Siemens Desigo PXC4.M16 User manual

Other Siemens Controllers manuals

Siemens

Siemens Flowrite 599 Series User manual

Siemens

Siemens OpenAir GIB13.1 Series User manual

Siemens

Siemens SKD62UA User manual

Siemens

Siemens MT Series Owner's manual

Siemens

Siemens SINUMERIK 808D User manual

Siemens

Siemens SQM45 Series User manual

Siemens

Siemens SIPROTEC 5 V7.80 Instruction Manual

Siemens

Siemens Simatic S7-300 User manual

Siemens

Siemens SKB32 Series User manual

Siemens

Siemens LOGO! 24RC User manual

Siemens

Siemens SIMATIC S7-200 User manual

Siemens

Siemens SIMATIC S7-1200 User manual

Siemens

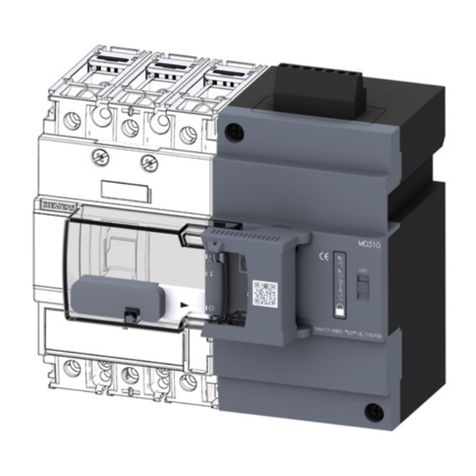

Siemens MO310 User manual

Siemens

Siemens Simatic S7-300 User manual

Siemens

Siemens SIMATIC S5-115U User manual

Siemens

Siemens LME7 Series Operator's manual

Siemens

Siemens Simatic S7 Series User manual

Siemens

Siemens SSC161.05U User manual

Siemens

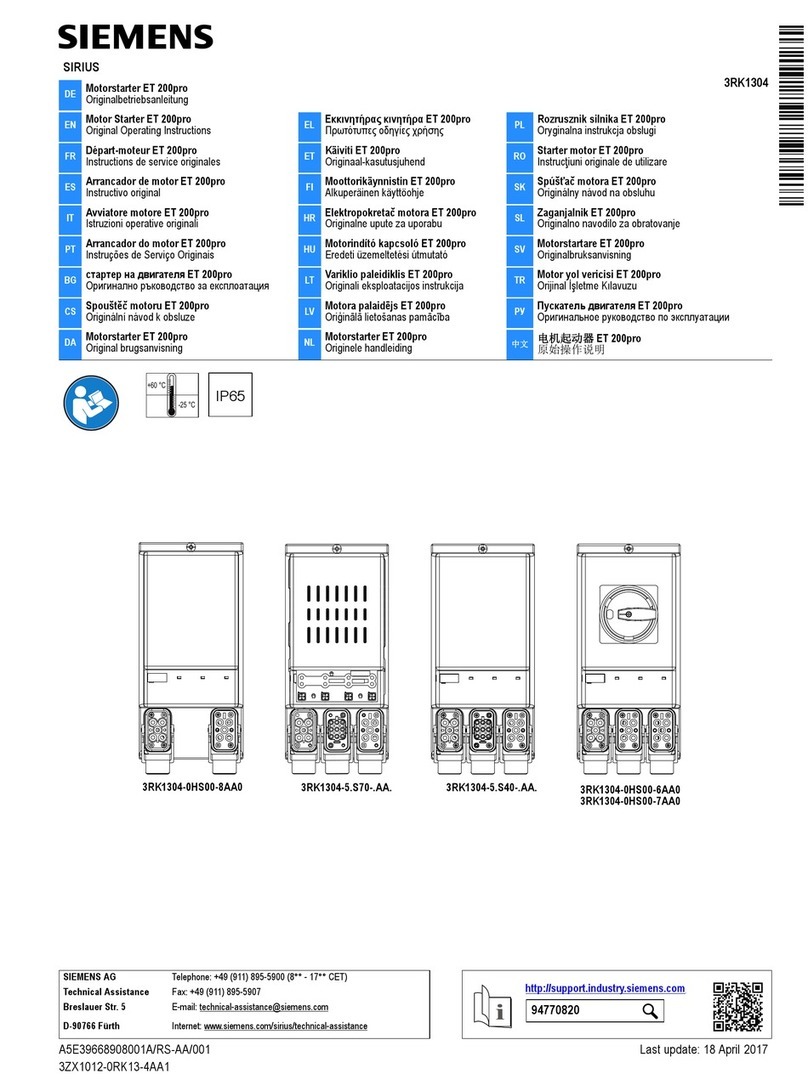

Siemens 3RK1304-5 S70 Series User manual

Siemens

Siemens SINUMERIK 808D User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions