THE ESSENTIAL PRINCIPLES FOR USERS OF PERSONAL PROTECTIVE EQUIPMENT AGAINST FALLS FROM A HEIGHT:

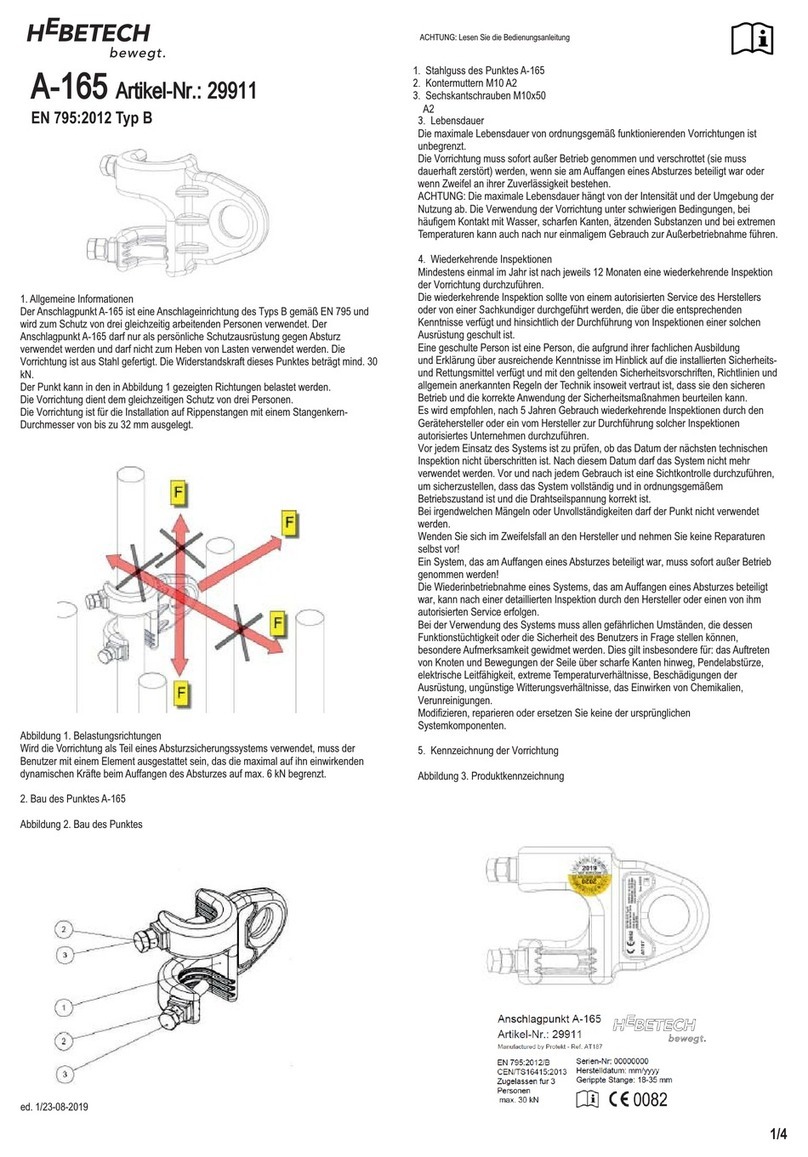

!personal protective equipment shall only be used by a person trained and competent in its safe use.

!personal protective equipment must not be used by a person with medical condition that could affect the safety of the equipment user in normal and emergency

use.

!a rescue plan shall be in place to deal with any emergencies that could arise during the work.

!being suspended in PPE (e.g. arresting a fall), beware of suspension trauma symptoms.

!to avoid symptoms of suspension trauma, be sure that the proper rescue plan is ready for use. It is recommended to use foot straps.

!it is forbidden to make any alterations or additions to the equipment without the manufacturer's prior written consent.

!any repair shall only be carried out by equipment manufacturer or his certified representative.

!personal protective equipment shall not be used outside its limitations, or for any purpose other than that for which it is intended.

!personal protective equipment should be a personal issue item.

!before use ensure about the compatibility of items of equipment assembled into a fall arrest system. Periodically check connecting and adjusting of the

equipment components to avoid accidental loosening or disconnecting of the components.

!it is forbidden to use combinations of items of equipment in which the safe function of any one item is affected by or interferes with the safe function of another.

!before each use of personal protective equipment it is obligatory to carry out a pre-use check of the equipment, to ensure that it is in a serviceable condition and

operates correctly before it is used.

!during pre-use check it is necessary to inspect all elements of the equipment in respect of any damages, excessive wear, corrosion, abrasion, cutting or incorrect

acting, especially take into consideration:

-in full body harnesses and belts - buckles, adjusting elements, attaching points, webbings, seams, loops;

-in energy absorbers - attaching loops, webbing, seams, casing, connectors;

-in textile lanyards or lifelines or guidelines - rope, loops, thimbles, connectors, adjusting element, splices;

-in steel lanyards or lifelines or guidelines - cable, wires, clips, ferrules, loops, thimbles, connectors, adjusting elements;

-in retractable fall arresters - cable or webbing, retractor and brake proper acting, casing, energy absorber, connector;

- in guided type fall arresters - body of the fall arrester, sliding function, locking gear acting, rivets and screws, connector, energy absorber;

- in metalic components (connectors, hooks, anchors) - main body, rivets, gate, locking gear acting.

!after every 12 months of utilization, personal protective equipment must be withdrawn from use to carry out periodical detailed inspection. The periodic

inspection must be carried out by a competent person for periodic inspection. The periodic inspection can be carried out also by the manufacturer or his authorized

representative.

!in case of some types of the complex equipment e.g. some types of retractable fall arresters the annual inspection can be carried out only by the manufacturer or

his authorized representative.

!regular periodic inspections are the essential for equipment maintenance and the safety of the users which depends upon the continued efficiency and durability

of the equipment.

!during periodic inspection it is necessary to check the legibility of the equipment marking. Don’t use the equipment with the illegible marking.

!it is essential for the safety of the user that if the product is re-sold outside the original country of destination the reseller shall provide instructions for use, for

maintenance, for periodic examination and for repair in language of the country in which the product is to be used.

!personal protective equipment must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again until confirmed

in writing by equipment manufacturer or his representative after carried out the detailed inspection.

!personal protective equipment must be withdrawn from use immediately and destroyed (or another procedures shall be introduced according detailed instruction

from equipment manual) when it have been used to arrest a fall.

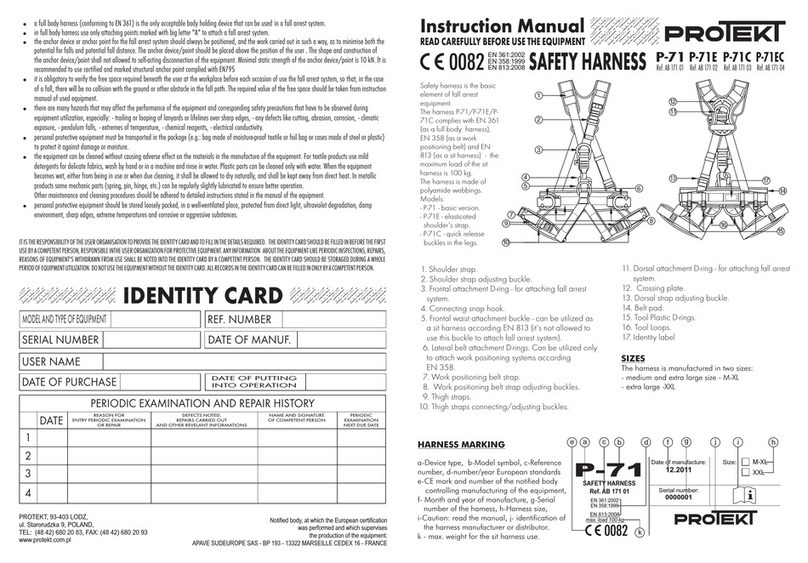

!a full body harness (conforming to EN 361) is the only acceptable body holding device that can be used, in a fall arrest system.

!in full body harness use only attachment points marked with a capital letter "A" to attach a fall arrest system.

!the anchor device or anchor point for the fall arrest system should always be positioned, and the work carried out in such a way, as to minimise both the potential

for falls and potential fall distance. The anchor device/point should be placed above the position of the user . The shape and construction of the anchor device/point

shall not allowed to self-acting disconnection of the equipment. Minimal static strength of the anchor device/point is 12 kN. It is recommended to use certified and

marked structural anchor point complied with EN795

!it is obligatory to verify the free space required beneath the user at the workplace before each occasion of use the fall arrest system, so that, in the case of a fall,

there will be no collision with the ground or other obstacle in the fall path. The required value of the free space should be taken from instruction manual of used

equipment.

!there are many hazards that may affect the performance of the equipment and corresponding safety precautions that have to be observed during equipment

utilization, especially: - trailing or looping of lanyards or lifelines over sharp edges, - any defects like cutting, abrasion, corrosion, - climatic exposure, - pendulum falls, -

extremes of temperature, - chemical reagents, - electrical conductivity.

!personal protective equipment must be transported in the package (e.g.: bag made of moisture-proof textile or foil bag or cases made of steel or plastic) to protect

it against damage or moisture.

!the equipment can be cleaned without causing adverse effect on the materials in the manufacture of the equipment. For textile products use mild detergents for

delicate fabrics, wash by hand or in a machine and rinse in water. For energy absorbers use only a damp cloth to wipe away dirt. It's forbidden to immerse energy

absorbers into the water. Plastic parts can be cleaned only with water. When the equipment becomes wet, either from being in use or when due cleaning, it shall be

allowed to dry naturally, and shall be kept away from direct heat. In metallic products some mechanic parts (spring, pin, hinge, etc.) can be regularly slightly lubricated to

ensure better operation.

!personal protective equipment should be stored loosely packed, in a well-ventilated place, protected from direct light, ultraviolet degradation, damp environment,

sharp edges, extreme temperatures and corrosive or aggressive substances.

!Using the harness in connection with personal protective equipment agains falls from a height must be compatible with manual instructions of this equipment and

obligatory standards:

- EN353-1, EN353-2, EN355, EN354, EN360 - for the fall arrest systems;

- EN362 - for the connectors;

- EN1496, EN341 - for rescue devices;

- EN795 - for anchor devices.

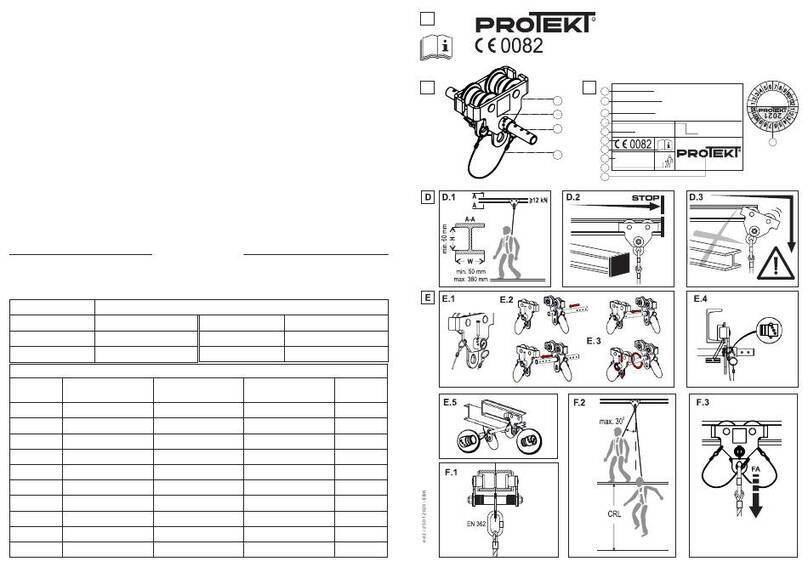

Line deflection angle on the edge when arresting a fall must be at least 90°. Minimum

required free space under the work level for fall from edges must be 2.5m + distance “l”. In

case of falls from edges pay particular attention to a potential pendulum effect and potential

contact of the user with parts of the structure.

In order to prevent a pendulum effect fall, it is necessary to limit the movement from

structural anchor point axis to 1.5m (see figure). Otherwise instead of a structural anchor

point, please use an anchor device compliant with EN 795 Class D. The device CR250HV

has not been tested with C class anchor devices.

NOTE: After a fall from edge there is a risk of injuries as a result of hitting elements of

building or structure. Thus, prepare and practice special rescue procedures related to falls

from edges.

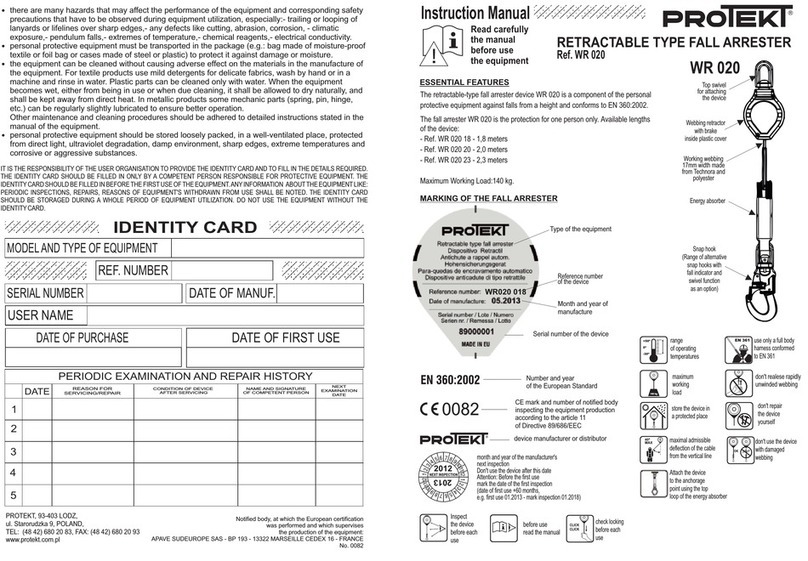

INSPECTION BEFORE USE

Before each use of the device the user must carry out a detailed inspection of components of the device: housing, snap hook, holder, work cable or webbing (over the whole

length) for mechanical, chemical and thermal damages. It is necessary to check operation of retracting and braking gear by dynamically pulling the work cable/ webbing.

The cable/ webbing should be locked and stop extending any further. After the cable/ webbing is released, it should be easily folded (retracted) by the device. Inspections

and checks should be carried out by the user of the device. If there are any defects or doubts in regard of the correct condition and function of the device, it should be

withdrawn from use immediately.

During usage protect all parts of the device from contact with oils, solvents, acids and alkali, open flame, molten metal spatters and objects with sharp edges. During

operation on truss structures avoid interweaving the work cable/webbing between individual parts of the structure. Avoid usage of the device in dusty and oily environments.

Use of retractable type fall arrester as a part of a fall protection system must be in accordance with instructions for individual parts of the system and standards in force:

- EN 361 - Full body harness;

- EN 362 - Connectors;

- EN 795 - Anchor devices (anchor points).

The device must be attached to a structural anchor point only

with rotary holder using snap hook [A] or attachment [B]

compliant with EN 362 or EN 795. It is forbidden to attach the

device using handle for device transportation [C]. Structural

anchor point should be located above the user and have static

strength of min. 12 kN.

Shape and construction of a structural anchor point must

prevent self-acting disconnection or slipping of the device. It is

recommended to use marked and certified structural anchor

points compliant with EN 795.

FORBIDDEN!!

A

B C

v

retractable

type fall arrester

retractable

type fall arrester

structural anchor pointstructural anchor point

l

z

work

station (level)

pendulum

effect

ground

level

o

max 40 REQUIREMENTS FOR STRUCTURAL ANCHOR POINTS

Structural anchor point which the retractable type fall arrester is attached to,

should be located above the user.

If retractable type fall arrester is attached vertically above the user,

minimum required free space below the work station (level) must be 1.5m.

When work cable of the retractable type fall arrester is deflected from the

vertical line, a pendulum effect may occur. To avoid a related risk, pay

attention that the device work line deflection from the vertical never

reaches 40º. In such case the user may move in the horizontal over a

distance “l” no greater than 1/2 “v”. Then the minimum required free space

under the work station (level) must be 1.5m + distance “l”.

! Snap hook of work line of the device should be

connected directly to front [D] or dorsal [E]

attachment point (buckle or loop) on full body

harness compliant with EN 361. It is forbidden to

connect work line of the device using additional

element attached between snap hook of work

line and attachment point [D] [E] of full body

harness [F].

!Always secure the locking gear!

!snap hooks on work cable should be connected

only to front or dorsal attachment point on the

harness. Full body harness should be compliant

with requirements of EN 361

!always secure the snap hook locking gear with

locking gear

USE OF RETRACTABLE TYPE FALL ARRESTER DURING WORKS ON A ROOF

It is acceptable to use retractable type fall arresters CR250HV for vertical application and protection against falls from edges which is confirmed by a special marking – see

pictogram. These devices have been successfully tested in accordance with new Directive on personal protective equipment 89/686/EEC (Document CNB/P/11.060). The

device can be used in areas where any type of edges with radius >0.5mm are present.

Example edge materials: roller steel profiles, and other metal structures, wooden beams or planks, roof parapets and similar concrete edges (it is recommended to chamfer

concrete edges using e.g. steel profile).

However, for edges posing a high risk of cutting the cable or with burrs, it is necessary to conduct a proper risk assessment, provide additional edge protection or contact

the manufacturer.

During horizontal work the device must be installed on the edge level or above.

edgeedge

max. 1,5 mmax. 1,5 m

max. 1,5 mmax. 1,5 m

anchor pointanchor point

CONNECTING THE FALL ARRESTER TO STRUCTURAL ANCHOR POINT

DE F

FORBIDDEN!!!

CONNECTING WORK LINE OF RETRACTABLE TYPE FALL ARRESTER TO FULL BODY HARNESS