General Information

SGH25 Date: 27/03/2019 Art. No. 89925 Change Status 063/19 Page 3 of 74

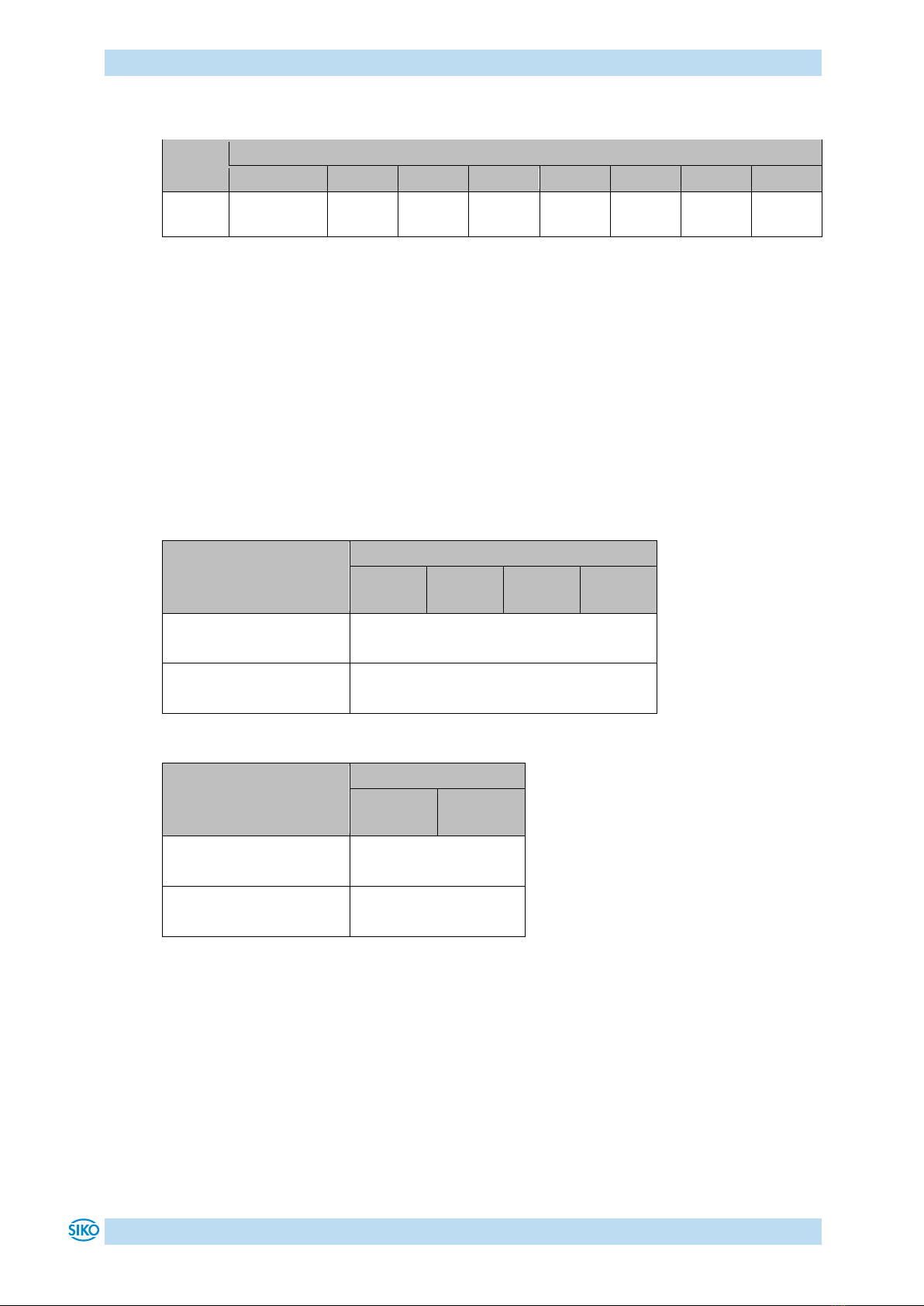

4.7.2 Configuration .....................................................................................................24

4.7.2.1 Node ID Setting (Configure Node ID)..................................................................24

4.7.2.2 Configuration of the baud rate (Configure bit timing parameters)...........................25

4.7.2.3 Activate Baud Rate (Activate bit timing parameters) ............................................26

4.7.2.4 Store configuration..........................................................................................27

4.7.3 Request parameters .............................................................................................27

4.7.3.1 Request vendor ID ...........................................................................................27

4.7.3.2 Request product code.......................................................................................28

4.7.3.3 Request revision number...................................................................................28

4.7.3.4 Request serial number ......................................................................................28

4.7.3.5 Request Node ID..............................................................................................29

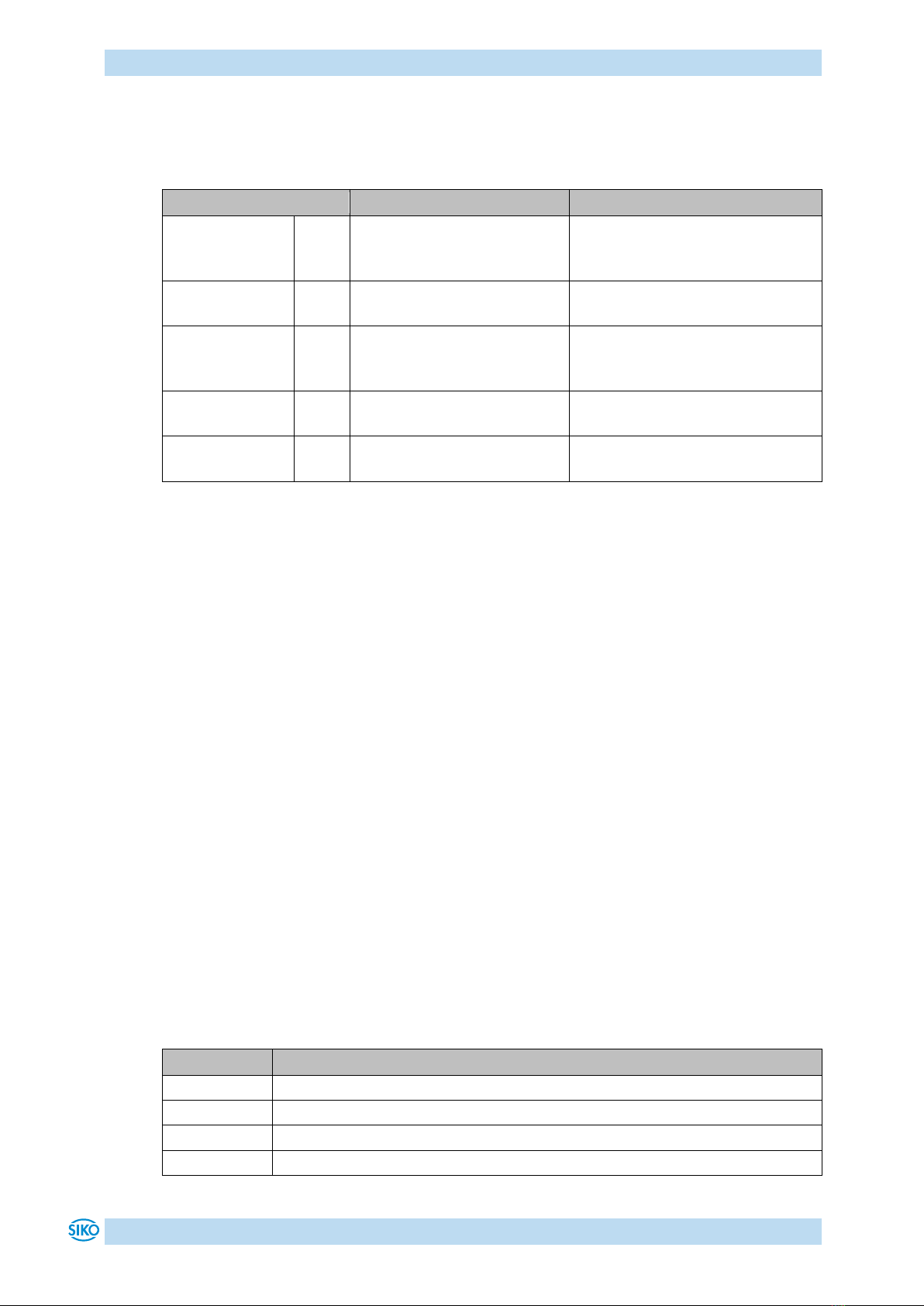

4.8 Table of Objects .....................................................................................................29

4.8.1 Object Overview..................................................................................................29

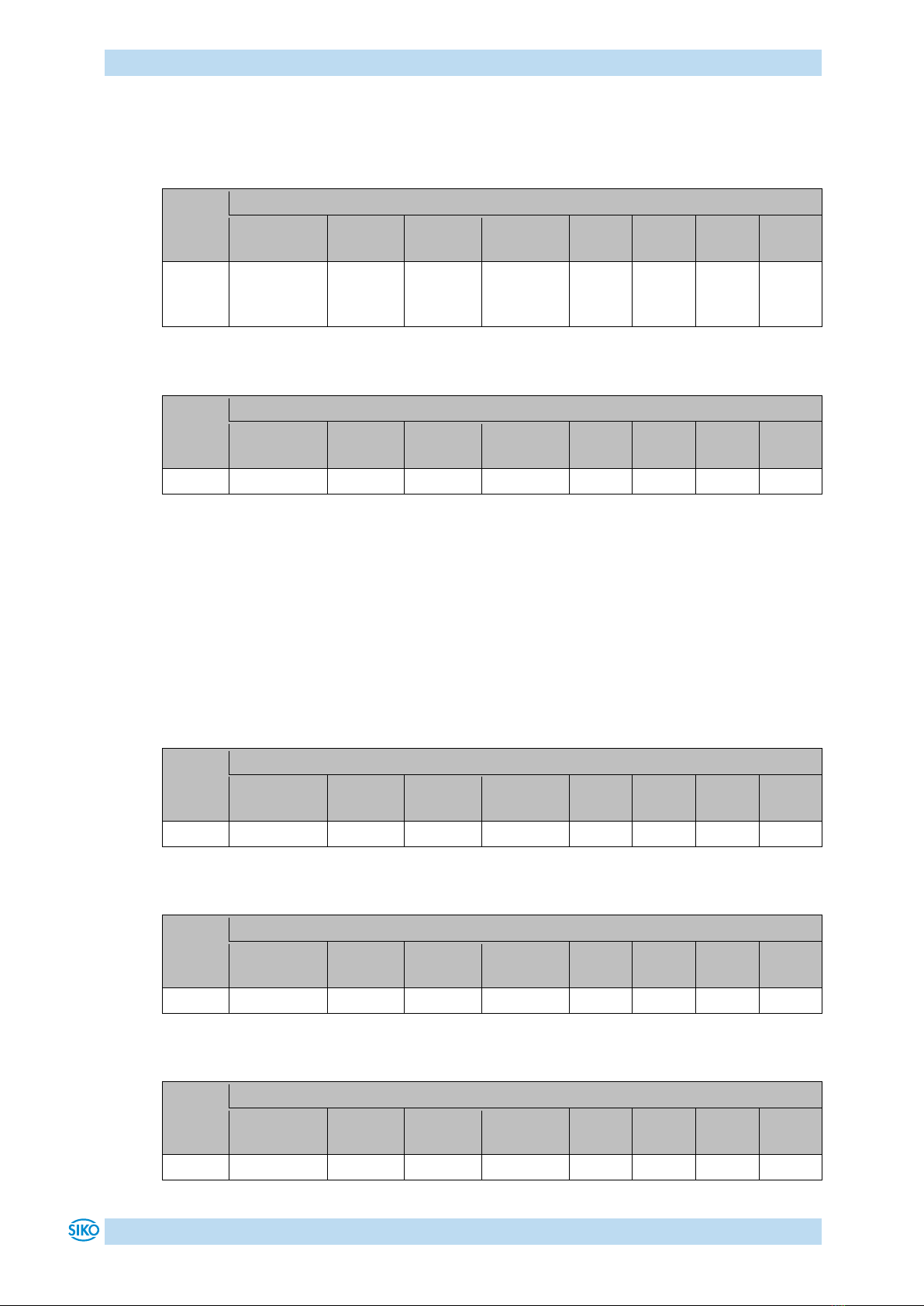

4.8.2 Object Description...............................................................................................32

4.8.2.1 1000h Device Type...........................................................................................32

4.8.2.2 1001h: Error Register .......................................................................................32

4.8.2.3 1002h: Manufacturer Status Register ..................................................................33

4.8.2.4 1003h: Pre-defined Error Field...........................................................................33

4.8.2.5 1005h: COB-ID SYNC Message ............................................................................34

4.8.2.6 1008h: Manufacturer Device Name .....................................................................34

4.8.2.7 1009h: Manufacturer Hardware Version ...............................................................34

4.8.2.8 100Ah: Manufacturer Software Version................................................................35

4.8.2.9 100Ch: Guard Time...........................................................................................35

4.8.2.10 100Dh: Life Time Factor....................................................................................35

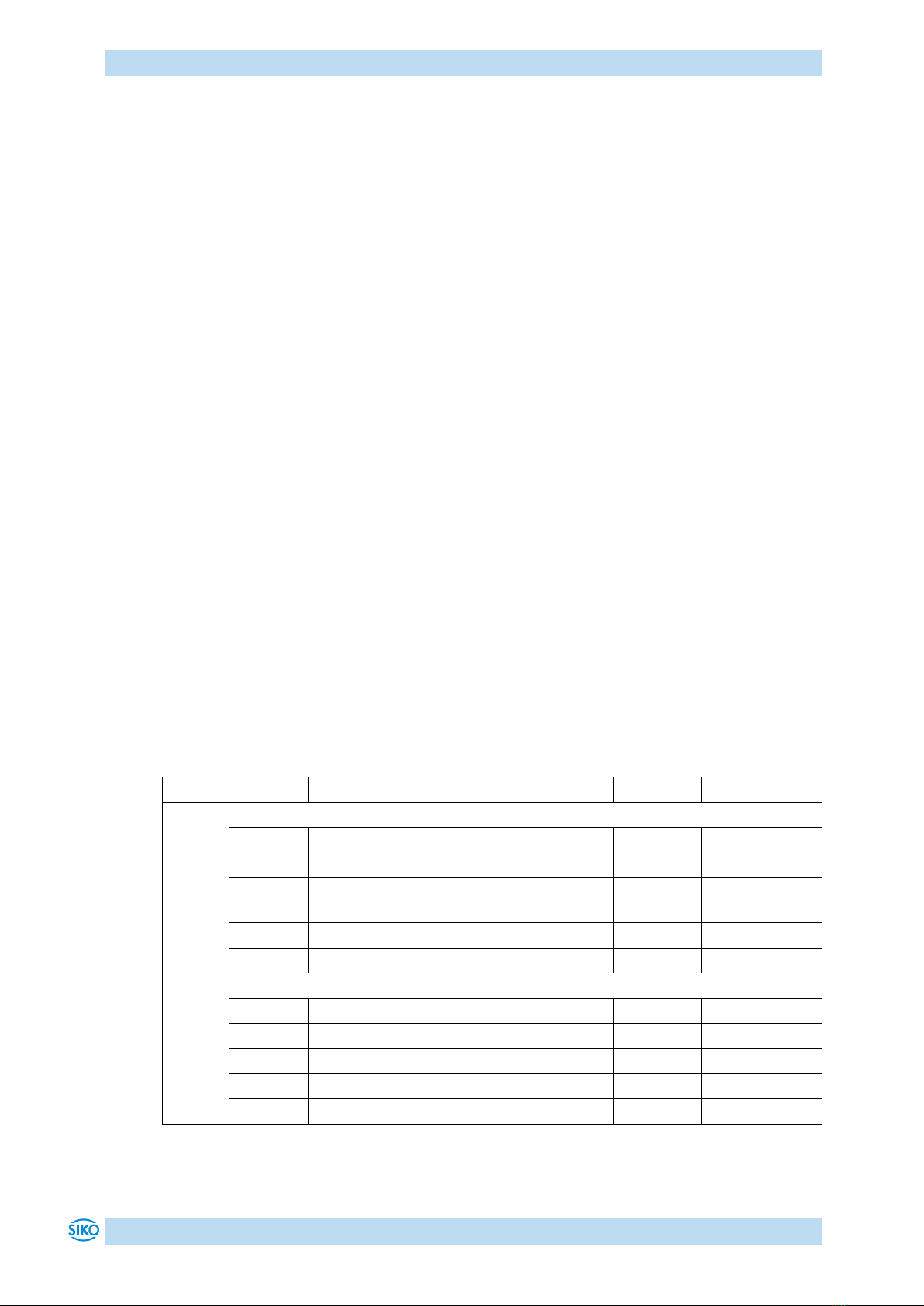

4.8.2.11 1010h: Store Parameter....................................................................................36

4.8.2.12 1011h: Restore Parameter.................................................................................37

4.8.2.13 1014h COB ID emergency message .....................................................................39

4.8.2.14 1017h: Producer Heartbeat Time........................................................................40

4.8.2.15 1018h: Identity Object.....................................................................................40

4.8.2.16 1200h: Server SDO Parameter ............................................................................41

4.8.2.17 1301h: SRDO1 Communication Parameter ............................................................42

4.8.2.18 1302h: SRDO2 Communication Parameter ............................................................43

4.8.2.19 1381h: SRDO1 mapping parameters ....................................................................45

4.8.2.20 1382h: SRDO2 mapping parameters ....................................................................46

4.8.2.21 13FEh: Safety Configuration ..............................................................................47

4.8.2.22 13FFh: Safety configuration signature (checksum)................................................47

4.8.2.23 1800h 1. Transmit PDO Parameter ......................................................................49

4.8.2.24 1801h: 2. Transmit PDO Parameter .....................................................................50

4.8.2.25 1A00h: 1. Transmit PDO Mapping Parameter ........................................................51

4.8.2.26 1A01h: 2. Transmit PDO Mapping Parameter ........................................................52

4.8.2.27 5000h: Diagnose CAN bus error..........................................................................53

4.8.2.28 5F09h: Bus terminal.........................................................................................53

4.8.2.29 5F0Ah: Node ID and baud rate Bus CAN ..............................................................53

4.8.2.30 6000h: Operating Parameters ............................................................................54