Siemens LOK16 Series User manual

Other Siemens Control Unit manuals

Siemens

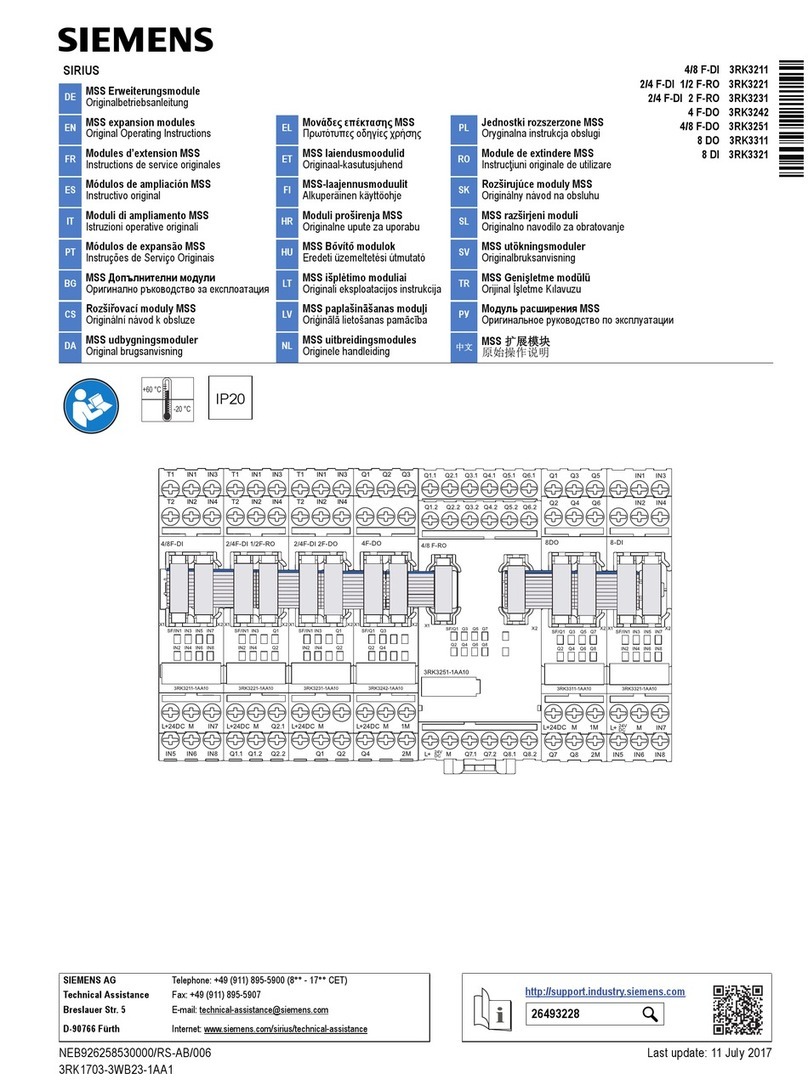

Siemens SIRIUS 3RK3211 User manual

Siemens

Siemens VAG61 Series User manual

Siemens

Siemens SIMATIC NET 6GK1110-1AA00 User manual

Siemens

Siemens Simatic S7-1500 User manual

Siemens

Siemens SCALANCE S623 User manual

Siemens

Siemens SIPROTEC User manual

Siemens

Siemens SITRANS LU SAM User manual

Siemens

Siemens LFL Series Owner's manual

Siemens

Siemens LOGO! Series User manual

Siemens

Siemens SLT-1 User manual

Siemens

Siemens LGB21.130A17 User manual

Siemens

Siemens Simatic S5 IP 240 Technical Document

Siemens

Siemens SINUMERIK 840D User manual

Siemens

Siemens SIRIUS 3SB3 User manual

Siemens

Siemens SIMOCODE DP User manual

Siemens

Siemens SIMATIC FM 353 User manual

Siemens

Siemens SINUMERIK 808D User manual

Siemens

Siemens SIPROTEC 7SJ80 User manual

Siemens

Siemens SIMATIC ET 200SP User manual

Siemens

Siemens SIMOTION Technical Document

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual