REBOUNDER M MOUN ING INS RUC IONS

John Deere Drills 455,515,1520, & 8300

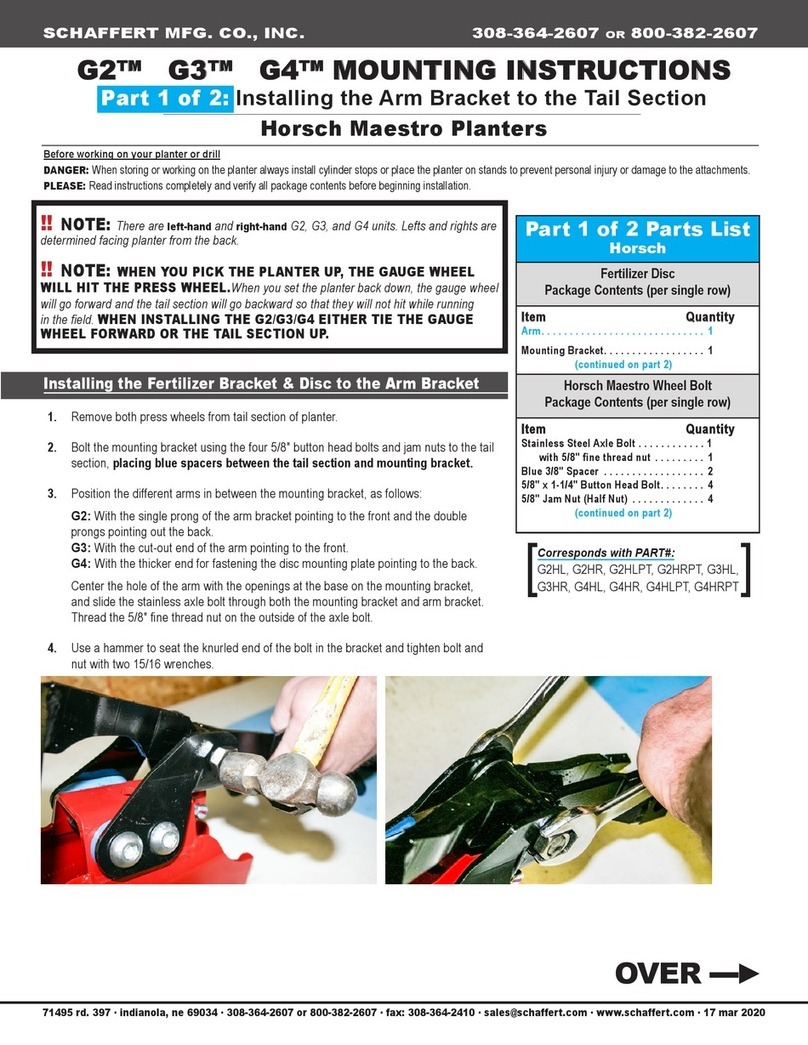

(Read Instructions Completely before Beginning Installation)

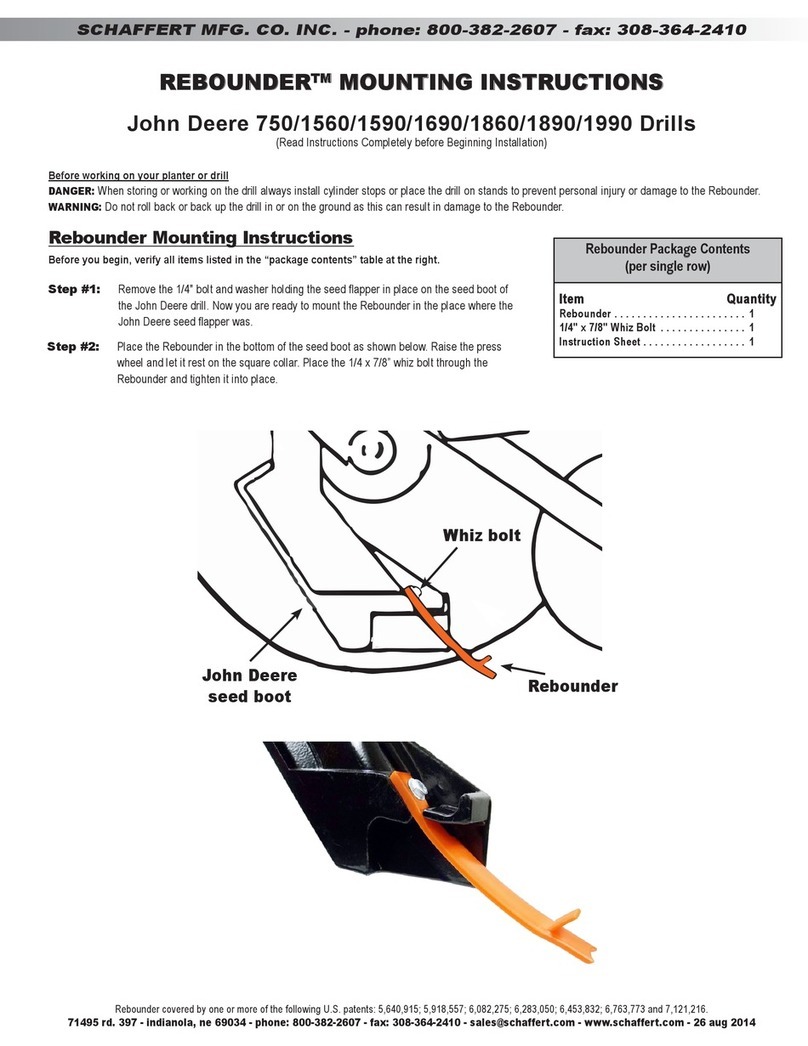

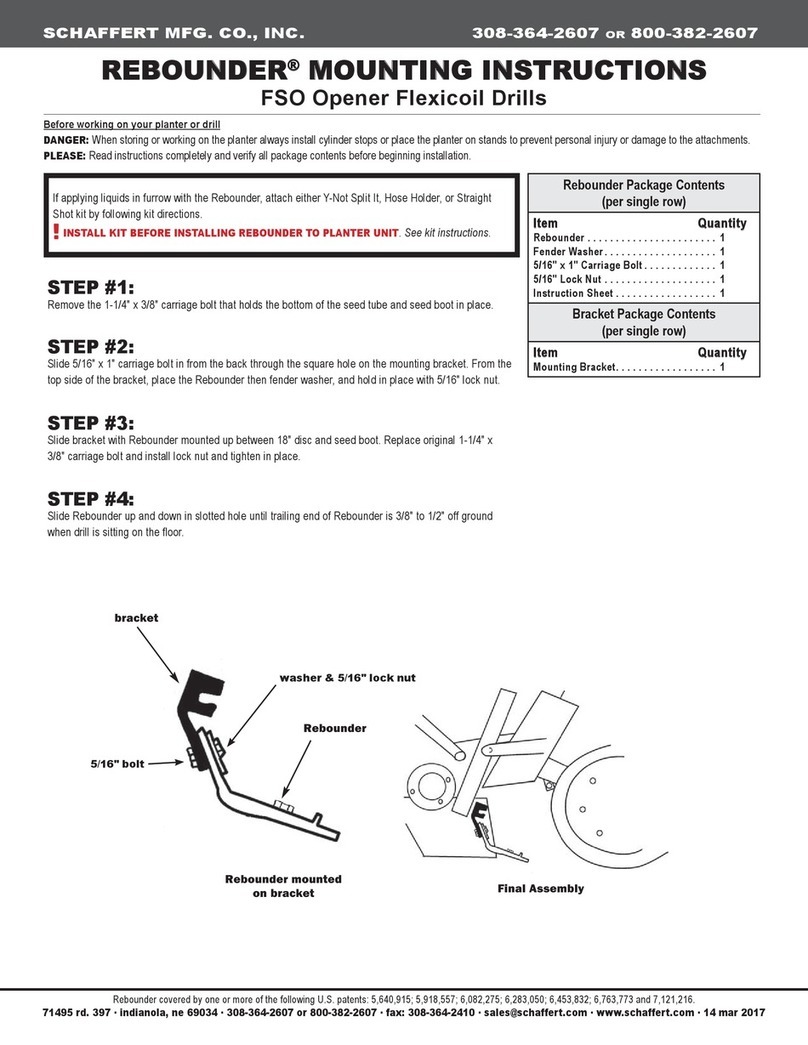

Before worki g o your pla ter or drill

DANGER:when storing or working on the planter always install cylinder stops or place the planter on stands to prevent personal injury or damage to the

Rebounder. WARNING:do not roll back or back up the planter in or on the ground as this can result in damage to the Rebounder.

Mou ti g I structio s

Before you begi locate the “package co te ts” list to verify all items are i cluded.

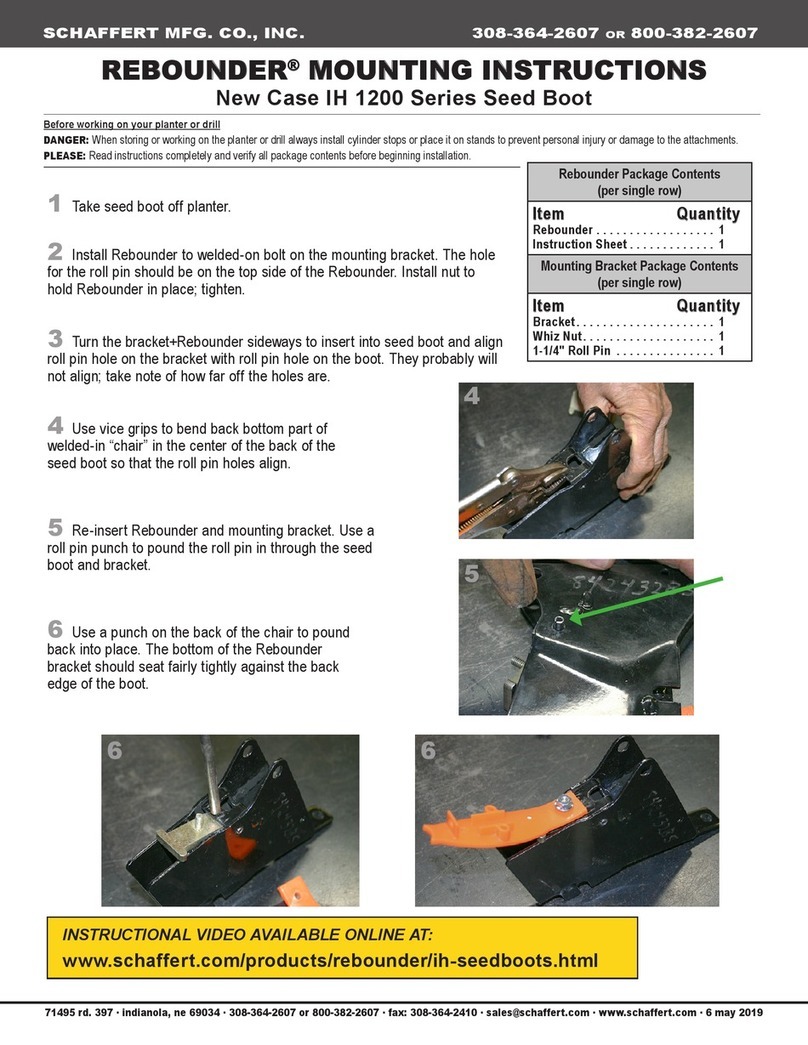

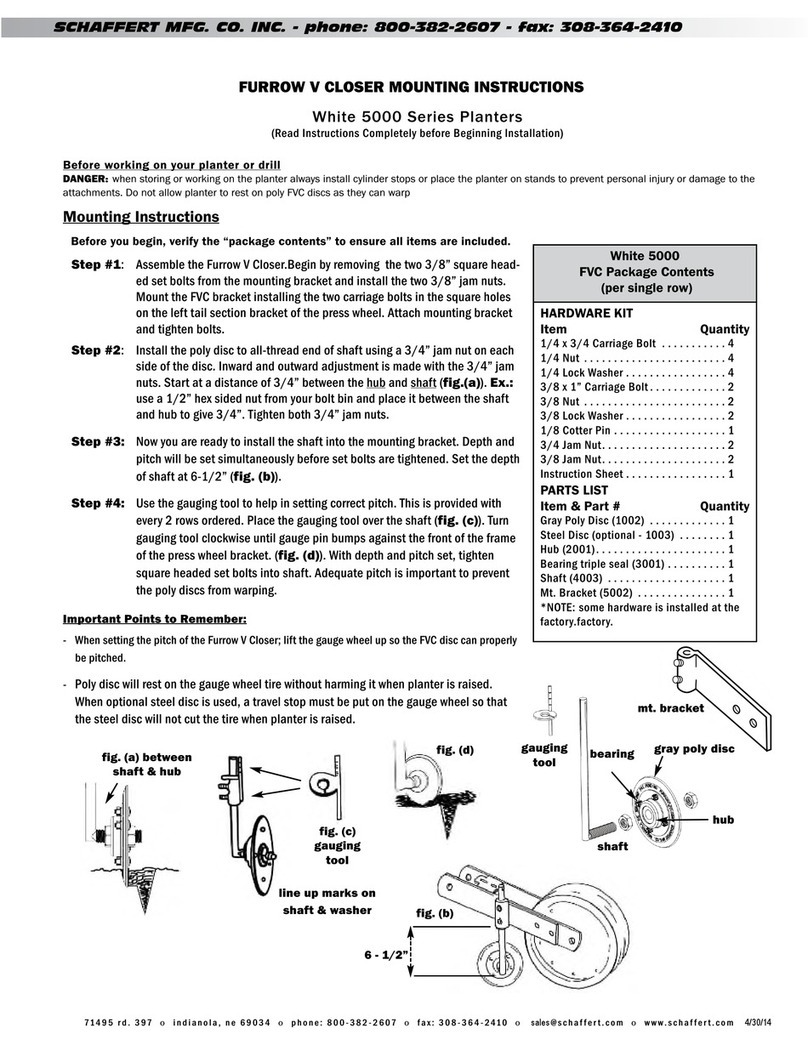

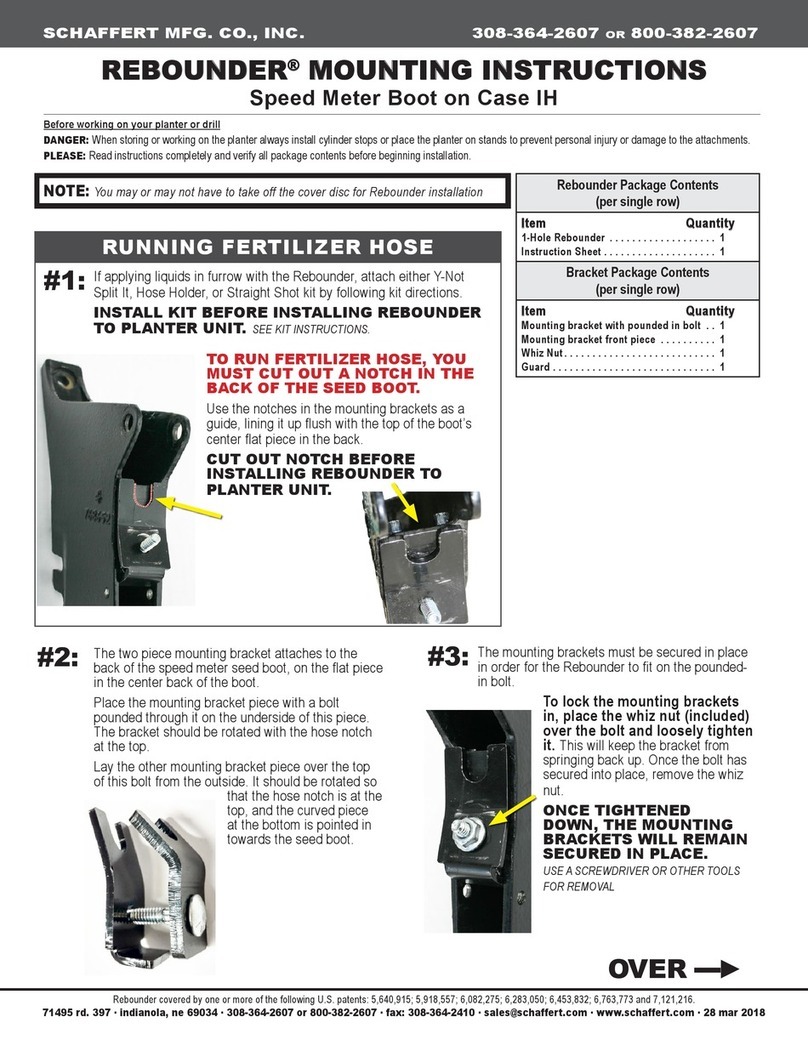

Step #1: See HELPFUL HIN S FOR MOUN ING REBOUNDERS O DRILLS.

Remove one disc from each drill unit so the Rebounder and bracket can be installed

properly.

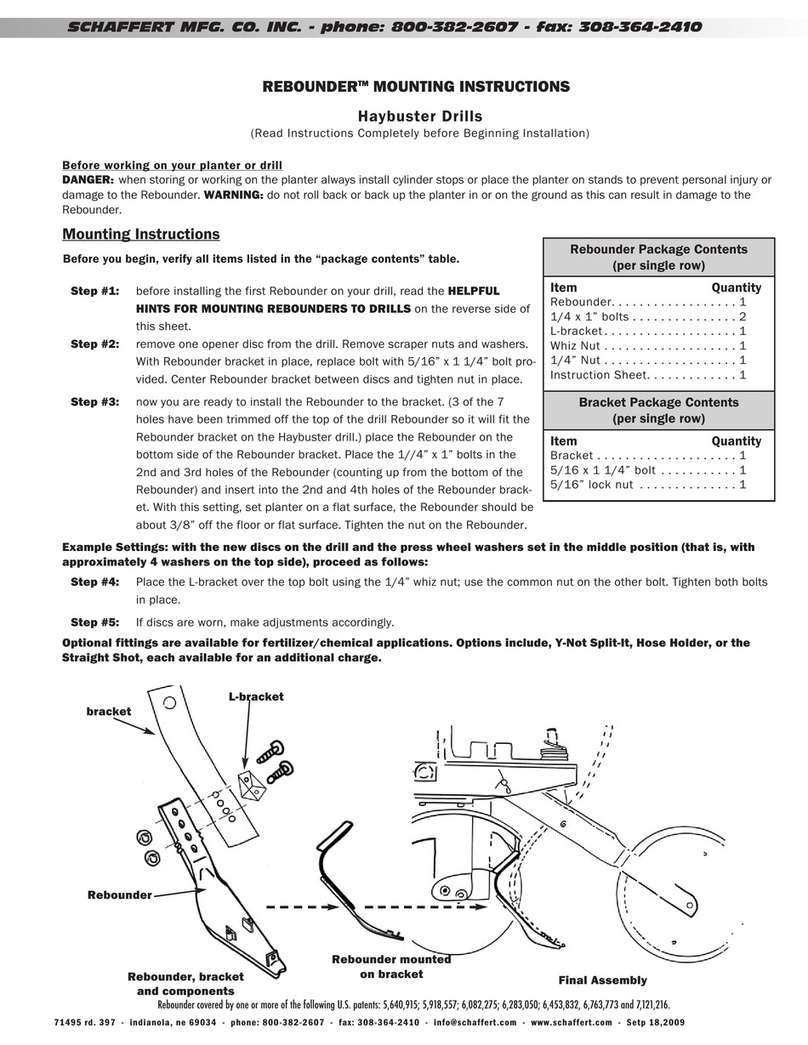

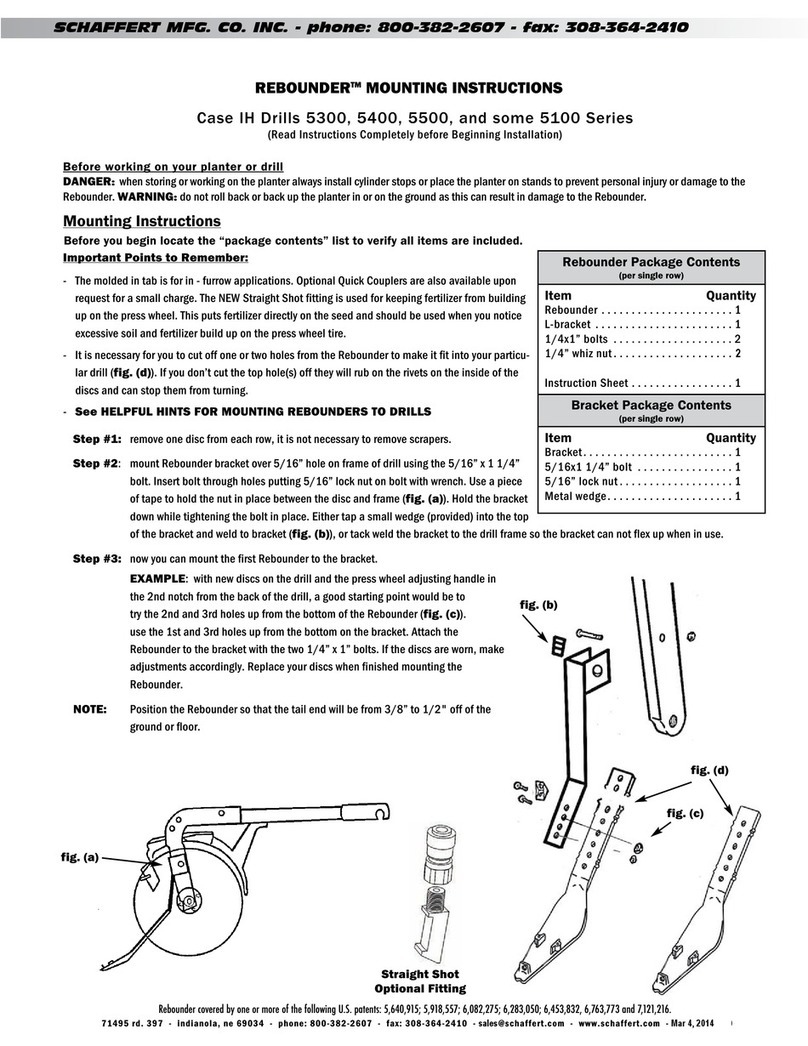

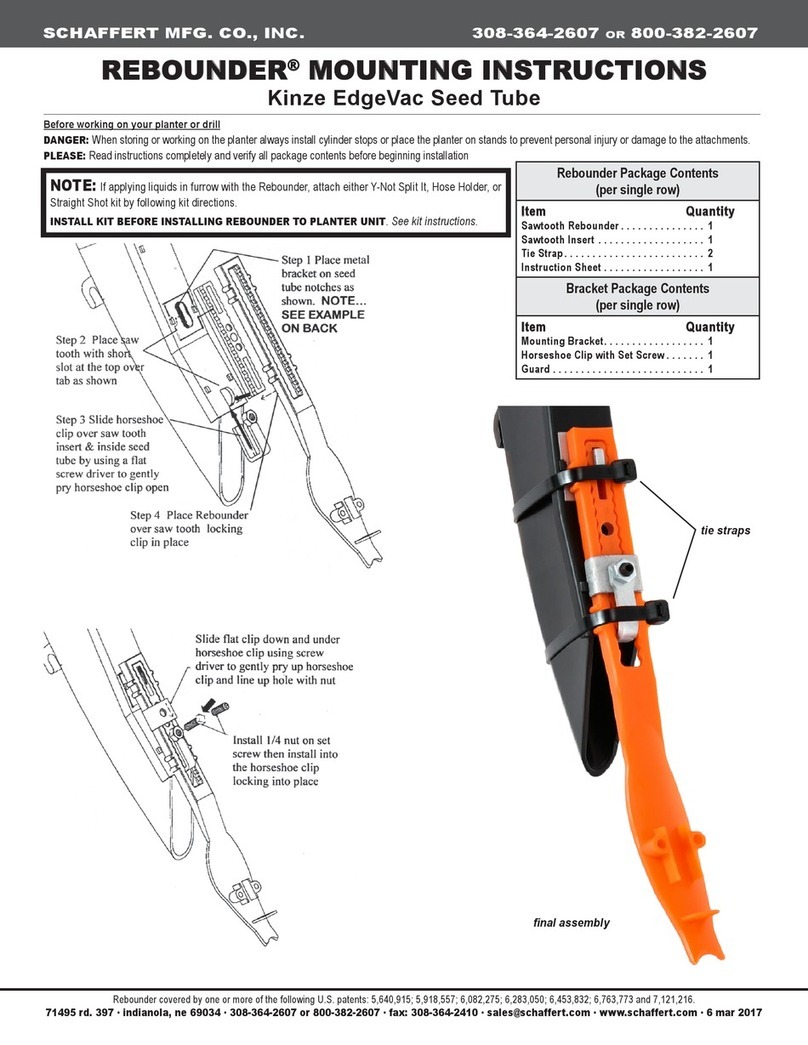

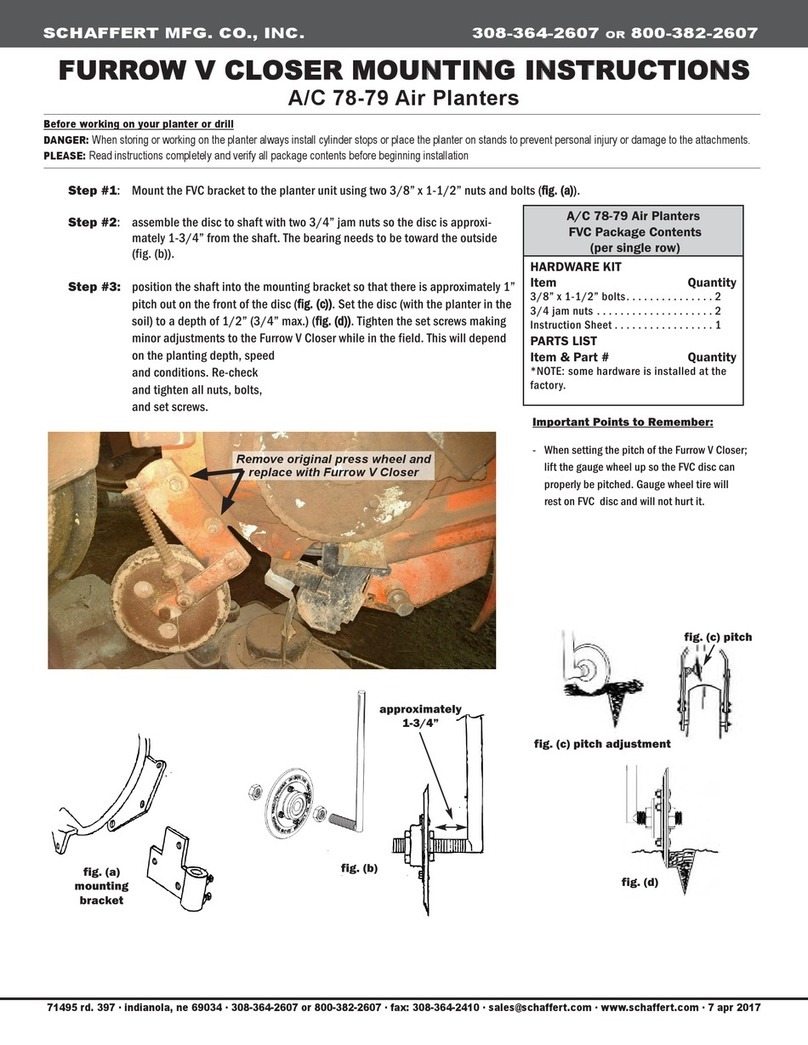

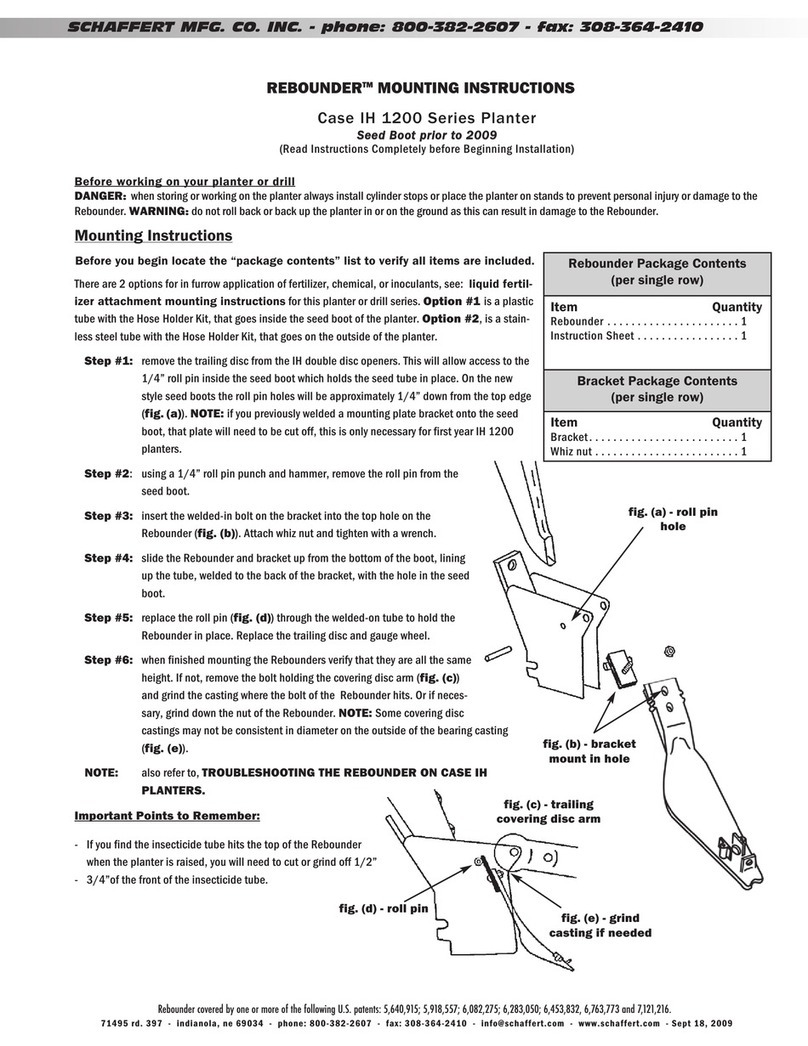

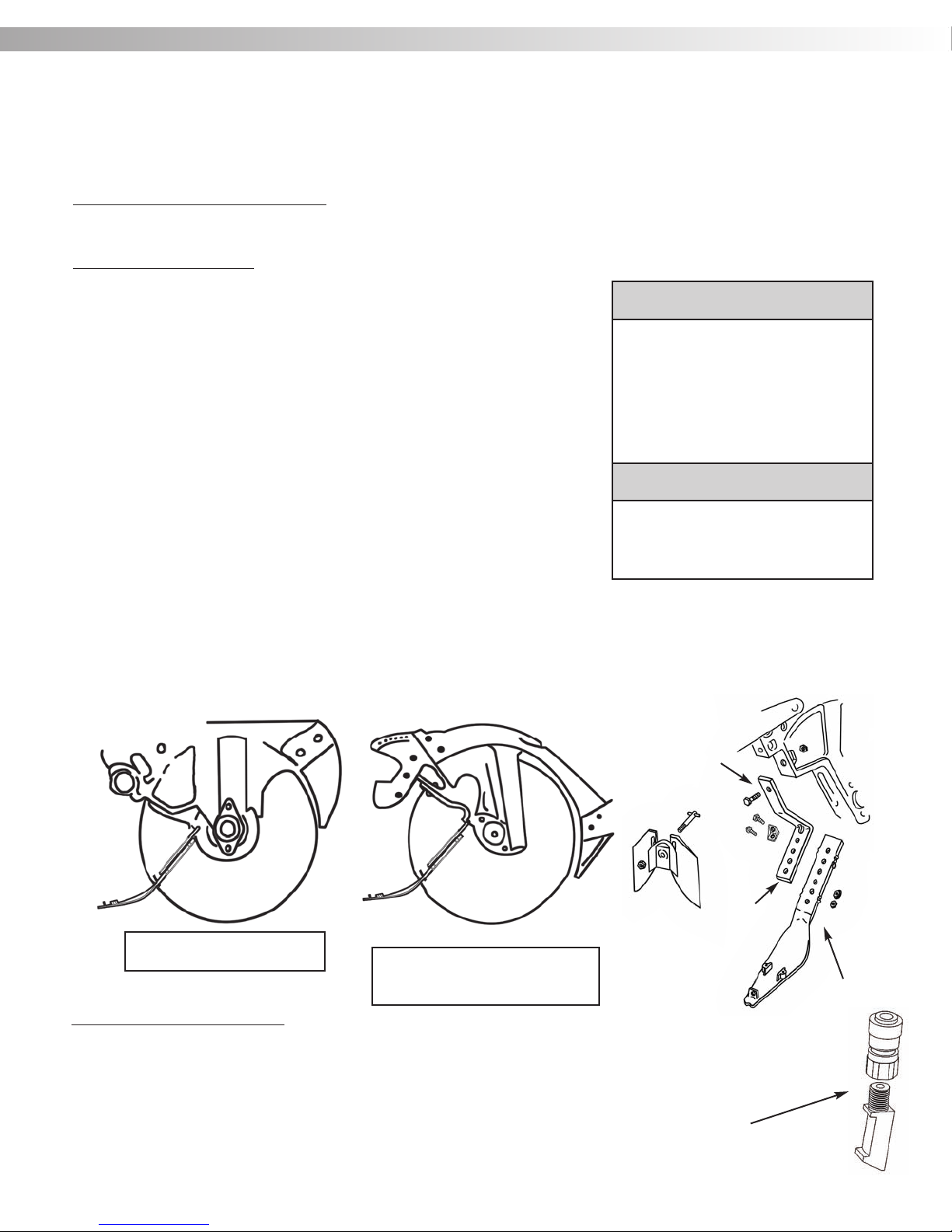

Step #2: remove the angel wing disc scrapers and hardware from each unit (fig. (a)). he

scrapers will not be used as the Rebounder and bracket take the place of the scrapers

(the Rebounder bracket also acts as a scraper).

Step #3: use one of the 1/4” x 1” bolts and lock nut provided to mount the Rebounder bracket

into the place where the scraper had been (fig. (b)).

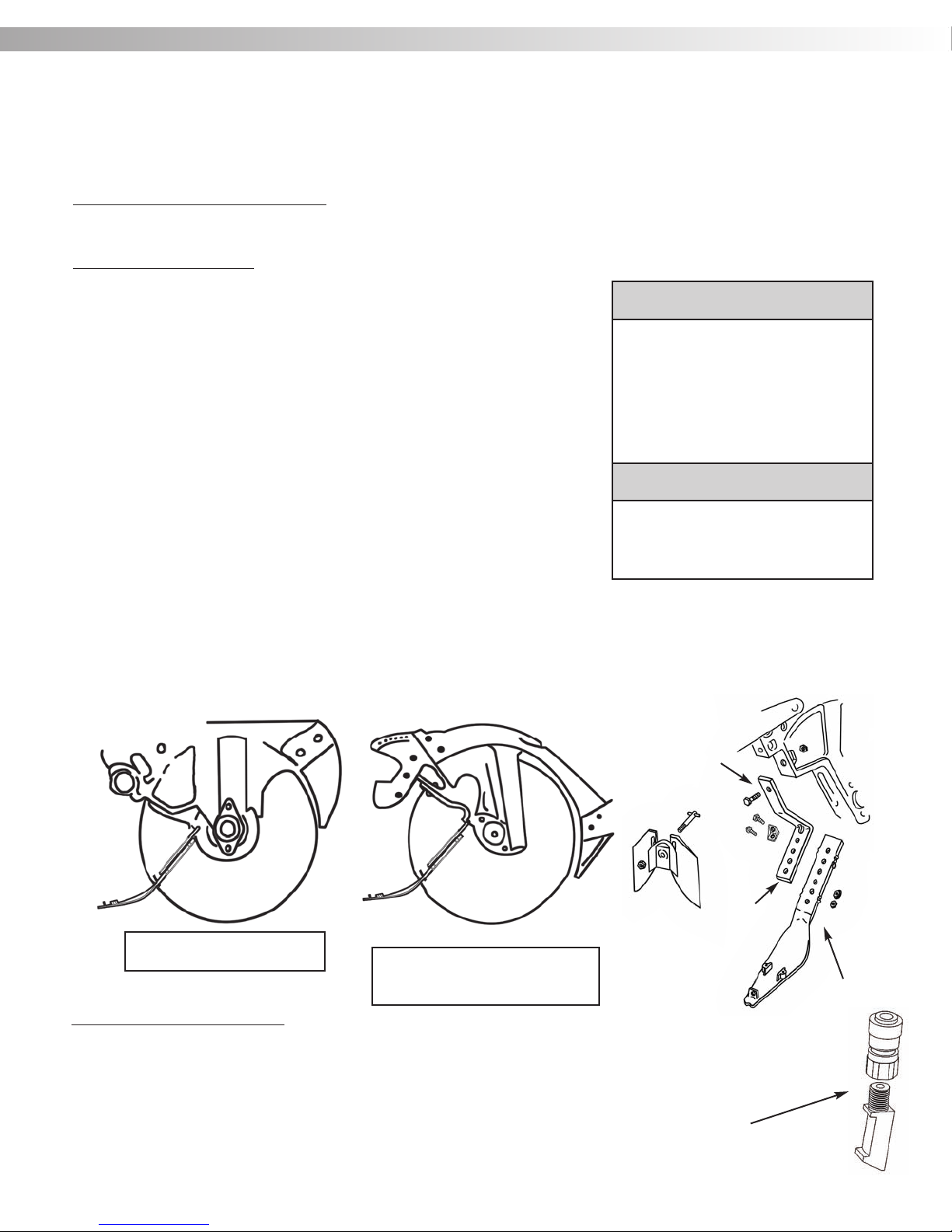

Step #4: see JD Drill Bracket template sheet to match your drill.

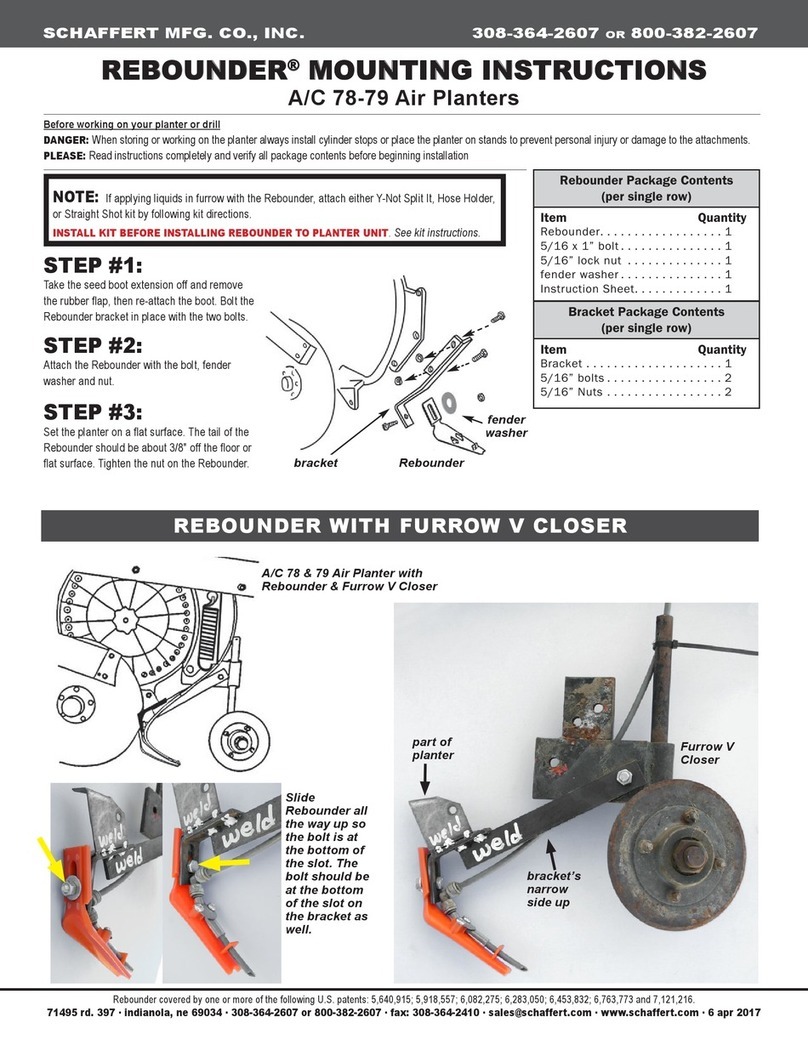

Step #5: you are now ready to bolt the Rebounder to the bracket on the drill. For Example: with

new discs on the drill and the press wheel adjusting handle in the 3rd and 4th notches

down from the top, a good starting point would be putting the 1/4” bolts in the 1st and 3rd holes from the top of the bracket. Place the

Rebounder on the bottom side of the bracket in the 1st and 2nd holes closest to the spoon. Mount the Rebounder (fig. (c)) to the bracket

(fig. (d)) along with the L-bracket, using two 1/4” x 1” bolts.

Step #6: Position the Rebounder so that the tail end will be from 3/8” or 3/8” to 1/2" off the ground or floor. Re-install the discs.

JD Drills 455, 515, 1520 & 8300

w/ si gle or double closi g wheels

JD 455 Drill

fig. (b)

fig. (c)

Rebou der Package Co te ts

(per si gle row)

Item Qua tity

Rebounder......................1

L-bracket .......................1

1/4x1”bolts ...................2

1/4”whiznut....................1

1/4”nut........................1

Instruction Sheet . . . . . . . . . . . . . . . . . 1

Bracket emplate Sheet . . . . . . . . . . . . 1

Bracket Package Co te ts

(per si gle row)

Item Qua tity

Bracket.........................1

1/4x1”bolt .....................1

locknut ........................1

fig. (e) Straight Shot

fig. (a) fig. (d)

Important Points to Remember:

- If the fertilizer holder is used, the flange nut will be used on that bolt and other 1/4” plain nut on the second bolt. Replace

the disc when finished. he molded in tab is for in-furrow applications.

- Optional Straight Shot Fittings are also available upon request for a small charge. he Straight Shot fitting (see fig. (e)) is

used for keeping fertilizer from building up on the press wheel. his puts fertilizer directly on the seed and should be used

when you notice excessive soil and fertilizer build up on the press wheel tire.

JD Drills 455, 515, 1520 & 8300 w/

depth gauge wheels mou ted alo g side

the double disc ope ers

Rebounder covered by one or more of the following U.S. atents: 5,640,915; 5,918,557; 6,082,275; 6,283,050; 6,453,832, 6,763,773 and 7,121,216.

71495

rd.

397

-

i

dia

ola,

e

69034

-

pho

e:

800-382-2607

-

fax:

308-364-2410

-

i

[email protected] -

www.schaffert.com

-

Sept

18,

2009

SCHAFFERT MFG. CO. INC. - phone: 8 -382-26 7 - fax: 3 8-364-241