71495 rd. 397 @indianola, ne 69034 @phone: 800-382-2607 @fax: 308-364-2410 @ info@schaffert.com @www.schaffert.com

SCHAFFERT MFG. CO. INC. - phone: 800-382-2607 - fax: 308-364-2410

FURROW V CLOSER MOUNTING INSTRUCTIONS

White 5000 Series Planters

(Read Instructions Completely before Beginning Installation)

Before working on your planter or drill

DANGER: when storing or working on the planter always install cylinder stops or place the planter on stands to prevent personal injury or damage to the

attachments. Do not allow planter to rest on poly FVC discs as they can warp

Mounting Instructions

Before you begin, verify the “package contents” to ensure all items are included.

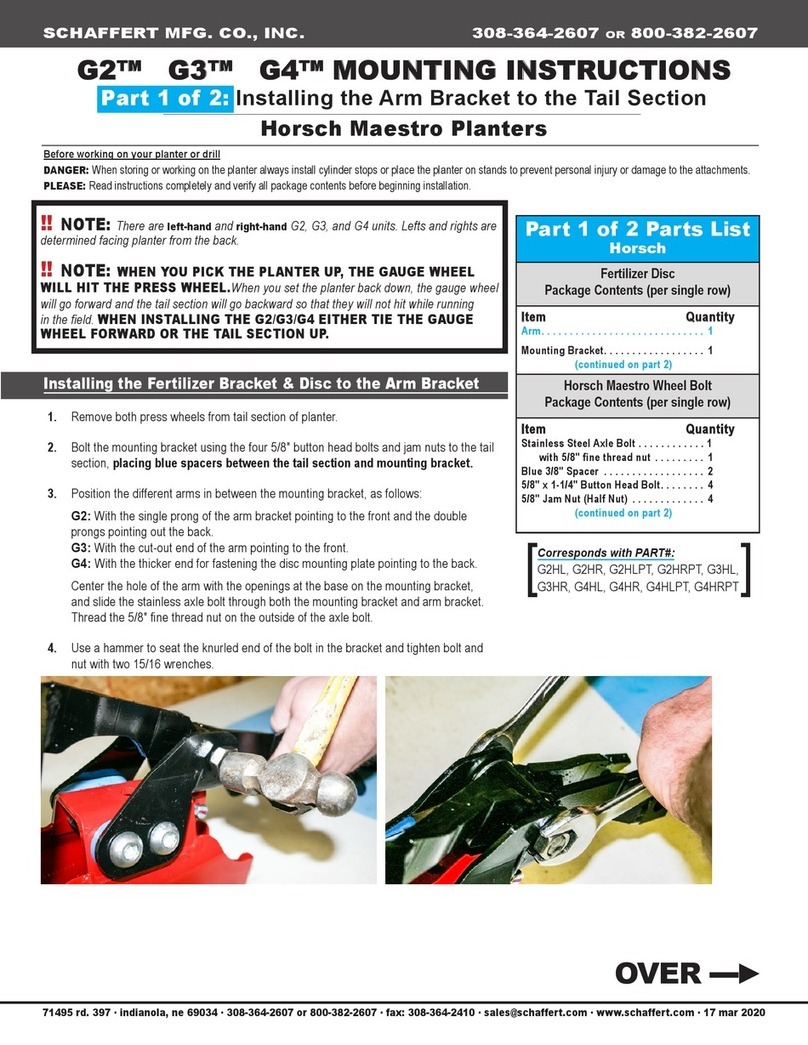

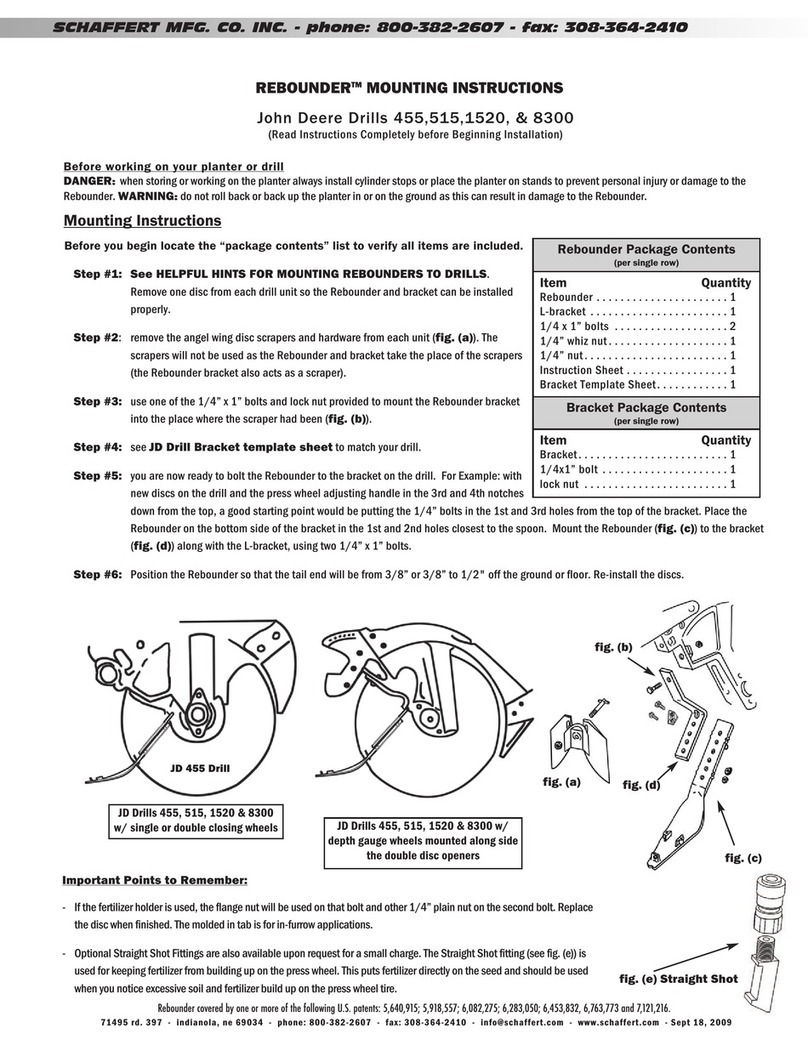

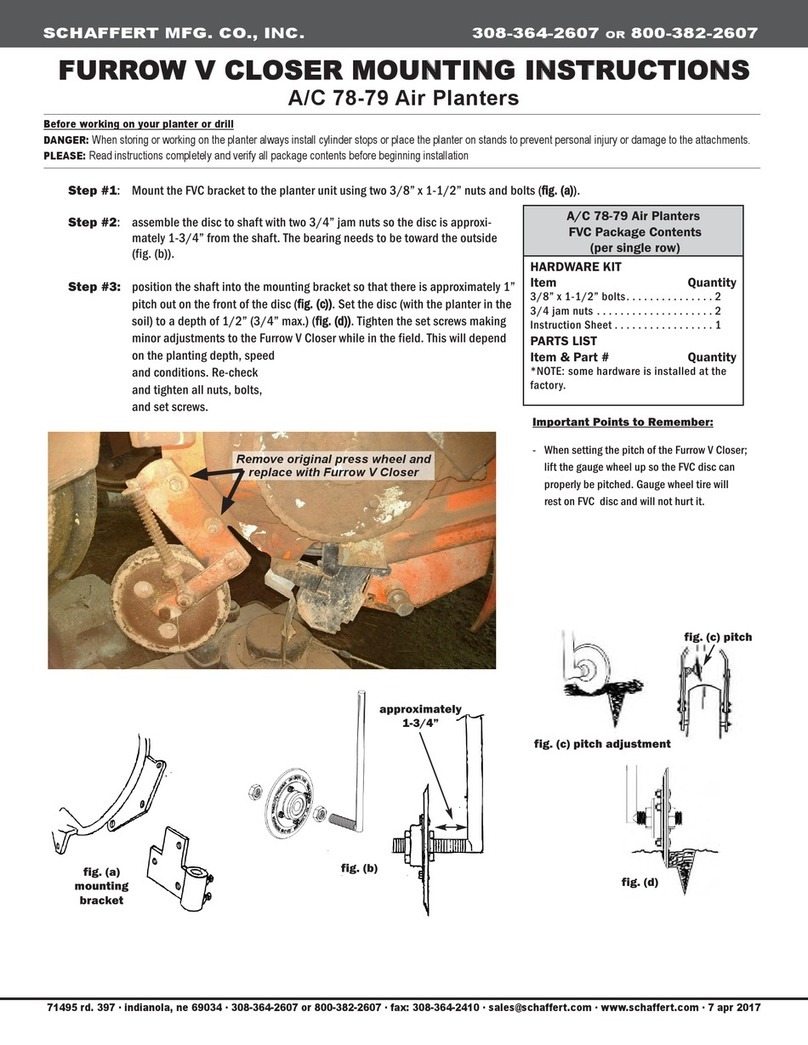

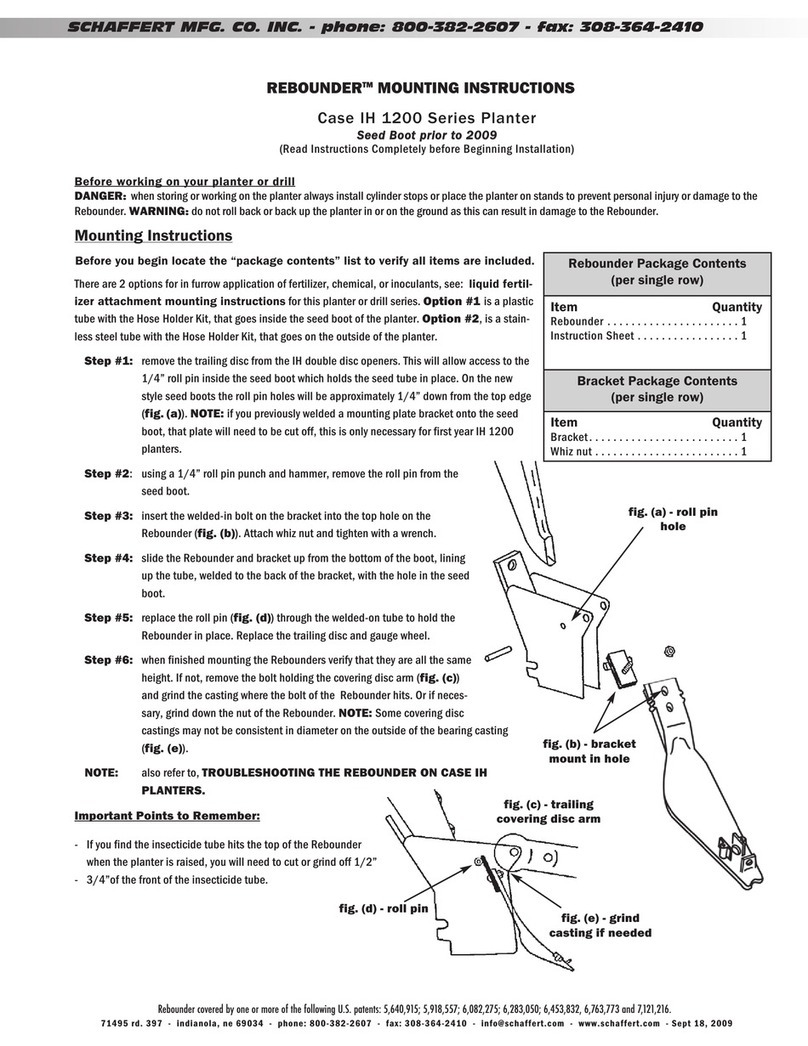

Step #1:Assemble the Furrow V Closer.Begin by removing the two 3/8” square head-

ed set bolts from the mounting bracket and install the two 3/8” jam nuts.

Mount the FVC bracket installing the two carriage bolts in the square holes

on the left tail section bracket of the press wheel. Attach mounting bracket

and tighten bolts.

Step #2: Install the poly disc to all-thread end of shaft using a 3/4” jam nut on each

side of the disc. Inward and outward adjustment is made with the 3/4” jam

nuts. Start at a distance of 3/4” between the hub and shaft (fig.(a)). Ex.:

use a 1/2” hex sided nut from your bolt bin and place it between the shaft

and hub to give 3/4”. Tighten both 3/4” jam nuts.

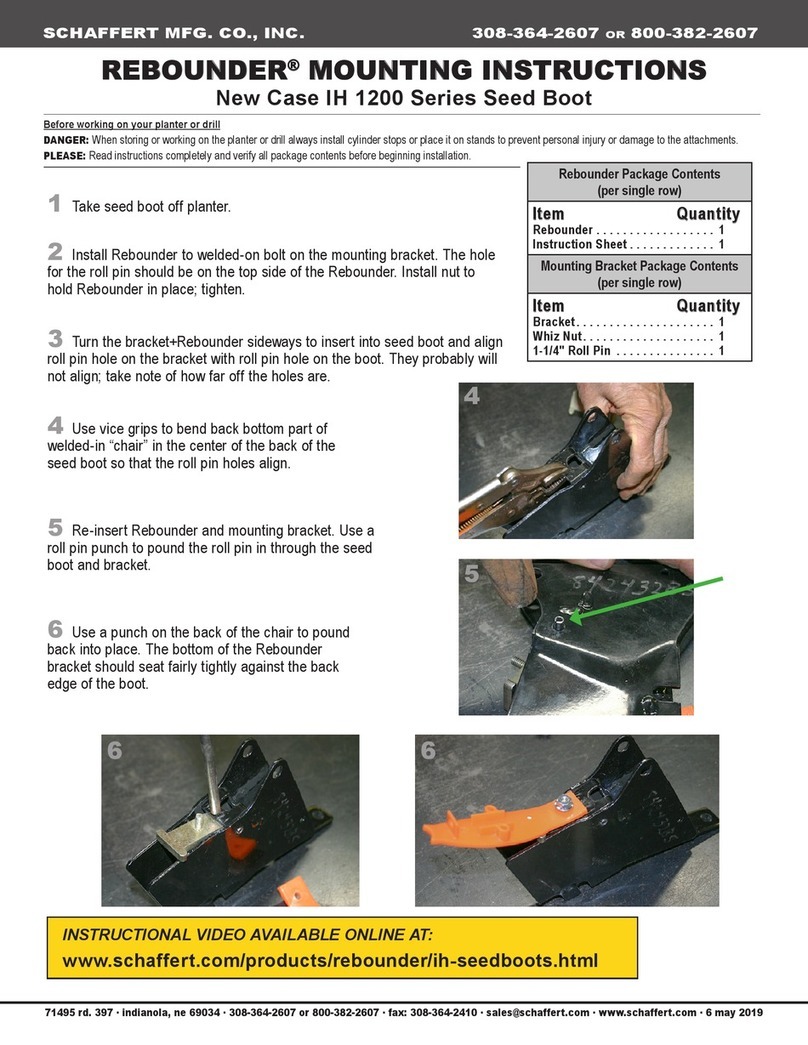

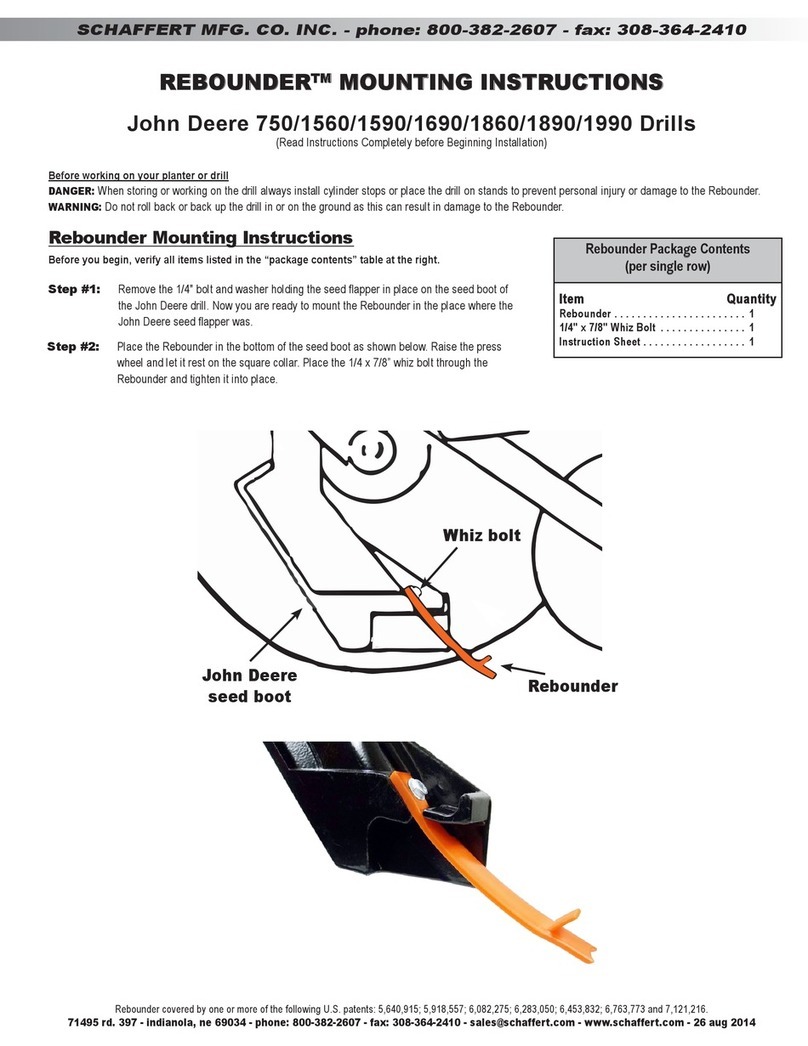

Step #3: Now you are ready to install the shaft into the mounting bracket. Depth and

pitch will be set simultaneously before set bolts are tightened. Set the depth

of shaft at 6-1/2” (fig. (b)).

Step #4: Use the gauging tool to help in setting correct pitch. This is provided with

every 2 rows ordered. Place the gauging tool over the shaft (fig. (c)). Turn

gauging tool clockwise until gauge pin bumps against the front of the frame

of the press wheel bracket. (fig. (d)). With depth and pitch set, tighten

square headed set bolts into shaft. Adequate pitch is important to prevent

the poly discs from warping.

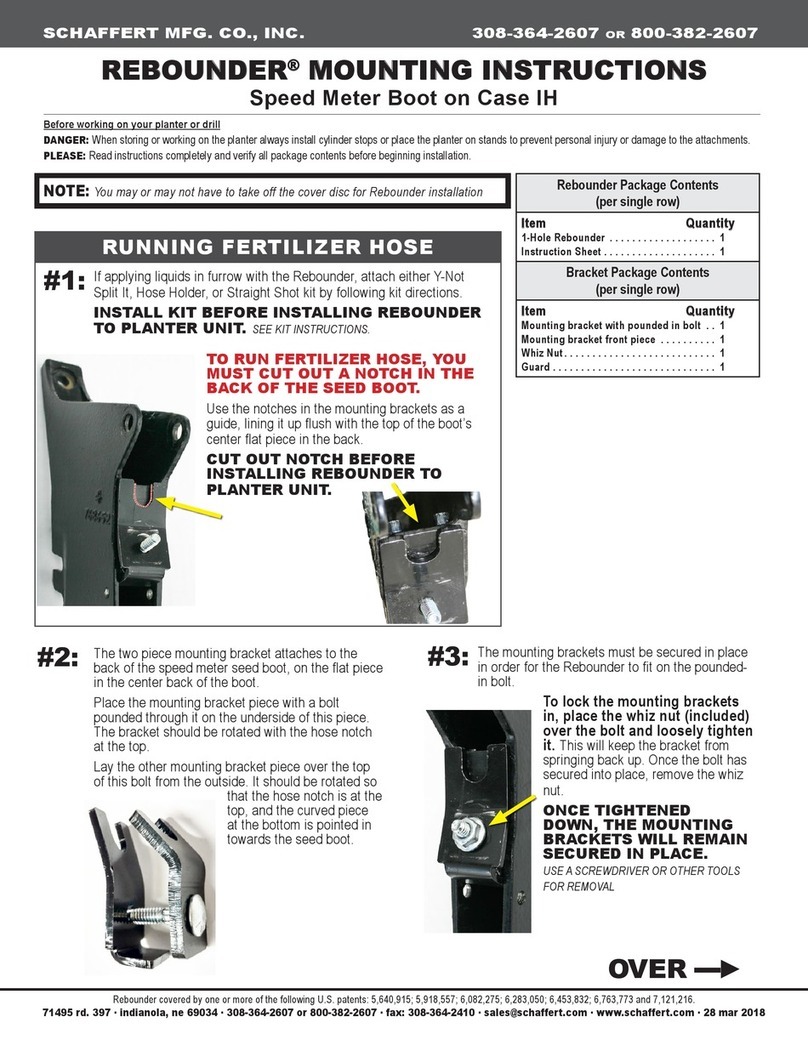

Important Points to Remember:

-When setting the pitch of the Furrow V Closer; lift the gauge wheel up so the FVC disc can properly

be pitched.

-Poly disc will rest on the gauge wheel tire without harming it when planter is raised.

When optional steel disc is used, a travel stop must be put on the gauge wheel so that

the steel disc will not cut the tire when planter is raised.

White 5000

FVC Package Contents

(per single row)

HARDWARE KIT

Item Quantity

1/4 x 3/4 Carriage Bolt . . . . . . . . . . . 4

1/4 Nut . . . . . . . . . . . . . . . . . . . . . . . . 4

1/4 Lock Washer . . . . . . . . . . . . . . . . . 4

3/8 x 1” Carriage Bolt . . . . . . . . . . . . . 2

3/8 Nut . . . . . . . . . . . . . . . . . . . . . . . . 2

3/8 Lock Washer . . . . . . . . . . . . . . . . . 2

1/8 Cotter Pin . . . . . . . . . . . . . . . . . . . 1

3/4 Jam Nut. . . . . . . . . . . . . . . . . . . . . 2

3/8 Jam Nut. . . . . . . . . . . . . . . . . . . . . 2

Instruction Sheet . . . . . . . . . . . . . . . . . 1

PARTS LIST

Item & Part # Quantity

Gray Poly Disc (1002) . . . . . . . . . . . . . 1

Steel Disc (optional - 1003) . . . . . . . . 1

Hub (2001). . . . . . . . . . . . . . . . . . . . . . 1

Bearing triple seal (3001) . . . . . . . . . . 1

Shaft (4003) . . . . . . . . . . . . . . . . . . . . 1

Mt. Bracket (5002) . . . . . . . . . . . . . . . 1

*NOTE: some hardware is installed at the

factory.factory.

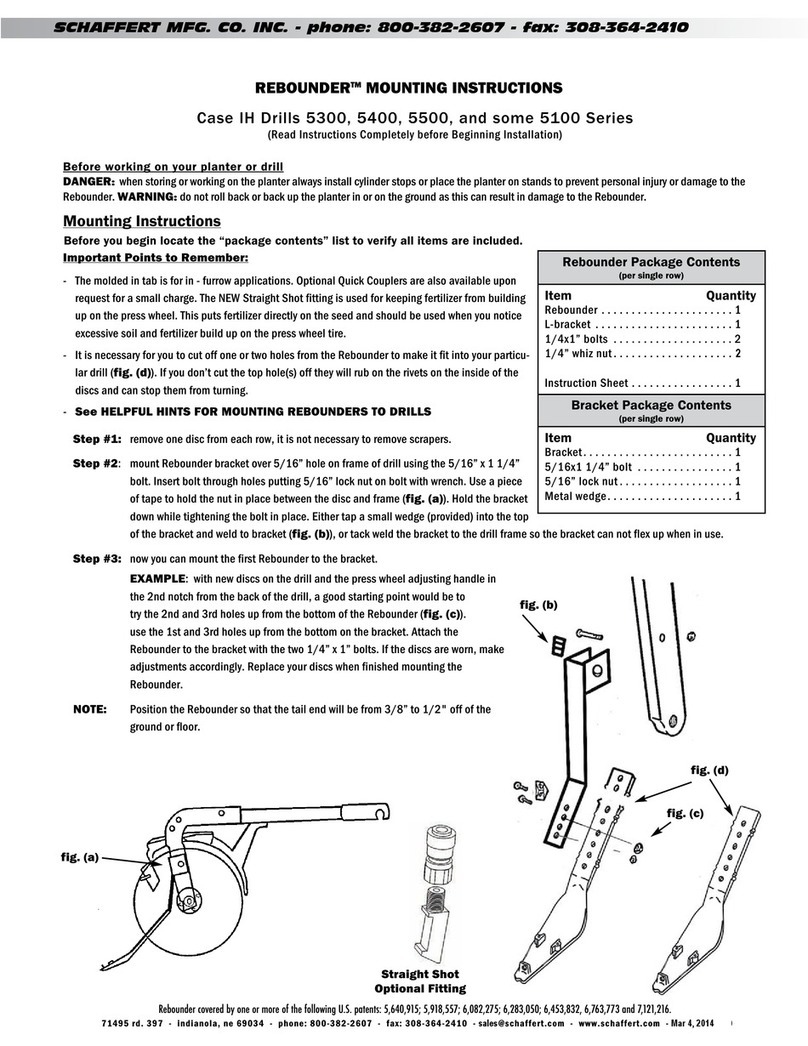

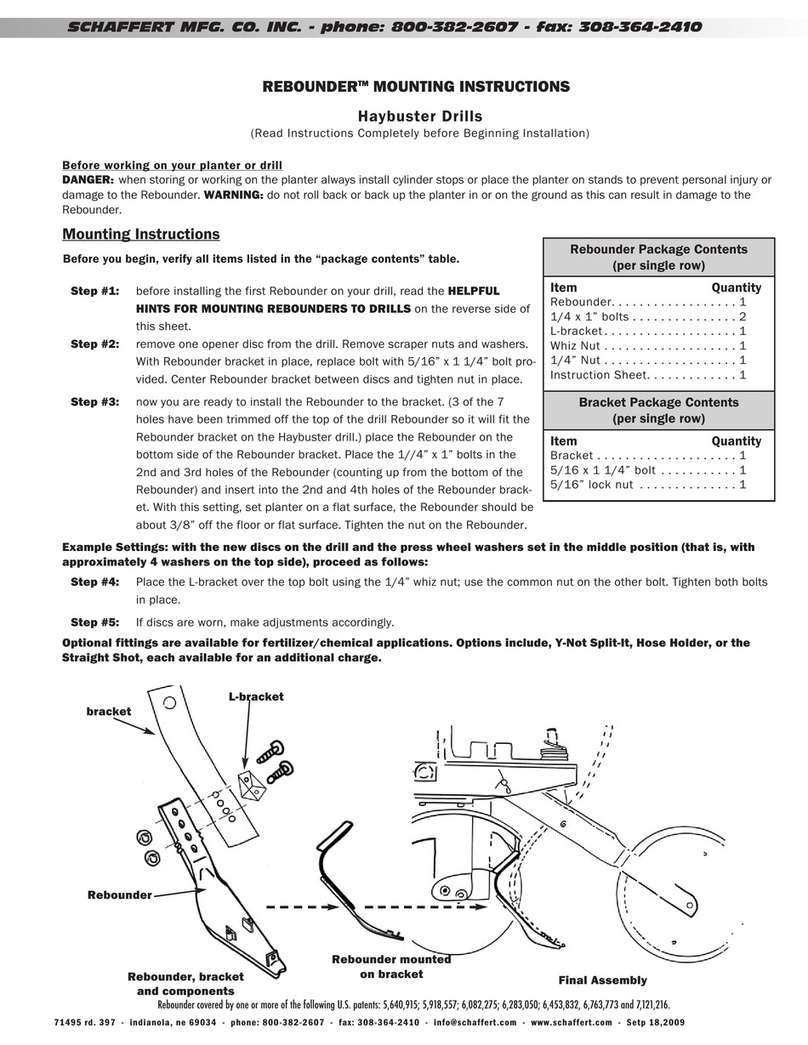

fig. (d)

fig. (c)

gauging

tool

line up marks on

shaft & washer

6 - 1/2”

fig. (b)

fig. (a) between

shaft & hub

hub

gray poly disc

bearing

gauging

tool

shaft

mt. bracket

sales 4/30/14