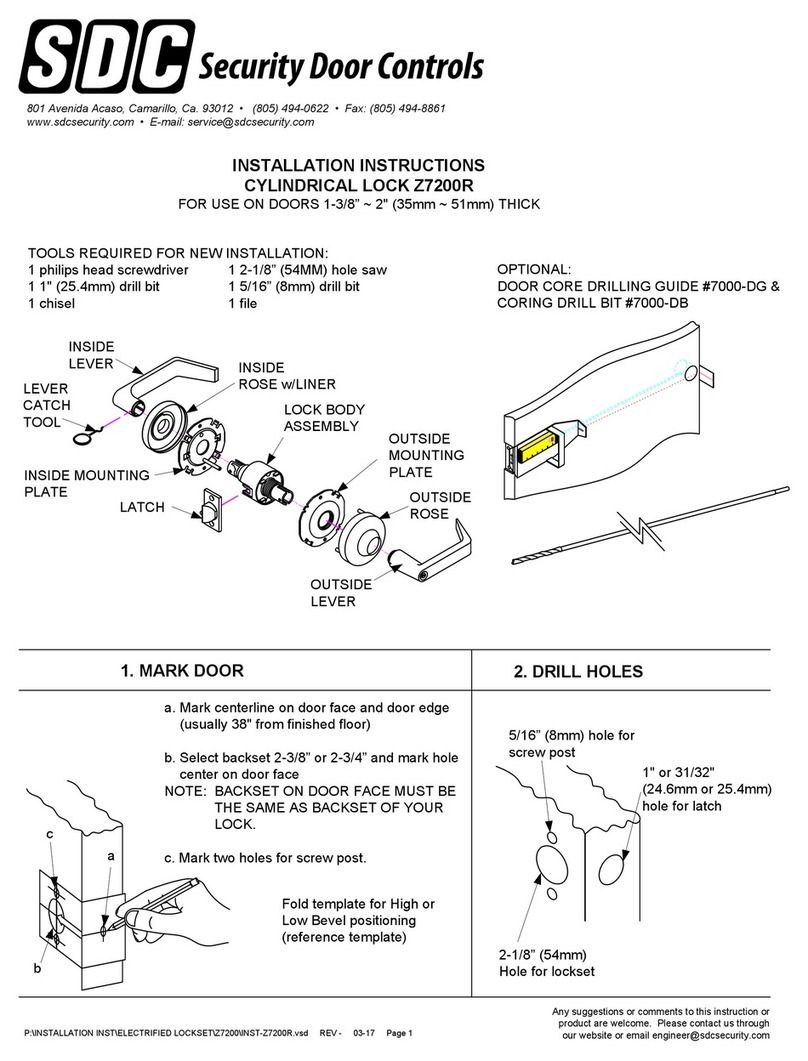

SDC ZA7200 Series User manual

Other SDC Door Lock manuals

SDC

SDC 352 Narrow Line EMLock User manual

SDC

SDC HiTower R7500 User manual

SDC

SDC 1190A Series User manual

SDC

SDC 30-4-12 User manual

SDC

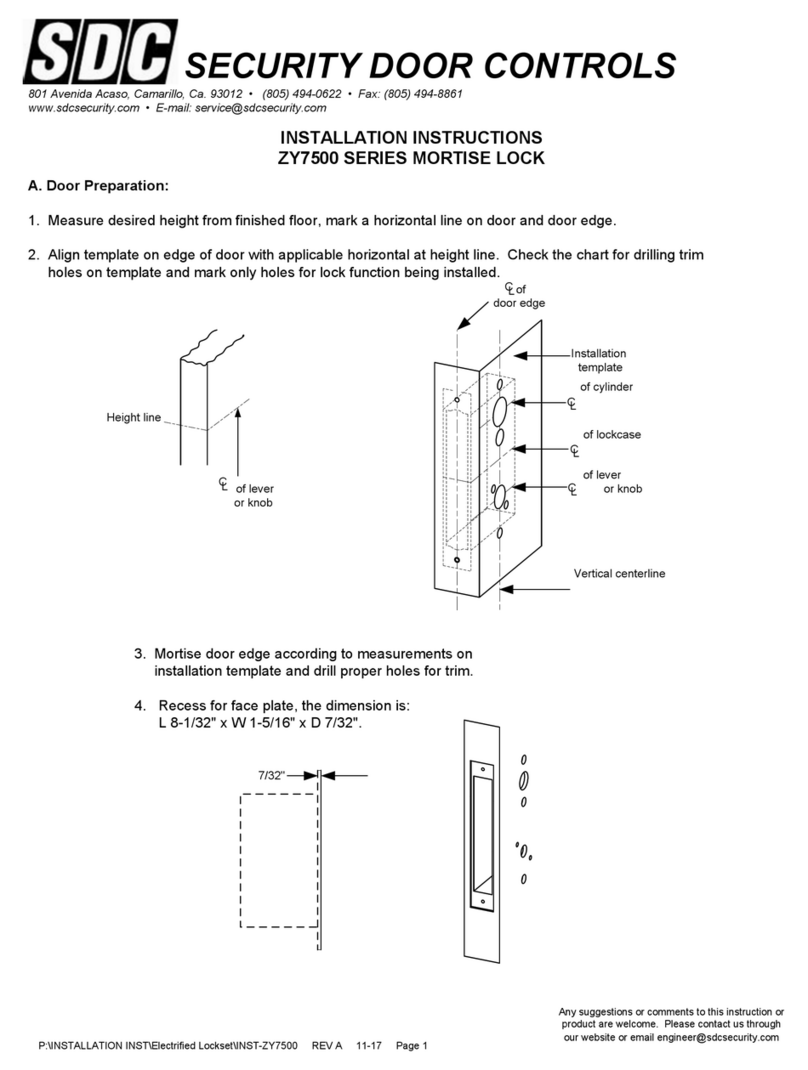

SDC Z7500 Series User manual

SDC

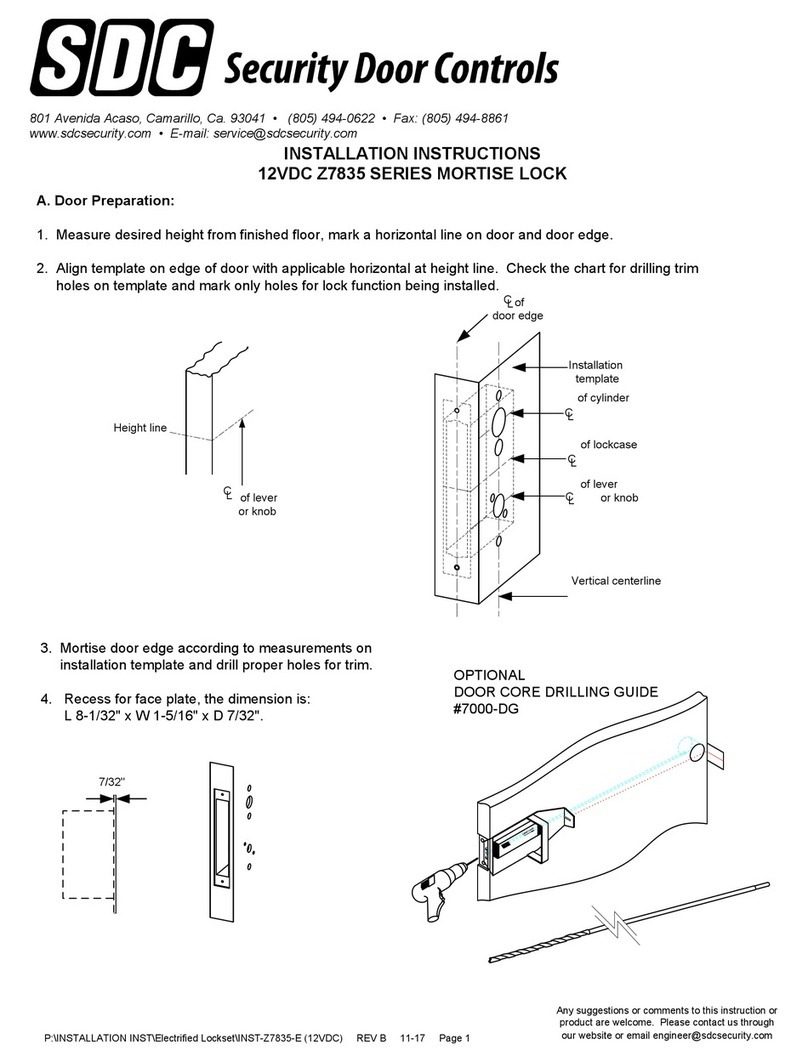

SDC Z7835 User manual

SDC

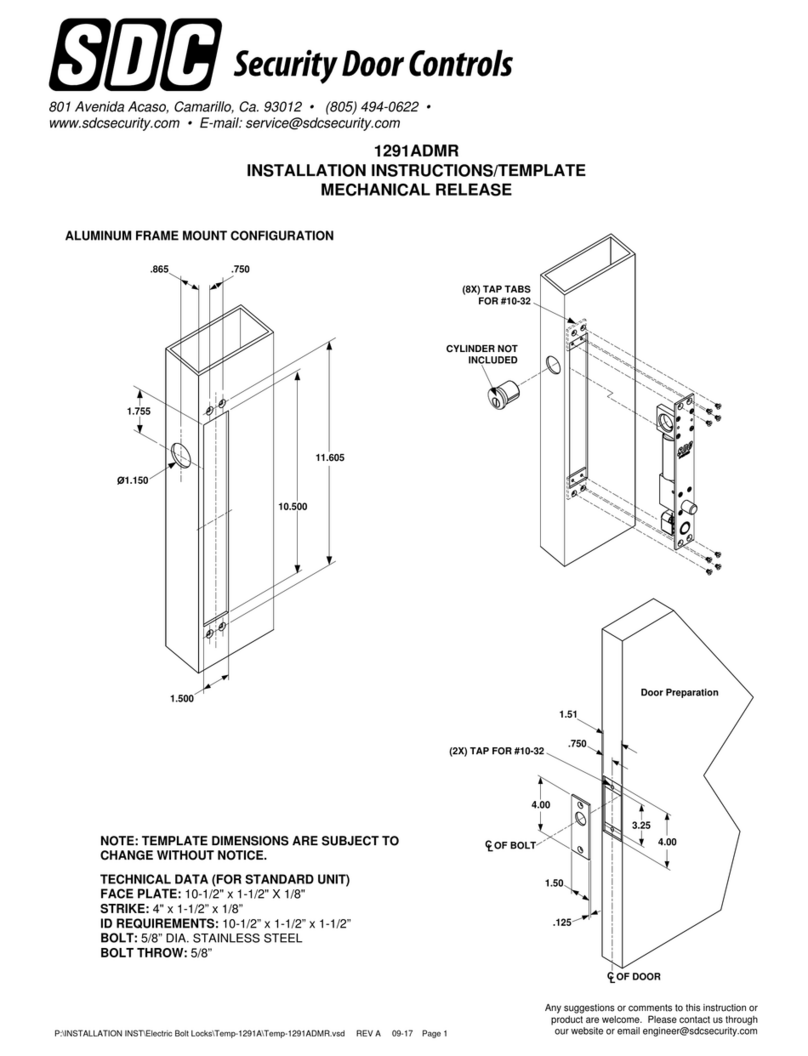

SDC Spacesaver 1091 ADMR User manual

SDC

SDC TEMPLATE 180 SERIES User manual

SDC

SDC S6200 Series User manual

SDC

SDC E75 Series User manual

Popular Door Lock manuals by other brands

SCOOP

SCOOP Pullbloc 4.1 FS Panik Assembly instruction

Yale

Yale MORTISE 8800 SERIES installation instructions

Siegenia

Siegenia KFV AS3500 Assembly instructions

Saflok

Saflok Quantum ädesē RFID installation instructions

ArrowVision

ArrowVision Shepherd 210 installation manual

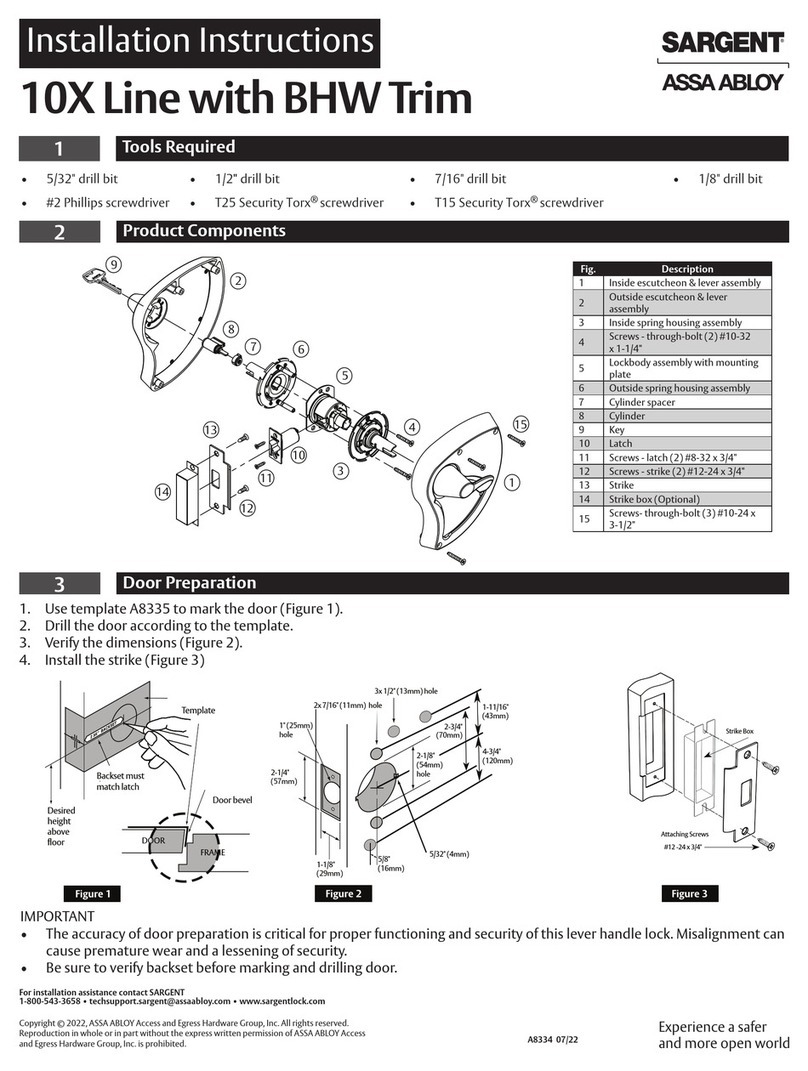

Assa Abloy

Assa Abloy Sargent 10X Line installation instructions