General Information

WV58MR/WH58MR Datum: 05.03.2019 Art. Nr. 89117 Änd. Stand 066/19 Seite 3 von 110

5.7.1.2 Switch states of individual LSS devices (Switch state selective)..............................26

5.7.2 Configuration .....................................................................................................27

5.7.2.1 Setting the node ID (Configure Node-ID) ............................................................27

5.7.2.2 Configuration of the baud rate (Configure bit timing parameters)...........................27

5.7.2.3 Activate baud rate (Activate bit timing parameters) .............................................28

5.7.2.4 Store configuration..........................................................................................29

5.7.3 Requesting parameters.........................................................................................29

5.7.3.1 Request Vendor ID...........................................................................................30

5.7.3.2 Request Product Code.......................................................................................30

5.7.3.3 Request revision number...................................................................................30

5.7.3.4 Request serial number ......................................................................................31

5.7.3.5 Request Node ID..............................................................................................31

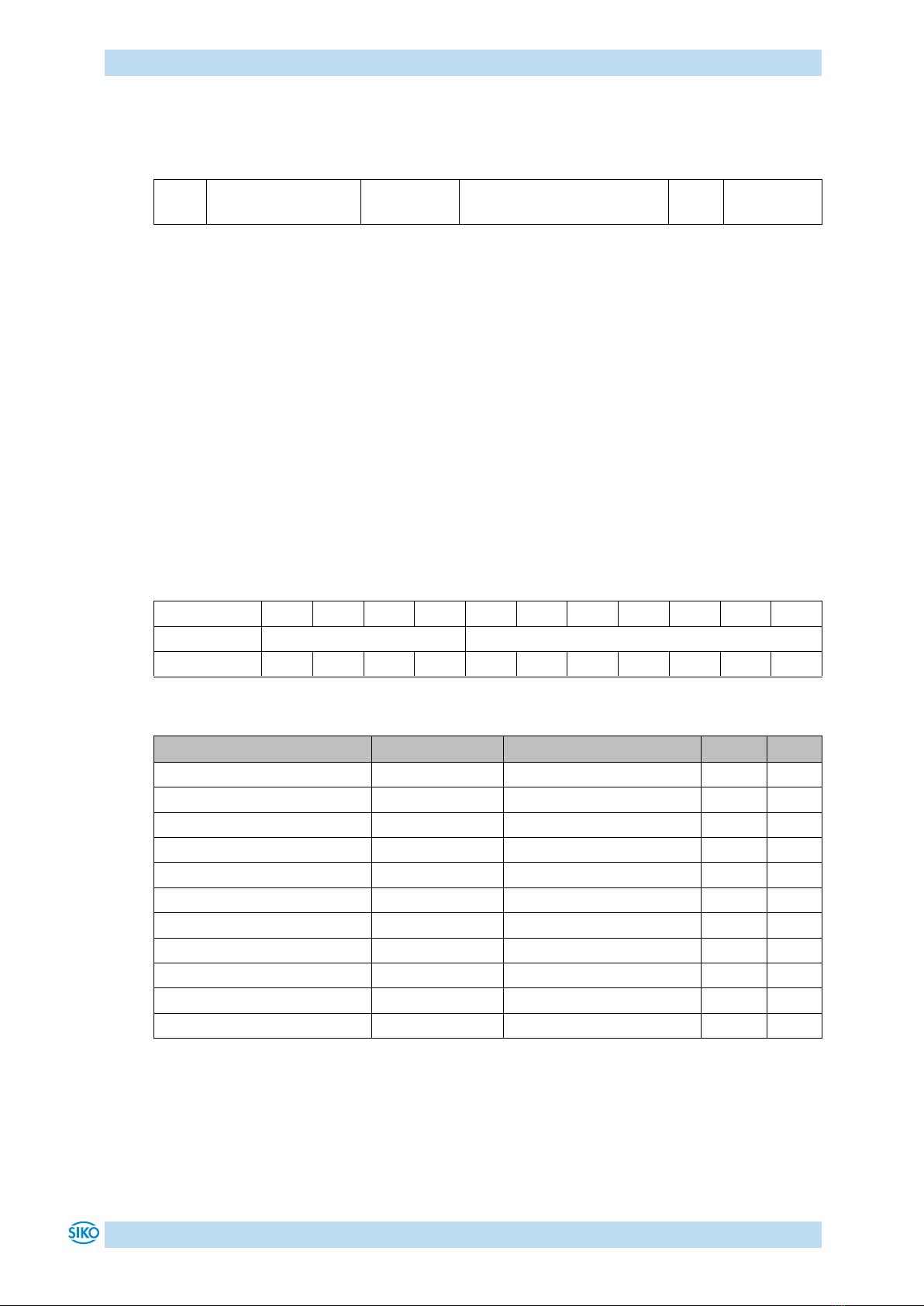

5.8 Directory of objects ....................................................................................32

5.8.1 Overview of objects .............................................................................................32

5.8.2 Object Description...............................................................................................54

5.8.2.1 1000h: Device Type..........................................................................................54

5.8.2.2 1001h: Error Register .......................................................................................54

5.8.2.3 1002h: Manufacturer Status Register ..................................................................55

5.8.2.4 1003h: Pre-defined Error Field...........................................................................55

5.8.2.5 1005h: COB-ID SYNC-message............................................................................56

5.8.2.6 1008h: Manufacturer Device Name .....................................................................56

5.8.2.7 1009h: Manufacturer Hardware Version...............................................................56

5.8.2.8 100Ah: Manufacturer Software Version................................................................57

5.8.2.9 100Ch: Guard Time...........................................................................................57

5.8.2.10 100Dh: Life Time Factor....................................................................................57

5.8.2.11 1010h: Store Parameter....................................................................................58

5.8.2.12 1011h: Restore Parameter.................................................................................59

5.8.2.13 1014h: COB-ID Emergency message....................................................................61

5.8.2.14 1017h: Producer Heartbeat Time........................................................................62

5.8.2.15 1018h: Identity Object.....................................................................................62

5.8.2.16 1200h: Server SDO Parameter ............................................................................63

5.8.2.17 1301h: SRDO1 communication parameters...........................................................64

5.8.2.18 1302h: SRDO2 communication parameters...........................................................65

5.8.2.19 1381h: SRDO1 mapping parameters ....................................................................67

5.8.2.20 1382h: SRDO2 mapping parameters ....................................................................69

5.8.2.21 13FEh: Safety configuration ..............................................................................70

5.8.2.22 13FFh: Safety configuration signature (checksum)................................................71

5.8.2.23 1800h: 1. Transmit PDO Parameter.....................................................................73

5.8.2.24 1801h: 2. Transmit PDO Parameter.....................................................................74

5.8.2.25 1A00h: 1. Transmit PDO Mapping Parameter ........................................................75

5.8.2.26 1A01h: 2. Transmit PDO Mapping Parameter ........................................................76

5.8.2.27 2001h: Application offset .................................................................................77

5.8.2.28 2002h: Calibrate encoder value..........................................................................77

5.8.2.29 2003h: Limit speed low ....................................................................................78