5. OPERATING INSTRUCTIONS

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

INSTRUCTIONS FOR: AIR OPERATED WATER

BASED SPRAY GUN CLEANING TANK

MODEL NO: SM233

!WARNING! Ensure Health & Safety, local authority, general

workshop practice regulations are adhered to when using

equipment.

!WARNING! Installation site must be equipped with suitable

fire extinguishers (water must not be used) and escape routes.

!WARNING! Disconnect the air supply from the tank before

changing accessories, servicing or performing any maintenance.

"Maintain the tank in good condition (use an authorised service agent).

"Replace or repair damaged parts. Use genuine parts only.

Unauthorised parts may be dangerous and will invalidate the warranty.

"Locate the tank in a suitable working area. Ensure the tank

stands on a firm level surface. Keep area clean and tidy and free

from unrelated materials. Ensure the area is well ventilated and

has adequate lighting.

!WARNING! Ensure correct air pressure is maintained and not

exceeded. Recommended pressure (40 - 60psi).

"Keep air hose away from heat, oil and sharp edges. Check air

hose for wear before each use, and ensure that all connections

are secure.

!WARNING! This tank is for use only with solvents for water

based paints.

"Use only recommended solvents as a cleaning agent, do not pour

any other type of cleaning fluid into the tank.

"Keep the tank clean. Remove and clean the suction filter regularly

for best performance.

!WARNING! DO NOT SMOKE and keep sources of ignition,

such as heaters, lamps, etc. away from the unit, together with

flammable or combustible materials, as there is an explosion risk.

!WARNING! Wear approved safety eye protection, mask and

gloves. If solvent gets on skin or in eyes wash thoroughly

with water and take any other action as required by the

solvent instructions.

"Remove ill fitting clothing, ties, watches, rings and other loose

jewellery, contain long hair, and wear appropriate protective clothing.

"Maintain correct balance and footing. Ensure the floor is not

slippery and wear non-slip shoes.

"Keep non-essential persons away from the working area.

"In case of fire in tank, do not attempt to move the unit or remove

spray guns.

#DO NOT use the tank with the lid open and DO NOT use it for

spray gun testing.

#DO NOT use the tank for any purpose other than for which it is

designed.

#DO NOT operate the tank if any parts are missing or damaged as

this may cause failure and/or possible personal injury.

#DO NOT over-fill the tank (max capacity 19 litres).

#DO NOT direct air from the air hose at yourself or others.

#DO NOT operate the tank when you are tired or under the

influence of alcohol, drugs or intoxicating medication.

"When cleaning is complete, ensure all control valves are in the

‘off’ position and that the air supply is turned off.

!WARNING! It is operator’s responsibility to ensure that there

is no uncontrolled discharge of any fluids used with this unit

and that appropriate arrangements have been made for correct

disposal of waste in accordance with government/local authority

regulations.

!WARNING! Do run the washer without the screen platform.

SM233 - 1 - 210607

2. INTRODUCTION & SPECIFICATION

SPECIFICATION:

Operating pressure . . . . . . . . . . . . . . . . . . . . . . . . . .40-60 psi

Air consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4 cfm

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75db

Interior tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Polythene

Cleans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 pots + 2 guns

Water capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19ltr

Width x depth x height . . . . . . . . . . . . . . .470 x 650 x 1000mm

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33.5kg

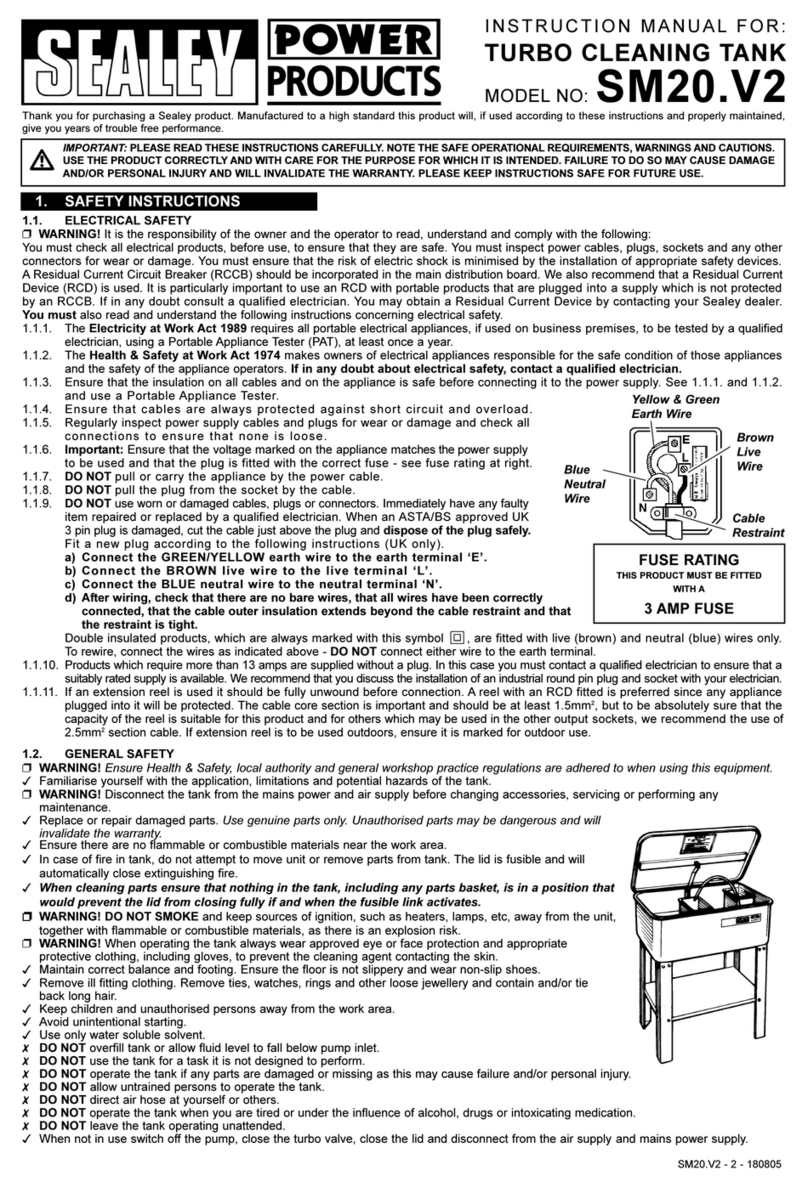

NOTE: The air supply for the SM233 must be equipped with a

regulator, filter/separator and oiler in order to ensure safe

operation and to prolong the life of the product. These items are

not supplied and must be purchased separately.

Consult your local Sealey dealer for a suitable product.

For recommended hook-up, see diagram below.

4.1.Ensure that the pump air valve and air inlet ball valve are closed

before connecting the air supply. See fig.3.

4.2.An air pressure of 40-60psi, and an available air volume of

2 - 4cfm will be required to operate the unit.

!WARNING! Ensure air supply is clean and does not exceed

60psi. Too high an air pressure and/or unclean air will

shorten the product life due to excessive wear, and may be

dangerous, causing possible damage and personal injury.

4.3.Drain the air supply tank daily. Water in the air line will damage

the unit.

4.4.Clean the air supply filter weekly.

4.5.Line pressure should be increased to compensate for unusually

long air hoses (over 8 metres). The minimum hose internal

diameter should be 10mm and fittings must have the same

internal dimension.

4.6.Keep hose away from heat, oil and sharp edges. Check hoses for

wear, and make certain that all connections are secure.

4.7.The air inlet connection is 1/4”NPT.

4. AIR SUPPLY

HOOK-UP

3. ASSEMBLY

Refer to fig.4.

3.1.Attach legs to the cabinet with the screws, washers and nuts

provided . Fit drain valve to base of tank.

Fully enclosed, corrosion resistant tank suitable for containing

water and detergent necessary for cleaning spray guns using

water-based paint. Powerful and reliable diaphragm pump system

washes up to two guns simultaneously. Semi automatic operation.

!WARNING! Ensure you follow the safety instructions.

Wear approved safety gloves, goggles, mask, and

suitable clothing.