Original Language Version

© Jack Sealey Limited

9Avoid unintentional starting.

8DO NOT overfill tank or allow fluid level to fall below pump inlet.

8DO NOT use the tank for a task it is not designed to perform.

8DO NOT operate the tank if any parts are damaged or missing as this may cause failure and/or personal injury.

8DO NOT allow untrained persons to operate the tank.

8DO NOT operate the tank when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT leave the tank operating unattended.

9 When not in use switch off the tank, close the lid and remove the plug from the power supply.

9Dispose of waste liquids in accordance with local authority regulations.

WARNING! Protect the environment - DO NOT allow uncontrolled discharge of pollutants.

9Keep the tank clean for the best and safest performance.

2. INTRODUCTION

Heavy duty one-piece tank. Fully sealed electric motor with magnetic drive pump unit. Lid features self-latching fusible link which automatically

snaps lid shut in the event of re. Includes removable shelf and small parts basket. Flexible metal nozzle directs solvent over work. Stand tted

with four Ø100mm castors for easy manoeuvrability, two of which are lockable.

3. SPECIFICATION

Model no .......................................................................SM28

Max. working capacity..................................................... 50ltr

Min. working capacity...................................................... 40ltr

Motor power ....................................................................25W

Weight....................................................................... 26.82kg

Dimensions (W x D x H)..........................810 x 540 x 898mm

Tank dimensions .....................................810 x 540 x 260mm

Pump output/hr ............................................................. 200ltr

Supply............................................................................230V

Degreasing solvent emulsiable 20ltr............................ AK20

25ltr............................................................................... AK25

Degreasing solvent 25ltr ........................................... AK2501

20ltr........................................................................... AK2001

4. ASSEMBLY

Refer to Parts List

4.1. Remove parts from packing and take items out of the tank. Before assembly check parts to ensure they are complete and not damaged.

4.2. Close lid (4) of tank (1), gently turn unit upside down. Rest tank on a clean soft surface (i.e. cardboard) ensuring lid is secured in the

closed position.

4.3. Attach the four legs (21) to the tank brackets with the pan head screws, spring washers and hex nuts (22, 23, 24) but do not tighten.

4.4. Place the lower shelf (20) between the four legs (21) with flat surface facing downward and fix with screws, washers and hex nuts (22,

23, 24).

4.5. With the legs pressed tightly against the lower shelf, tighten all the screws commencing with those attaching the shelf.

4.6. Fit one castor wheel assembly (47) to each rear leg, and one lockable wheel (46) to each of the front legs, and secure in place with a

nut (48) and washer (49) on each.

4.7. Hold the lid closed and stand the assembled unit upright. Open the lid but do not extend the lid too far.

4.8. Place the tank work shelf (42) on the two welded supports located inside the tank.

4.9. Remove the self tapping screws (35) from the cover of the pump unit and check to see if there is any supporting packing inside. If so,

remove the supporting packing and replace the cover and tighten the screws.

4.10. Place the pump into the tank unit and pass the switch unit through the slot in the cleaning tank side. As the unit protrudes through the

slot, secure it by placing the underside lip over the edge of the tank. Attach the flexible pipe (27) to the pump.

5. OPERATION

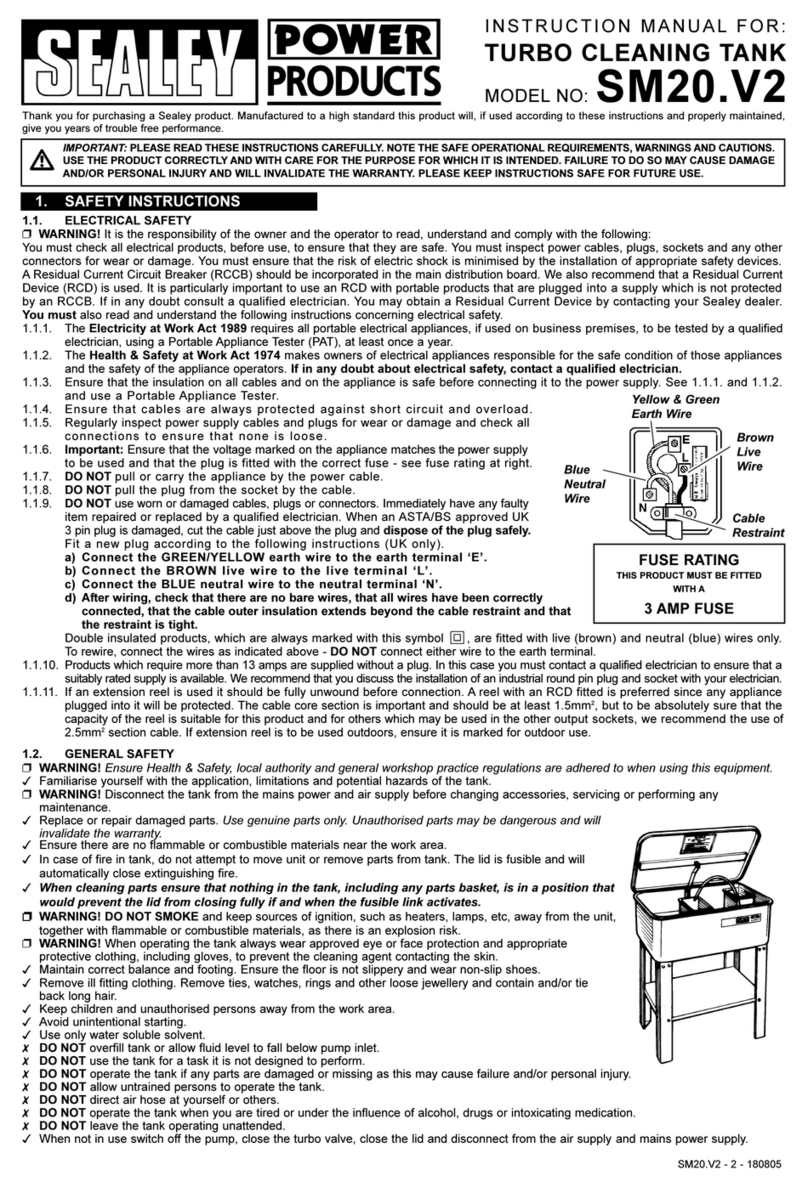

WARNING! Wear safety clothing, eye protection and gloves and ensure you read, understand and apply the safety instructions in

Section 1.

5.1. Ensure the unit is located on a firm level surface in a well ventilated area and is switched off and unplugged from the mains power supply.

5.2. Ensure the castors are locked once in position.

5.3. Fill the tank with solvent (see below), tank capacity is 50 litres. Minimum level must cover pump inlet, approximately 40 litres. Follow the

solvent’s safety instructions on its packaging.

5.4. Plug the unit into the mains power supply and switch the unit on. The cleaning agent will flow through the flexible tube.

5.5. Place parts to be washed into the basket, or directly into the tank. Direct solvent flow onto parts. Heavily soiled items may be left to soak

before cleaning.

8DO NOT leave the unit operating unattended. Check the fluid level does not fall below the pump inlet.

5.6. When cleaning is complete, remove all parts, whilst ensuring the minimum of cleaning agent spillage.

5.7. Switch off the unit, close the lid and disconnect the unit from the mains power supply. Clean up any spillage.

5.8. Dispose of waste liquids in accordance with local authority regulations.

IMPORTANT! The SM28 has an anti-fire device built into the unit. In the event of a fire, the lid will automatically close.

8DO NOT prop the lid open as this will prevent the automatic safety feature from operating.

When cleaning parts, ensure that nothing in the tank, including any parts basket, is in a position that would prevent the lid from closing

fully, if and when the fusible link activates.

Once actuated, the fire detection device cannot be re-used and must be replaced before further use.

SM28 | Issue:2 (H,F) 17/08/18