Operation

Variable Temperature Control

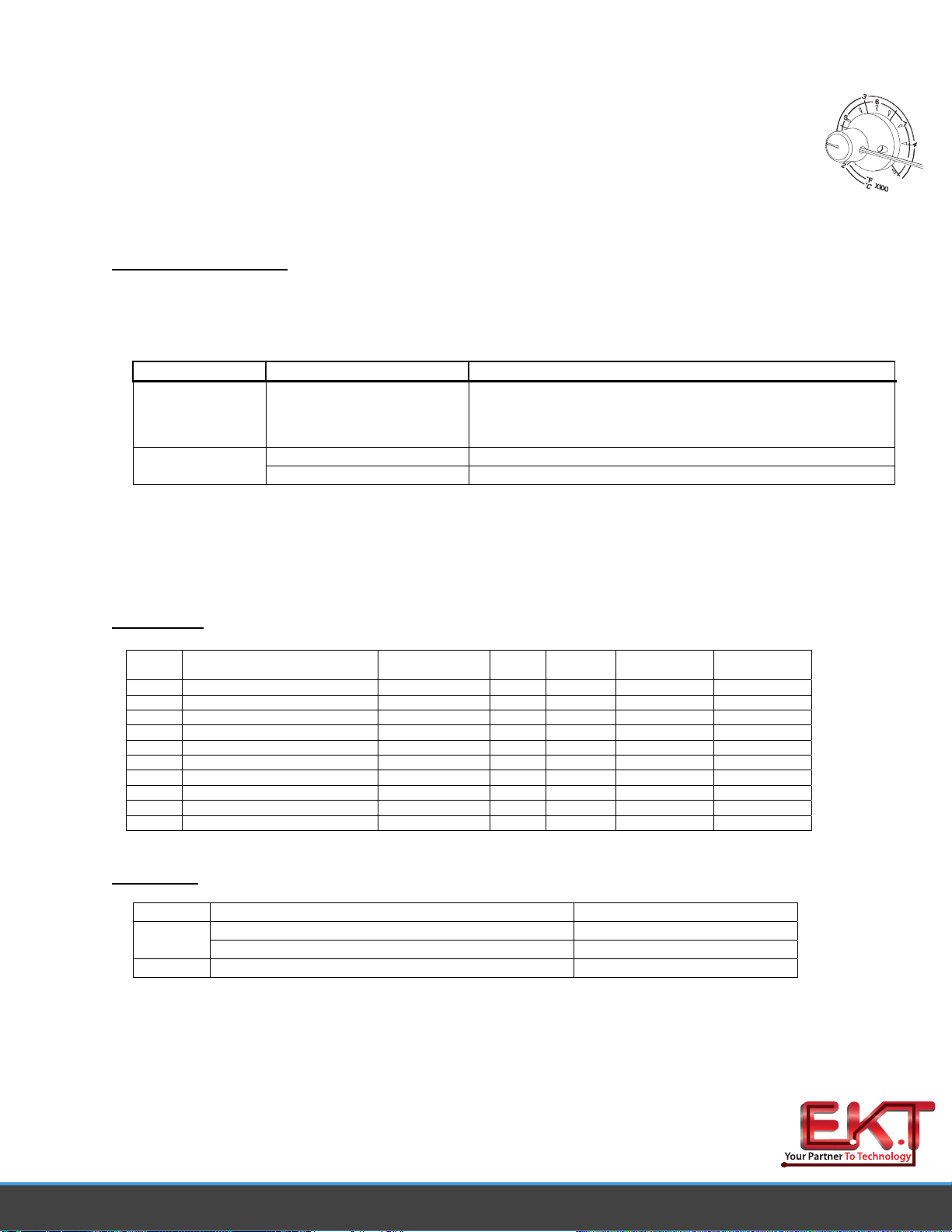

Adjust the Variable Temperature Control Knob to the desired temperature

setting. Notice that the control panel has an outer graphic scale denoting

temperature in °C (Celsius) and an inner graphic scale denoting temperature in

°F (Fahrenheit). These numerical scales denote the set tip temperature times

100 (e.g., “3” on the outer scale is 3 x 100 or 300°C).

Temperature/Dial Lock

The Variable Temperature Control Knob can be locked in position to avoid accidental or unauthorized

changes of the temperature setting.

1. Adjust the Temp. Control Knob to the desired temperature setting.

2. Using the Temp. Locking Key (hex key supplied with system), tighten

the set screw on the Temp. Locking Ring closest to the front panel.

LED Operation

The Green colored LED on the power source front panel indicates System Status and Power

Receptacle output status (LED OFF, ON or Flashing).

LED Full On - Continuous power is being delivered to the handpiece. This

condition is evident when the system is first powered up (handpiece heater

cold) or the Variable Temperature Control setting is increased.

LED Flashing - Indicates that the set tip temperature (as set on the

Variable Temperature Control) has been reached. Power to the handpiece

is cycling Off and On to maintain set temperature.

LED Off - No power is being delivered to the handpiece heater. This condition is evident for a

short period of time when set temperature is reached and stabilizing or if the Variable

Temperature Control setting is decreased. If the LED never illuminates, check for a faulty

handpiece (see Corrective Maintenance section). Also, if no handpiece is connected to the

power source, the LED will not illuminate.

Temperature Dial Adjustment

The ST 25 system is tested for temperature accuracy at the factory and can be

checked for calibration according to PACE requirements. Also, a temperature setting

normally used by the operator can be adjusted to the precise temperature indicated on

the Dial/Display. No internal adjustments can be made to the power supply. To verify

calibration of the Temperature selection dial, perform the following procedure.

1. Install a tip with an embedded thermocouple into the handpiece connected to the system.

Tips with K type thermocouples are available from PACE.

2. Connect the thermocouple assembly to an appropriate temperature meter.

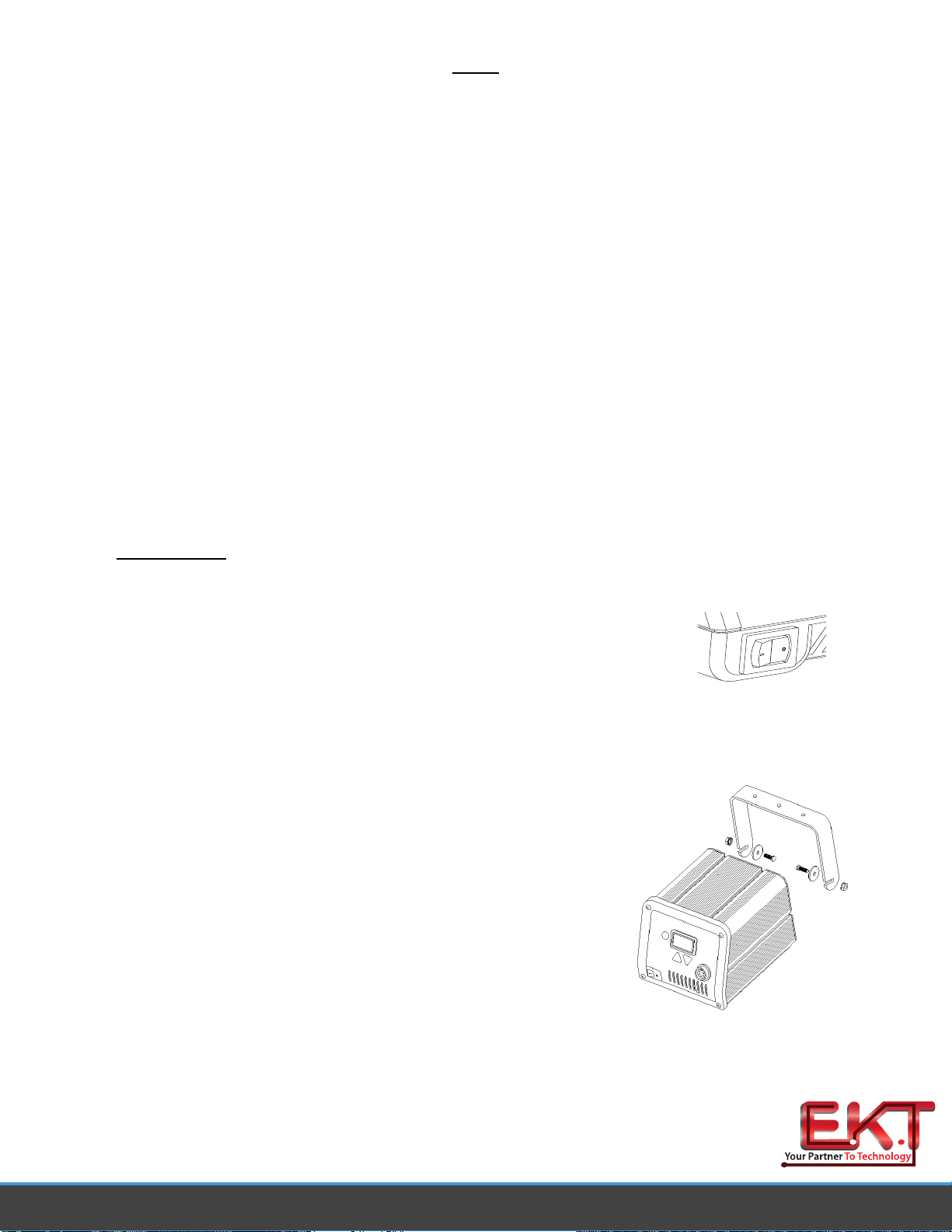

3. When set fully counterclockwise, the pointer of the Variable Temperature

Control knob will align to the Calibration Mark as shown. With the system

turned on, adjust the Variable Temperature Control to obtain a stable tip

temperature of 300°C (for PACE factory specifications) or the temperature

setting normally used by the operator.

If the temperature displayed on temperature meter is within ±15°C (27°F),

perform steps 4 thru 6 to obtain a precise reading. If the temperature is off by more than

www.ekt2.com