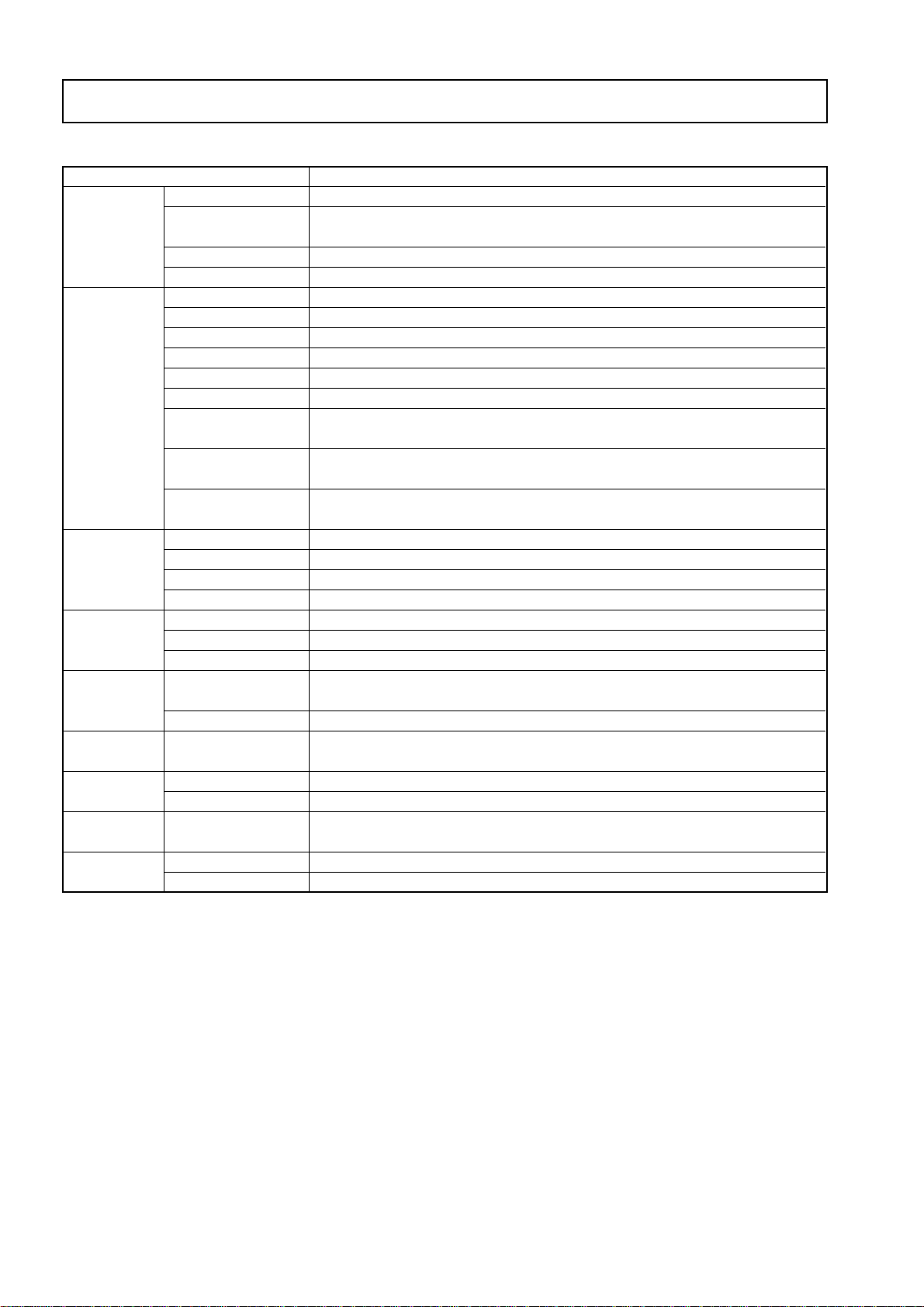

6

Error display number

Printer not connected

No printing paper

Printer problem

USB Memory

not recognized

USB Memory storage

problem

Reading problem

System error

Page detection error

Security protection

Restrict color mode

USB memory not

connected

When the “USB” letter is flowing...

Warning that disconnection of

USB memory

has been forgotten

No Calibration data

USB Memory is full

An unsupported

printer is connected

Time setting error

Problem and Solution

•Is the printer cable connected?

•

Is power being supplied to the printer?

•

When the printer uses an AC power adapter,

is the cable disconnected somewhere?

•Has paper been set in the printer?

•

Is the printer error indicator flashing (or lit)?

•Is the USB memory unformatted.

•Is a USB memory that is not supported

by the copyboard being used?

•

Is the USB memory device plugged in fully?

•Is the USB memory damaged?

• An error occurred during USB memory

storage.

•There is a lighting fault of the reading

light source, or a read signal error.

•There is a memory or internal fault.

•The pages are not being properly

detected.

•You have attempted to use a function

disabled by the security settings.

•Setting for disabling printing/storing in the

color mode.

•USB memory device is not plugged into

the main unit.

• Did you press the ON/Standby button

while the USB memory device was

plugged into the main unit?

•This is the state in which calibration data

is not written.

• There is no available space.

• A printer that is not supported by the

copyboard has been connected.

• An error has arisen when setting the time.

•Connect the printer properly and

switch on the printer power.

•Turn the power of the printer off and

then on again, and load the printer

with A4 paper.

•Read the printer instruction manual.

•This unit supports the FAT and FAT 32

formats. Perform the formatting with

the personal computer.

•Please see our home page for informa-

tion about USB memories that can be

used with the copyboard.

( http://www.plus-vision.com )

• Please check the operation with a

personal computer.

• Please perform USB memory storage

again.

• Do not insert or remove the USB

memory during processing.

• Unplug the power plug from the power

outlet and then plug it in again.

• Unplug the power plug from the power

outlet and then plug it in again.

• Unplug the power plug from the power

outlet and then plug it in again.

•The settings can be changed using

the exclusive software. For details,

contact your nearby PLUS Vision

sales office, dealer or store.

•Can be changed in the copyboard’s

“Function Settings”.

• Plug the USB memory device into the

USB port.

•AUSB memory device is plugged into

the main unit. When the USB memory

device is disconnected, the power will

be switched off and the unit will enter

the standby mode.

•Perform calibration.

• Please delete unnecessary data using a

personal computer.

• Press the ON/Standby button and

switch off the power. When a record is

required, switch on the power and

save to USB memory.

• When the ON/Standby button is

pressed, the display switches to “c1”.

Start the setting over from the year.

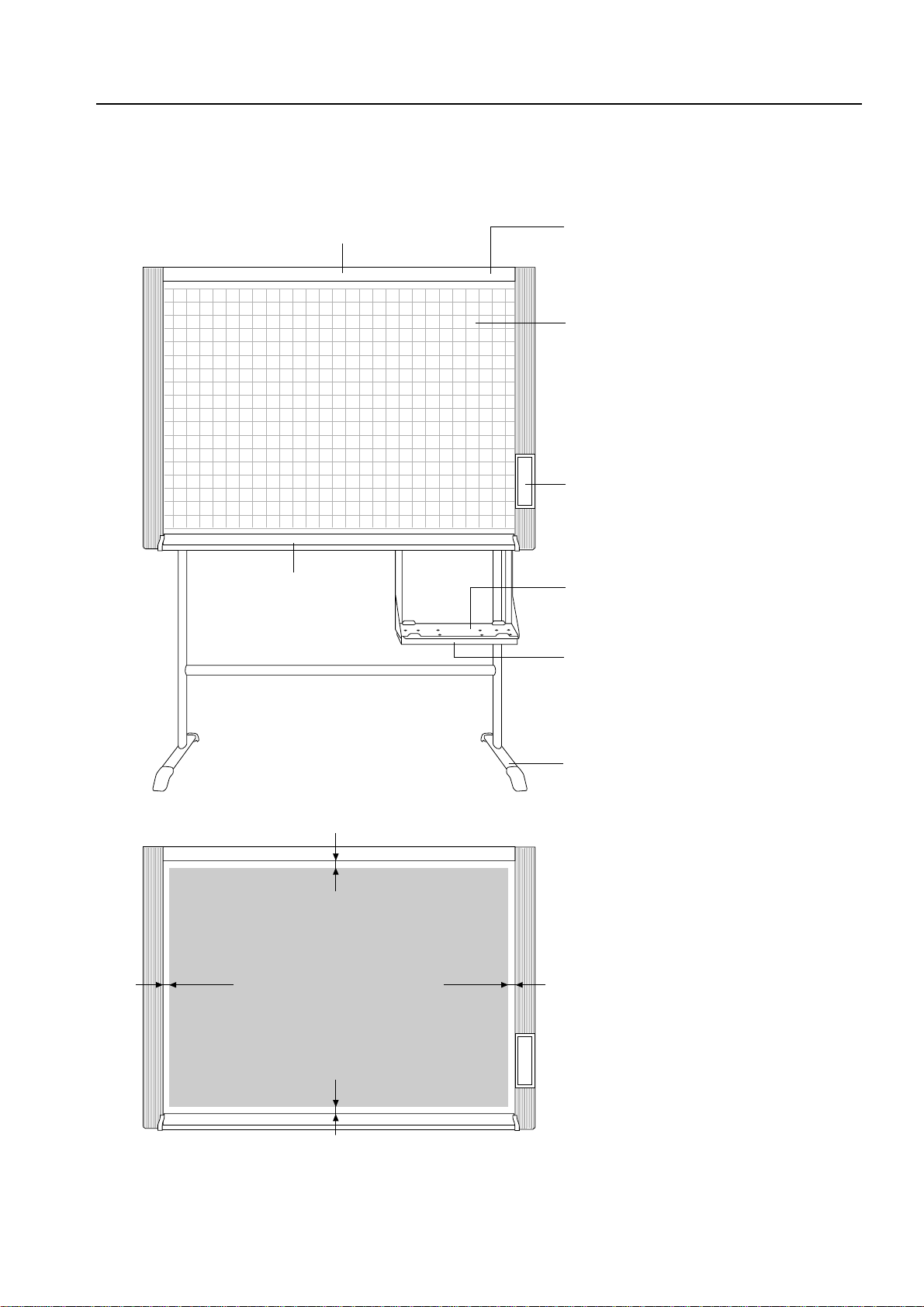

SPECIFICATIONS

2-4. Error Display

If any of the following flashing indications appear in the display window

of the control panel, please check the matters described below.

M-125

Number of Copies