INSTRUCTIONS FOR:

TOPCHEST 9 DRAWER/ ROLLCAB 14 DRAWER,

BALL BEARING RUNNERS, HEAVY DUTY - RED

MODEL No's:AP420913T/AP421413T

Thank you for purchasing a Sealey product. Manufactured to a high standard these products will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCTS CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH THEY ARE INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

2. INTRODUCTION

3. SPECIFICATION

AP420913T

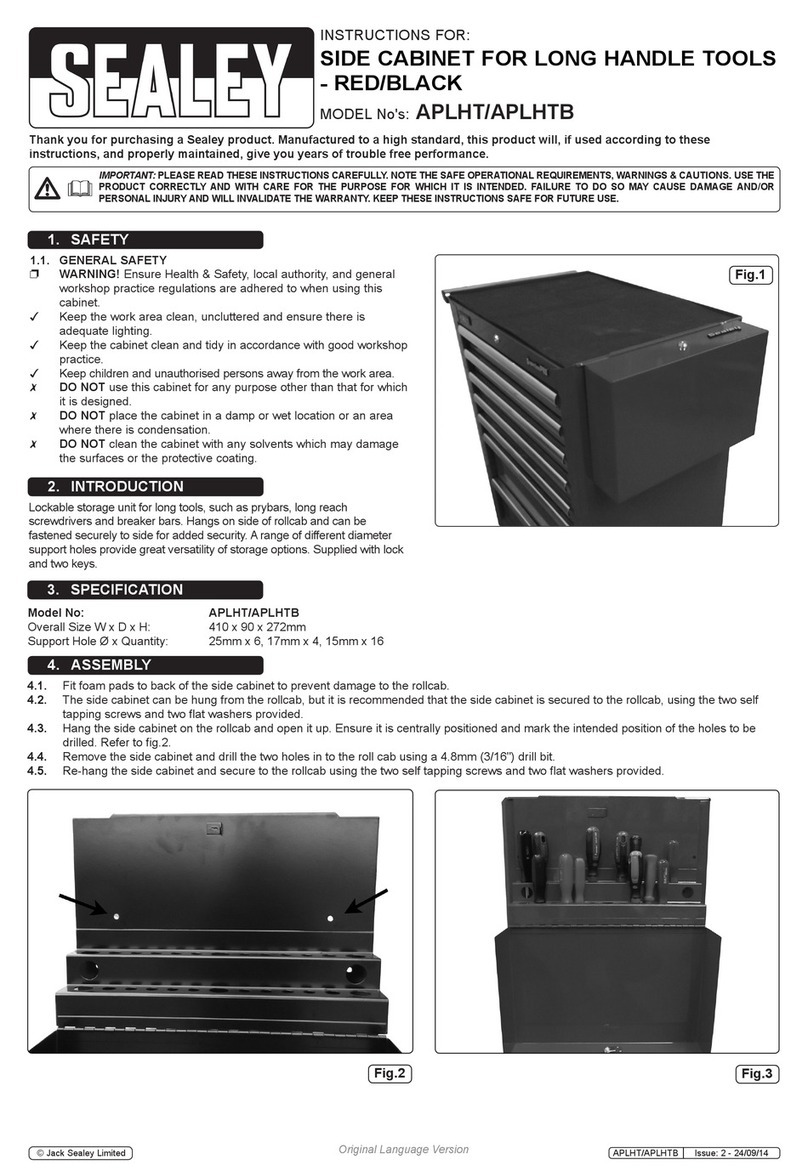

Heavy gauge steel construction for strength and durability. Sealey embossed topchest lid tted with gas dampers for smooth opening and

closing. All drawers are on heavy duty ball bearing runners for ease of use and heavier loads. Drawers have stainless steel pulls, non-slip

liners are compatable with Sealey Premier Line tool trays. External features are: rust and solvent resistant powder coated nish; heavy duty side

handles and side storage areas. An integral locking system secures all drawers with the turning of one key. For use alone or in conjunction with

AP421413T rollcab.

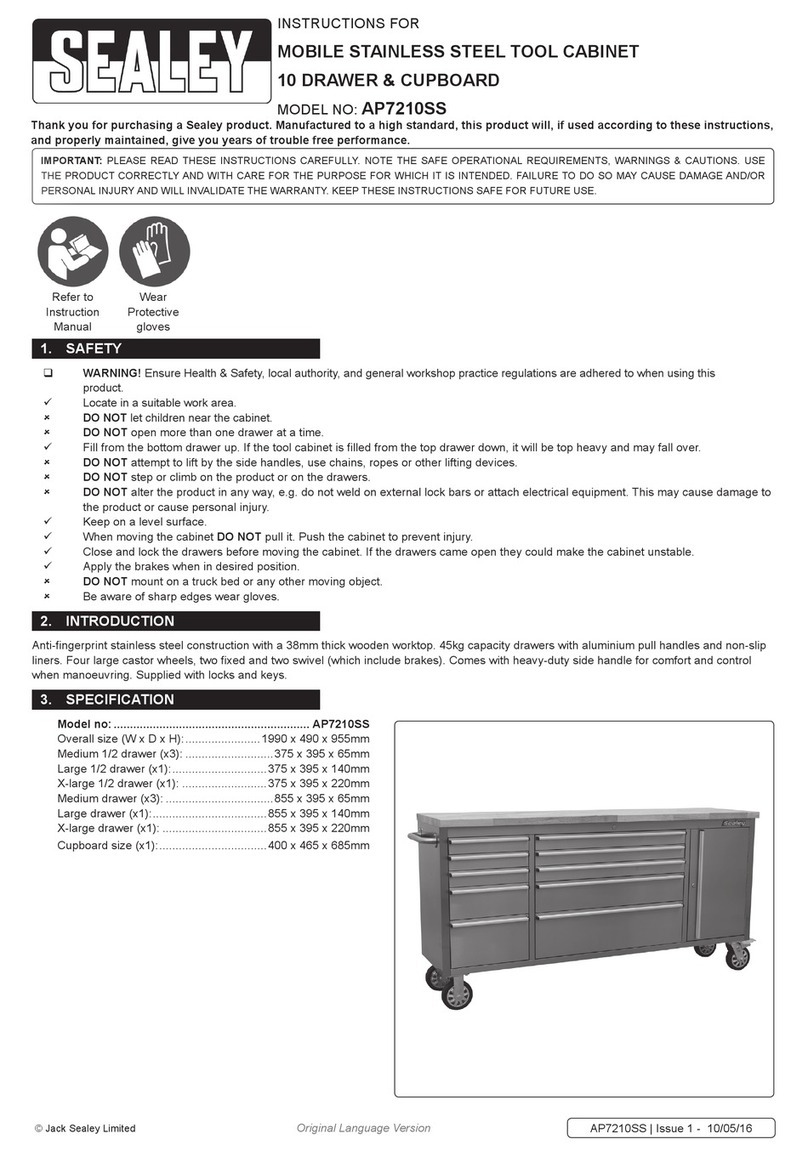

AP421413T

As above plus bumpers to protect rollcab and surrounding objects when unit is moved. Four composite Ø125mm wheels, two castors with toe

locks and two xed wheels, make for easy maoeuvrability using heavy duty side handles. Supplied with two keys.

Topchest Model No: AP420913T

Overall Size W x D x H: 1150x470x525mm

Large Drawer (x5): 530x390x50mm

Medium Drawer (x1): 350x390x120mm

Small Drawer (x3): 350x390x50mm

Top Tray: 1060x420x45mm

Rollcab Model No: AP421413T

Overall Size W x D x H: 1200x500x1060mm

Large Drawer (x1): 900x395x55mm

Medium Drawer (x1): 530x395x130mm

Medium Drawer (x2): 350x395x130mm

Small Drawer (x6): 530x395x50mm

Small Drawer (x4): 350x395x50mm

Original Language Version

© Jack Sealey Limited

1.1. GENERAL SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using these units.

Locate the units in a suitable work area.

Keep the work area clean, uncluttered and ensure there is adequate lighting.

WARNING! Use the Rollcab on level and solid ground, preferably concrete.

Keep the units clean and tidy in accordance with good workshop practice.

Keep children and unauthorised persons away from the work area.

DO NOT use these units for any purpose other than that for which they are designed.

DO NOT use the units outdoors.

DO NOT place the units in a damp or wet location or an area where there is condensation.

DO NOT clean the units with any solvents which may damage the surfaces or the protective coating.

DO NOT move the units with the drawers out. To avoid tipping, open one drawer at a time and close and secure all drawers whilst

moving the rollcab.

DO NOT step on the drawers.

DO NOToverload the drawers.

AP420913T, AP421413T Issue: 1 - 19/06/13

4. ASSEMBLY AND USE

4.1. These units are heavy, obtain the help of at least one other person before attempting to unpack them.

AP421413T

4.2. Attach the wheels to the bottom of the rollcab using 4 bolts and washers per wheel. Two of the wheels have brakes on them, ensure

these are xed to one side.

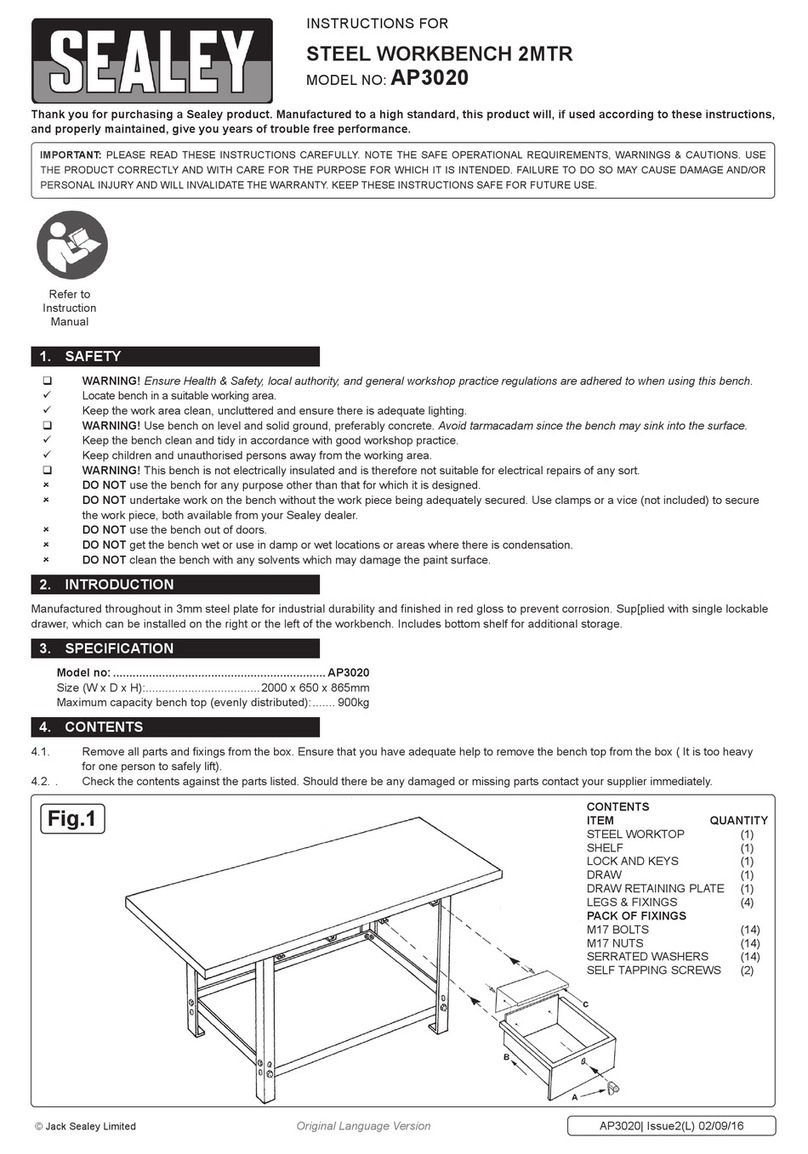

AP420913T & AP421413T

4.3 Fit the external tool holder and screwdriver racks to the outside using the screws provided.

AP420913T

4.4 To unlock the topchest turn the key clockwise and lift open the lid to allow the two draw locking buttons to disengage and allow the

drawers to be opened. To lock the topchest, close the lid, ensure all drawers are fully in, and turn the key counter clockwise.

AP421413T

4.5 To lock the rollcab, ensure all drawers are fully in and turn the key counter clockwise.

4.6 To remove a draw, the black retaining clips need to be released. Push the left hand side clip down, and pull the right hand side clip up

simultaneously and pull the drawer out. To re-install drawers, place the drawer onto the slides and push in fully.

4.7. Periodically lubricate wheel axles and ensure all nuts and bolts are tight. Lubricate the top and bottom channels of the drawer slides

at least twice a year.