I

N

A

U

S

T

R

A

L

I

A

P

R

O

U

D

L

Y

B

U

I

L

T

2

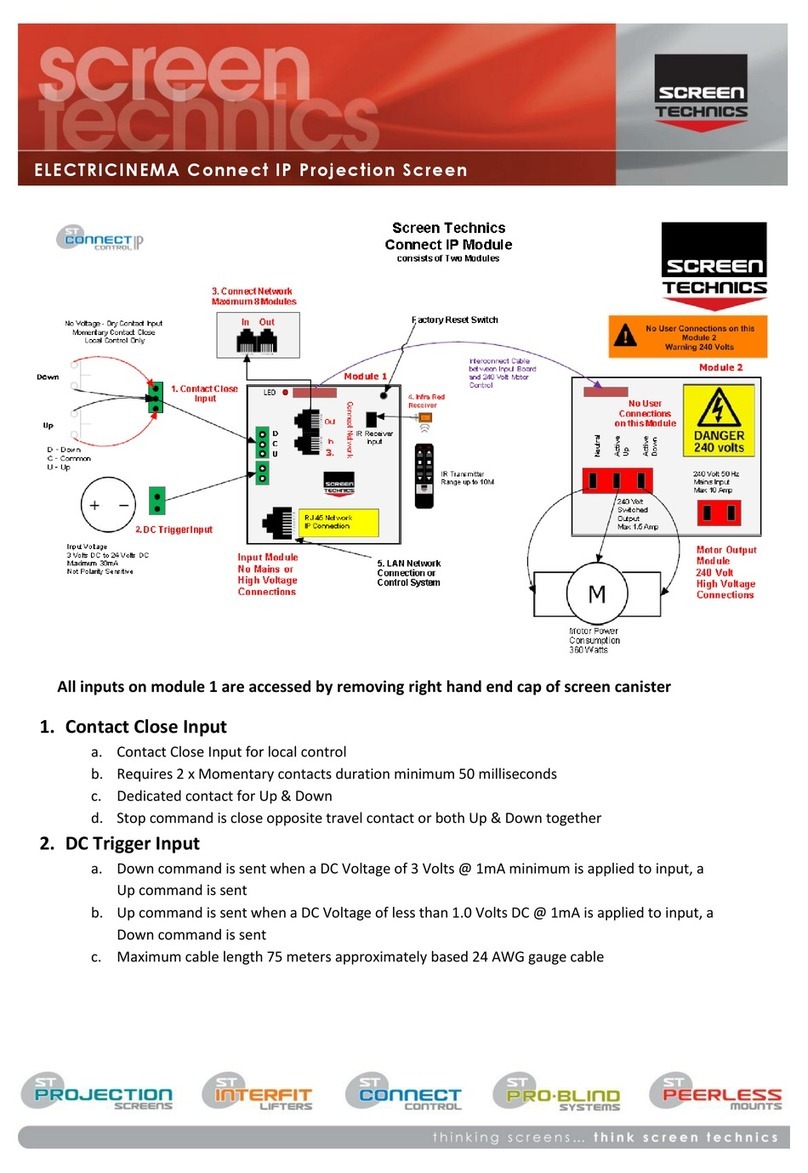

INSTRUCTIONS - ELECTRICINEMA 235 PROJECTION SCREEN

CONTROL EQUIPMENT

The Electricinema 235 utilises three iConnect Motor

Controllers that have been specically programmed

to work in unison. They are all controlled by IR, with a

300mm and 2000mm long lead and sensor supplied in

the kit, along with a two channel hand held transmitter.

The three power leads exiting the screen box left

hand side have been labelled to suit the individual

iConnect controllers. Please ensure the correct leads

are plugged into the motor controllers, as each unit

performs a different function.

The 3 x iConnect Motor Controllers are labelled as

follows:

1. Screen – which is designed to control the screen

surface – IR Channel One

2. Masking – which is designed to control the masking

up & down – IR Channel Two

3. Motor – which is designed to work in a delayed

action with the masking motor – Channel Two

Channel One – Controls the main projection screen up and down.

Channel Two – Controls the masking up and down, and then the masking moves to lay against

screen surface, on a delayed action.

The use of momentary contacts for control is possible, with a separate pair of momentary

contacts for the main screen surface (replicating IR Channel One) and another pair of momentary

contacts, parallel wired into the two masking motor controllers (replicating IR Channel Two).

NB: iConnect motor controllers 2 and 3 must be controlled together or damage to the screen

surface may result.

MASKING TRACKING ADJUSTMENT:

Due to temperature and humidity the masking material may expand or contract a small amount

whilst the projection and masking material acclimatise to the installation location.

This may cause the masking to marginally track in a left or right direction when the masking is

moving up or down.

To x the tracking issue:

1. Roll Main projection surface down.

2. Roll masking down

3. Note which direction the masking is tracking (Left or Right).

4. Open the door covering the mechanism

5. Using a small piece of masking tape, (10mm – 15mm piece) and place the tape on the back

of the masking roller opposite to the direction of the masking movement

6. Roll masking back up and conrm that masking is straight.

7. You may have to add tape or remove depending on how much the masking is moving

LIMIT ADJUSTMENT

The following instructions are for the adjustment of

the limit switches that alter the upper and lower stop

positions on ElectriCinema 235 Projection Screen only

WHERE ARE THE LIMIT SWITCHES?

Left hand side of the screen box, accessed through the 2 bottom doors, look up and you will see

3 sets of limit adjustment Allen Key type switches.

Do not adjust the limit at the front of the box, this being the black steel tube that has wire cable

wrapped around it. It is not adjustable and to do so will cause damage to the unit and void any

warranty.

WHICH SWITCH IS FOR WHAT?

Inspect the switches and identify the lower motor that controls the screen surface, now look

above this to the motor that controls the masking up & down. These are the two sets of limits

you may need to adjust, again do not adjust the limit at the front of the box, this being the black

steel tube that has wire cable wrapped around it. It is not adjustable and to do so will cause

damage to the unit and void any warranty.

WHAT TOOLS DO I NEED?

Either the limit setting tool (supplied), a narrow tip screw driver (less than 4mm) or a 4mm Allen

Key

WHICH WAY DO I TURN THE SWITCH?

Either Clockwise always increases the amount of rotation (travel) of the motor.

Anti-clockwise always reduces the amount of rotation (travel) of the motor.

So pick the switch responsible for the limit position, up or down. Clockwise turning of the

switch will always let the motor travel further in that direction. Anti-clockwise turning of the

switch will lessen the amount of travel in that direction.

Now remove the tape on the brown paper that wraps the main screen and carefully motor the screen down

(please refer to Control Equipment notes below to achieve this) while applying downward pressure to the brown

paper, assisting its removal as the screen descends. Once the paper is removed you should be looking at both

screen and masking being free to travel independently.

Control Equipment

The Electricinema 235 utilises three iConnect Motor Controllers that have

been specifically programmed to work in unison. They are all controlled by

IR, with a 300mm and 2000mm long lead and sensor supplied in the kit, along

with a two channel hand held transmitter.

The three power leads exiting the screen box left hand side have been

labelled to suit the individual iConnect controllers. Please ensure the correct

leads are plugged into the motor controllers, as each unit performs a

different function.

The 3 x iConnect Motor Controllers are labelled as follows:

1. Screen – which is designed to control the screen surface – IR

Channel One

2. Masking – which is designed to control the masking up & down – IR

Channel Two

3. Motor – which is designed to work in a delayed action with the

masking motor – Channel Two

Channel One – Controls the main projection screen up and down.

Channel Two – Controls the masking up and down, and then the masking

moves to lay against screen surface, on a delayed action.

The use of momentary contacts for control is possible, with a separate pair of

momentary contacts for the main screen surface (replicating IR Channel

One) and another pair of momentary contacts, parallel wired into the two

masking motor controllers (replicating IR Channel Two).

NB: iConnect motor controllers 2 and 3 must be controlled together or damage to the screen surface may result.

Masking Tracking Adjustment:

Due to temperature and humidity the masking material may expand or contract a small amount whilst the

projection and masking material acclimatise to the installation location.

This may cause the masking to marginally track in a left or right direction when the masking is moving up or

down.

To fix the tracking issue,

1. Roll Main projection surface down.

2. Roll masking down

3. Note which direction the masking is tracking (Left or Right).

4. Open the door covering the mechanism

5. Using a small piece of masking tape, (10mm – 15mm piece) and place the tape on the back of the

masking roller opposite to the direction of the masking movement

6. Roll masking back up and confirm that masking is straight.

7. You may have to add tape or remove depending on how much the masking is moving

Now remove the tape on the brown paper that wraps the main screen and carefully motor the screen down

(please refer to Control Equipment notes below to achieve this) while applying downward pressure to the brown

paper, assisting its removal as the screen descends. Once the paper is removed you should be looking at both

screen and masking being free to travel independently.

Control Equipment

The Electricinema 235 utilises three iConnect Motor Controllers that have

been specifically programmed to work in unison. They are all controlled by

IR, with a 300mm and 2000mm long lead and sensor supplied in the kit, along

with a two channel hand held transmitter.

The three power leads exiting the screen box left hand side have been

labelled to suit the individual iConnect controllers. Please ensure the correct

leads are plugged into the motor controllers, as each unit performs a

different function.

The 3 x iConnect Motor Controllers are labelled as follows:

1. Screen – which is designed to control the screen surface – IR

Channel One

2. Masking – which is designed to control the masking up & down – IR

Channel Two

3. Motor – which is designed to work in a delayed action with the

masking motor – Channel Two

Channel One – Controls the main projection screen up and down.

Channel Two – Controls the masking up and down, and then the masking

moves to lay against screen surface, on a delayed action.

The use of momentary contacts for control is possible, with a separate pair of

momentary contacts for the main screen surface (replicating IR Channel

One) and another pair of momentary contacts, parallel wired into the two

masking motor controllers (replicating IR Channel Two).

NB: iConnect motor controllers 2 and 3 must be controlled together or damage to the screen surface may result.

Masking Tracking Adjustment:

Due to temperature and humidity the masking material may expand or contract a small amount whilst the

projection and masking material acclimatise to the installation location.

This may cause the masking to marginally track in a left or right direction when the masking is moving up or

down.

To fix the tracking issue,

1. Roll Main projection surface down.

2. Roll masking down

3. Note which direction the masking is tracking (Left or Right).

4. Open the door covering the mechanism

5. Using a small piece of masking tape, (10mm – 15mm piece) and place the tape on the back of the

masking roller opposite to the direction of the masking movement

6. Roll masking back up and confirm that masking is straight.

7. You may have to add tape or remove depending on how much the masking is moving

Continued Over.../

Limit Adjustment

The following instructions are for the adjustment of the limit switches that alter

the upper and lower stop positions on ElectriCinema 235 Projection Screen

only

Where are The Limit Switches?

Left hand side of the screen box, accessed through the 2 bottom doors, look

up and you will see 3 sets of limit adjustment Allen Key type switches.

Do not adjust the limit at the front of the box, this being the black steel tube

that has wire cable wrapped around it. It is not adjustable and to do so will

cause damage to the unit and void any warranty.

Which Switch is for What?

Inspect the switches and identify the lower motor that controls the screen surface, now look above this to the

motor that controls the masking up & down. These are the two sets of limits you may need to adjust, again do

not adjust the limit at the front of the box, this being the black steel tube that has wire cable wrapped around it.

It is not adjustable and to do so will cause damage to the unit and void any warranty.

What Tools do I Need?

Either the limit setting tool (supplied), a narrow tip screw driver (less than 4mm) or a 4mm Allen Key

Which Way do I Turn the Switch?

Clockwise always increases the amount of rotation (travel) of the motor.

Anti-clockwise always reduces the amount of rotation (travel) of the motor.

So pick the switch responsible for the limit position, up or down. Clockwise turning of the switch will always let the

motor travel further in that direction. Anti-clockwise turning of the switch will lessen the amount of travel in that

direction.

Can I adjust the switch while the screen is sitting on the limit - i.e. fully up or down?

Clockwise adjustment? – YES. But it is better to back the screen away from the limit and then adjust

Anti-clockwise adjustment? - NO you will damage the micro switch if you turn it anti-clockwise while the screen is

sitting on the limit. Never attempt this. You must back the screen away from the limit

before adjustment. After adjustment you will need to run the screen up and down to pick up the new limit

Will I void the product warranty if I damage the screen whilst making these adjustments?

Yes.

BEWARE

Rollers screens have a finite amount of leader, the standard being 300mm.

If you order a custom leader length then that becomes the finite amount.

DO NOT ADJUST THE BOTTOM LIMIT SO AS TO EXPOSE MORE THAN THIS FINITE AMOUNT

If you do you will:

Experience poor layflat of the surface which may bring complaints from your customer.

Weaken the hold of the surface on the roller and, one day, the surface will be on the floor.

THIS IS NOT COVERED UNDER WARRANTY

Should you have any questions regarding the installation of our products

Please call our sales desk on +61 2 4869 2100 for assistance