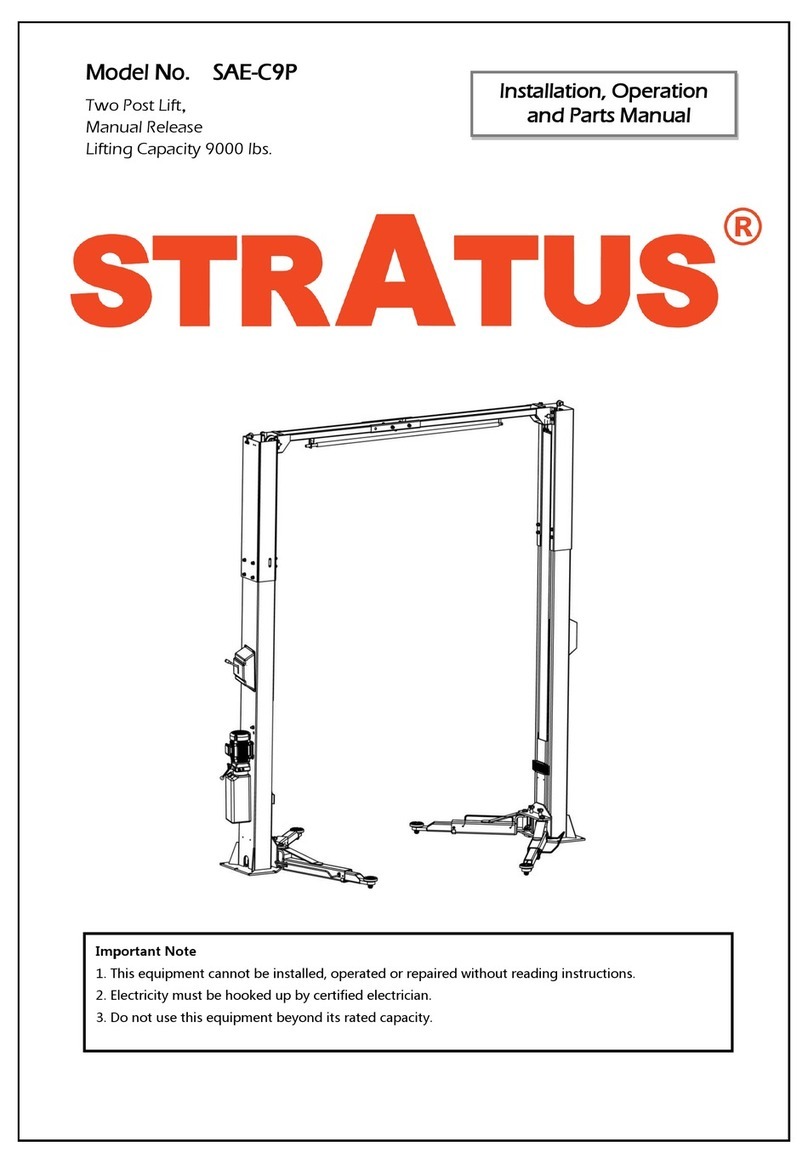

STRATUS Clear Floor 2 post Lift Installation & Operation & Maintenance Instructions

2

TABLE OF CONTENTS

1. Packing, transport and storage .......................................................................................................................................5

1.1 Packing..............................................................................................................................................................................5

1.2 Transport...........................................................................................................................................................................5

1.3 Storage..............................................................................................................................................................................5

2. Technical specifications ....................................................................................................................................................6

3. Safety......................................................................................................................................................................................9

3.1 Important notices .............................................................................................................................................................9

3.2 Qualified personnel .........................................................................................................................................................9

3.3 Danger notices.................................................................................................................................................................9

3.4 Training..............................................................................................................................................................................9

3.5 Warning signs.................................................................................................................................................................10

4. Installation...........................................................................................................................................................................11

4.1 Tool required...................................................................................................................................................................11

4.2 Checking for room suitability........................................................................................................................................12

4.3 Lighting.......................................................................................................................................................................12

4.4 Floor requirement .....................................................................................................................................................12

4.5 Site layout..................................................................................................................................................................12

4.6 Assemble columns.........................................................................................................................................................13

4.7 Installation overhead top beam ...................................................................................................................................14

4.8 Position columns ......................................................................................................................................................16

4.9 Install overhead top beam ............................................................................................................................................17

4.10 Install limit switch.........................................................................................................................................................18

4.11 Adjust carriage..............................................................................................................................................................20

4.12 Install cables (2 Cables in total ) ...............................................................................................................................20

4.13 Routing the safety release cable...............................................................................................................................21

4.14 Installation of power unit.............................................................................................................................................22

4.15 Connection of hydraulic hoses ..................................................................................................................................22

4.16 Make the electrical connection ..................................................................................................................................23

4.17 Oil filling and bleeding.................................................................................................................................................23

4.18 Installation of lifting arms and adjustment of arm locks.........................................................................................24

4.19 Check before start-up .................................................................................................................................................26

4.19.1 General checks...................................................................................................................................................26

4.19.2 Mechanical safeties for proper installation.................................................................................................26

4.19.3 Equalizer cable for proper installation .........................................................................................................26

4.19.4 Hydraulic system for proper operation........................................................................................................26

4.20 Check with load ...........................................................................................................................................................26

5. Operation and use.............................................................................................................................................................27

5.1 Controls...........................................................................................................................................................................27

5.2 Vehicle positioning....................................................................................................................................................27

5.3 Lifting..........................................................................................................................................................................27

5.4 Standing.....................................................................................................................................................................28

5.5 Lowering ....................................................................................................................................................................28

6. Maintenance........................................................................................................................................................................29

6.1 Ordinary maintenance...................................................................................................................................................29

6.2 Periodic maintenance....................................................................................................................................................29

7. Troubleshooting.................................................................................................................................................................30

8. Parts list ...............................................................................................................................................................................31

8.1 Explosive view and parts list ........................................................................................................................................31

8.2 Hydraulic system and parts list....................................................................................................................................33

8.3 Steel cable assembly and parts list.............................................................................................................................34

8.4 Safety lock system and parts list.................................................................................................................................35

8.5 Cross beam assembly and parts list...........................................................................................................................37

8.6 Lifting carriage and parts list ........................................................................................................................................39

8.7 Arm assembly and parts list .........................................................................................................................................40