4

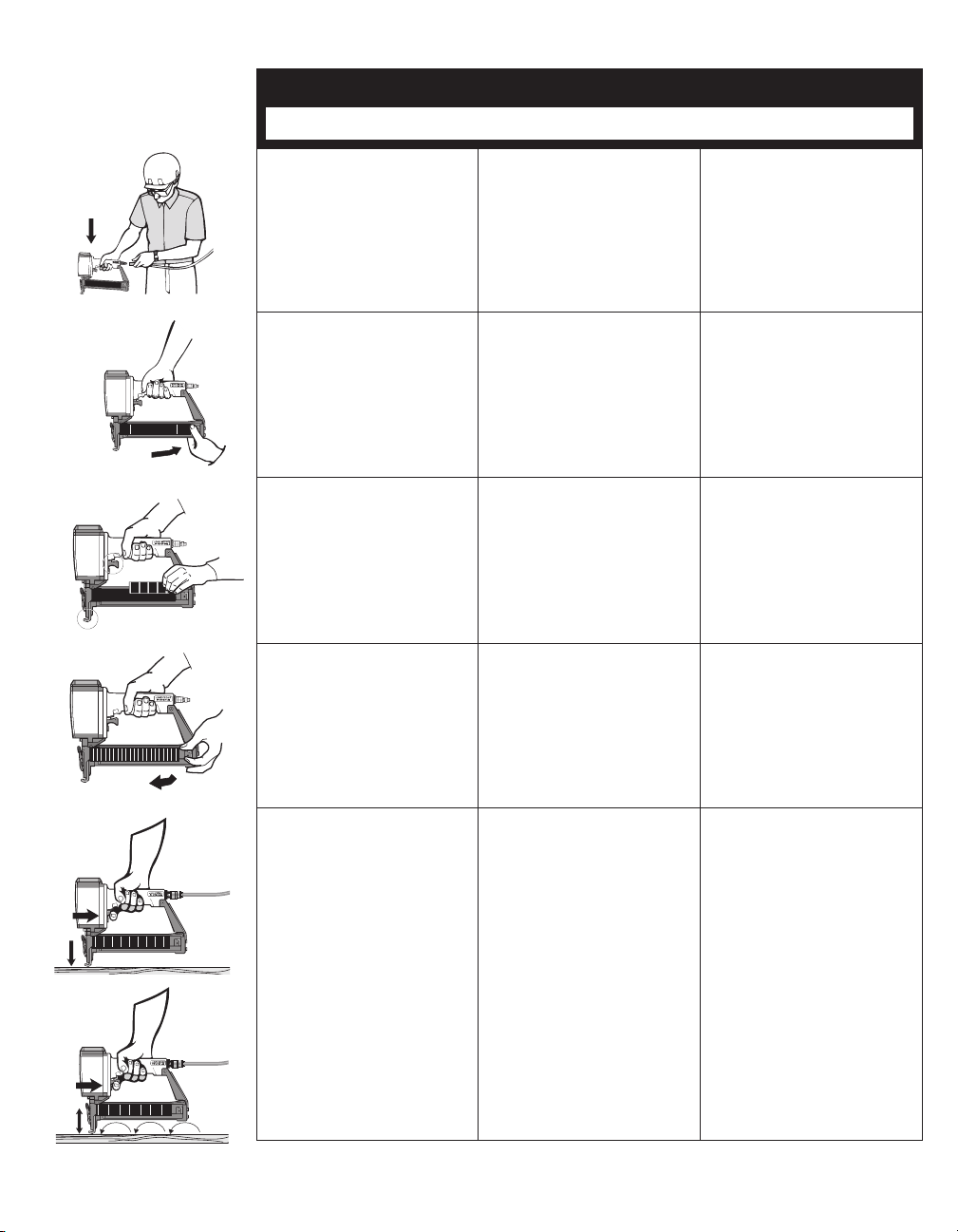

l Connect air supply and replace

fasteners. Release feeder shoe

and slide it forward.

l Conecte el suplemento de aire

y reemplace las grapas. Suelte

el alimentador y deslice hacia

adelante.

l Reconnecter l’appareil à la

source d’air comprimé et repla-

cer les agrafes.

English Español Français

Tool Use Uso de la Herramienta

Utilisation de l’Outil

3

1

2

lLas herramientas con “Ga-

tillo Restringido” solamente se

pueden disparar con el gatillo.

Primero apriete el elemento de

seguridadcontralasuperciede

trabajoydespuéstiredelgatillo.

Ésta característica es útil cuando

serequiereprecisiónenlacolo-

cacióndelossujetadores.

lLea el “Recordatorio de Seguri-

dadySatisfaccióndelCliente”

(CSSR)enlascajasdesujetado-

res y de las herramientas para in-

formaciónsobreseguridaddelos

GatillosRestringidoydeAcción

Dual.Bajociertascondiciones,el

Gatillo Restringido puede reducir

la posibilidad de heridas a su

personaoaotrosquetrabajen

con usted.

lWith a “Sequential” (Restric-

tive) trigger, nails can only be

driven one way. First depress

workpiece contact (safety ele-

ment) against work surface then

pull trigger.This feature is helpful

when precise fastener place-

ment is required.

lRead the “Customer Satisfaction

and Safety Reminder” (CSSR)

in the tool and fastener boxes

for safety information regarding

the Contact-Actuation and Se-

quential triggers. Under certain

conditions, the Sequential trigger

may reduce the possibility of

injurytoyouortoothersworking

with you.

lAvec une gachette “restrictive”,

les clous ne peuvent être tirés

que dans une seule direction.

Appuyer d’abord le palpeur de

sécurité sur la surface de travail,

puis tirer sur la gachette. Cette

fonction est utile pour un place-

mentprécisdeprojectiles.

lLire le “Rappel de Sécurité et

Satisfaction du Client” (CSSR)

danslesboitesàoutilsetxa-

tions pour les informations de

sécurité concernant les Détentes

à Double Action et à Restriction.

Dans certaines circonstances, la

Détente à Restriction peut rédu-

ire la possibilité de se blesser ou

de blesser d’autres personnes.

l This tool is equipped with a

depth control safety element.To

adjustthedepthofthestaple

being driven, loosen the screw

and slide the lower safety

element up or down and lock in

place by tightening the screw. Be

sure the safety element moves

freelyafteradjustment.

l Esta herramienta está equipada

con un dispositivo de seguridad

para el control de la profundidad.

Paraajustarlaprofundidaddela

grapaaclavar,aojeeltornilloy

deslice el dispositivo de seguri-

dad inferior hacia arriba o hacia

abajoyasegúreloapretandoel

tornillo. Asegúrese de que el dis-

positivo de seguridad se mueva

librementedespuésdelajuste.

l Cet appareil est équipé d’un ré-

glage en profondeur d’agrafage.

Pour régler la pénétration de

l’agrafe, désserrez la vis et faites

glisser vers le haut ou le bas la

partie inférieure du palpeur de

sécurité. Bloquez-le en position

par l’intermédiaire de la vis.

Assurez-vous que le palpeur de

sécurité bouge librement, une

fois le réglage fait.

l Shouldanailjamoccur,discon-

nect air supply.

l Si se produce un altascamiento

de un clavo, desconecte el

suministro de aire.

l Si un enrayage se produit, cou-

pez l’arrivée d’air.

l Pull feeder shoe back into

“locked” position and remove

staples.

l Tire del alimentador hacia atrás

alaposición“cerrada”yretire

las grapas.

l Tirez en arrière le sabot du

chargeur dans la position de

“verrouillage” et enlevez les

projectiles.

l Release E-Z Clear latch and

open door.

Removejammedfastener.Close

door and latch.

l Suelte el pestillo de alivio fácil

(E-Z) y abra la puerta. Retire la

grapa atascado. Cierre la puerta

con pestillo.

l Relâchez le loquet “E-Z” et

ouvrez le volet de front.

Enlevezleprojectilecoincé.

Fermez le volet de front et le

loquet.