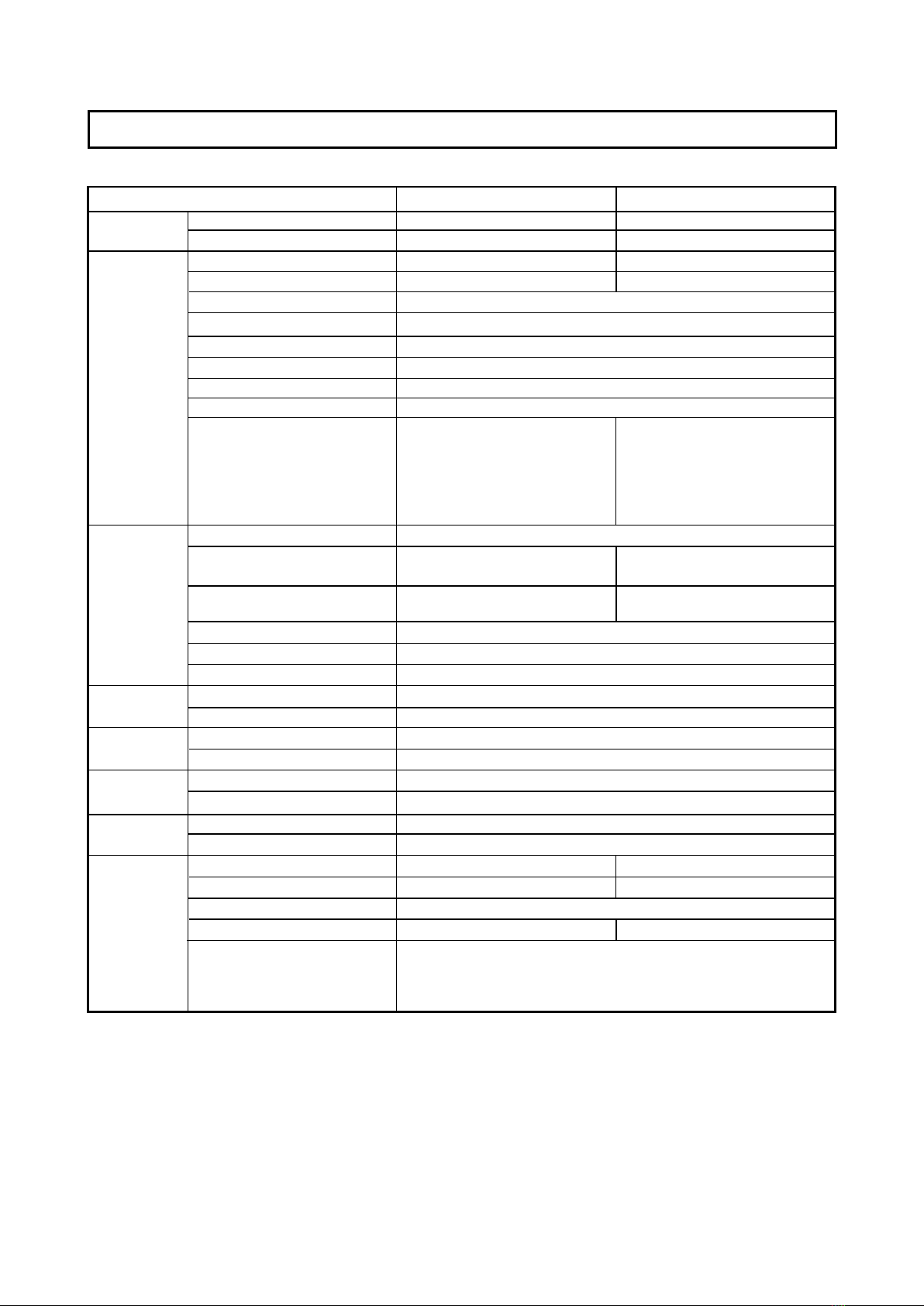

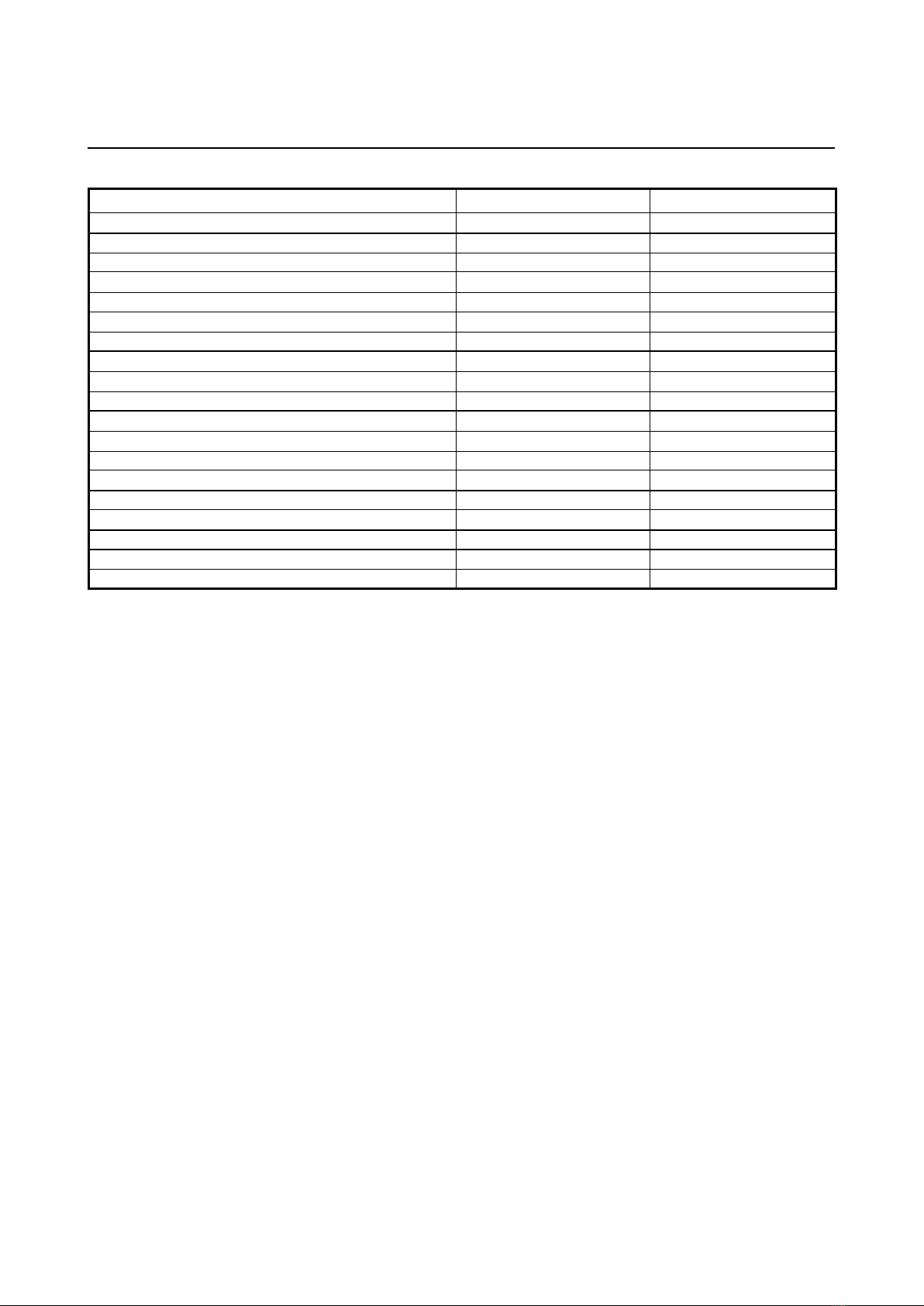

K-10S K-10W

W1480 x D675 x H1847 W1980 x D675 x H1847

W1300 x H910mm W1800 x H910mm

W1280 x H900mm W1780 x H900mm

2

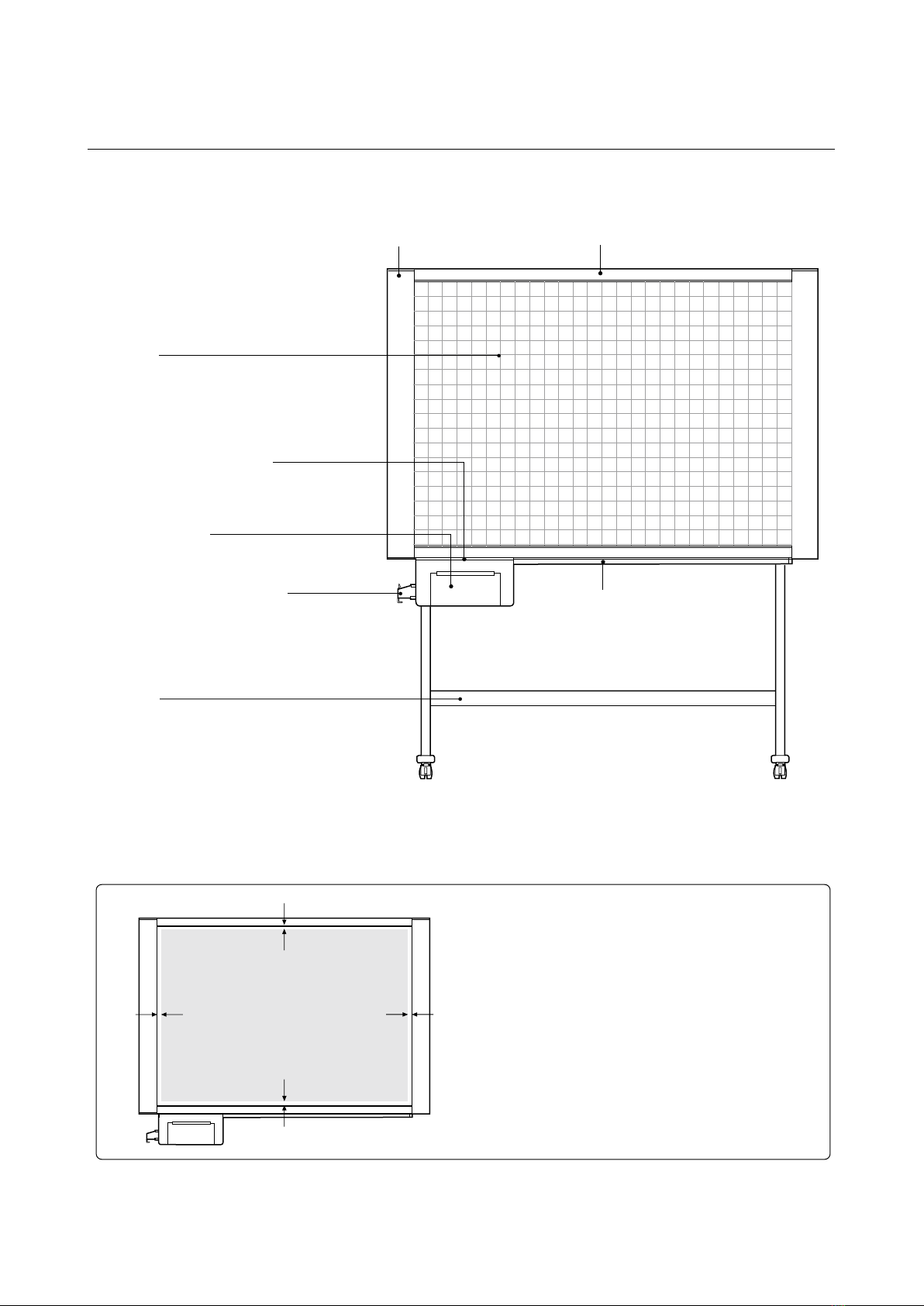

External dimensions

weight

Board surface dimension

Effective reading dimensions

No. of board sufaces

Sheet feeding

Drive system

Reading method

Reading illumination light source

Reading resolution

Reading and printing time

(* Print time will vary according

to the amount of data.)

Reading method

Reading size

Reading paper size

Reading color

Print resolution

No. sheets printed

Clock

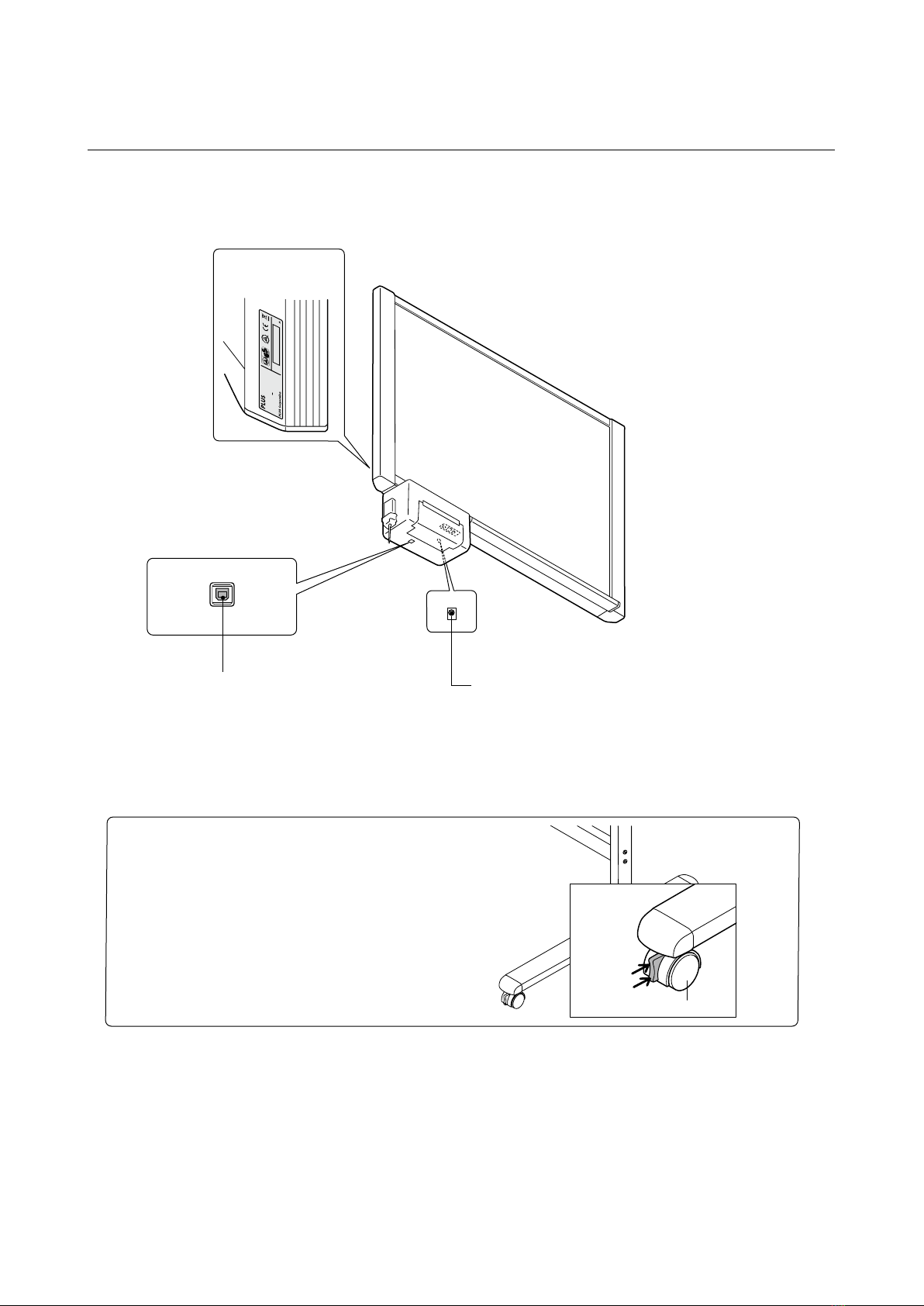

Computer connection

AC power adapter

Power consumption

Temperature

Humidity

Ruled lines

Writing tool

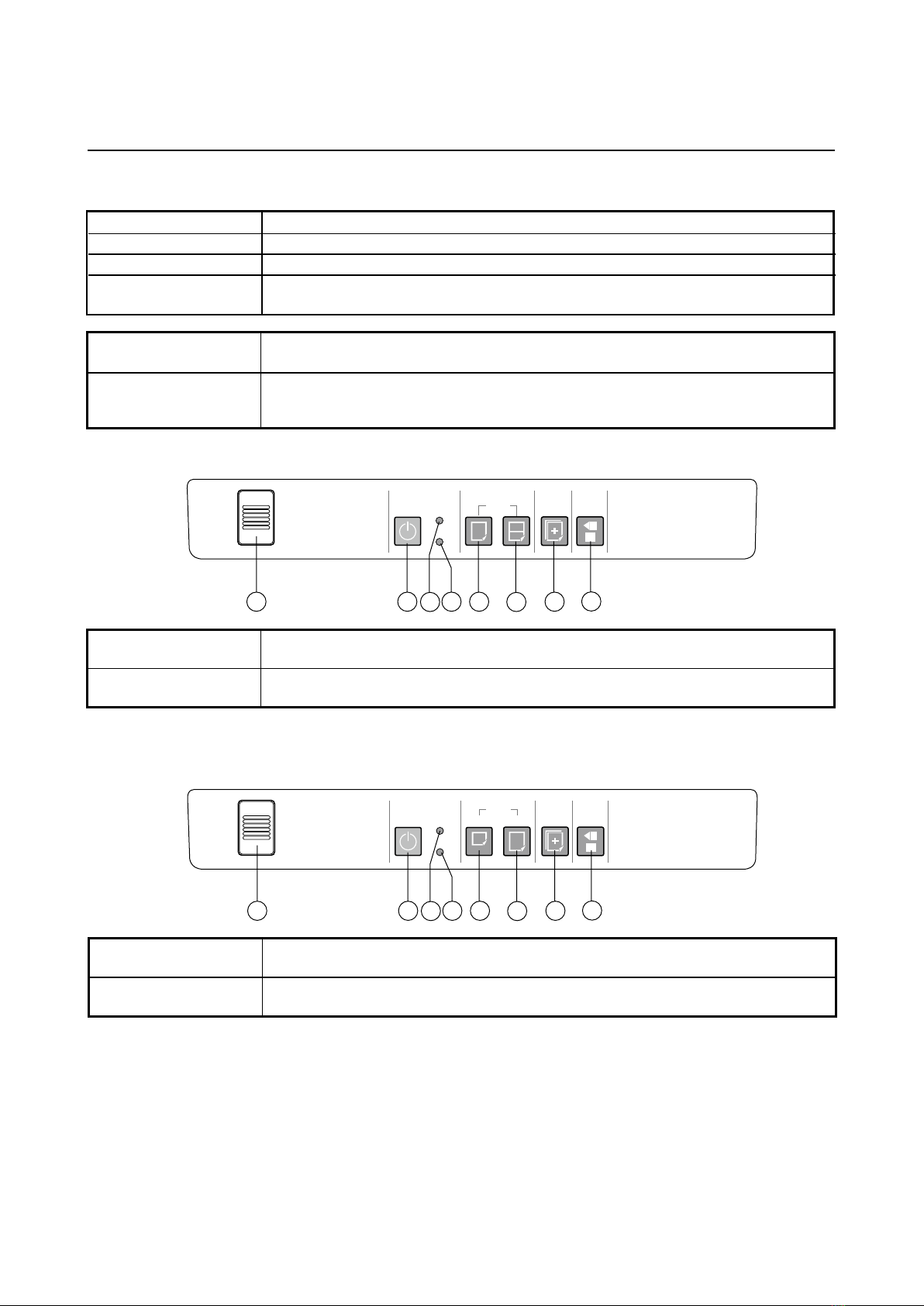

Equal ratio printing

2-sheet printing

Recording density adjustment

Manual board surface moving function

Accessories

○○

○

○

○—

Unidirectional, endless (Horizontal scrolling)

Sheet moving method

CIS (Contact Image Sensor)

RGB LED

1.92 dots/mm

A4 size (W210 x H297 mm) A4 size (W210 x H297 mm)

A4-L-size (W210 x H405 mm)

1-sheet printing

Approx. 10 seconds reading, approx.

11 seconds printing

2-sheet printing:

Approx. 20 seconds reading, approx.

22 seconds printing

1 sheet (A4 equal ratio), 2 sheets

compressed (A4 compression)

1 sheet (A4 compression, A4-L

equal ratio)

Thermal head thermosensitive recording

Monochrome

200 dpi

1 sheet

Used for time stamps

Device settings

Input: AC 100-240V, 50/60Hz, 1.5A Output: DC 24V, 2.5A

In power-saving mode: 1W Operating: 50W

10°C-35°C

30 to 85% (with no condensation)

50 mm grid

White board markers (black and red)

A4 compressed printing

Approx. 14 seconds reading, approx.

15 seconds printing

A4-L equal ratio printing:

Approx. 14 seconds reading, approx.

15 seconds printing

31.5kg 35.5kg

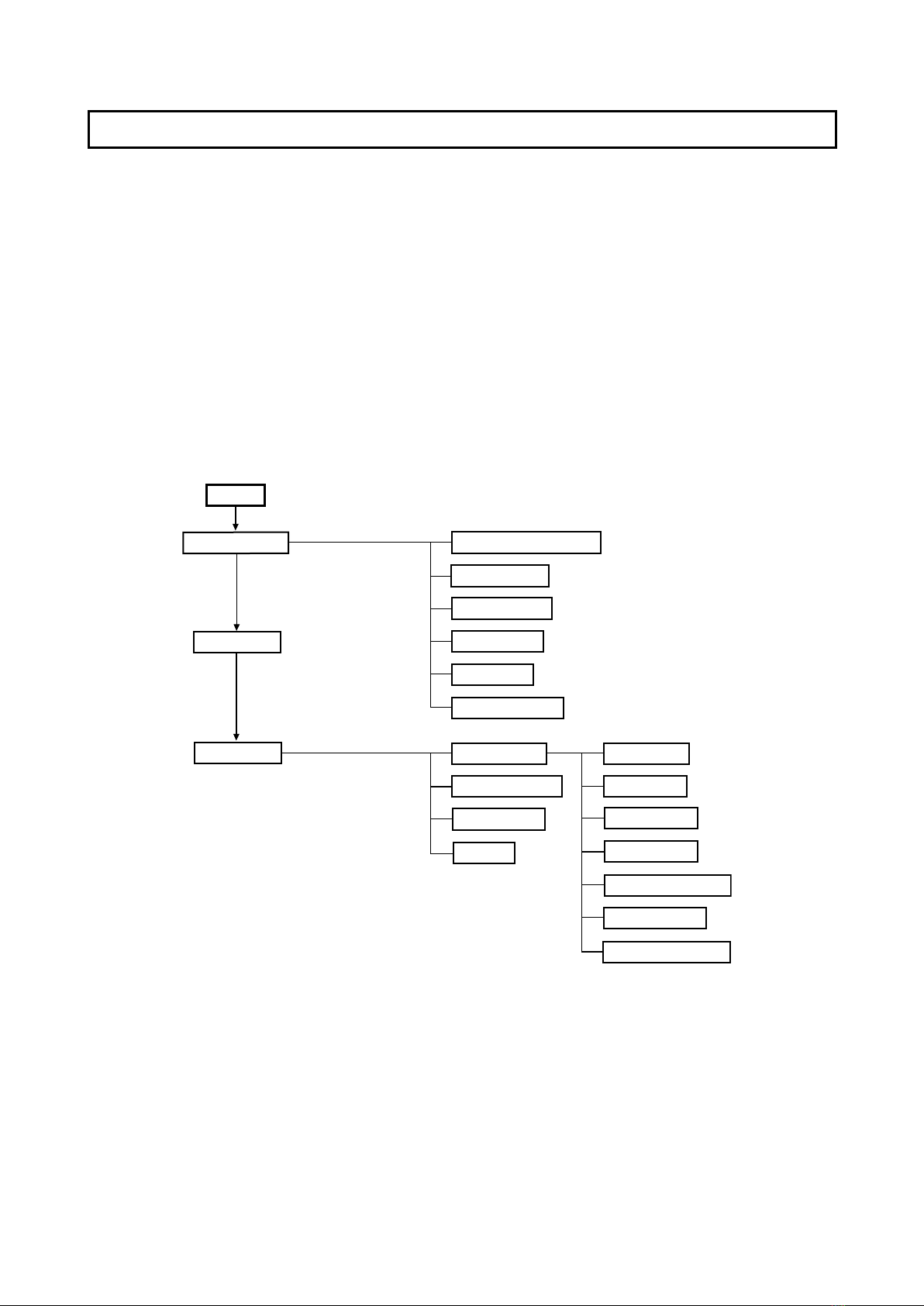

2.SPECIFICATIONS

2-1. Product Specications

Exterior

Board

Printer

Additional

functions

Power supply

Others

Functions

3 levels of adjustment in the device settings

Dedicated white board markers (back and red), dedicated eraser,

2 eraser replacement sponges, dedicated the rmosensitive paper

(30 m roll), AC power adapter (with 2.5 m power cord), instruction

manual

Usage conditions

BOARD TYPE (Model name)

*

Please note that product specications and appearance are subject to change without notice.