PNOZ e2.2p

Operating Manual PNOZ e2.2p

21360-EN-06 9

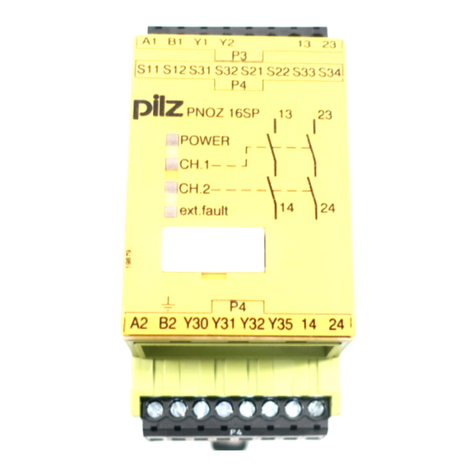

Function description

When supply voltage is applied and the set operating mode is detected (initialisation

phase), the "POWER" LED is lit. The unit is ready for operation when the feedback loops

are closed.

The two-hand control device is activated by simultaneously pressing two pushbuttons. It in-

terrupts the control command for the hazardous movement when one or both pushbuttons

are released. The movement can only be restarted when both pushbuttons have returned

to their start position (released) and are operated again.

}Both pushbuttons have been operated simultaneously, i.e. within 0.5 s:

– There are high signals at safety outputs 14 and 24 and auxiliary output Y32

– The LEDs "CH.1" and "CH.2" are lit.

}One pushbutton has been released following simultaneous operation:

– There are low signals at safety outputs 14 and 24 and auxiliary output Y32.

– The LEDs "CH.1" and "CH.2" go out.

}There are also low signals at safety outputs 14 and 24 and auxiliary output Y32 when:

– Only one control element is pressed,

– Simultaneity is not upheld,

– The feedback control loop is still open.

}The safety outputs will not return to a high signal until both control elements are re-

leased and then re-operated simultaneously.

Feedback loop

Before a safety output is switched on, a test is run to establish whether the contacts at

feedback loop inputs Y6 and Y7 are closed. If a contact is open, an error is detected and

LEDs CH.1 and CH.2 will flash alternately. It will not be possible to switch the unit back on

until the feedback loops are closed and the safety function has been reset.

The feedback loop contacts are also checked when the signal at the output changes from

high to low. After this signal change, the contacts at the feedback loop inputs must close

within 150 ms. If a contact is still open after 150 ms has elapsed, an error is detected and is

displayed as a flashing code 1,8 (see Faults - malfunctions [ 20]). It will not be possible

to switch the unit back on until the error has been rectified and the supply voltage has been

switched off and then on again.

AND/OR connection

The PNOZ e2.2p has two logic inputs S35 (OR) and S36 (AND) for logic connections

between several units.

Operating modes

}Automatic start: Unit is active once the input circuit has been closed within the simultan-

eity period.

}Increase in the number of available contacts by connecting contact expander modules

or external contactors/relays.