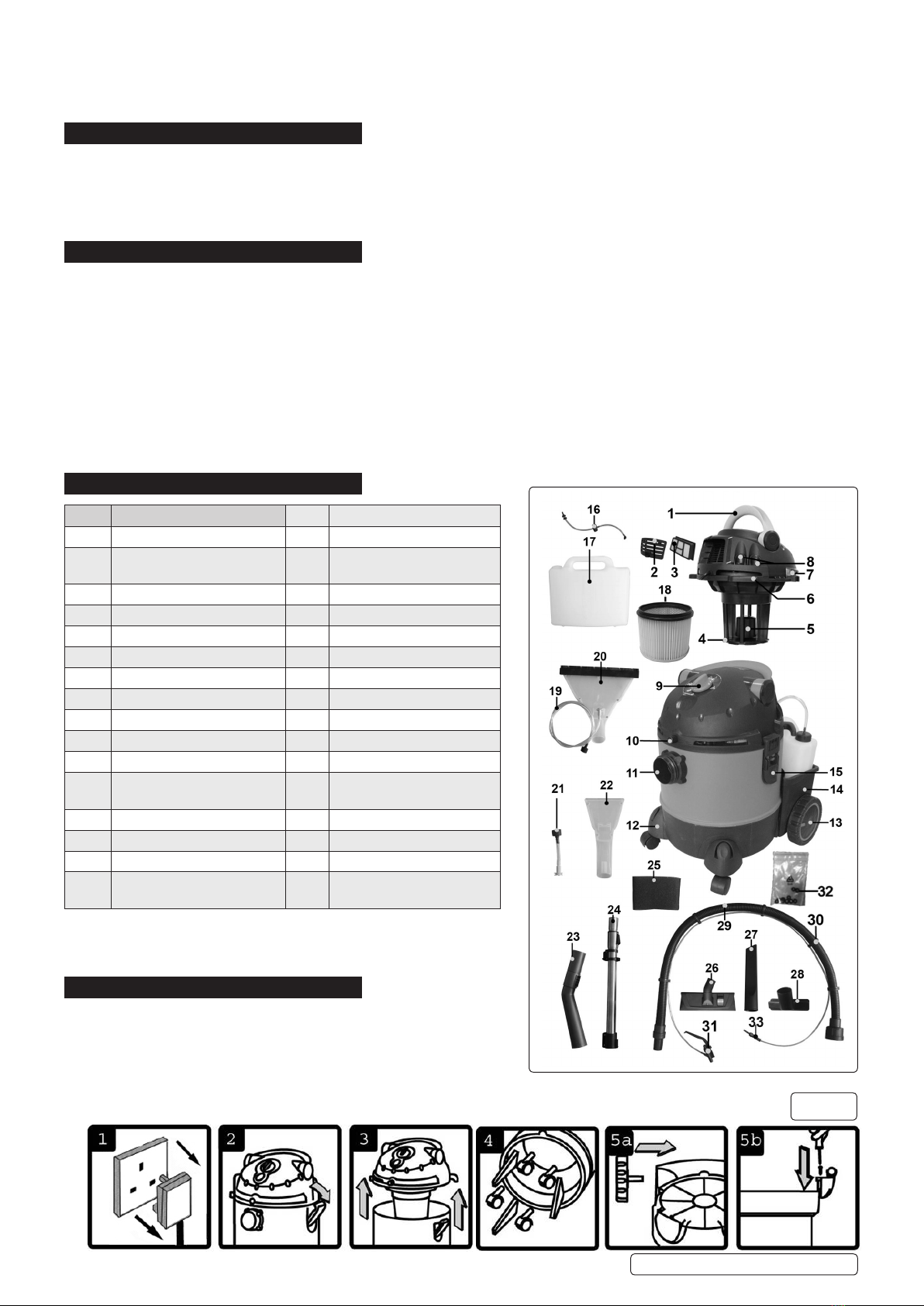

20L WET & DRY VALETING MACHINE

WITH ACCESSORIES 1250W

MODEL NO: PC310

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

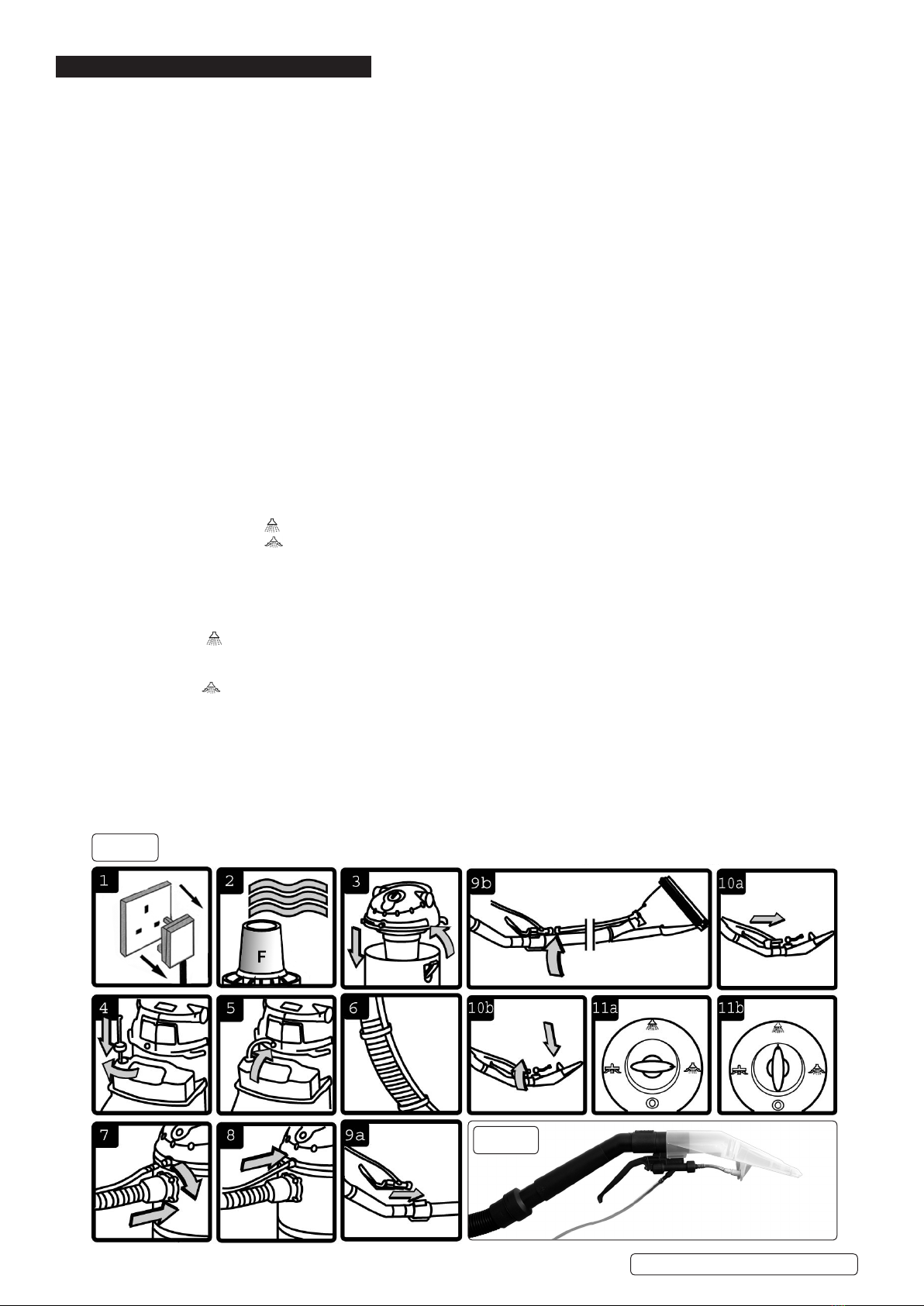

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and all

electrical connections for wear and damage. Ensure the risk of electric shock is minimised by the installation of appropriate safety

devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main distribution board. We recommend that

an RCD (Residual Current Device) is used with all electrical products. It is particularly important to use an RCD with portable products

thatarepluggedintoasupplynotprotectedbyanRCCB.Ifindoubtconsultaqualiedelectrician.YoumayobtainanRCDby

contacting your local Sealey dealer. Electrical safety information, it is important that the following information is read and understood.

1.1.1. TheElectricityatWorkAct1989requiresthatallportableelectricalappliances,ifusedonbusinesspremises,aretestedbyaqualied

electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those appliances

andthesafetyoftheapplianceoperators.Ifinanydoubtaboutelectricalsafety,contactaqualiedelectrician.

1.1.3. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply. See 1.1.1. and use a

PORTABLE APPLIANCE TESTER

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

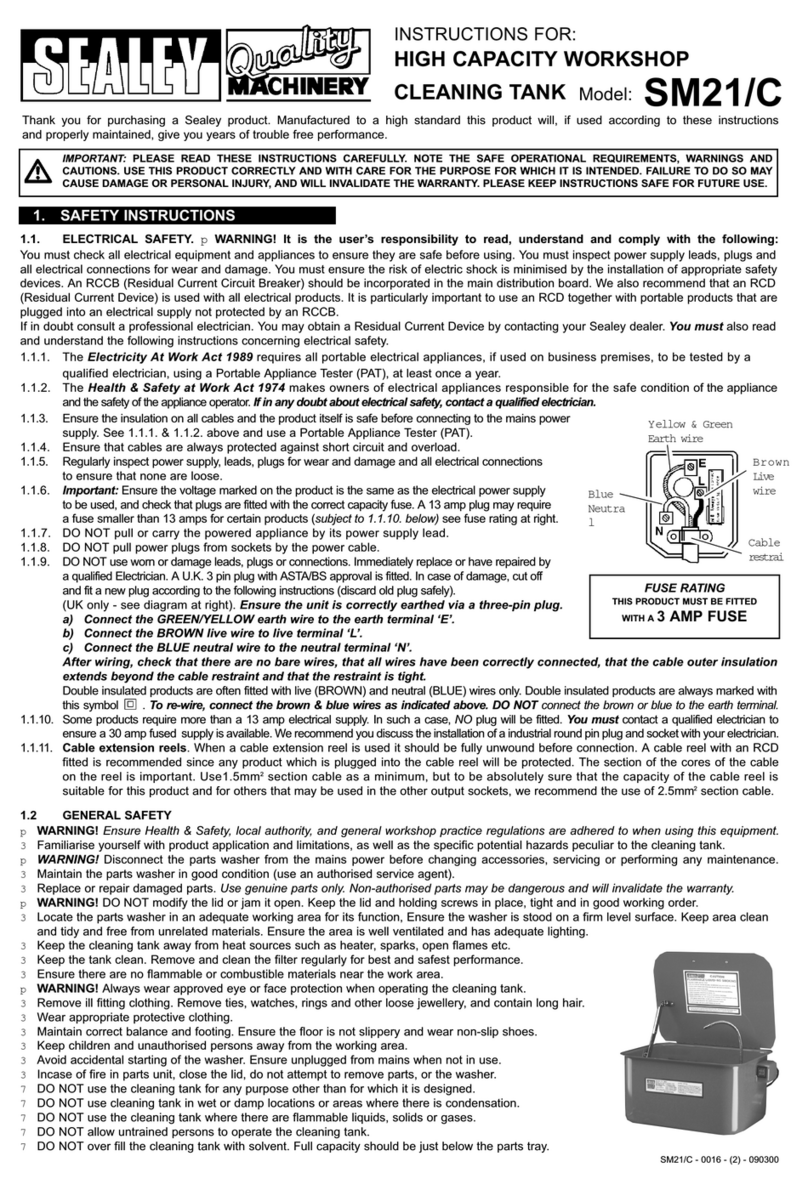

IMPORTANT:Ensurethatthevoltageratingontheappliancesuitsthepowersupplytobeusedandthattheplugisttedwiththe

correct fuse - see fuse rating in these instructions.

8DO NOT pull or carry the appliance by the power cable.

8DO NOTpulltheplugfromthesocketbythecable.Removetheplugfromthesocketbymaintainingarmgripontheplug.

8DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired or replaced immediately by a

qualiedelectrician.

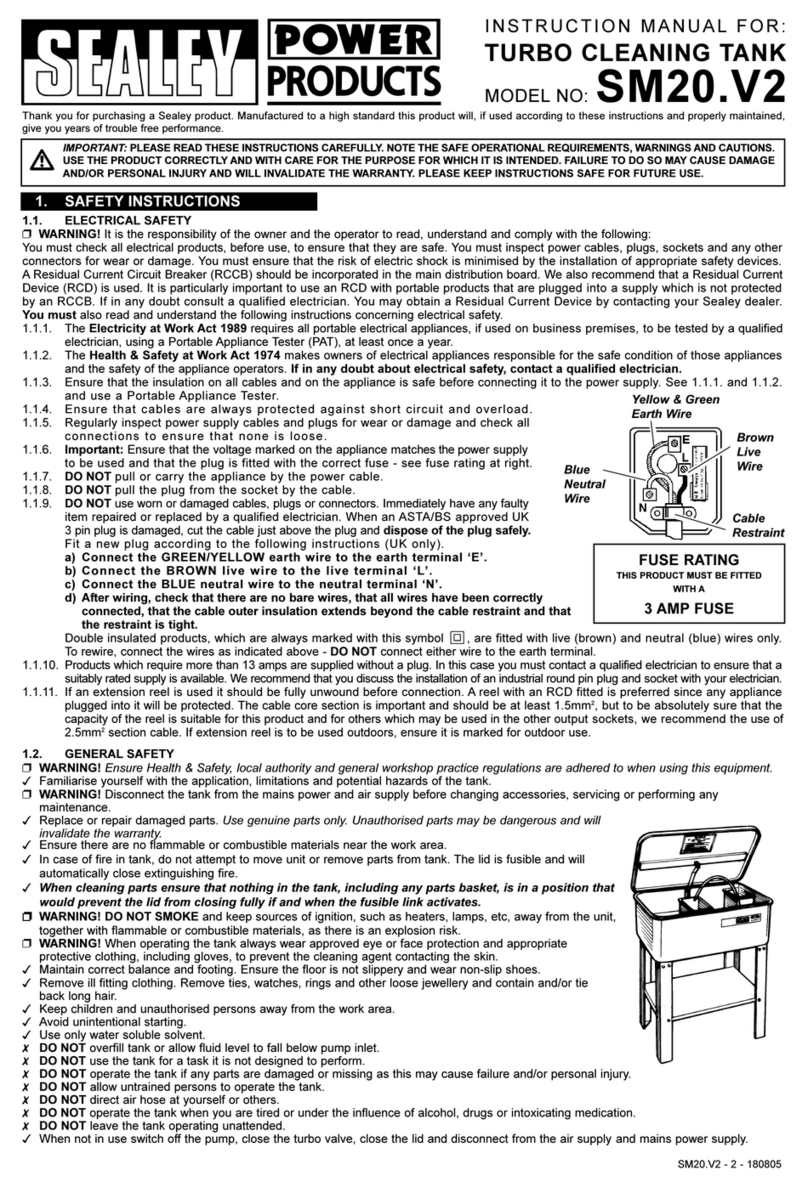

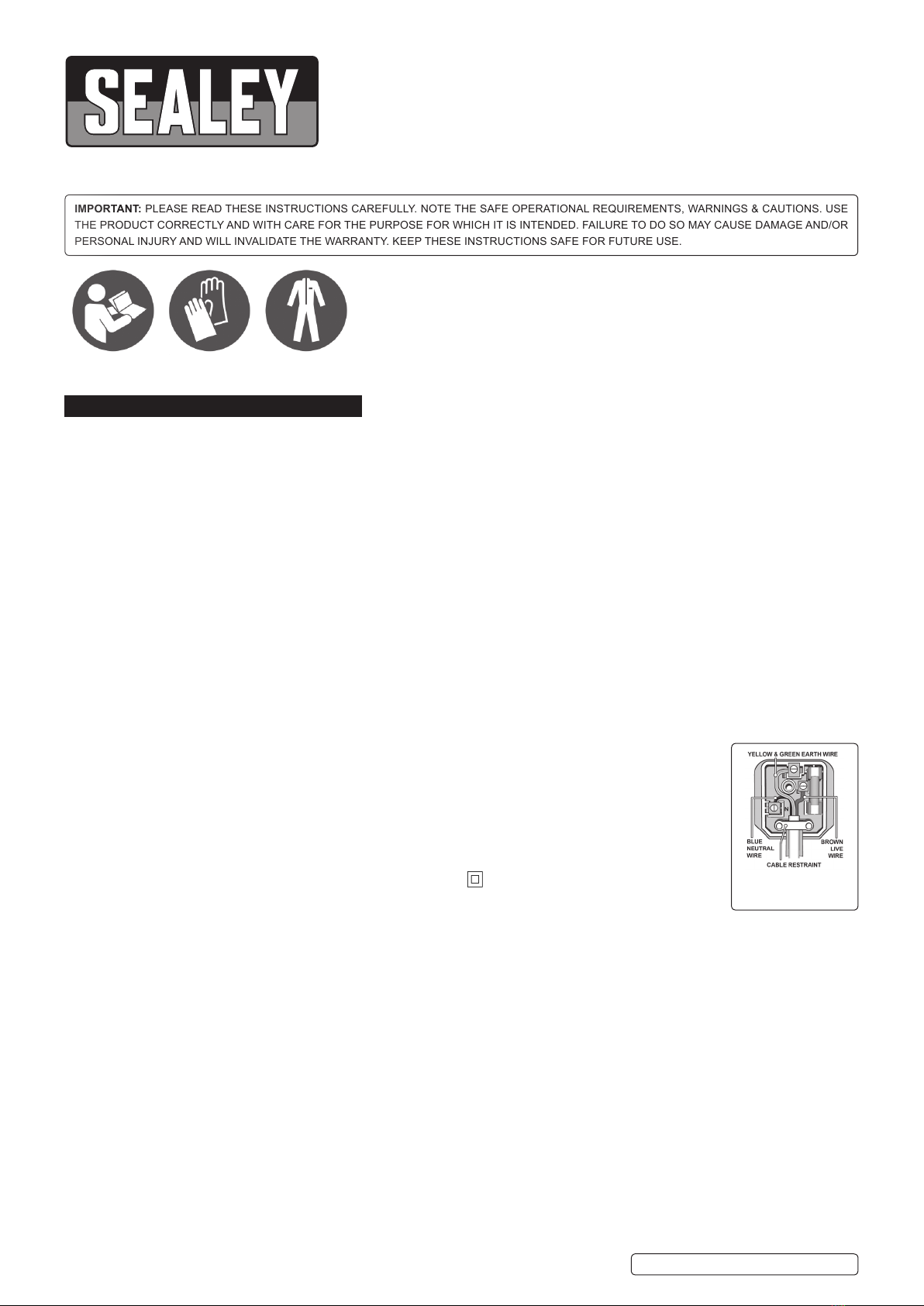

1.1.6. ThisproductisttedwithaBS1363/A13Amp3pinplug.Ifthecableorplugisdamaged,removefromuse

andensurethatrepairsarecarriedoutbyaqualiedelectrician.

ReplaceadamagedplugwithaBS1363/A13A3pinplug.Ifindoubtcontactaqualiedelectrician.

a) ConnecttheGREEN/YELLOWearthwiretotheearthterminal‘E’.

b) ConnecttheBROWNlivewiretotheliveterminal‘L’.

c) ConnecttheBLUEneutralwiretotheneutralterminal‘N’.

d) After wiring, check that there are no bare wires and ensure that all wires have been correctly connected.

Ensure that the cable outer sheath extends beyond the cable restraint and that the restraint is tight.

Double insulated products are marked with the Class II symbol; Class II products are wired with live

(brown) and neutral (blue) only.

To rewire, connect the wires as indicated in diagram. DO NOT connect either wire to the earth terminal.

1.1.7. Productswhichrequiremorethan13ampsaresuppliedwithoutaplug.Contactaqualiedelectriciantoensurethatasuitablyrated

supplyisavailable.Ensurethatanindustrialroundpinplugandsocketarettedbyaqualiedelectrician.

1.1.8. If an extension cable reel is used, ensure that it is fully unwound before connection. Use a reel that includes an RCD, an appliance

will be protected by the RCD. The cable core section is important and should be at least 1.5mm2. Ensure that the cable of the reel is

appropriate for this product. We recommend the use of 2.5mm² core section cable.

1.2. GENERAL SAFETY

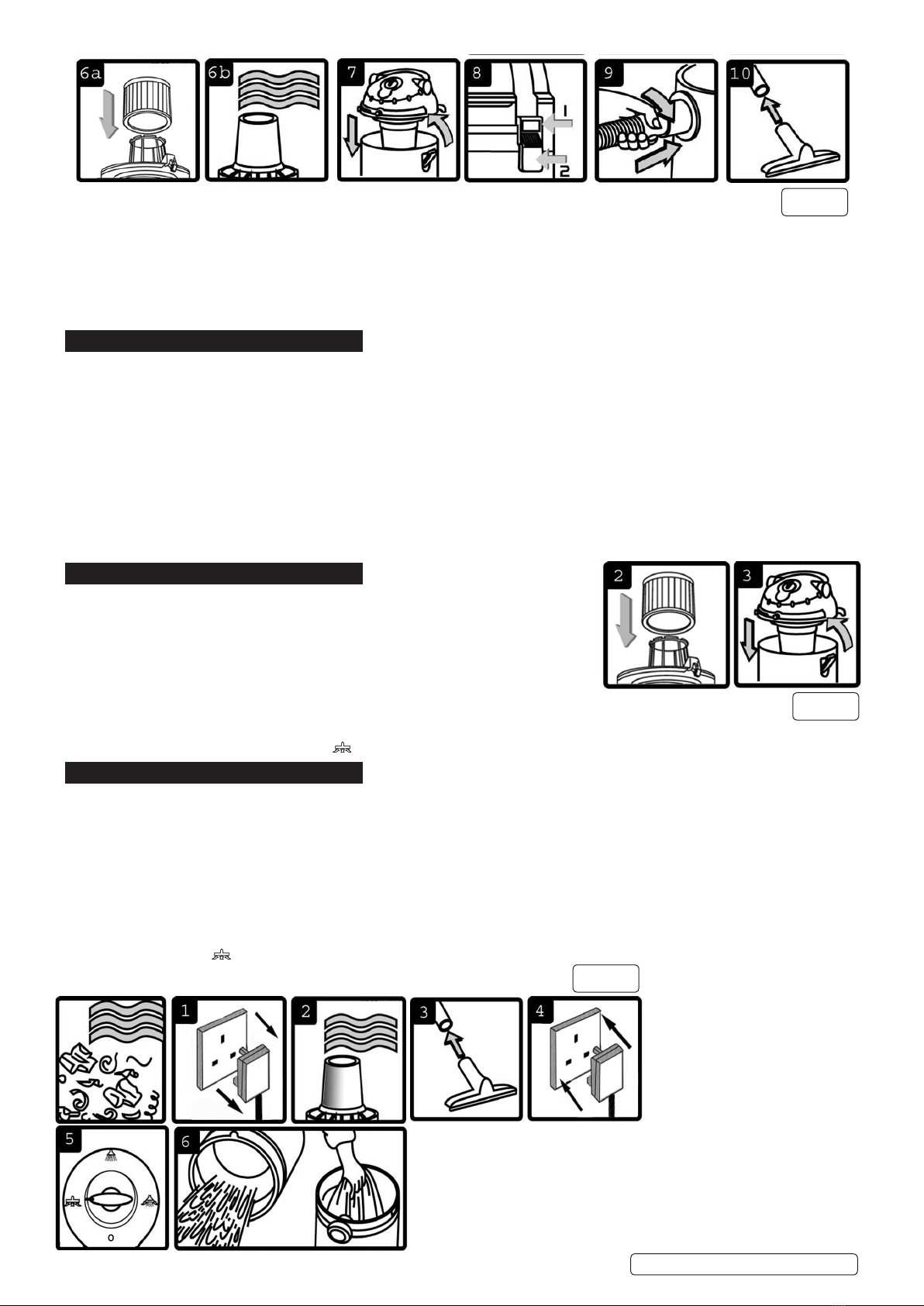

WARNING! Disconnect the cleaner from the power supply before servicing, changing accessories, or performing any maintenance.

9Use only genuine parts and accessories. Unauthorised parts and accessories may be dangerous and will invalidate your warranty.

9Maintain the cleaner in good condition. Use an authorised agent for servicing. Keep machine clean, but DO NOT use solvents.

8DO NOToperatetheunitwithoutthelockingcartridgelterinplace(exceptwhenwetvacuumingwhenthefoamsleevelterisused).

Usingthecleanerwithoutalockingcartridgelterwillcausemachinefaultsandwillinvalidateyourwarranty.

9Wear protective clothing and gloves.

8DO NOT allow children or untrained persons to operate the cleaner.

8DO NOT place attachments close to your face (especially eyes, ears, etc). DO NOT point the hose end at other persons or animals.

▲DANGER! DO NOTvacuumhotorglowingash,cigaretteends,inammable,explosive,corrosiveorotherdangeroussubstances.

8DO NOT leave machine running unattended. Turn power supply OFF and DO NOT leave the vicinity until motor has come to a

complete stop.

8DO NOToperatethecleanerwhileundertheinuenceofdrugs,alcoholorimpairingmedication,orifyouaretired.

8DO NOT use the cleaner in the rain or in very damp conditions.

WARNING! The warnings, cautions and instructions in this manual cannot cover all possible conditions and situations that may occur.

IMPORTANT: It must be understood by the operator that common sense and caution are factors which cannot be built into this

product, but must be applied by the operator.

PC310|Issue8(H,F,1...)08/08/2019

Original Language Version

© Jack Sealey Limited

Refer to

instructions

Wear protective

gloves

Wear protective

clothing

Recommended fuse rating

13 Amp