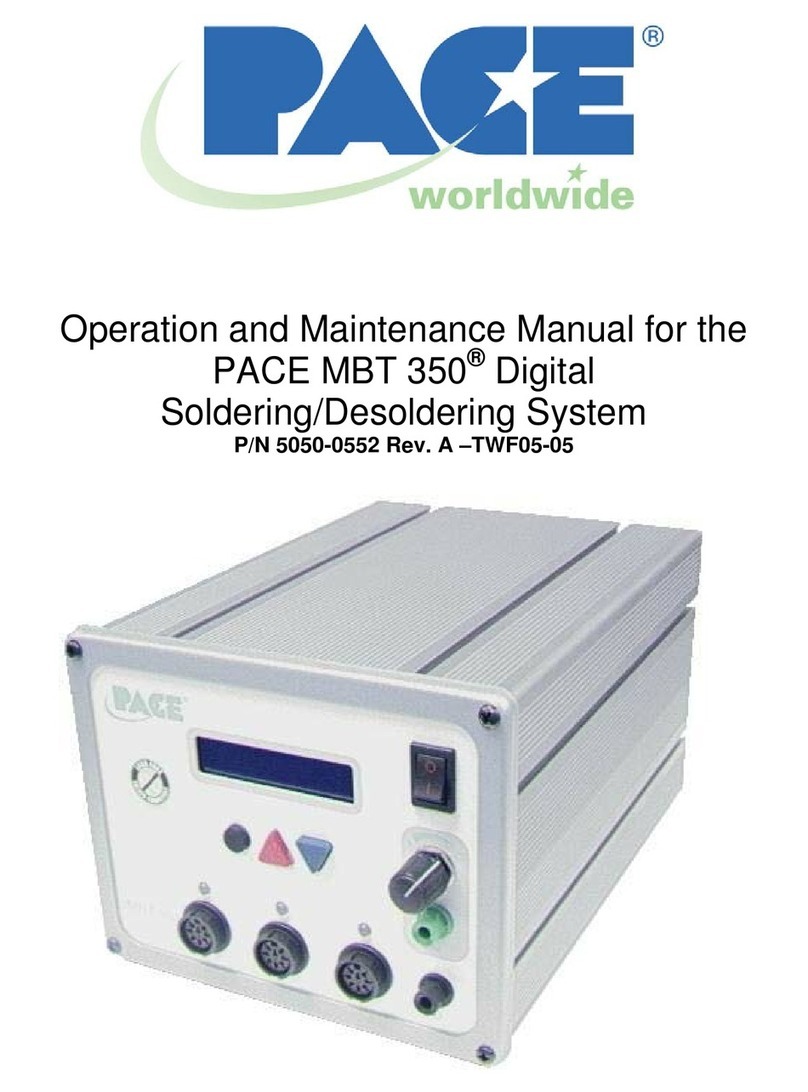

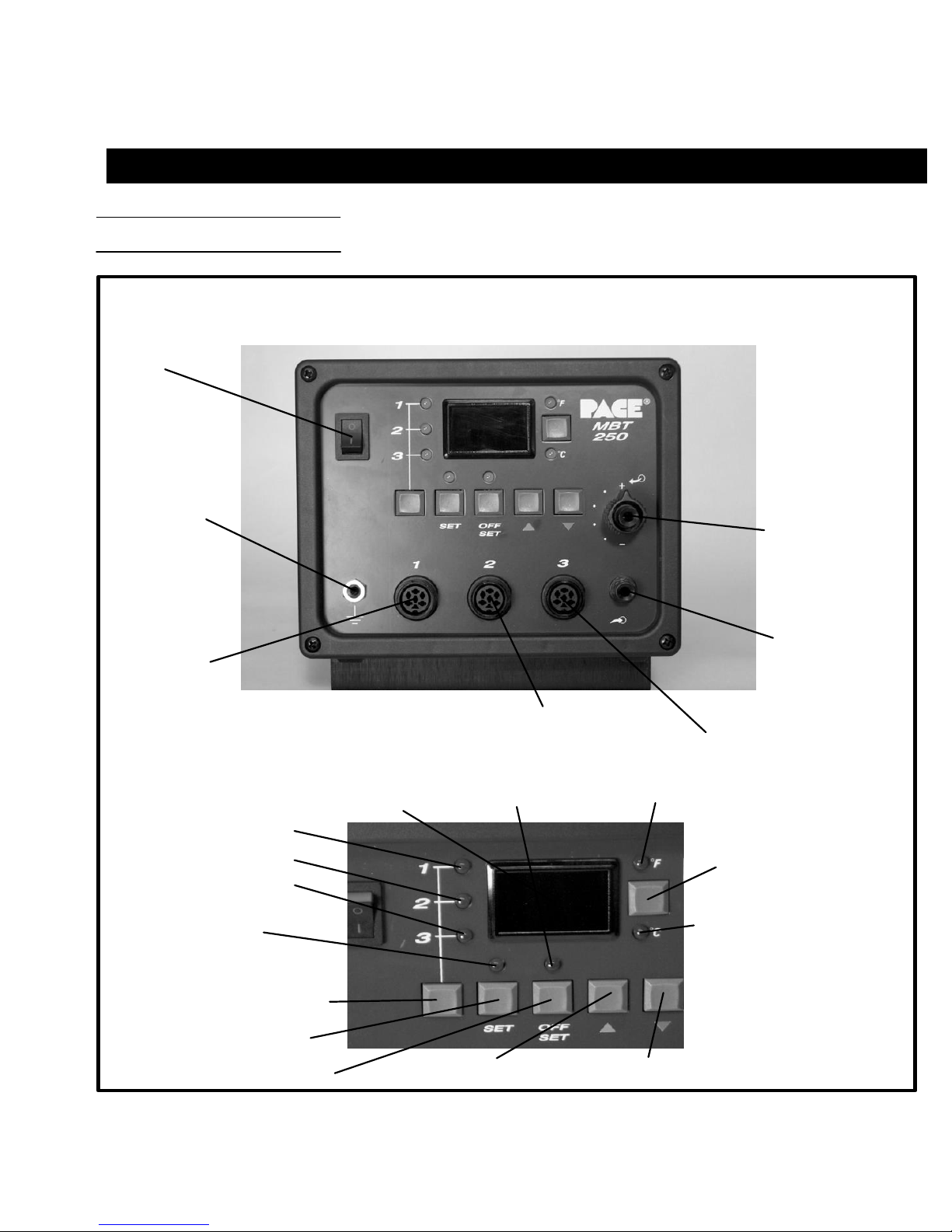

Parts Identification

Listed below is a description of the system power source parts. Use Figures 1 & 2 as a guide.

1. CH1POWERRECEPTACLE-Providespower,tipground,sensingcircuitryandfingerswitchconnection

fromMBT systemto handpiececonnectedto Channel1 (CH1).

2. CH2POWERRECEPTACLE-Providespower,tipground,sensingcircuitryandfingerswitchconnection

fromMBT systemto handpiececonnectedto Channel2 (CH2).

3. CH3POWERRECEPTACLE-Providespower,tipground,sensingcircuitryandfingerswitchconnection

fromMBT systemto handpiececonnectedto Channel3 (CH3).

4. POWERSWITCH-Turns systemON("1")and OFF("0");controlsinputpower tothesystem.

5. AUTOSNAP-VACPORT-Quickconnectfittingprovidesquick-risevacuumforSodr-X-Tractor,

ThermoPikandDualThermoPik handpieces. Vacuumispresentwhenhandpiecefingerswitchoroptional

foot pedal is actuated. Vacuumceases 1.2 seconds after switch (or foot pedal) released.

6. CONTROLLABLEPRESSUREPORT-Quickconnectfittingwithadjustablevalvewhichprovides

variableairflowforMiniThermoJethandpiece(inHotJetMode)andSodr-X-Tractorhandpiece. Air

pressure is present when handpiece finger switch or optional foot pedal is actuated. Air pressure ceases

1.2 seconds after switch (or foot pedal) is released.

7. DIGITALREADOUT-ProvidesathreedigitdisplayoftheCurrentChannel(channelwithilluminatedLED;

CH1,CH2orCH3)temperatureinformation. Thisincludes:OperatingTipTemperatureinTemperature

DisplayMode(normaloperation),TipOffsetConstantinTipOffsetMode,SetTipTemperatureinTipSet

ModeandotherinformationinCalibration(CAL)Mode.

8. °F/°CKEY-Selects°For°CdisplayofSetandOperatingTipTemperaturesandTipOffsetConstants.

9. °FLED- IlluminateswhenSet\OperatingTipTemperaturesandTipOffsetConstantsaredisplayedin°F.

10. °CLED-IlluminateswhenSet\OperatingTipTemperaturesandTipOffsetConstantsaredisplayedin°C.

11. CH1LED-IlluminateswhenChannel1(CH1)isthe“CurrentChannel”i.e.,thechannel(withconnected

handpiece\tip) whose temperature informationisdisplayed onthedigitalreadout.

12. CH2LED-IlluminateswhenChannel2(CH2)isthe“CurrentChannel”i.e.,thechannel(withconnected

handpiece\tip) whose temperature informationisdisplayed onthedigitalreadout.

13. CH3LED-IlluminateswhenChannel3(CH3)isthe“CurrentChannel”i.e.,thechannel(withconnected

handpiece\tip) whose temperature informationisdisplayed onthedigitalreadout.

14. CHSELECTKEY-SelectstheCurrentChannel(among"ActiveChannels"i.e.,thosewithaconnected

handpiece).

15. TIPSETKEY-AllowstheoperatortoadjusttheSetTipTemperatureforthe handpiece\tipcombination

connected to the Current Channel. Places the system in the Tip Set Mode.

7