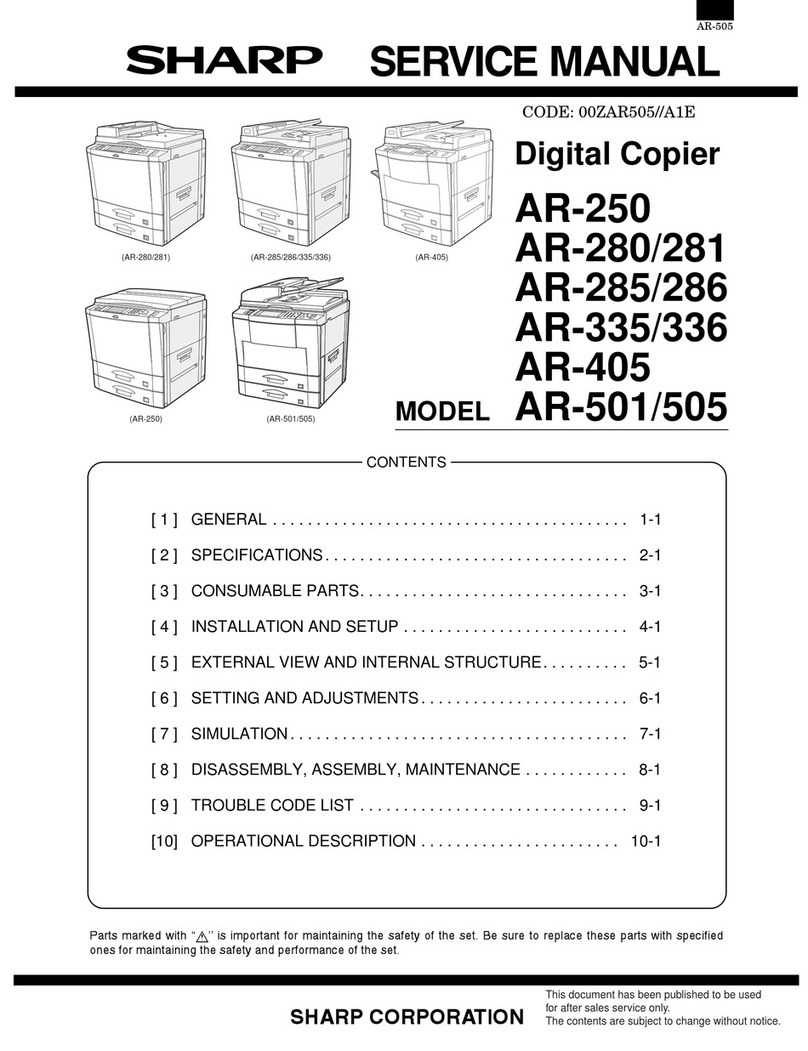

AR-5520 SPECIFICATIONS 3-1

[3] SPECIFICATIONS

1. Copy mode

A. Type

B. Machine composition

(1) Option

C. Copy speed

(1) Engine speed (ppm)

(2) Document replacement speed (Copy mode)

S to S : Tray1 A4/8.5”X11” document 11 sheets (11 pages), copy 1 set

S to D : Tray1 A4/8.5”X11” document 22 sheets (22 pages), copy 1 set

D to D : Tray1 A4/8.5”X11” document 11 sheets (22 pages), copy 1 set

(3) Job efficiency

S to S : Tray1 A4/8.5”X11” document 10 sheets (10 pages), copy 5 sets

S to D : Tray1 A4/8.5”X11” document 10 sheets (10 pages), copy 5 sets

D to D : Tray1 A4/8.5”X11” document 10 sheets (20 pages), copy 5 sets

(4) First copy time

600x300dpi, AE mode, A4/Letter, single surface copy with OC, in polygon

ready state

D. Document

E. Paper feed

(1) Paper feed section details

(2) Feedable paper

Type Desk-top

Paper exit Wing less

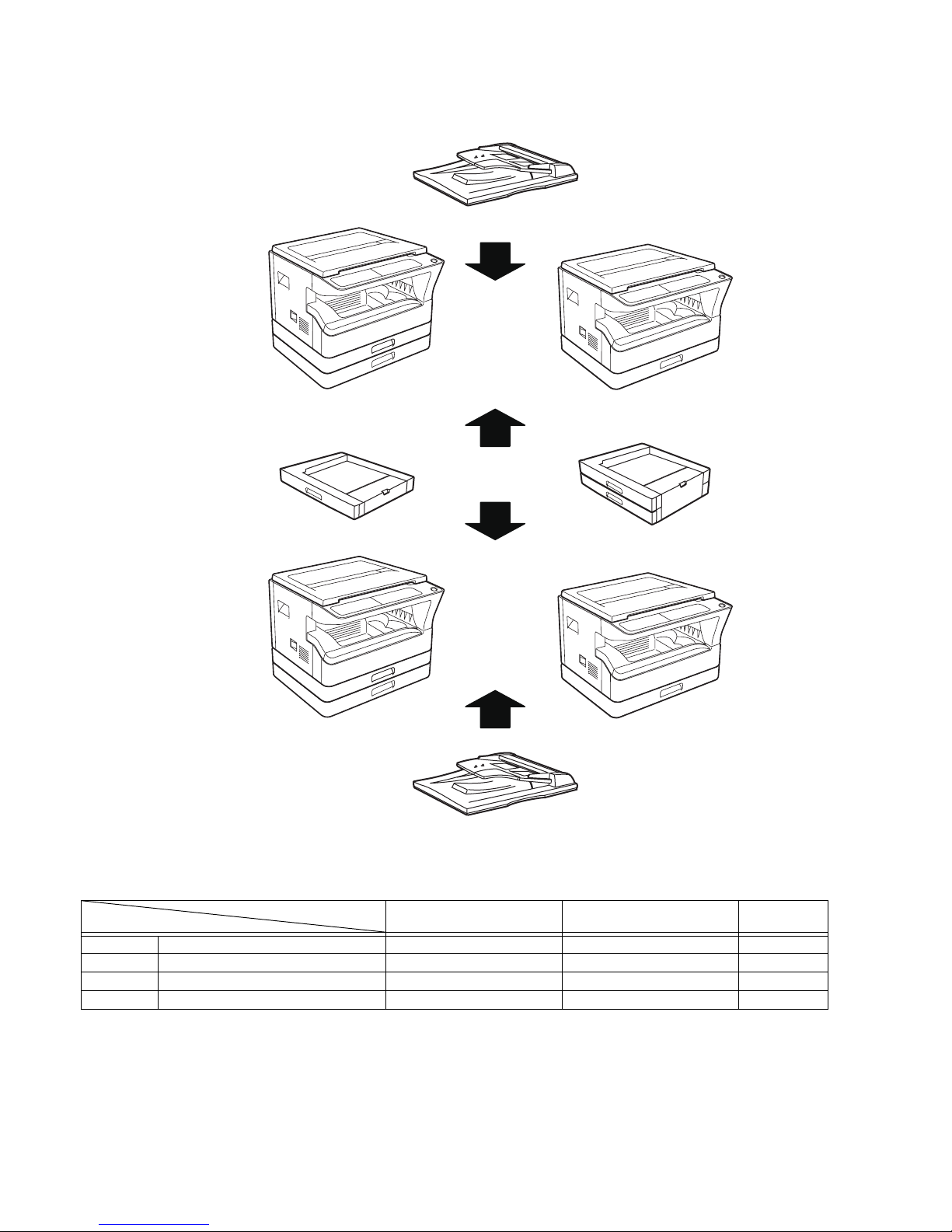

AR-5516 / AR-5516S / AR-5516D 16-CPM multi function model

AR-5520 / AR-5520S / AR-5520D 20-CPM multi function model

Machine Model

250 sheets paper feed unit AR-D34

250 sheets x 2 paper feed unit AR-D35

SPF AR-SP10 AR-5520/ AR-5520S

AR-5516 /AR-5516S

RSPF AR-RP10 AR-5520D/ AR-5516D

Paper size AR-5520 / AR-5520S

AR-5520D

AR-5516 / AR-5516S

AR-5516D

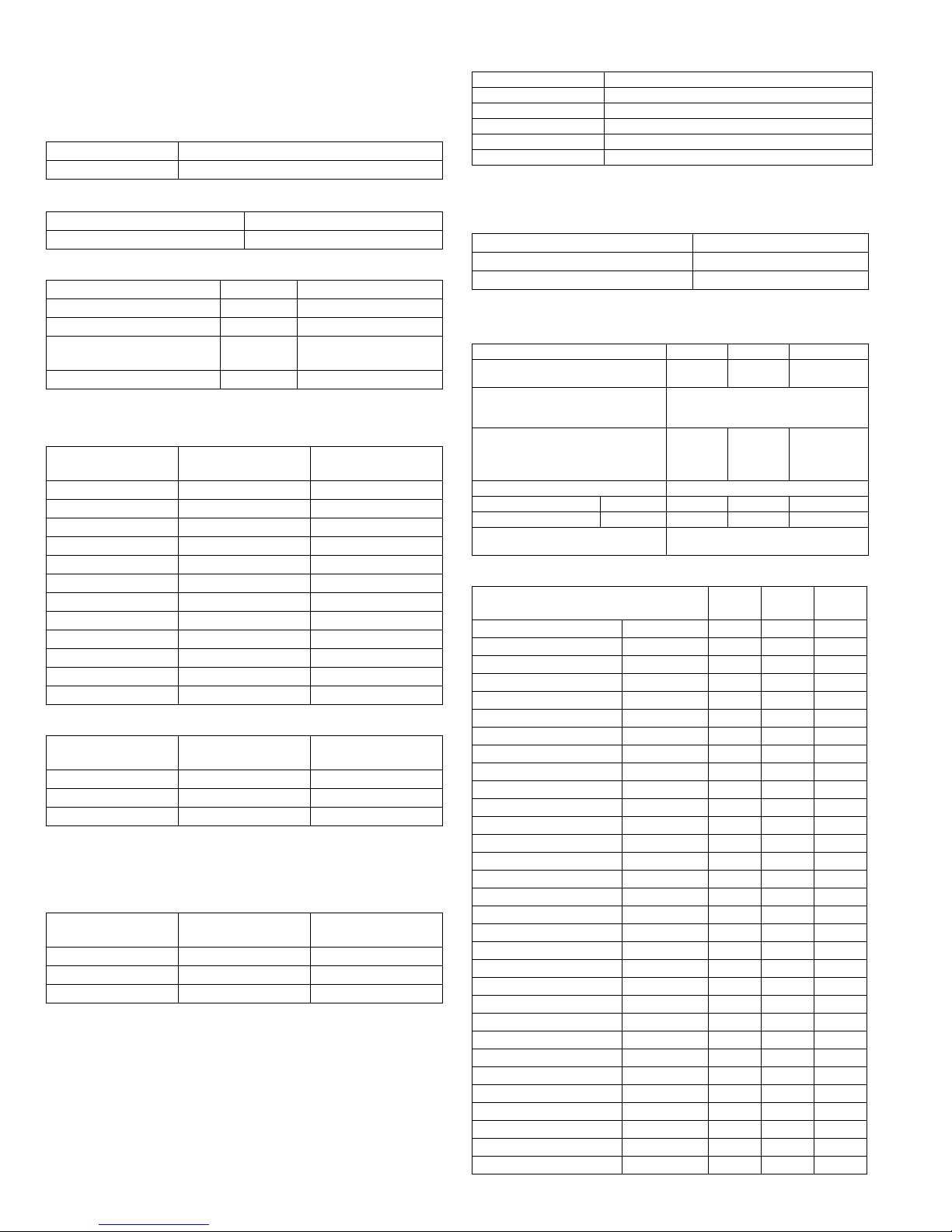

A4/ 8.5”x11” 20ppm 16ppm

A4R 14ppm 12ppm

8.5”x11”R 15ppm 12ppm

A5/ 5.5”x8.5” 20ppm 16ppm

B5/ 16K 20ppm 16ppm

B5R 16ppm 14ppm

16KR 15ppm 14ppm

8.5x13” 12ppm 11ppm

B4/ 8.5”x14 12ppm 10ppm

A3 11ppm 9ppm

11”x17” 10ppm 9ppm

8K 11ppm 10ppm

Copy mode AR-5520 / AR-5520S

AR-5520D

AR-5516 / AR-5516S

AR-5516D

S to S 20cpm (100%) 16cpm (100%)

S to D 9cpm (45%) 9cpm (56%)

D to D 8cpm (40%) 8cpm (50%)

Copy mode AR-5520 / AR-5520S

AR-5520D

AR-5516 / AR-5516S

AR-5516D

S to S 19cpm (95%) 15cpm (94%)

S to D 11cpm (55%) 10cpm (63%)

D to D 10cpm (50%) 10cpm (63%)

Tray Content

1st tray 7.2 sec or less

2nd tray 8.5 sec or less

3rd tray 9.5 sec or less

4th tray 10.5 sec or less

Bypass tray 7.5 sec or less

Max. document size A3, 11" X 17"

Document reference position Left side center

Detection (Platen) None

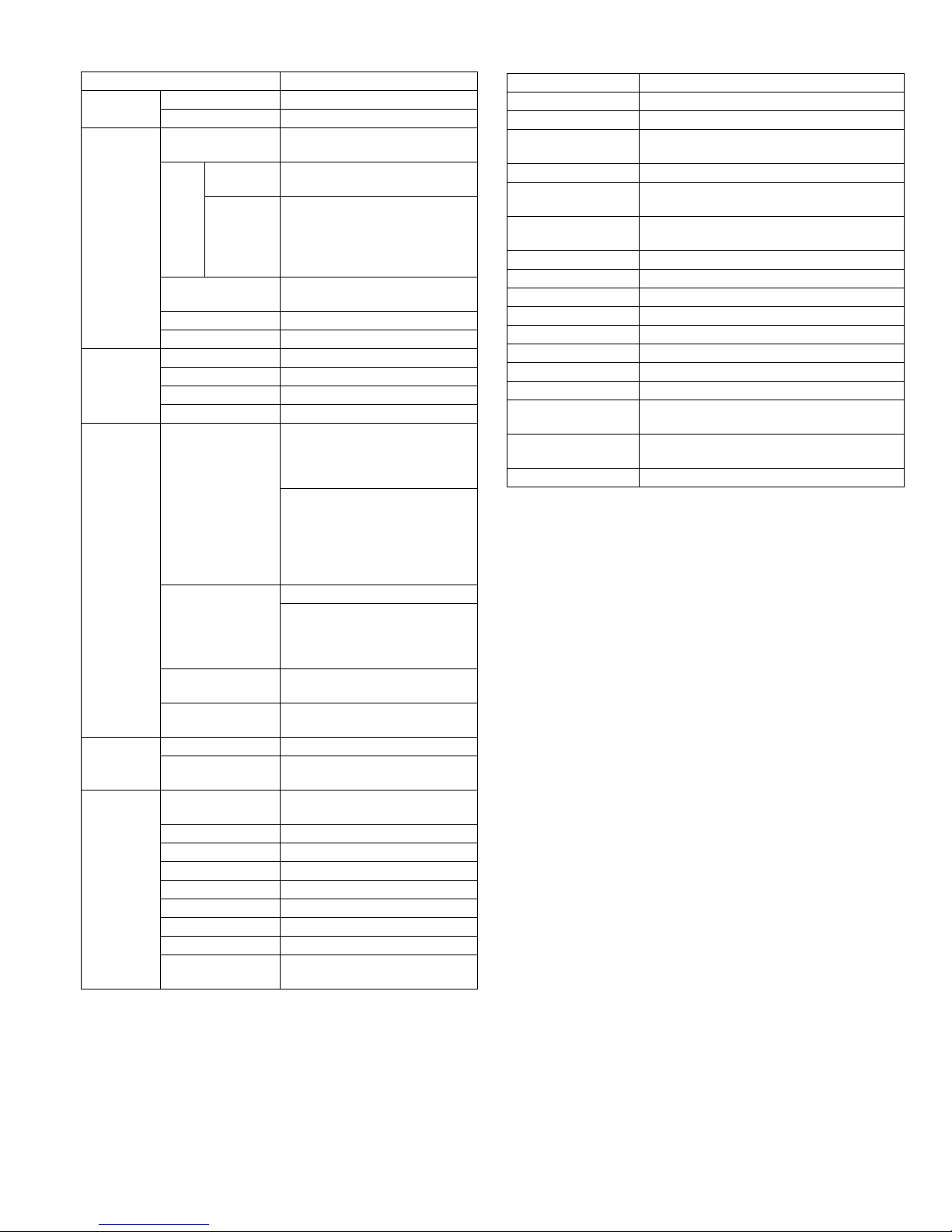

Item 1st tray 2nd tray

Bypass tray

Paper capacity 250

sheets 250

sheets 100 sheets

Paper size detection No

(Paper size is set with

the system setting.)

Paper type setting No No No

(Heavy

paper setting

is enabled.)

Paper size changing method The paper guide is set by the user.

Paper when shipping AB series A4 A4 -

Size setting Inch series

8 1/2” x11” 8 1/2” x11”

-

Remaining paper quantity

detection Only empty detection available

Paper size 1st tray 2nd tray Bypass

tray

A3 297x420 Ye s Ye s Ye s

B4 257x364 Ye s Ye s Ye s

A4 297x210 Ye s Ye s Ye s

A4-R 210x297 Yes Ye s Yes

B5 257x182 Ye s Ye s Ye s

B5R 182x257 Ye s Yes Yes

A5 210x148.5 Ye s N/A Yes

A5R 148.5x210 N/A N/A Yes

A6R 105x148.5 N/A N/A Yes

B6R 128.5x182 N/A N/A Yes

Ledger 11 x 17 in 279.4x431.8 Ye s Ye s Ye s

Legal 8.5x14in. 215.9x355.6 Ye s Ye s Ye s

Foolscap 8.5 x 13 in 215.9x330.2 Ye s Ye s Ye s

Letter 11x8.5in 279.4x215.9 Ye s Ye s Ye s

Letter-R 8.5x11in 215.9x279.4 Ye s Ye s Ye s

Executive-R 7.25x10.5in. 184.2x266.7 N/A N/A Yes

Invoice 8.5x5.5 in. 215.9x139.7 Ye s N/A Yes

Invoice-R 5.5x8.5 in 139.7x215.9 N/A N/A Yes

8K 270x390 Ye s Ye s Ye s

16K 270x195 Ye s Ye s Ye s

16KR 195x270 Ye s Ye s Ye s

COM10 104.8x241.3 N/A N/A Ye s

COM9 98.4x225.4 N/A N/A Yes

C5 162x229 N/A N/A Yes

DL 110x220 N/A N/A Yes

Postcard 100x148 N/A N/A Yes

Return postcard 200x148 N/A N/A Yes

Long format No. 3 120.1x235 N/A N/A Yes

Monarch 98.4x190.5 N/A N/A Yes

Western format No. 2 114x162 N/A N/A Yes

Western format No. 4 105x235 N/A N/A Yes