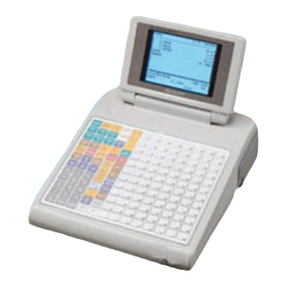

Function keys list (default keyboard and labels)

Caption (default) Function

HOME Used to return to HOME keyboard.

CANCEL Used to cancel your current operation or

menu or return to previous menu.

CLEAR Used to clear the entered data

(amounts/rates/parameters, etc.) and the

error state.

MODE Used to go to MODE selection window or

to return to HOME keyboard.

↑Used to control the cursor (up arrow).

↓Used to control the cursor (down arrow).

←MORE Used to change the keyboard.

→MORE Used to change the keyboard.

ENTER Used to select item/menu or entered data.

SUB Used to go to the sub-keyboard.

CASH Used to enter the direct cash/amount

tendered operation, or to finalize the PGM

job.

0 thru 9 Used to enter a numeric data (0 thru 9).

00 Used to enter a numeric data (00).

000 Used to enter a numeric data (000).

•Used to enter a fractional part, or to

toggle between two or more options.

X/TIMES Used to enter a quantity or time.

SBTL Used to display subtotals.

P UP Used to scroll page up.

P DOWN Used to scroll page down.

BKSPC Used to backs up the cursor for deleting

the character or figure at the left of the

cursor.

DEL Used to delete a character or figure in the

cursor position.

MDS ST Used to display the merchandise subtotal.

TRY ST Used to display the tray subtotal.

# Used to enter a non-add code.

NS Used to execute a no-sale function.

SCALE Used to enter a weight for the item entry.

PLU/SB Used to enter a PLU/subdepartment from

the list by using a code.

L1 thru L10 Used to shift the direct PLU key level

(level 1 thru 10).

P1 thru P5 Used to shift the PLU price level (level 1

thru 5).

TAX1SF Used to shift the taxability 1.

TAX2SF Used to shift the taxability 2.

TAX3SF Used to shift the taxability 3.

TAX4SF Used to shift the taxability 4.

BILL Used to print the bill.

RCPT Used to print the receipt after transaction.

CH TIP Used to enter the charge tip.

CA TIP Used to enter the cash tip.

TIP PD Used to execute the tip paid function.

VOID Used to void a last item, or used for the

cursor void function.

I.VOID Used to void a past item, or used for the

cursor void function.

ST VD Used to void an entire transaction

(subtotal void).

RFND Used to enter the refund item.

RETURN Used to enter the returned item.

Caption (default) Function

%1 thru %9 Used to enter the percent calculation

(percent 1 thru 9).

(–)1 thru (–)9 Used to execute the discount entry

(discount 1 thru 9).

TAX Used to enter the manual tax.

CV CNT Used to enter the cover count.

AUTO to AUTO7 Used to enter the automatic sequencing

(auto 1 thru auto 7).

$5 Used to enter the speed tender ($5).

$10 Used to enter the speed tender ($10).

$20 Used to enter the speed tender ($20).

AUTO11 to AUTO25 Used to enter the automatic sequencing

(auto 11 thru auto 25).

CA2 Used to enter the cash 2 payment.

CHK thru CHK4 Used to enter the check payment (check

1 thru 4).

CH1 thru CH8 Used to enter the charge payment

(charge 1 thru 8).

EMP CH Used to enter the employee charge

payment.

CONV1 to CONV4 Used to creates a subtotal in foreign

currency (conversion 1 thru 4).

PBAL Used to lookup the guest check.

PBAL2 Used to lookup the guest check (for

drive-thru function).

N.C. Used to open a new guest check.

N.C.2 Used to open a new guest check (for

drive-thru function).

SRVC Used to finalize the guest check

temporarily.

FINAL Used to finalize the guest check

temporarily (with the tax calculation).

DEPO Used to enter the deposit.

DEP.RF Used to return the deposit.

B.T. Used to enter the bill transfer/bill totalizing.

RA and RA2 Used to enter the received-on-account

(RA 1 and 2).

PO and PO2 Used to enter the paid-out (PO 1 and 2).

SRV# Used to enter the server code.

MGR# Used to enter the manager code.

EMPL# Used to enter the employee code.

EATIN1 thru EATIN3 Used to display the eat-in subtotal (eat-in

1 thru 3).

RP SND Used to send a partial order to the remote

printer.

GRT EX Used to exempt a customer from the

gratuity.

OPN TR Used to enter the open tare.

BAL Balance key

REPEAT Used to repeat a last item entry.

TR.OUT Used to enter the transfer-out function.

TR.IN Used to enter the transfer-in function.

PERSN# Used to enter the person number.

I.PAY Individual payment key

E.SALE Used to enter the sales for employees.

M.FUNC Used to display the miscellaneous

function menu.

RCP.SW Used to switch the receipt printing state

(ON/OFF).

1 – 5